Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Dense body" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dense body One of numerous structures found in the fibres of involuntary (smooth) muscle to which the thin filaments are anchored within the muscle cell. They are functionally analogous to the Z lines of voluntary muscle.

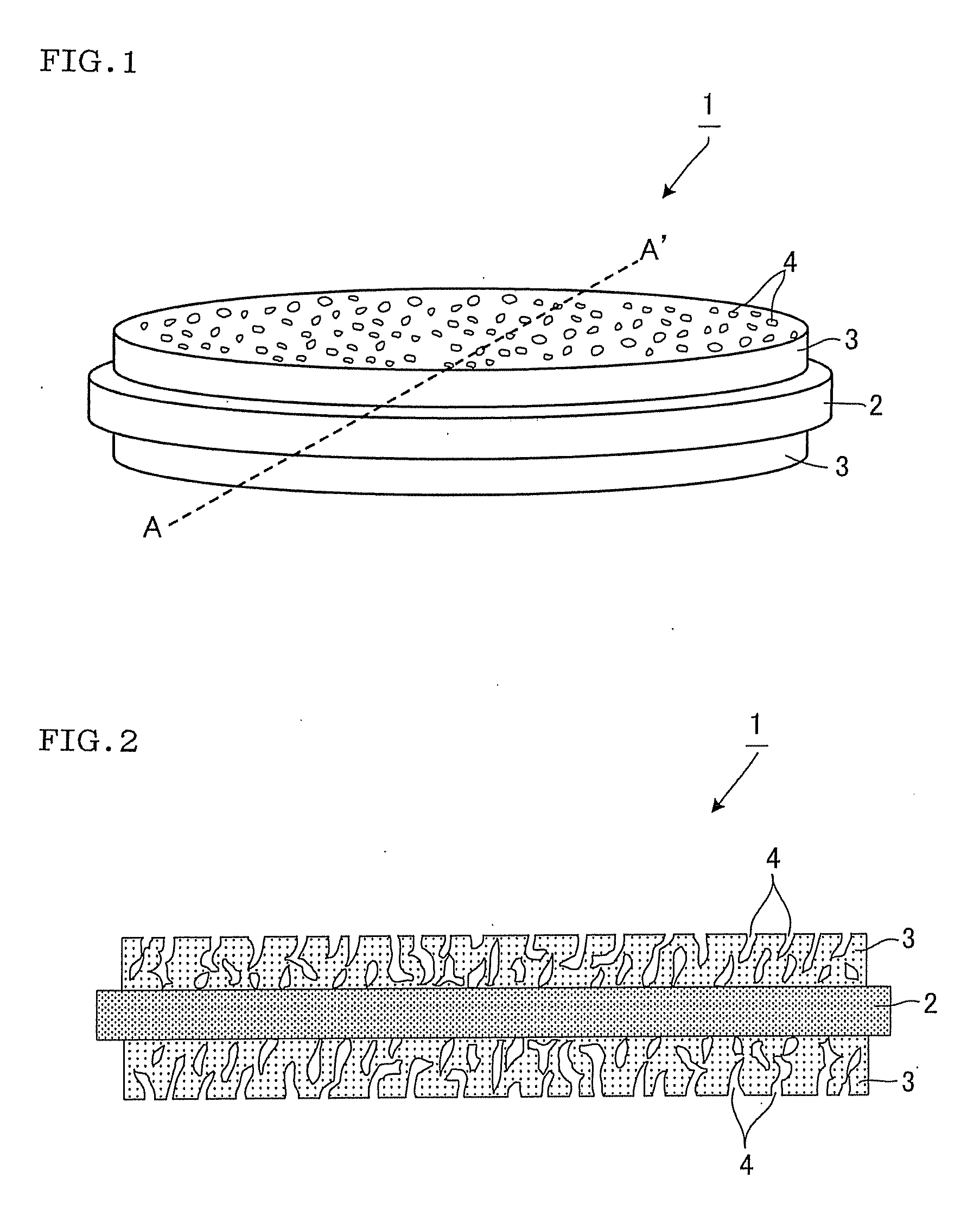

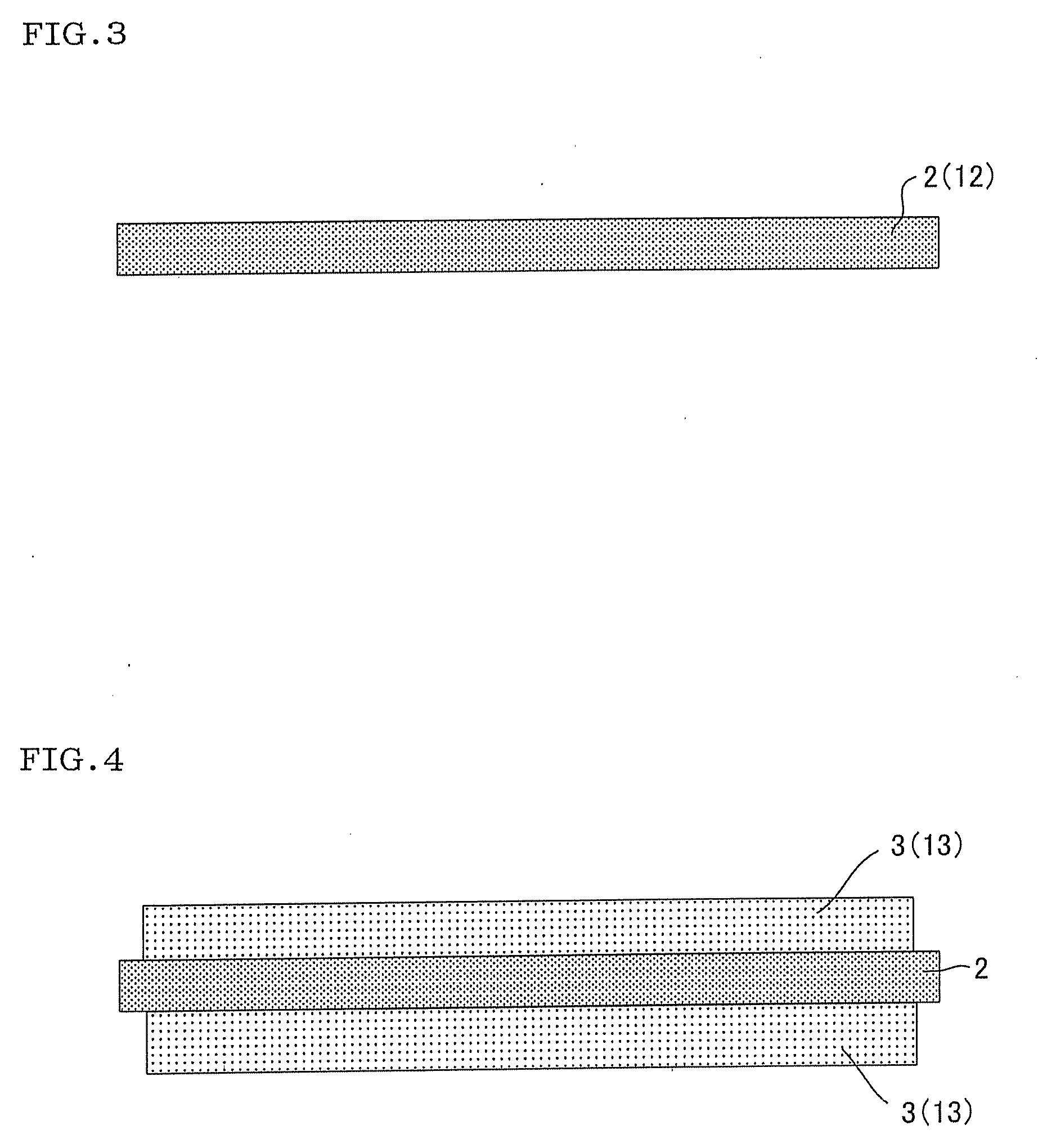

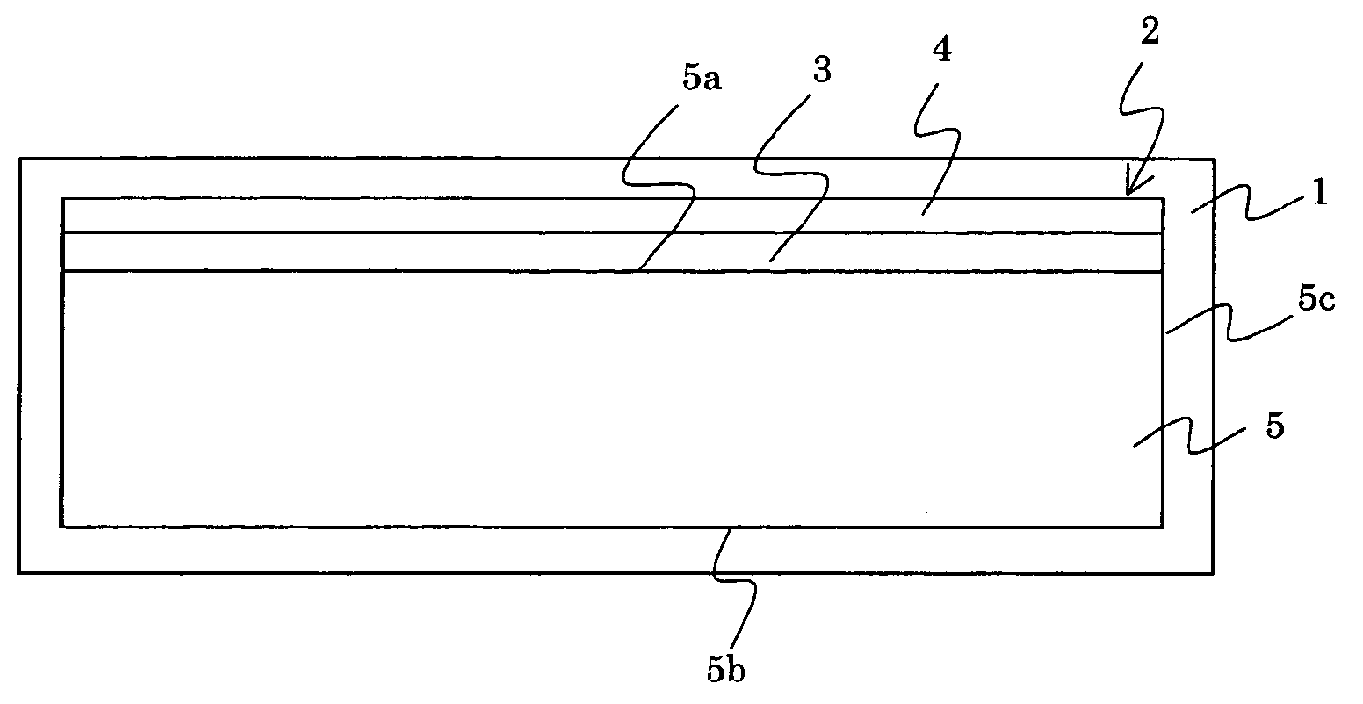

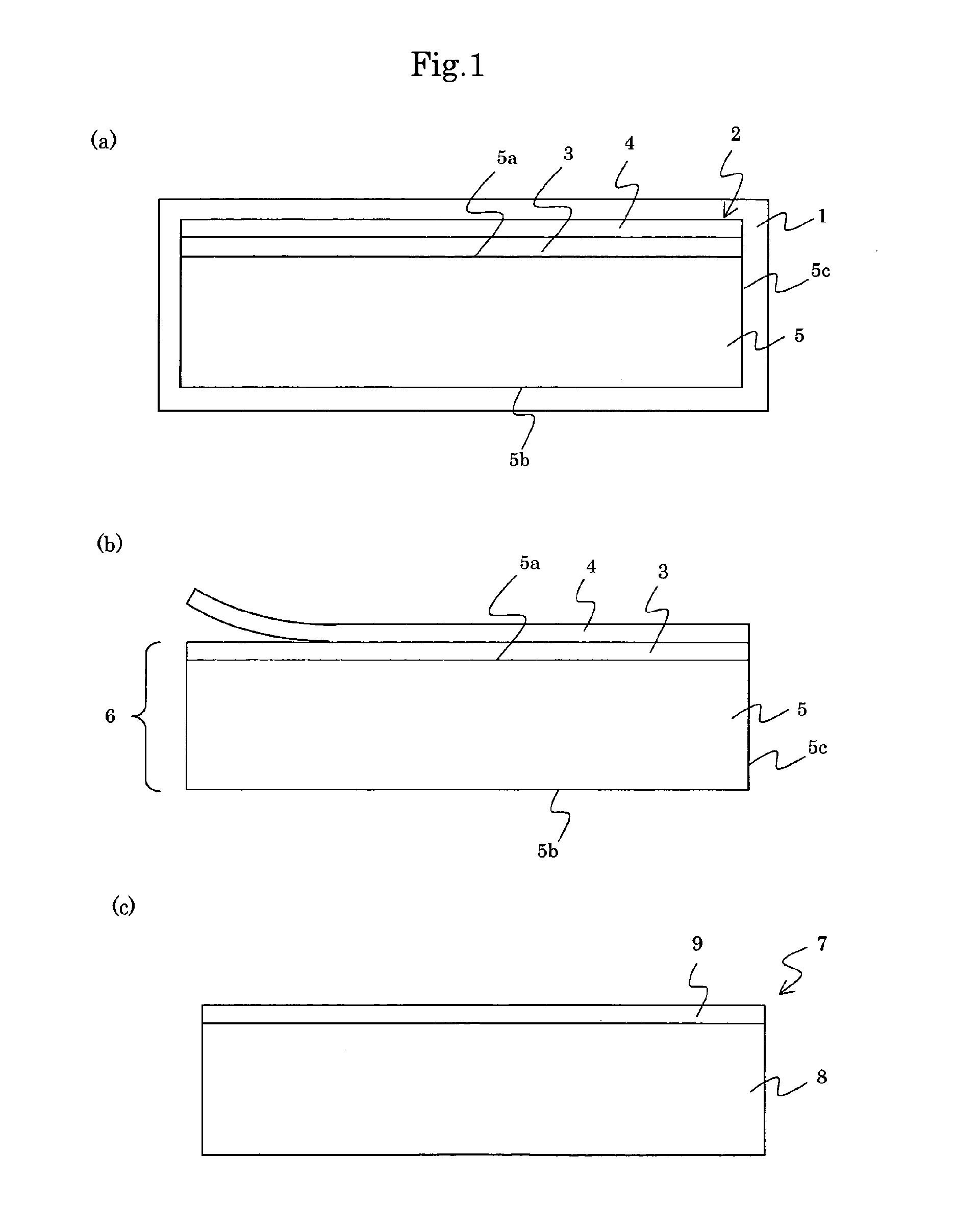

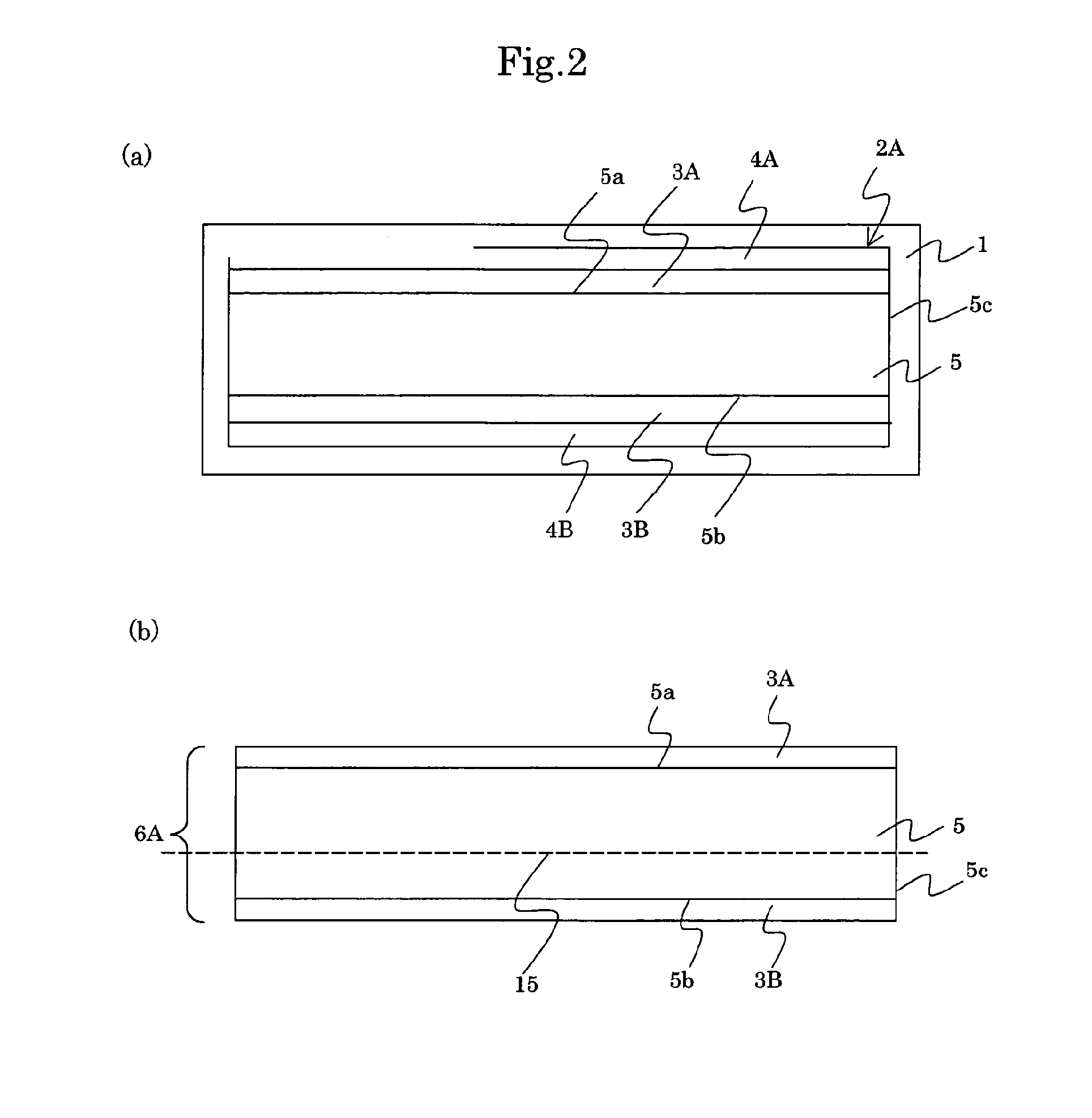

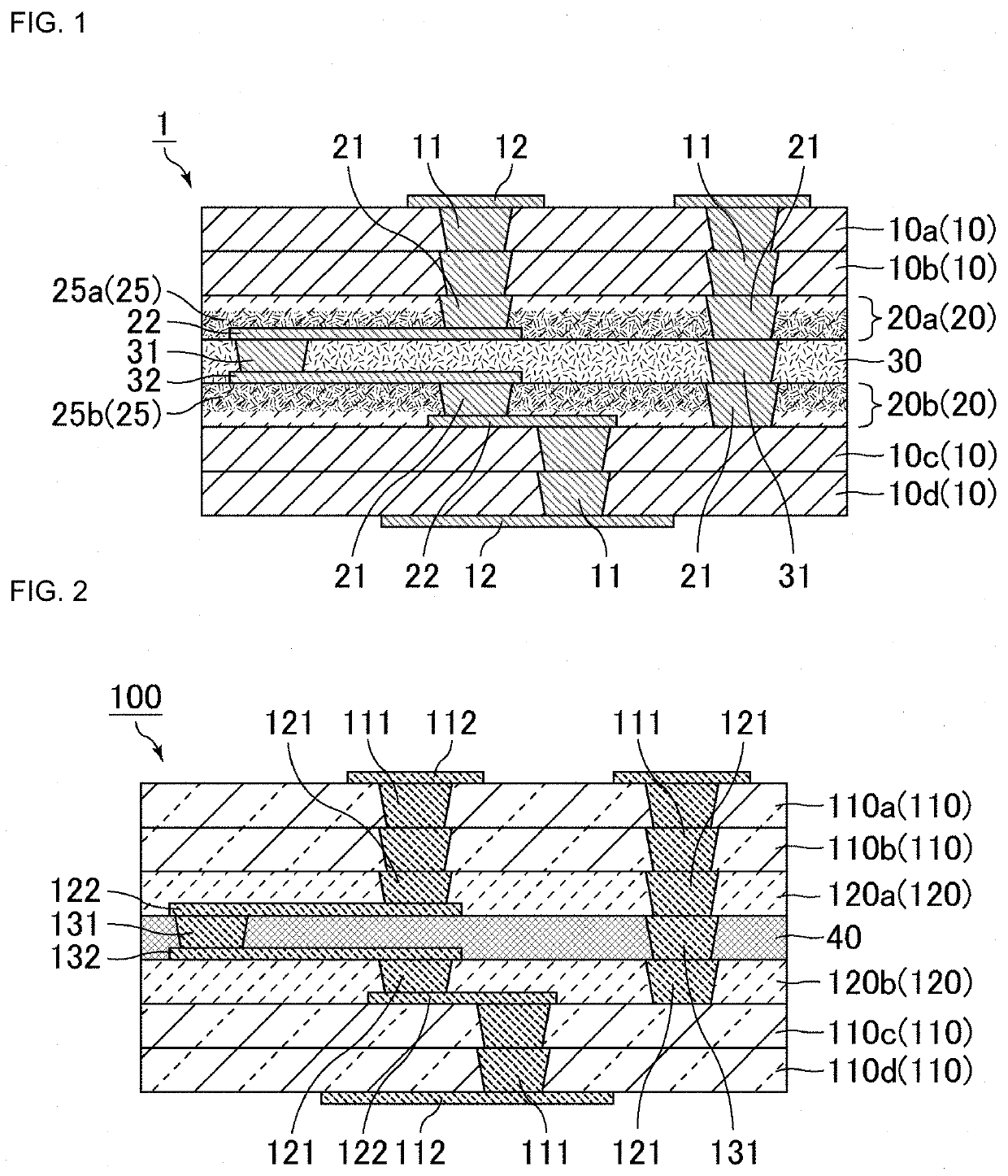

Solid electrolyte structure for all-solid-state battery, all-solid-state battery, and their production methods

InactiveUS20090226816A1Excellent charge and discharge characteristicsReduce contact resistanceFinal product manufactureSolid electrolyte cellsAll solid statePorous layer

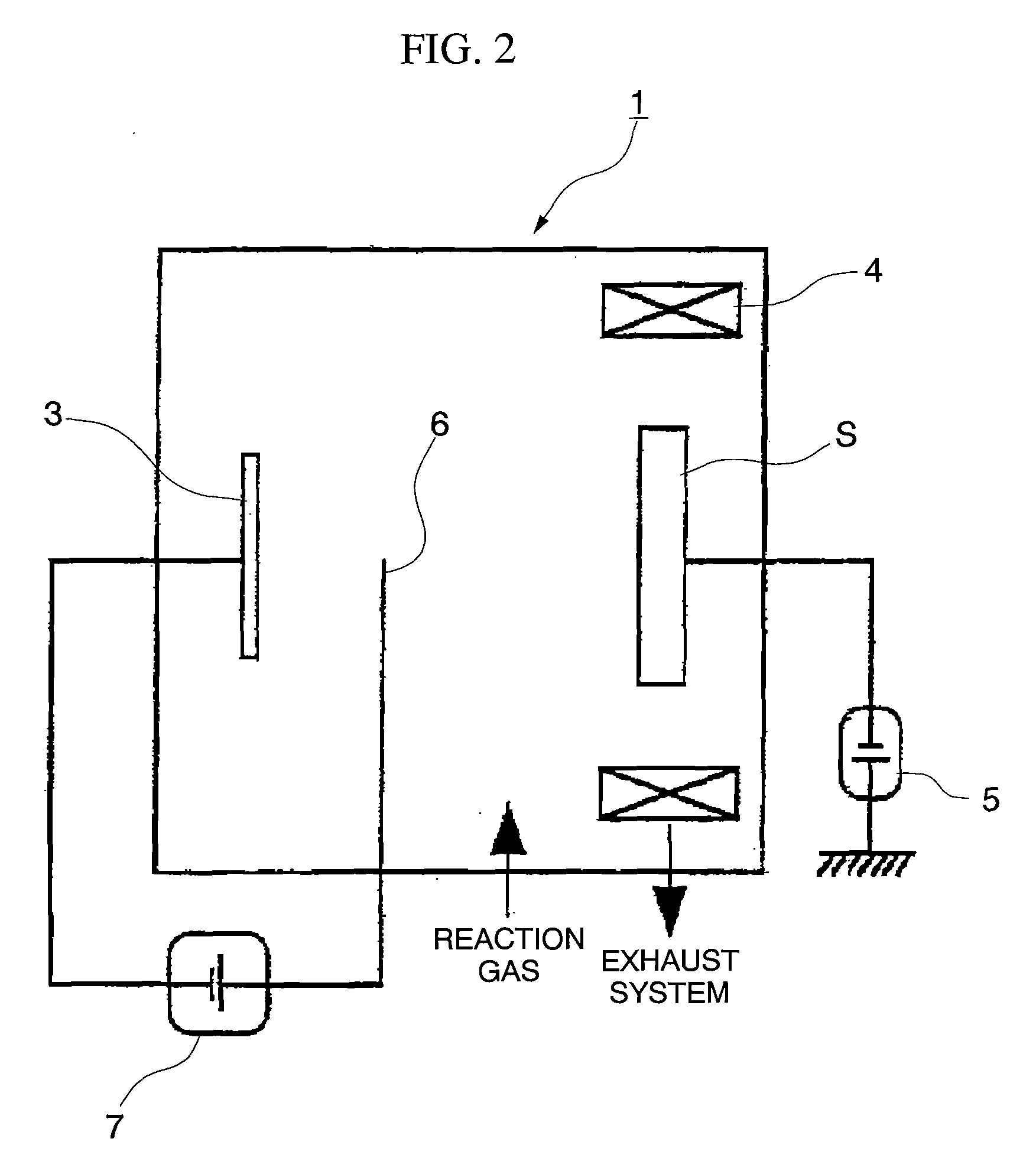

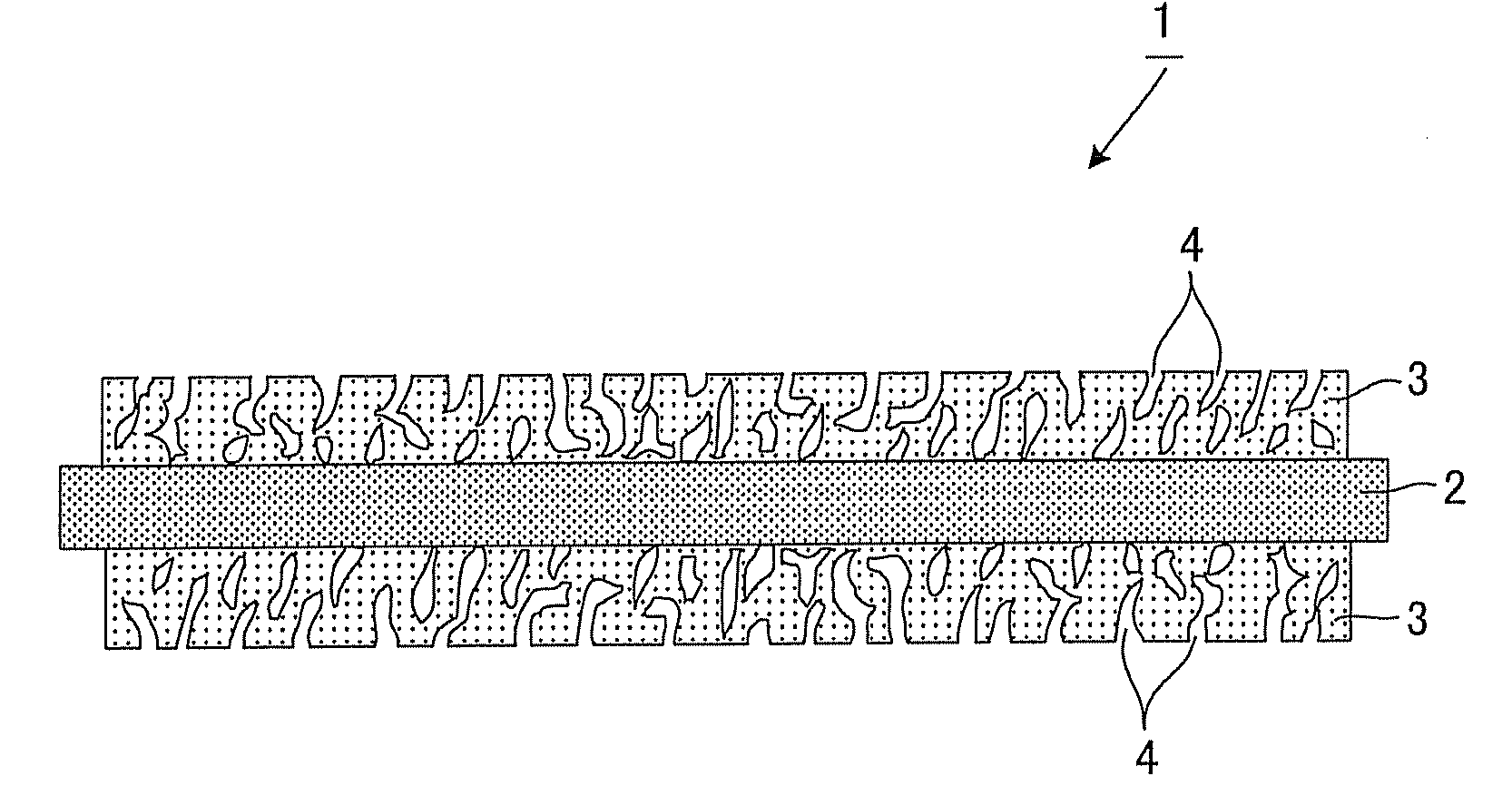

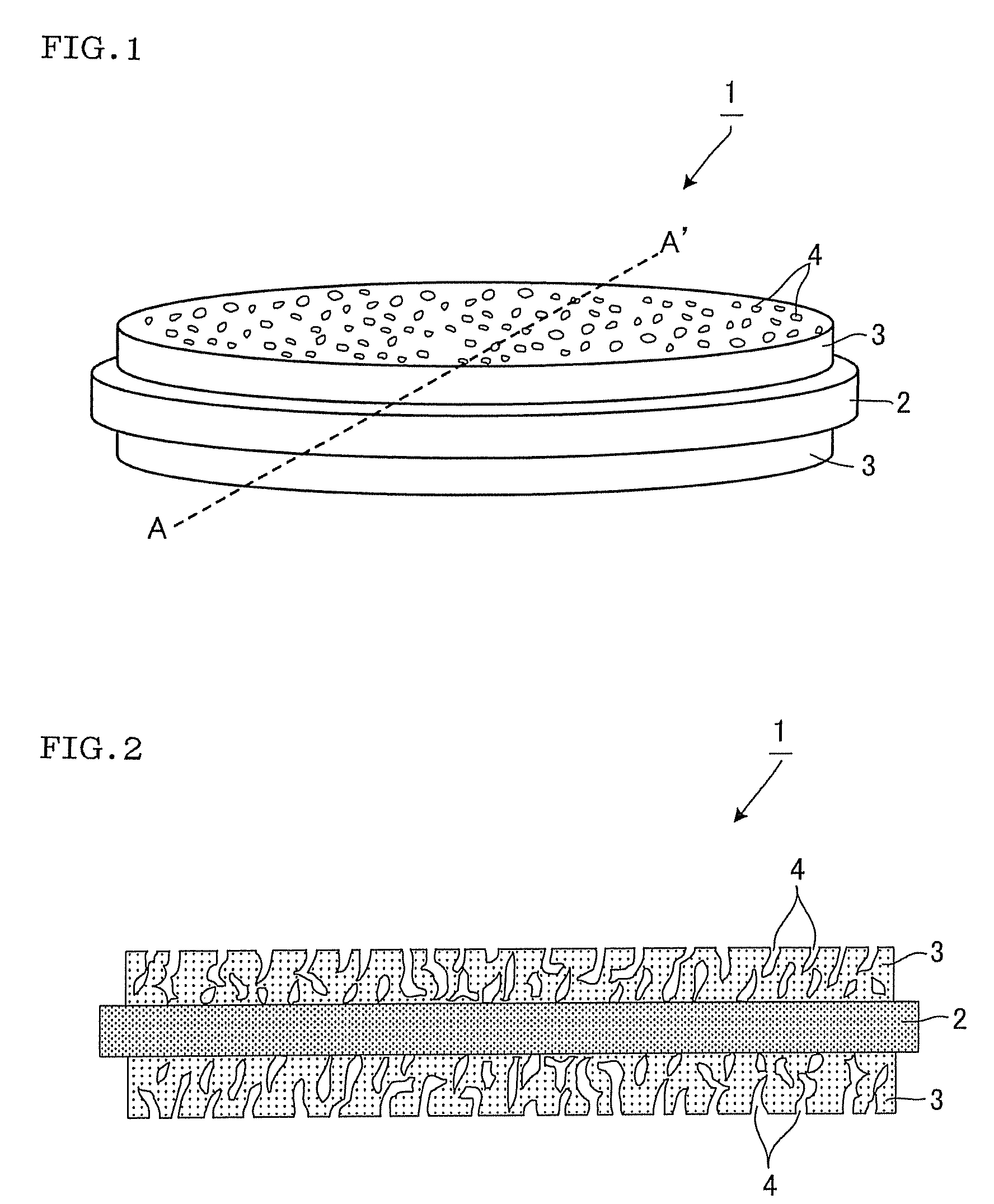

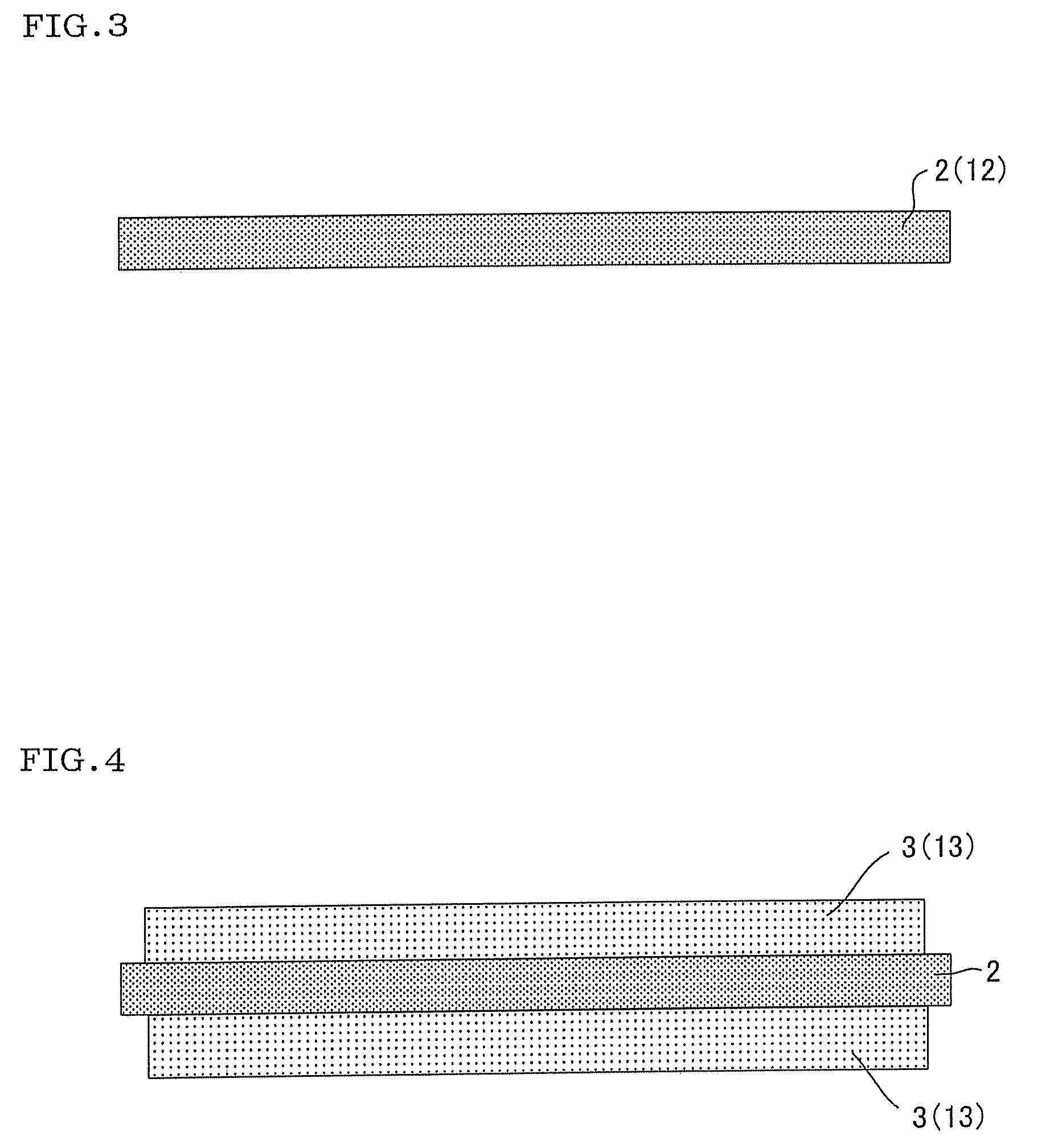

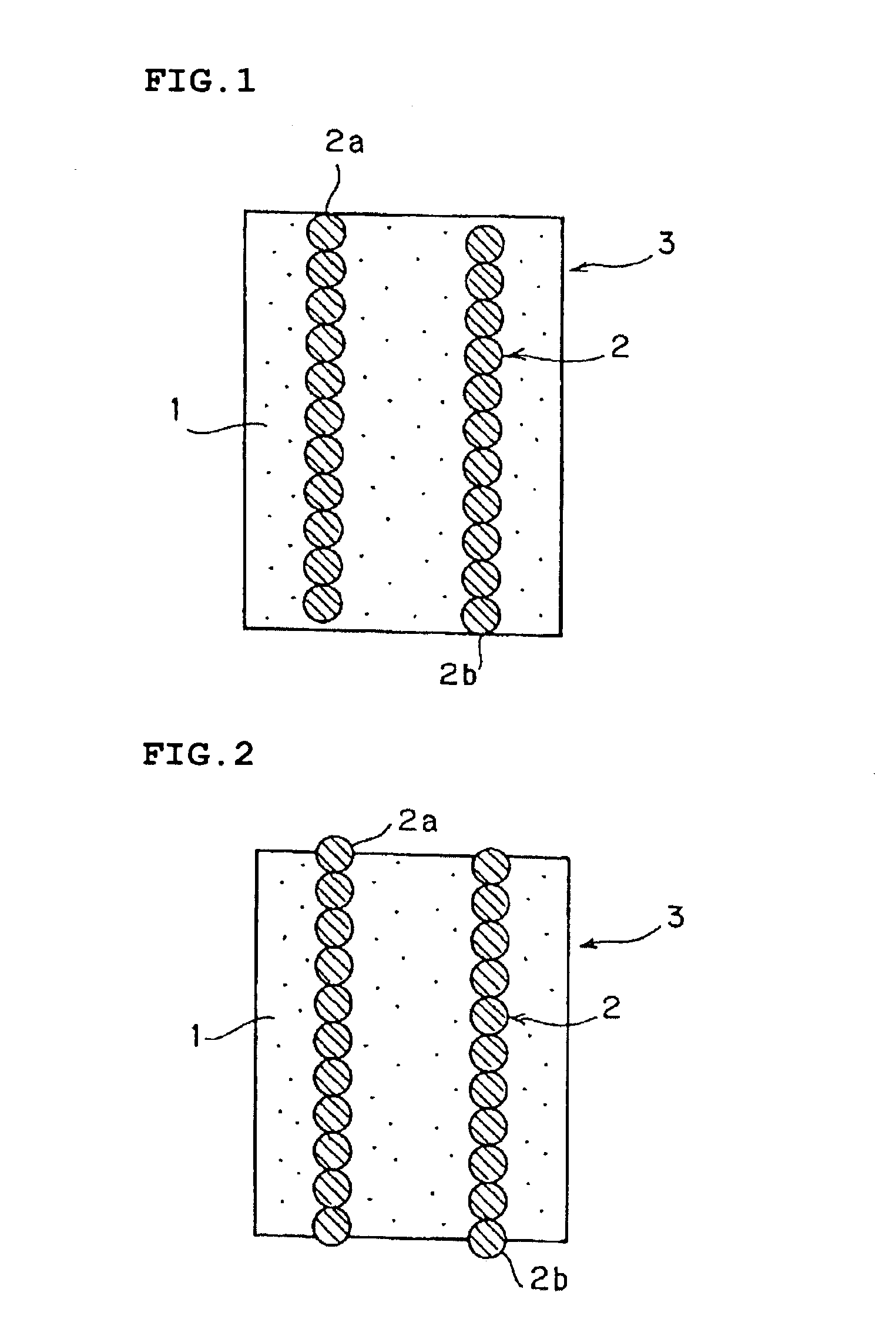

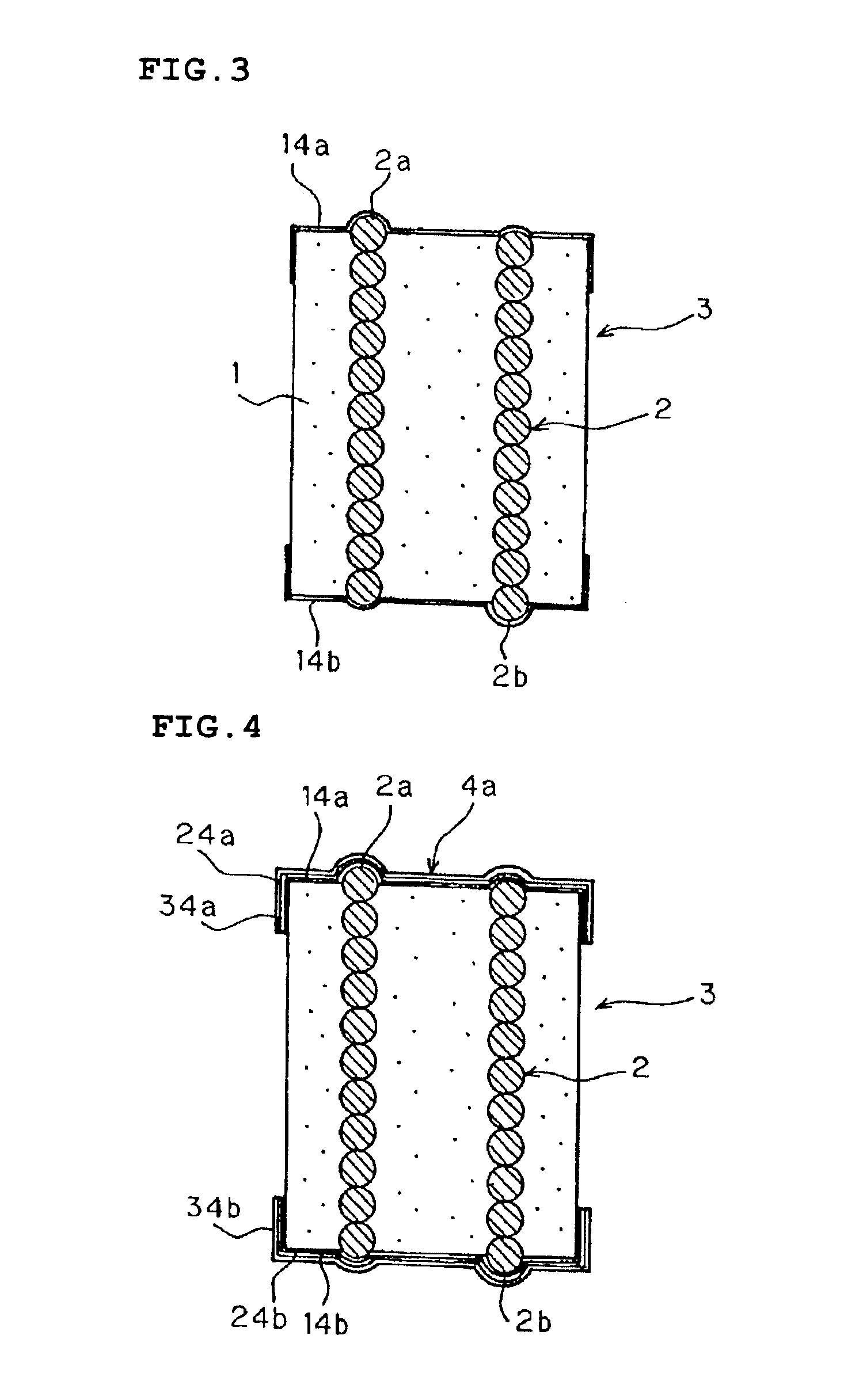

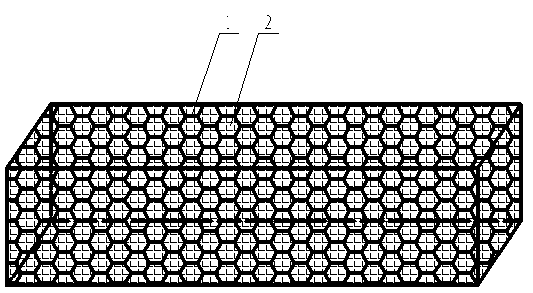

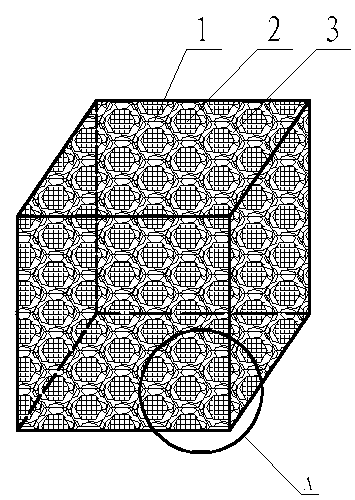

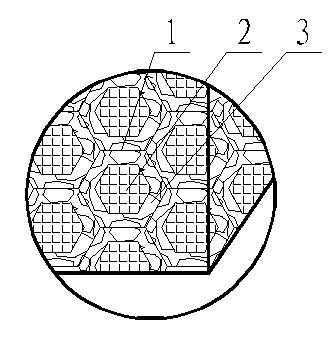

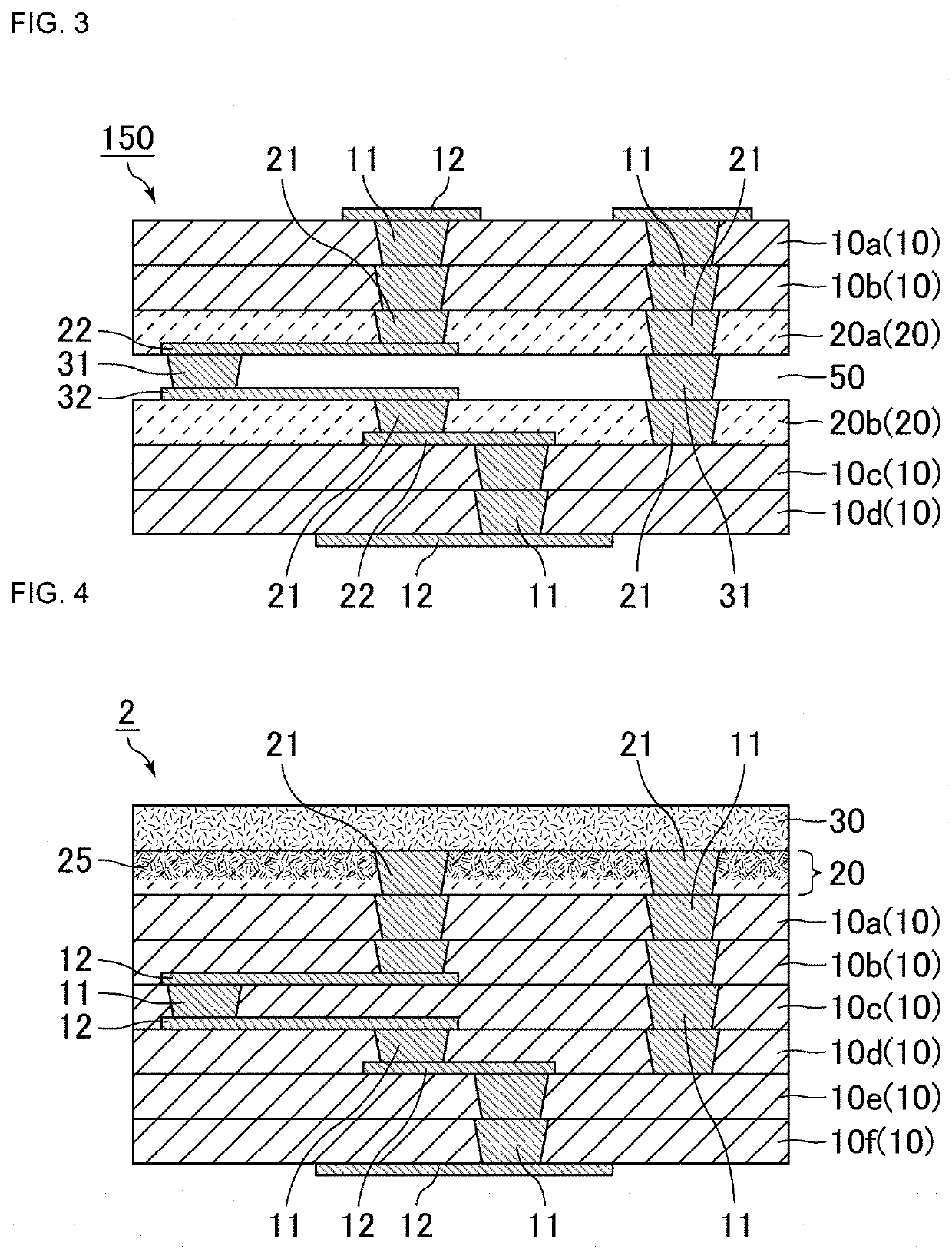

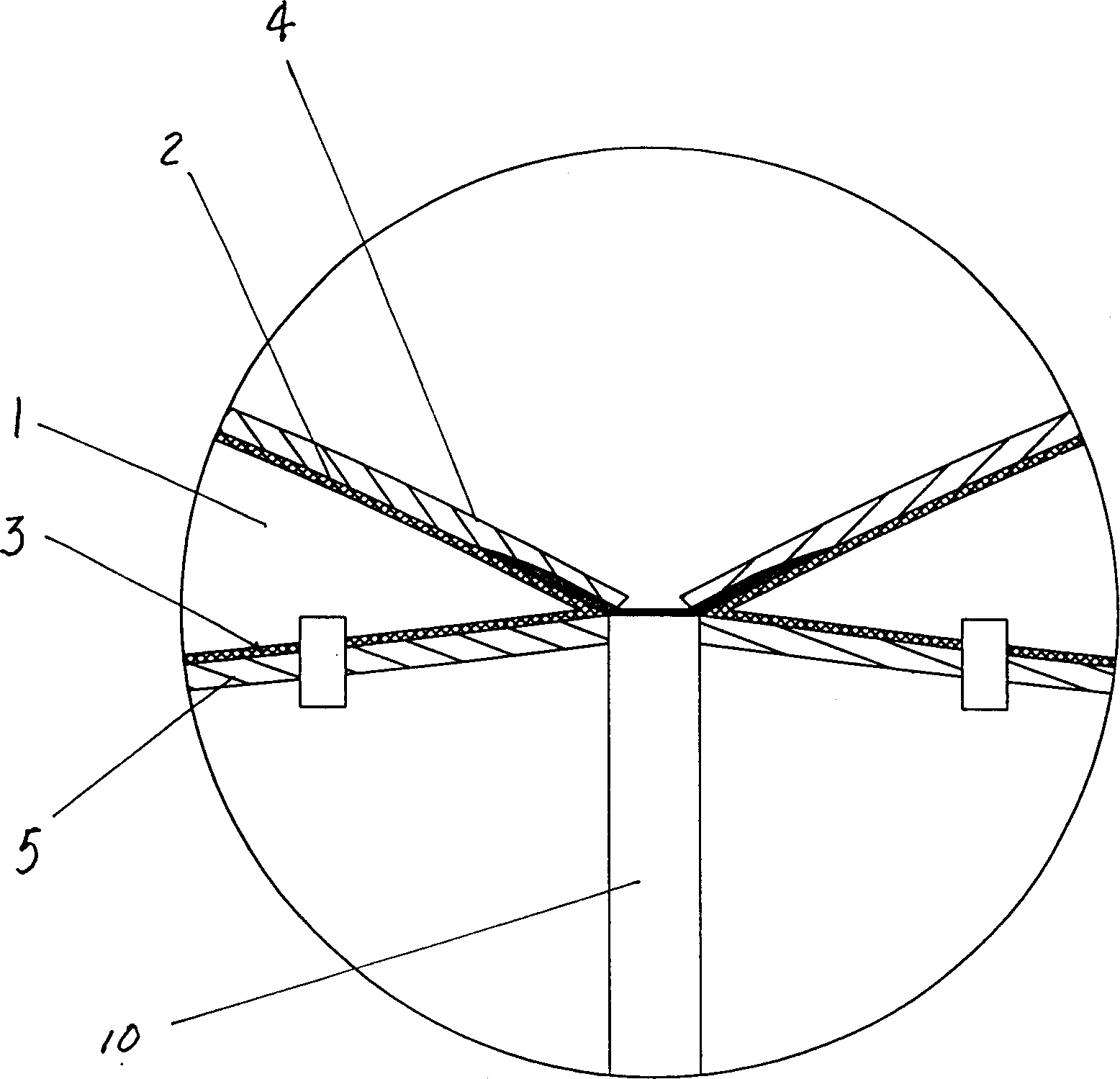

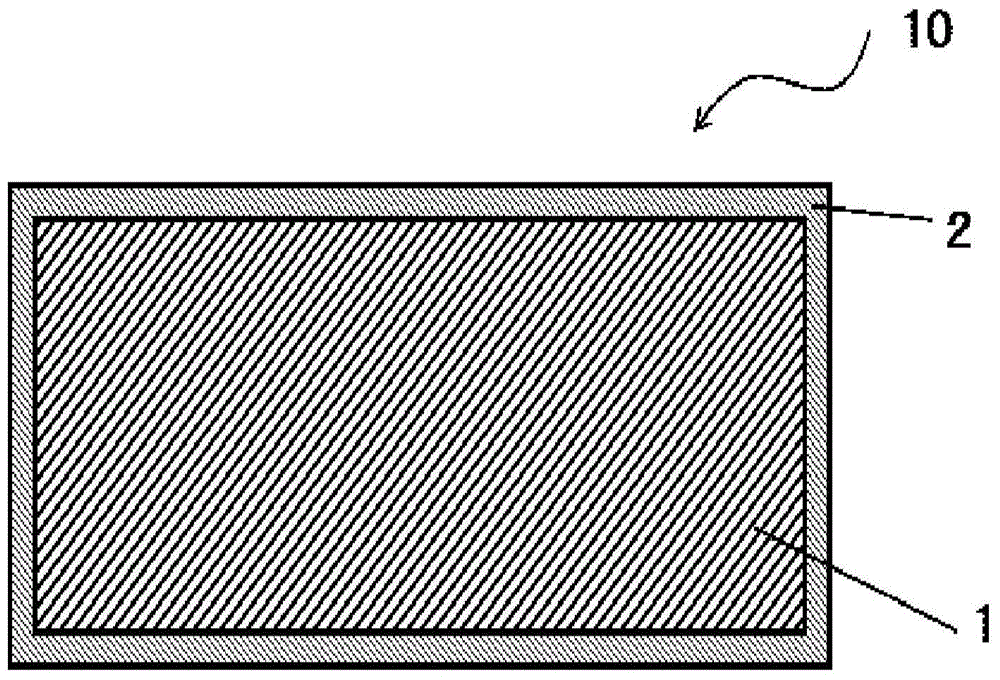

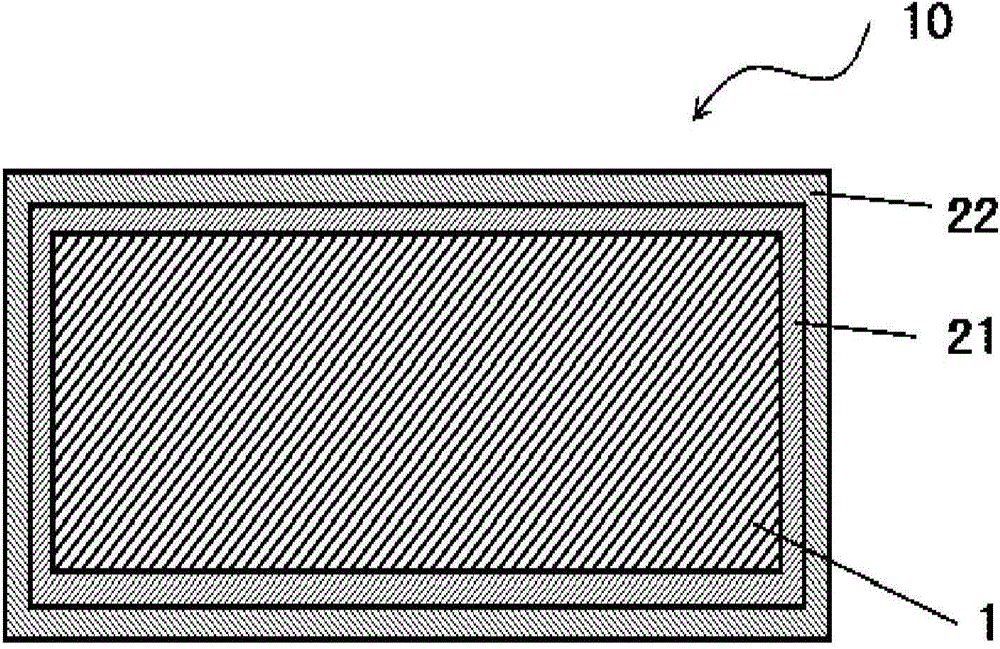

A solid electrolyte structure (1) for all-solid-state batteries includes a plate-like dense body (2) formed of a ceramic that includes a solid electrolyte, and a porous layer (3) formed of a ceramic that includes a solid electrolyte that is the same as or different from the solid electrolyte of the dense body (2), the porous layer (3) being integrally formed on at least one surface of the dense body (2) by firing. The solid electrolyte structure can reduce the contact resistance at the interface between the solid electrolyte and an electrode.

Owner:NGK INSULATORS LTD +1

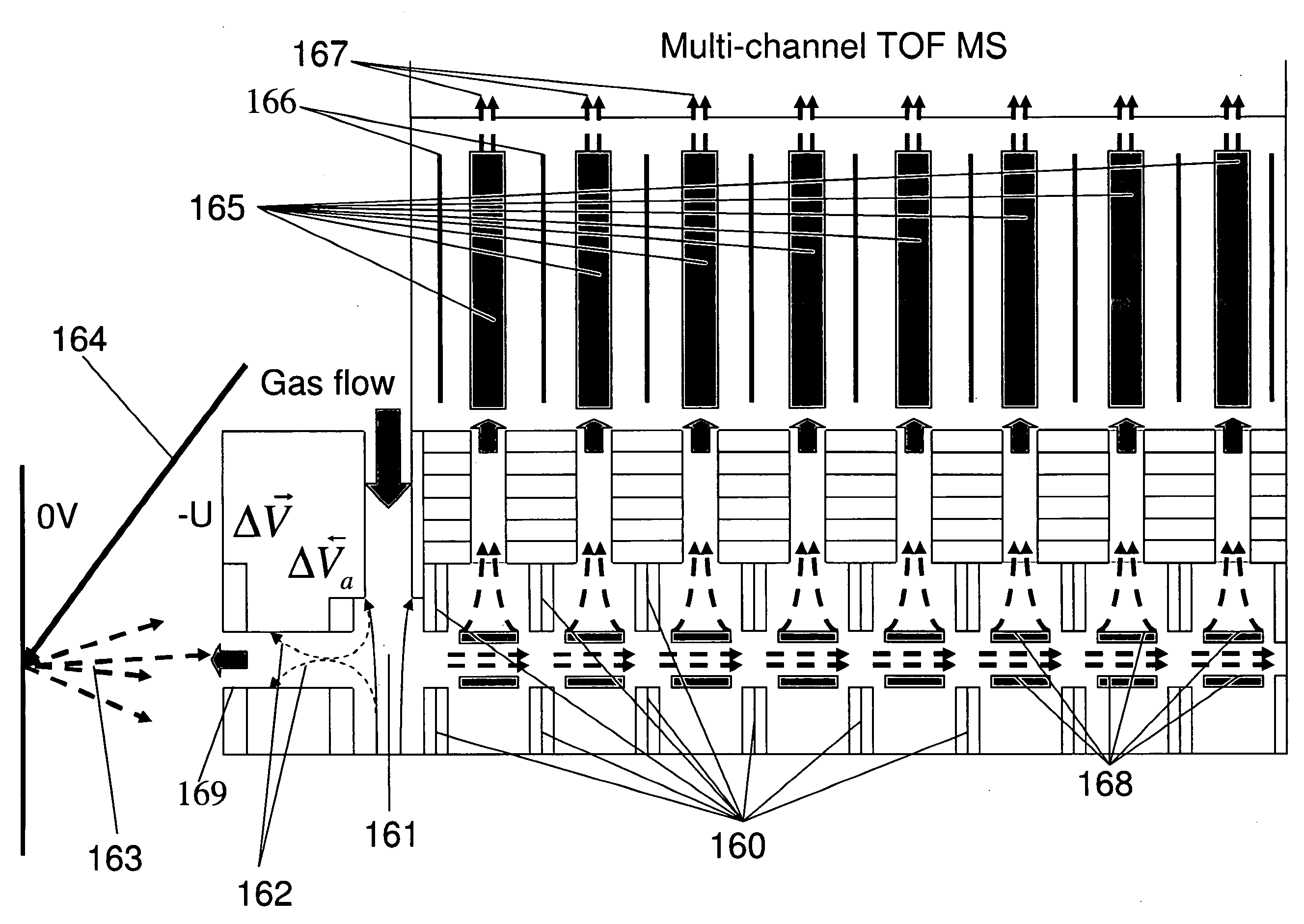

Multi-beam ion mobility time-of-flight mass spectrometry with multi-channel data recording

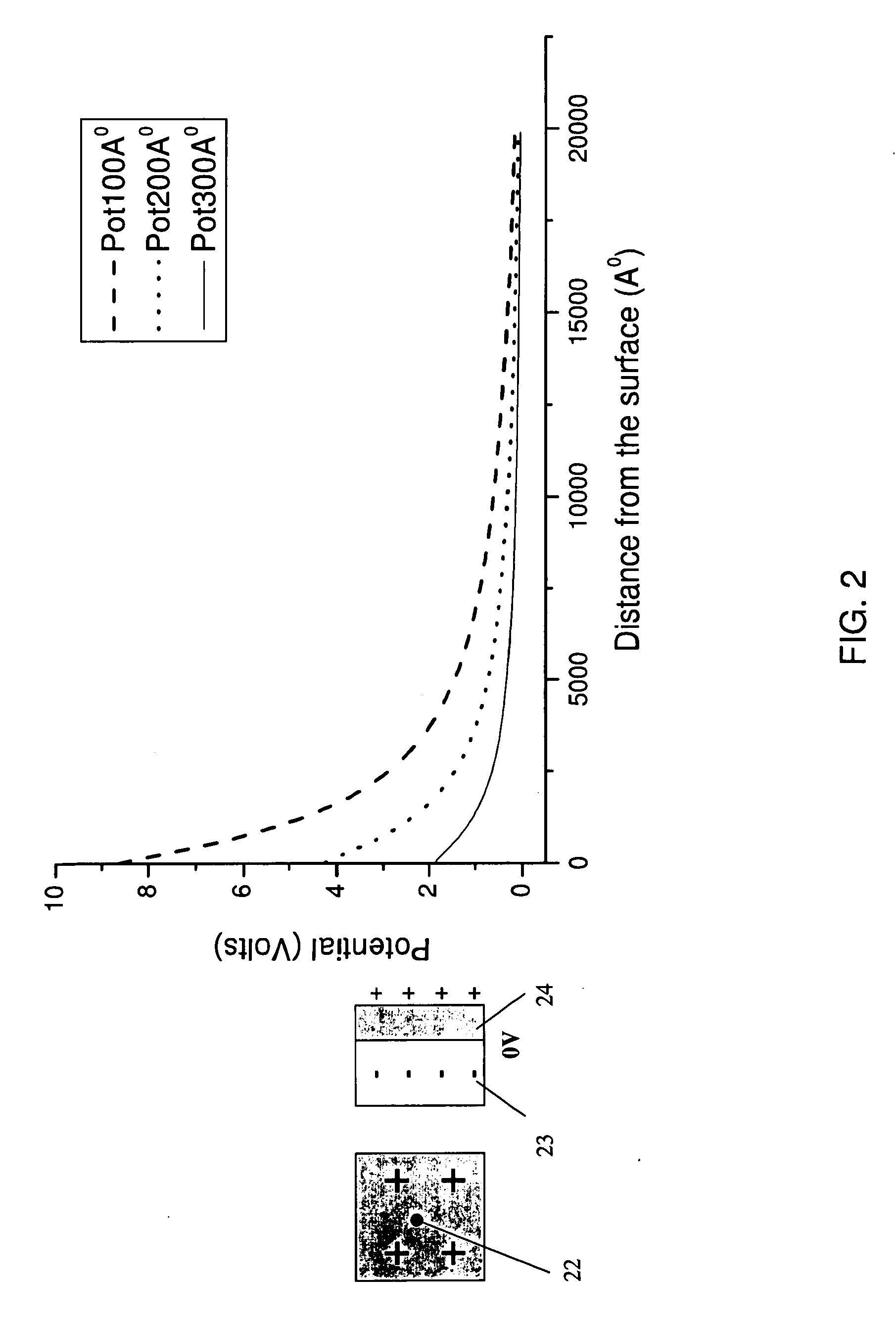

InactiveUS20090140140A1Improve efficiencyReduce divergenceTime-of-flight spectrometersMaterial analysis by electric/magnetic meansDense bodyData recording

The content of the invention comprises a concept of multi-beam ion pre-selection from a single sample, coordinated mobility (against the gas flow) separation, cooling ions in supersonic gas flow and mass separation of thus low divergent ions by single or plural compact high-resolution orthogonal time-of-flight mass spectrometers both linear or reflectron type with controlled collision-induced dissociation (CID) and multi-channel data recording for the optimization of sample use in the analysis, and obtaining as much useful information about the sample as possible in a reasonably short time.

Owner:IONWERKS

Porous cubic boron nitride based material suitable for subsequent production of cutting tools and method for its production

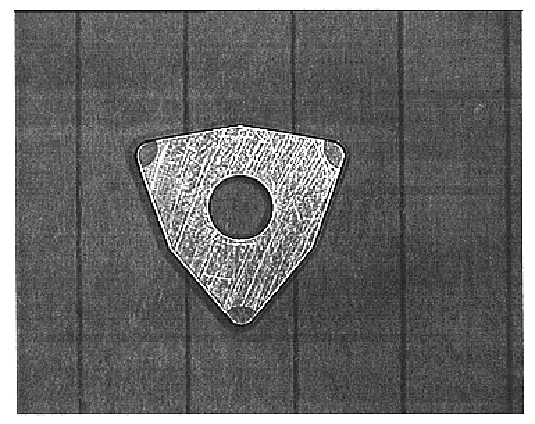

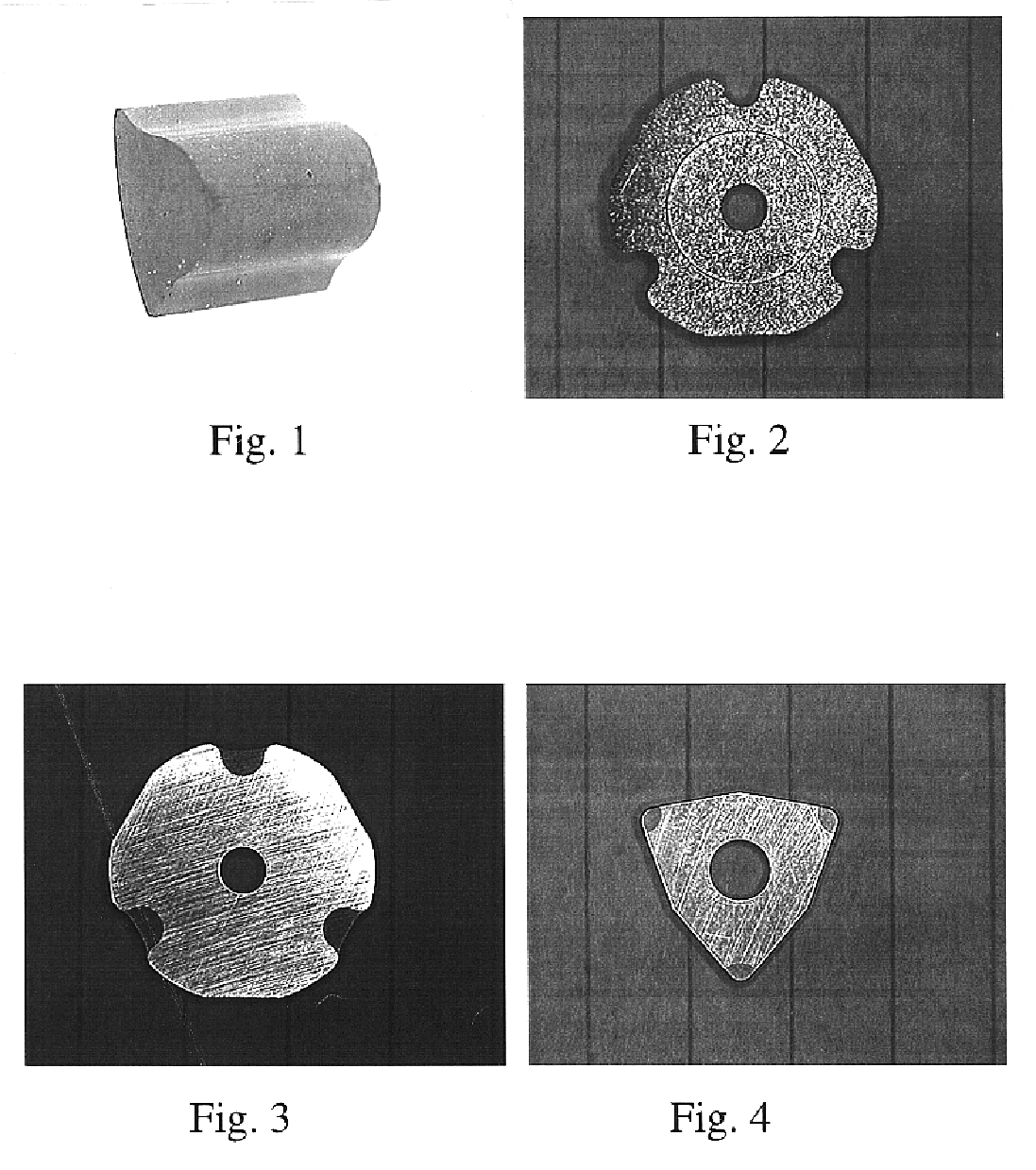

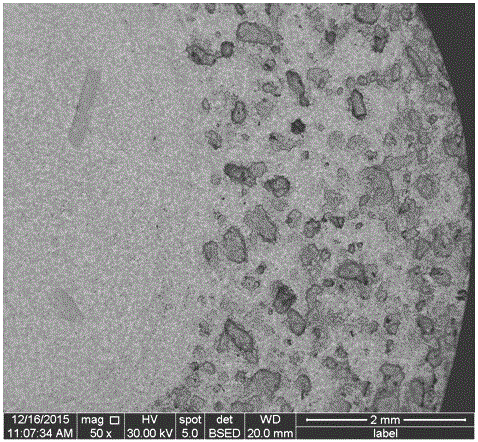

The presently claimed invention relates to a method of making a PcBN cutting tool insert. The method includes the following steps: mixing raw material powders, (e.g., cBN, hBN, TiC, TiN, Ti(C,N), WC, W, C, Co, Co2Al9, Al AlN, Al2O3) with a liquid (e.g., ethanol) and an agent (e.g., polyethylene glycol, PEG) to form a homogeneous slurry with the desired composition; forming spherical powder agglomerates, typically 100 mum in diameter, preferably by spray drying; pressing said agglomerates to form a body of desired dimensions and density using conventional tool pressing technology; removing the agent from the powder at a suitable temperature and atmosphere; raising the temperature to 1000-1350° C. in vacuum; solid state sintering the body at 1000-1350° C. in vacuum, for 1-90 minutes to form a body with 35-55 vol % porosity; optionally, adding 0.5-1000 mbar of nitrogen to the sintering atmosphere at the hold time or during cooling; and HP / HT treating the porous body to form a dense body of desired shape and dimension.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Cutting tool made of surface-coated cubic boron nitride-based ultrahigh pressure sintered material

ActiveUS20070148496A1Uneven appearanceAvoid uneven appearancePigmenting treatmentOther chemical processesDense bodyTitanium nitride

A cutting tool made of surface-coated cubic boron nitride-based ultrahigh pressure sintered material, comprising a cutting insert main body formed by ultrahigh pressure sintering of compact composed of titanium nitride, aluminum and / or aluminum oxide, and boron nitride, and a hard coating layer vapor deposited on the main body. The main body has a texture containing cubic boron nitride, titanium nitride and reaction product. The hard coating layer has a lower layer of composite nitride having a composition of [Ti1−XAlX]N, where X is in a range from 0.40 to 0.60 in an atomic ratio, and the upper layer comprises a thin layer A having the composition of [Ti1−XAlX]N, where X is in a range from 0.40 to 0.60 in an atomic ratio, and a thin layer B consisting of a Ti nitride (TiN). The upper layer has a consisting of the thin layer A and a thin layer B layered alternately.

Owner:MITSUBISHI MATERIALS CORP

Porous cubic boron nitride based material suitable for subsequent production of cutting tools and method for its production

InactiveUS6676893B2Electrically conductive connectionsRelieving strain on wire connectionPorosityDense body

The presently claimed invention relates to a method of making a PcBN cutting tool insert. The method includes the following steps:mixing raw material powders, (e.g., cBN, hBN, TiC, TiN, Ti(C,N), WC, W, C, Co, Co2Al9, Al AlN, Al2O3) with a liquid (e.g., ethanol) and an agent (e.g., polyethylene glycol, PEG) to form a homogeneous slurry with the desired composition;forming spherical powder agglomerates, typically 100 mum in diameter, preferably by spray drying;pressing said agglomerates to form a body of desired dimensions and density using conventional tool pressing technology;removing the agent from the powder at a suitable temperature and atmosphere;raising the temperature to 1000-1350° C. in vacuum;solid state sintering the body at 1000-1350° C. in vacuum, for 1-90 minutes to form a body with 35-55 vol % porosity;optionally, adding 0.5-1000 mbar of nitrogen to the sintering atmosphere at the hold time or during cooling; andHP / HT treating the porous body to form a dense body of desired shape and dimension.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Method for making dense polycrystalline aluminum oxynitride

InactiveUS7163656B1Consistently and uniformly dense and economically producedReduce wearCeramic shaping apparatusClaywaresPolycrystalline aluminumPowder mixture

A dense polycrystalline aluminum oxynitride body is produced. According the method of production, aluminum oxide (alumina) powder and 26 to 40 mole % aluminum nitride powder is mixed to form a very fine powder mixture. The powder mixture is shaped and hot pressed at a moderate temperature, preferably about 1600° C., which is below the temperature of aluminum oxynitride (AlON) formation to produce a dense intermediate body. The dense intermediate body is reacted to produce a highly dense polycrystalline aluminum oxynitride body. The dense body is particularly useful for ballistic armor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

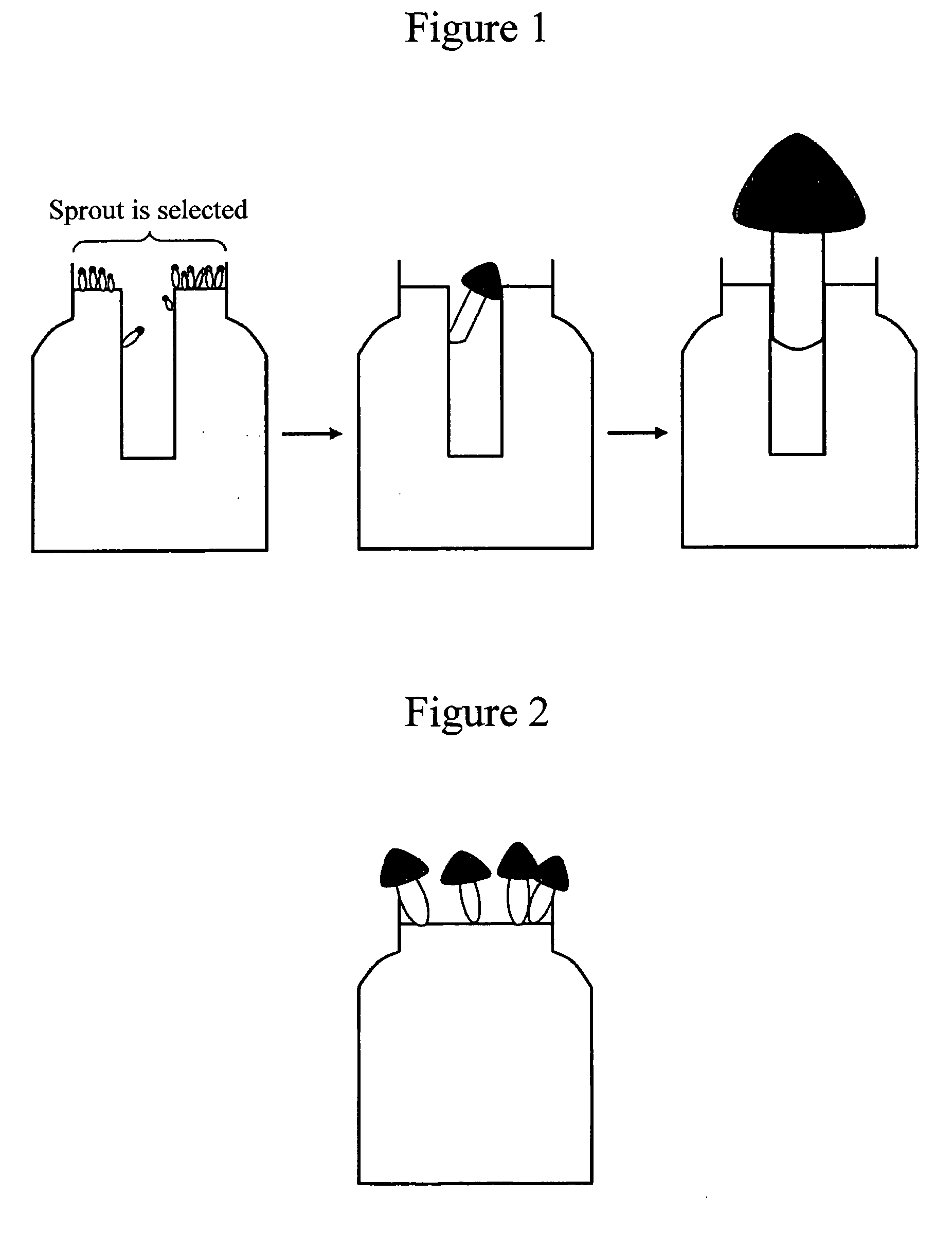

Solid electrolyte structure for all-solid-state battery, all-solid-state battery, and their production methods

InactiveUS7824795B2Reduce contact resistanceReduce dispersionFinal product manufactureSolid electrolyte cellsAll solid statePorous layer

A solid electrolyte structure (1) for all-solid-state batteries includes a plate-like dense body (2) formed of a ceramic that includes a solid electrolyte, and a porous layer (3) formed of a ceramic that includes a solid electrolyte that is the same as or different from the solid electrolyte of the dense body (2), the porous layer (3) being integrally formed on at least one surface of the dense body (2) by firing. The solid electrolyte structure can reduce the contact resistance at the interface between the solid electrolyte and an electrode.

Owner:NGK INSULATORS LTD +1

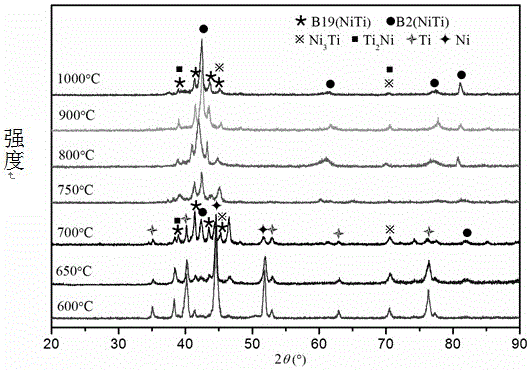

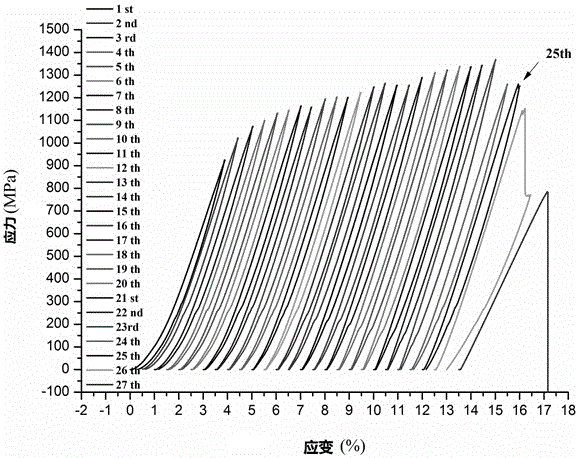

Preparation method of graded porous nickel-titanium alloy

InactiveCN106513681AImprove performanceStable structureTissue regenerationProsthesisPorosityORTHOPEDIC IMPLANT MATERIAL

The invention discloses a preparation method of a graded porous nickel-titanium alloy, and belongs to the technical field of preparation of biomedical materials. The preparation method comprises the steps that Ni metal powder and Ti metal powder are weighed according to the composition proportion and then subjected to ball milling mechanical mixing; the mixed metal powder is divided into a plurality of parts, and the parts and an ammonium bicarbonate pore forming agent are weighed according to different porosity ratios and mixed; and after mixing, powder of different compositions is mechanically pressed into a graded block compact, the graded block compact is placed in a discharge plasma sintering furnace, after a system is vacuumized to 2 Pa to 6 Pa, sintering is carried out, the temperature rising rate ranges from 50 min / DEG C to 100 min / DEG C, heat preservation is carried out for 5 min to 10 min under the temperature ranging from 600 DEG C to 1000 DEG C, furnace cooling is carried out to achieve room temperature, and a graded porous nickel-titanium alloy medical material can be obtained. The part, in contact with the bone tissue, of the implanted material has high porosity and the large aperture, bone cells can be bonded to the surface of the material to grow, and biological locking is formed; and the inner structure is provided with a dense body high in strength and superelasticity, the material can be matched with the bone tissue, cooperative deformation is generated, the stress shielding effect is weakened, and the material can adapt to stress bearing conditions of bones on different portions. Thus, the biomedical graded porous nickel-titanium alloy material prepared through the method can be used as a good bone bearing orthopedic implant material.

Owner:KUNMING UNIV OF SCI & TECH

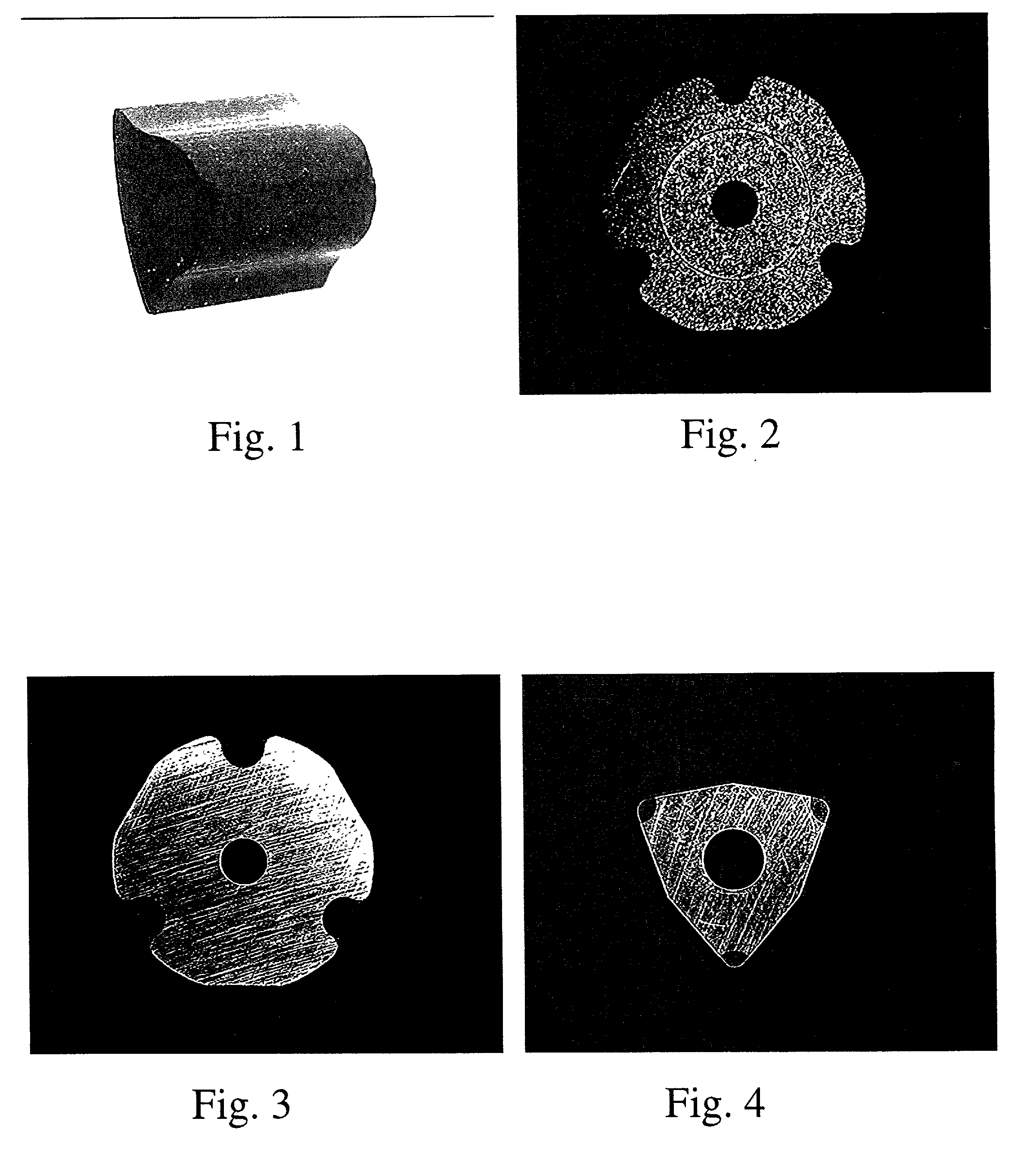

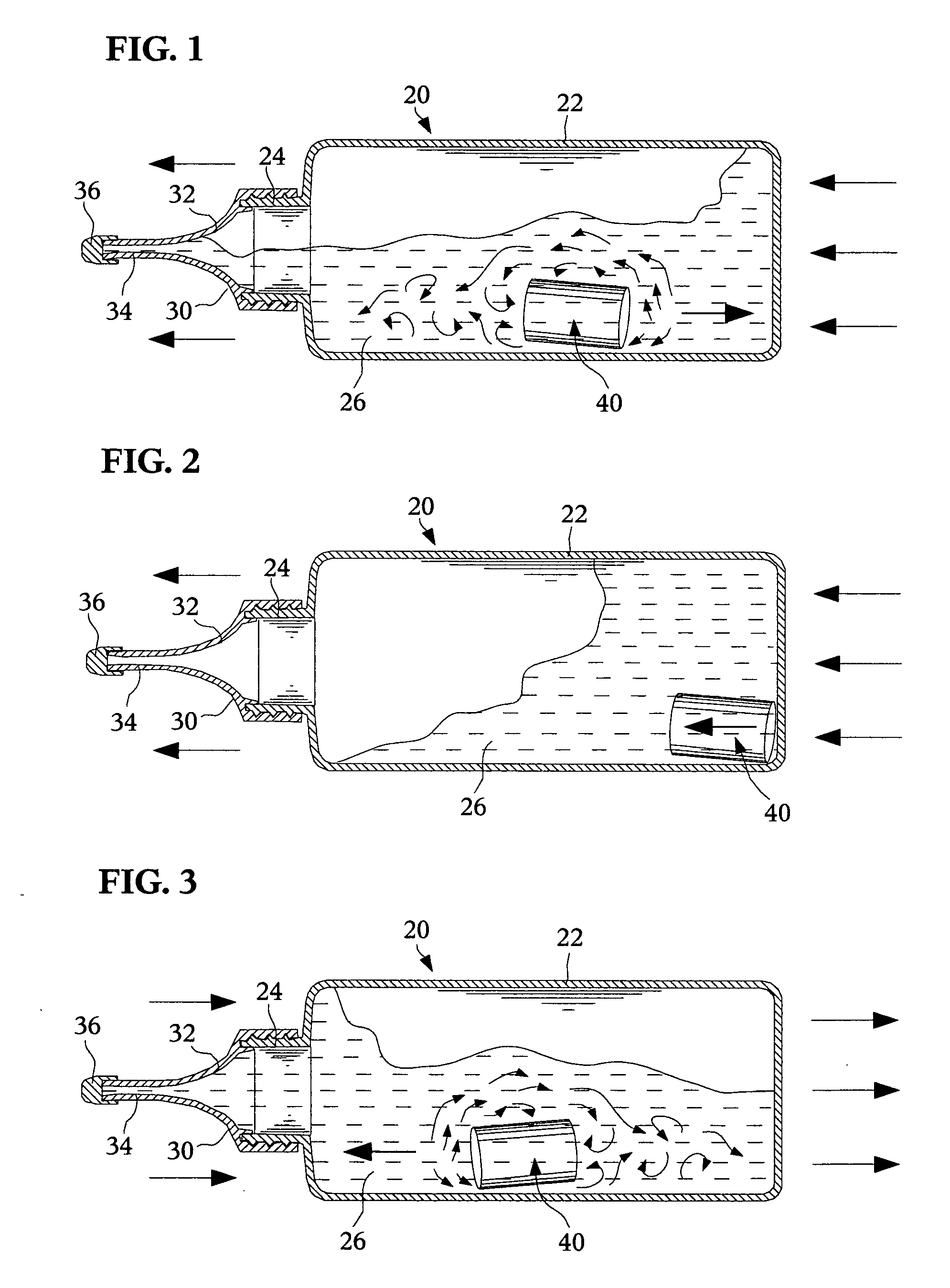

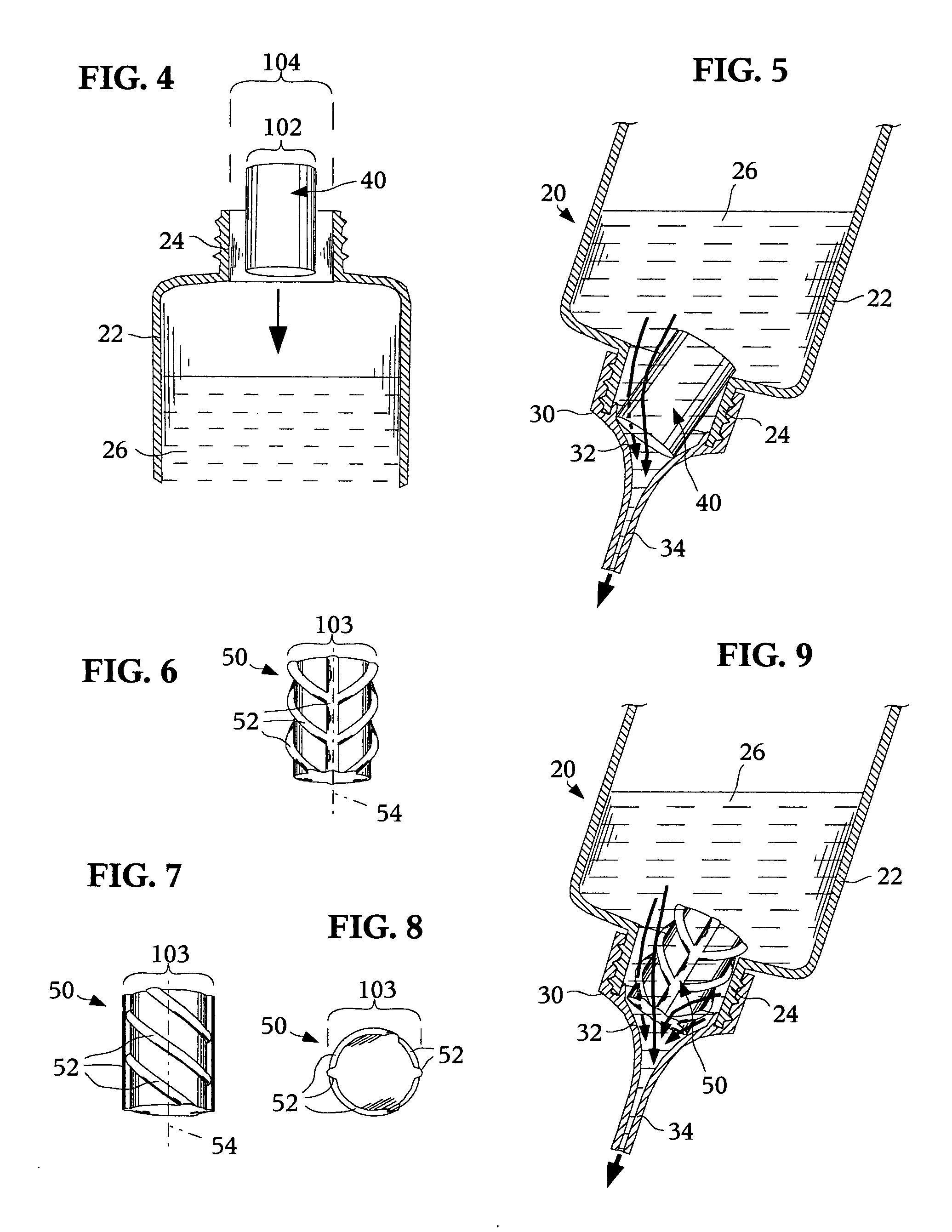

Agitator for mixing hair coloring dye

A generally cylindrical non-spherical dense body having rib members, used for agitating hair coloring dye within a mixing and application hair coloring dye container. When the container is shaken, the agitator travels randomly inside the container agitating the hair coloring dye liquids together and more thoroughly mixing the entire contents of the container. The shape of the agitator and protruding ribs improve agitation and prevent the blockage of the container applicator orifice when applying the hair coloring dye. The agitator can be dropped into the hair coloring dye container or provided with the container.

Owner:BACHMAN HELMUTH G

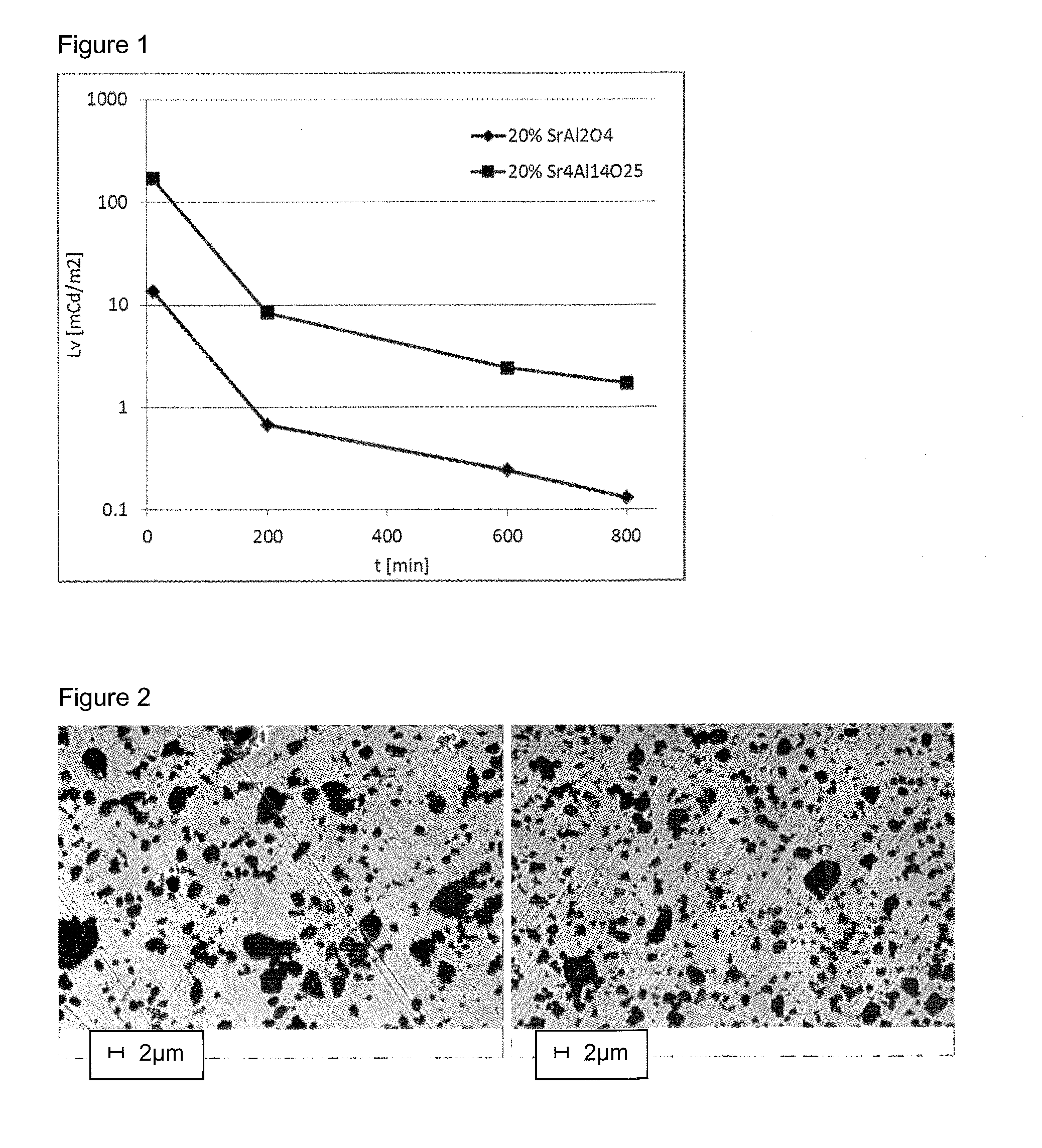

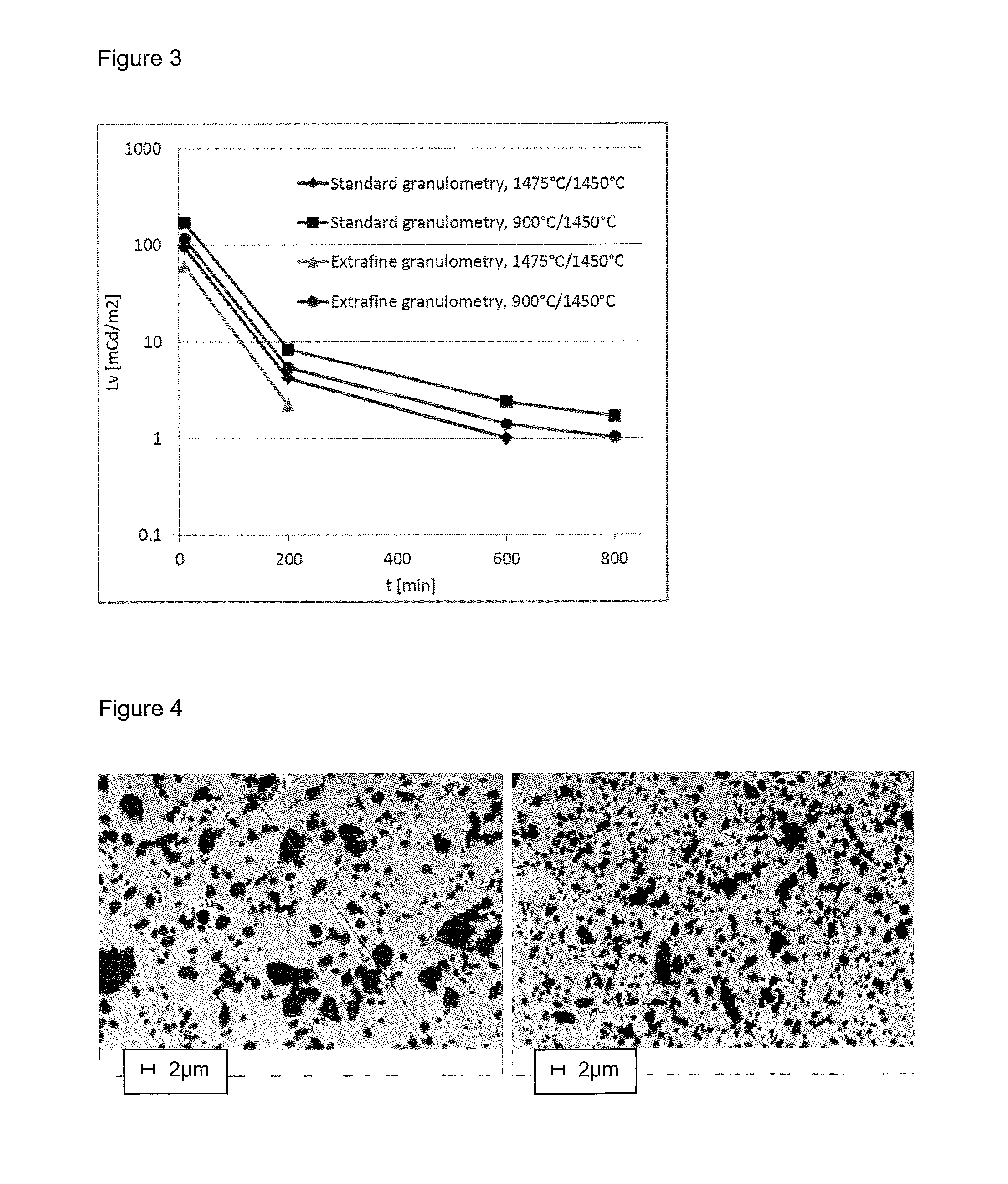

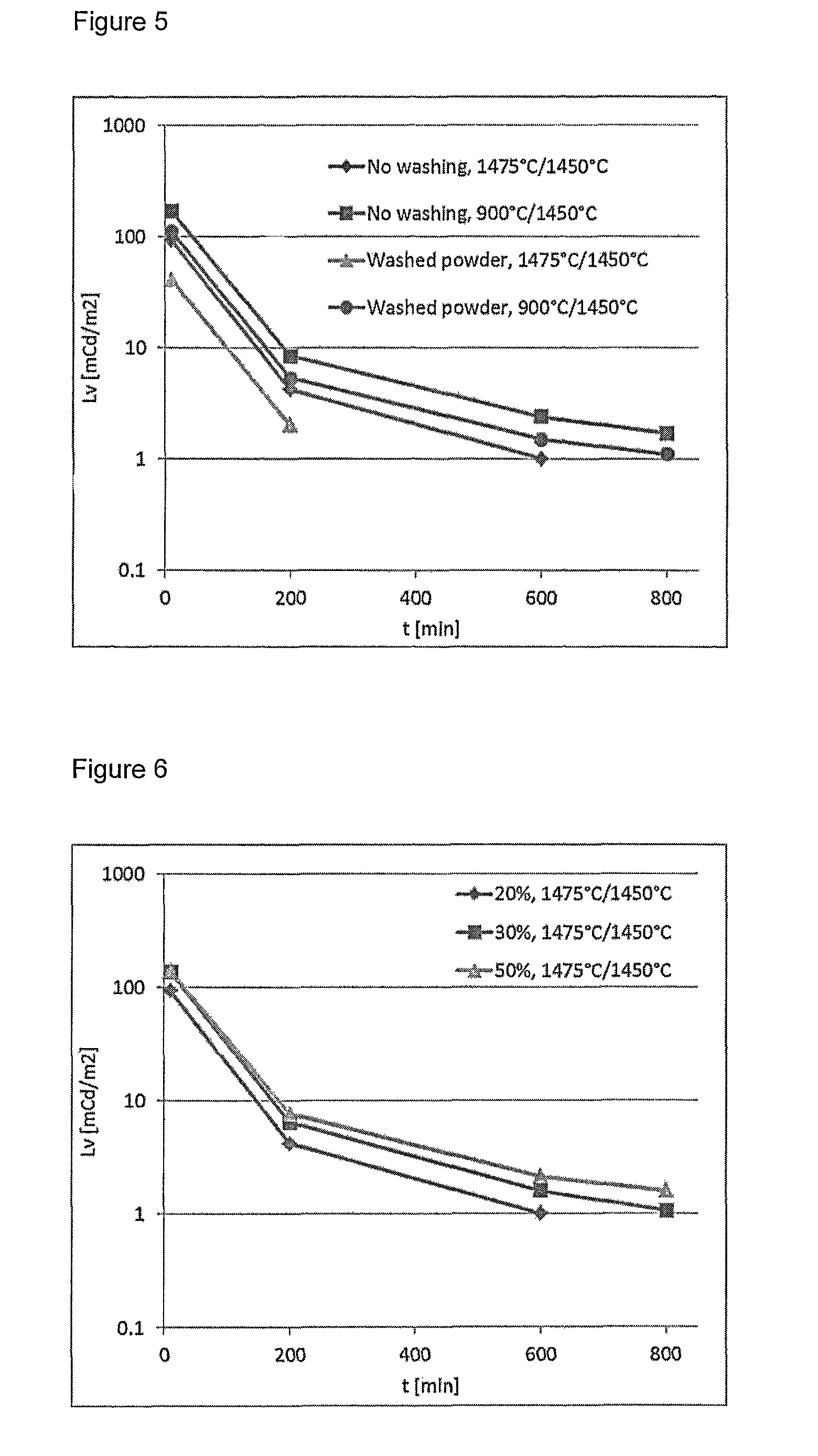

Persistent Phosphorescent Composite Material

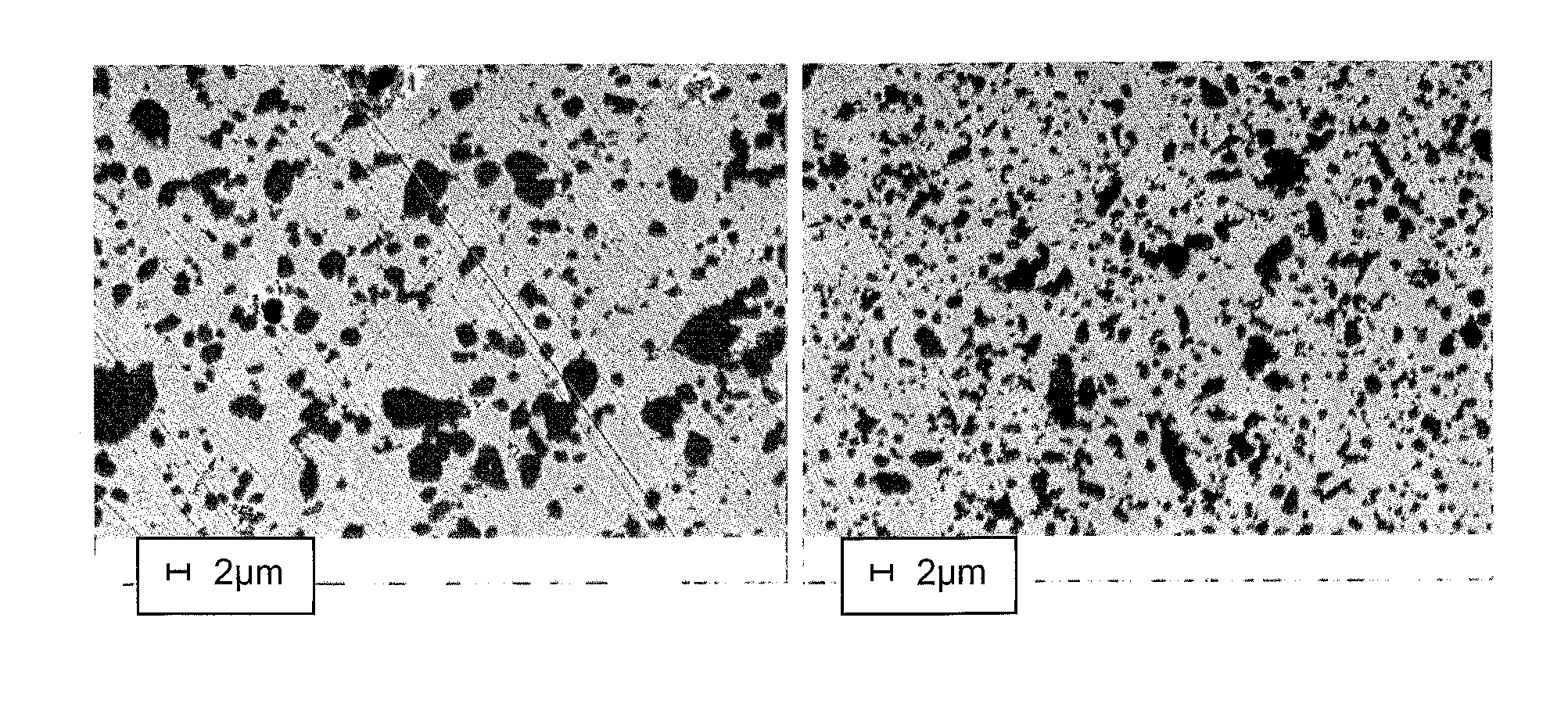

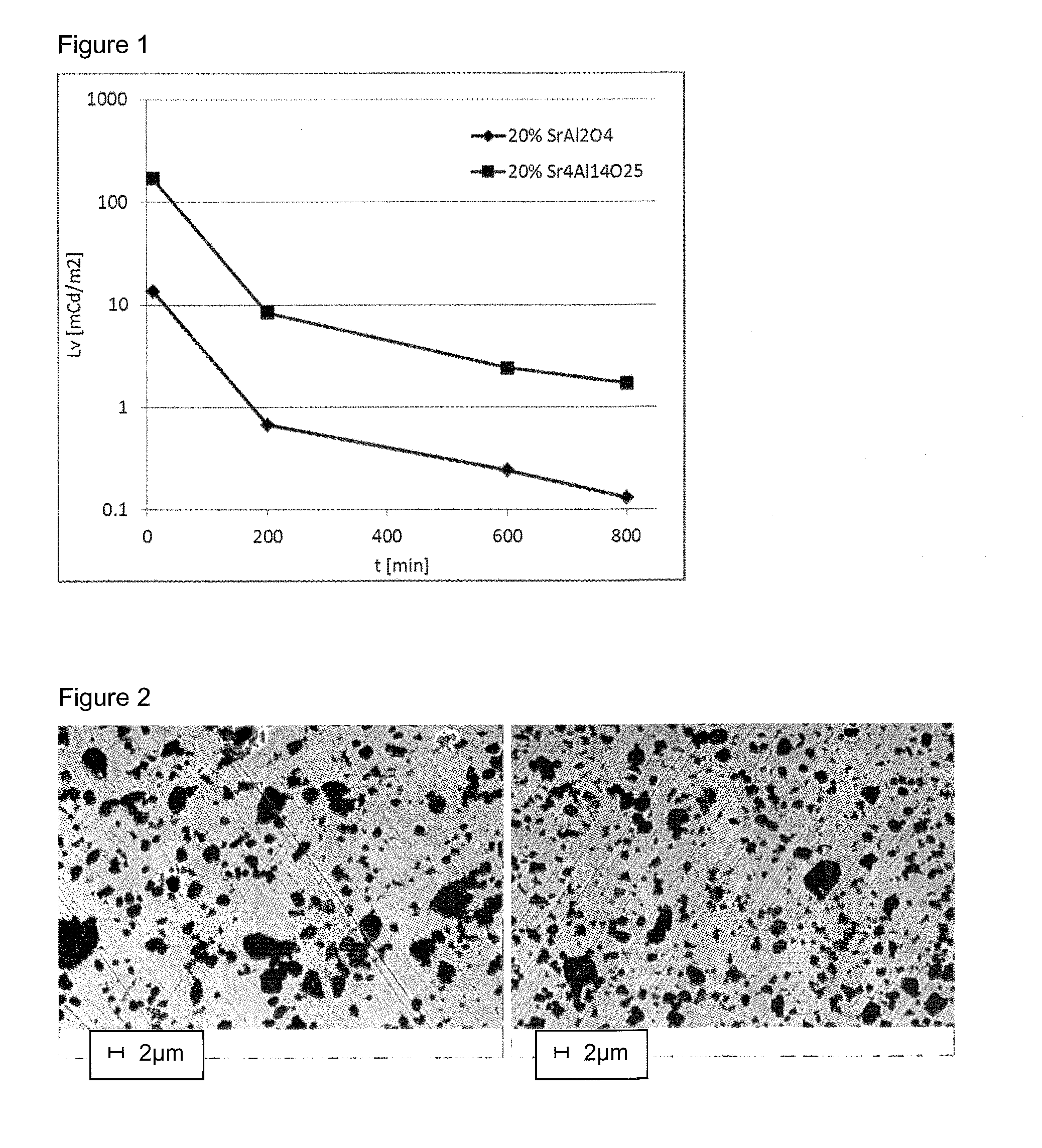

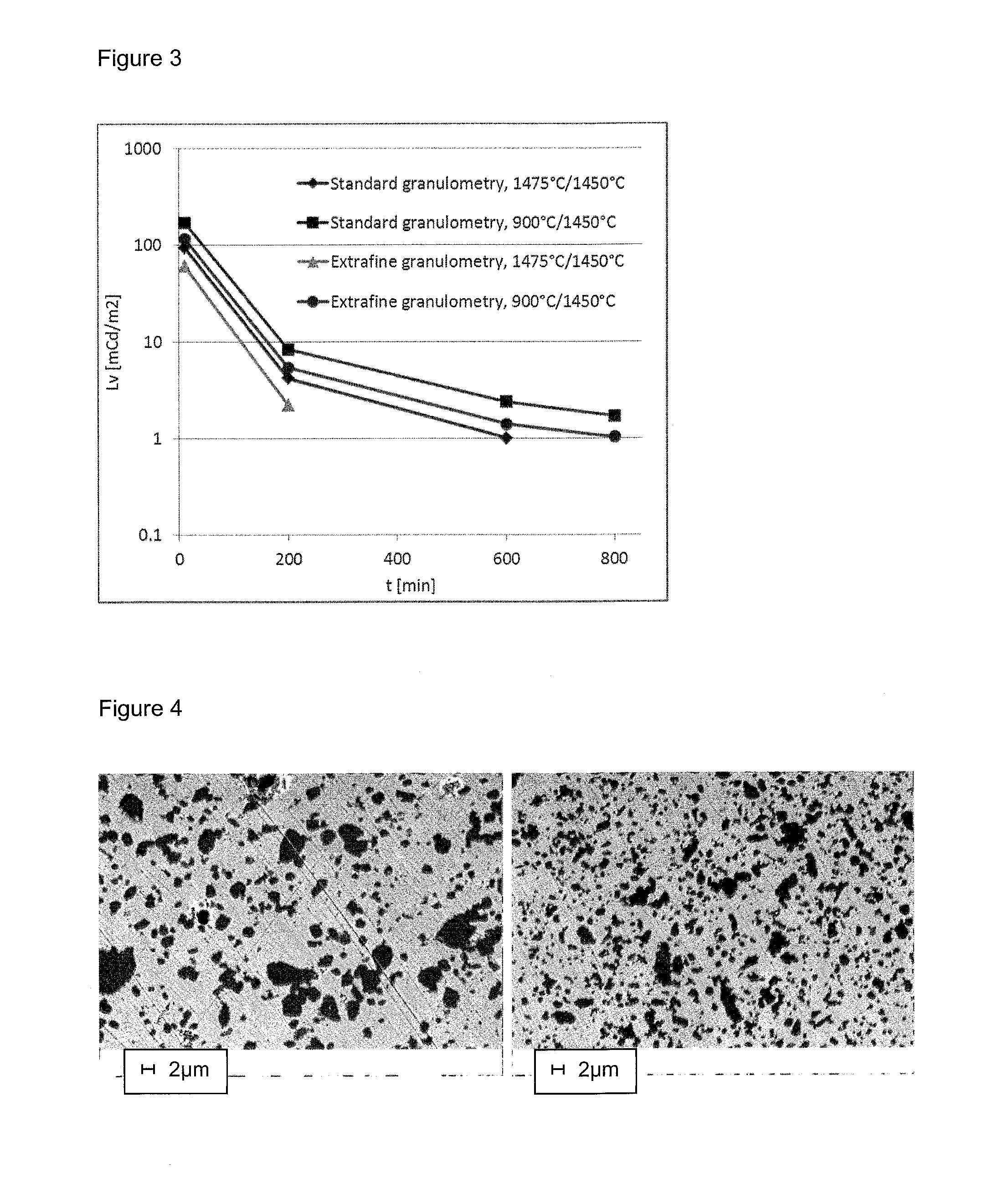

ActiveUS20140124702A1Improve mechanical propertiesIncrease brightnessVisual indicationClockwork casesCeramic compositePhosphor

The invention relates to a persistent phosphorescent ceramic composite material which is a sintered dense body comprising two or more phases, a first phase consisting of at least one metal oxide and a second phase consisting of a metal oxide containing at least one activating element in a reduced oxidation state. The invention furthermore relates to a method for the preparation of a phosphorescent ceramic composite material as defined in any of the previous claims, the method comprising the following steps: preparing a mixture of a metal oxide and a phosphor; fabricating a green body from the mixture; and heat treating the green body in a reducing atmosphere.

Owner:ROLEX SA

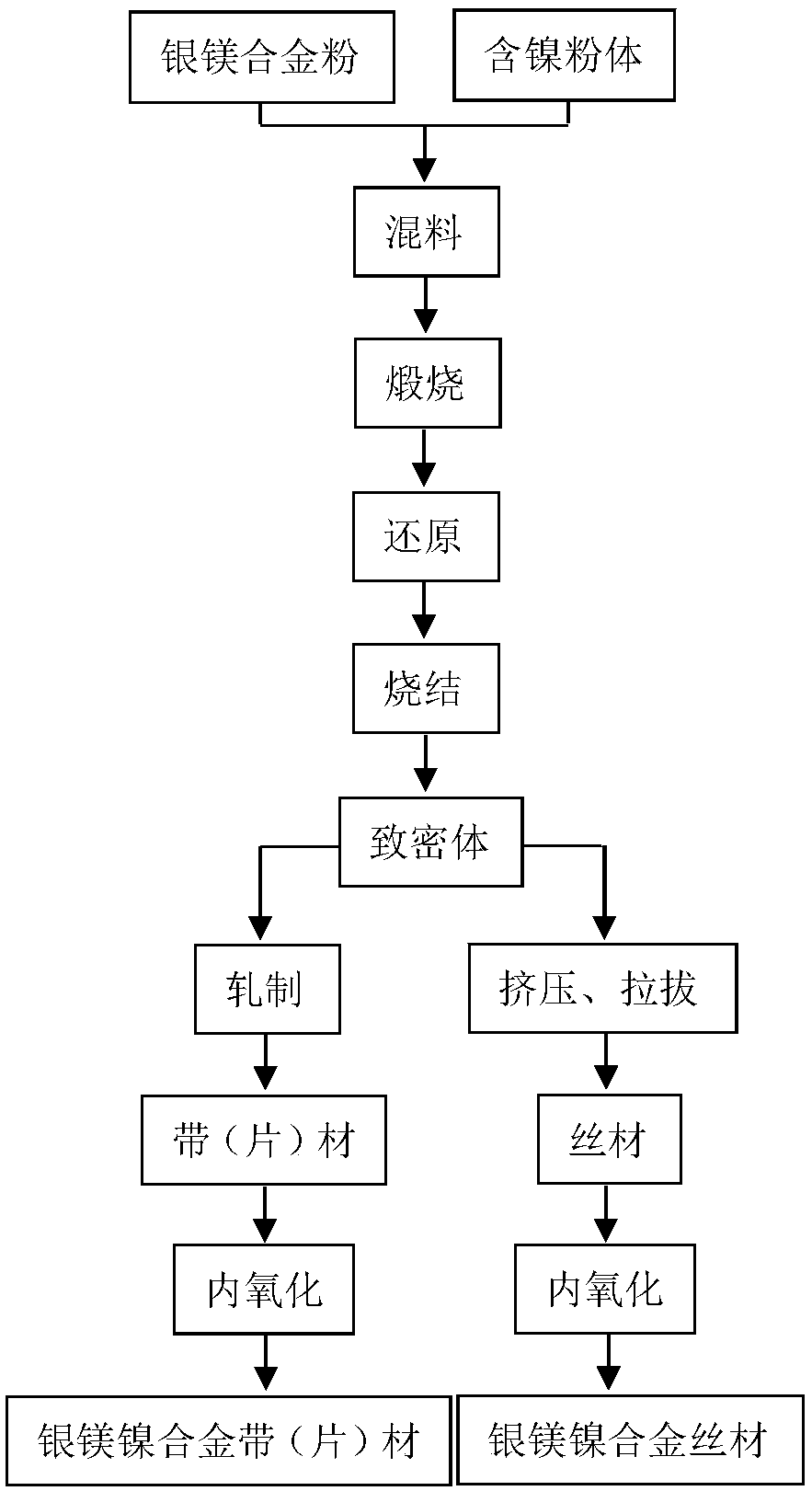

Preparation method of silver-magnesium-nickel alloy belt (slice) and wire

Owner:NORTHEASTERN UNIV +1

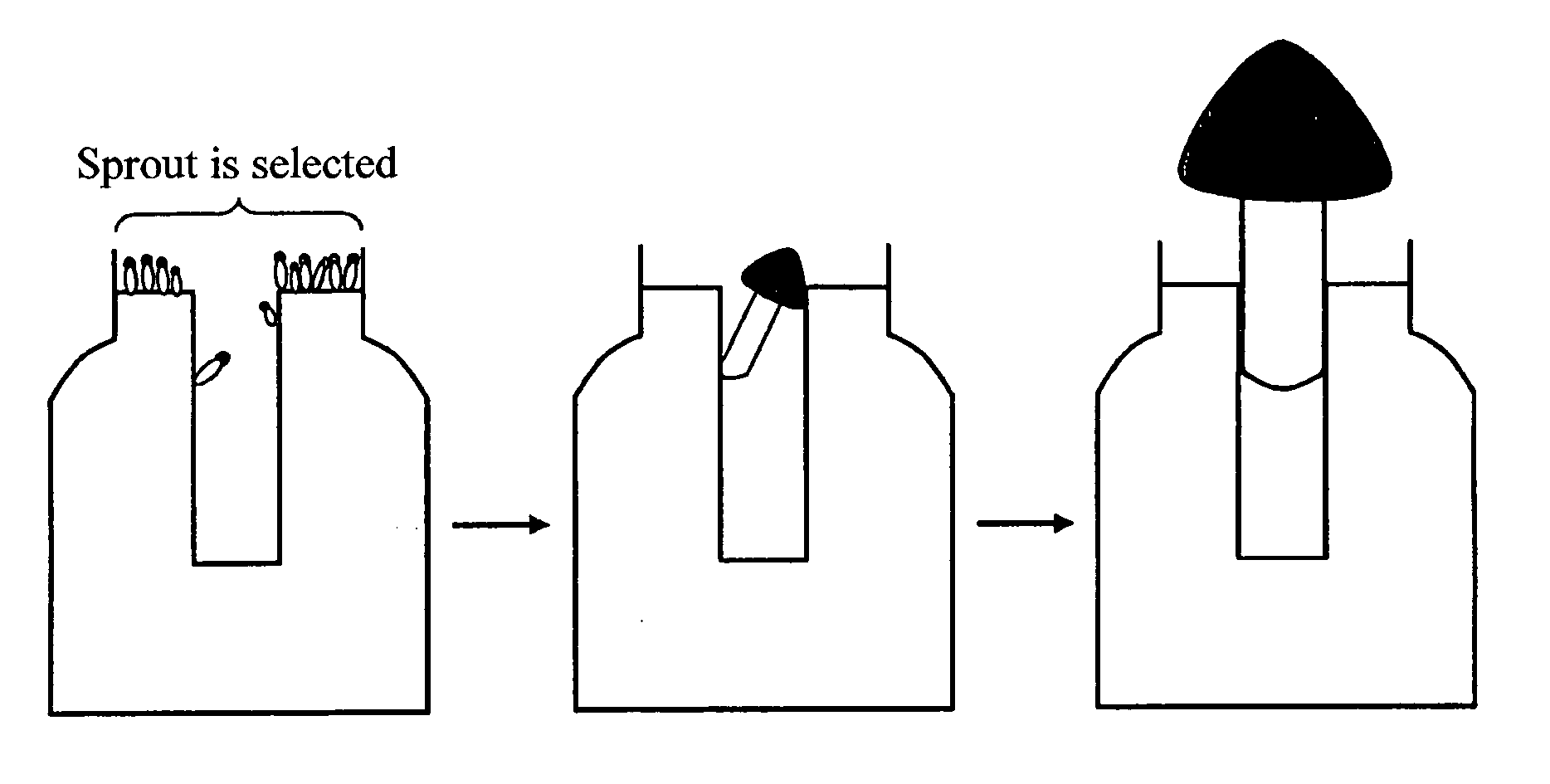

Method for cultivating mushroom

InactiveUS20060112618A1High densityNice appearanceCultivating equipmentsMushroom cultivationDense bodyMushroom

The present invention relates to a method for cultivating a mushroom of a large size having an excellent shape and crunchy texture, and a mushroom fruit body having the above-mentioned characteristics obtained by the method. According to the present invention, a mushroom fruit body of very high commercial value having a large size, an excellent shape and a dense body, which has never existed, and a method for cultivating the mushroom fruit body are provided.

Owner:TAKARA HOLDINGS

Inductor and method of producing the same

InactiveUS6876286B2Line/current collector detailsTransformers/inductances coolingElectrical conductorDense body

An inductor is constructed to achieve efficient formation of external electrodes, and exhibits high reliability of connection between the external electrodes and an internal conductor, and desired characteristics. In the method of manufacturing the inductor, a magnetic material formed by kneading a magnetic material and a resin is molded to form a magnetic material compact body in which the internal conductor is partially exposed from the external surface thereof, and then the surface of the magnetic material compact body is plated to form the external electrodes including a plated metal film and connected to the internal conductor. The surface of the magnetic material compact body is roughened, and then the external electrodes are formed via plating.

Owner:MURATA MFG CO LTD

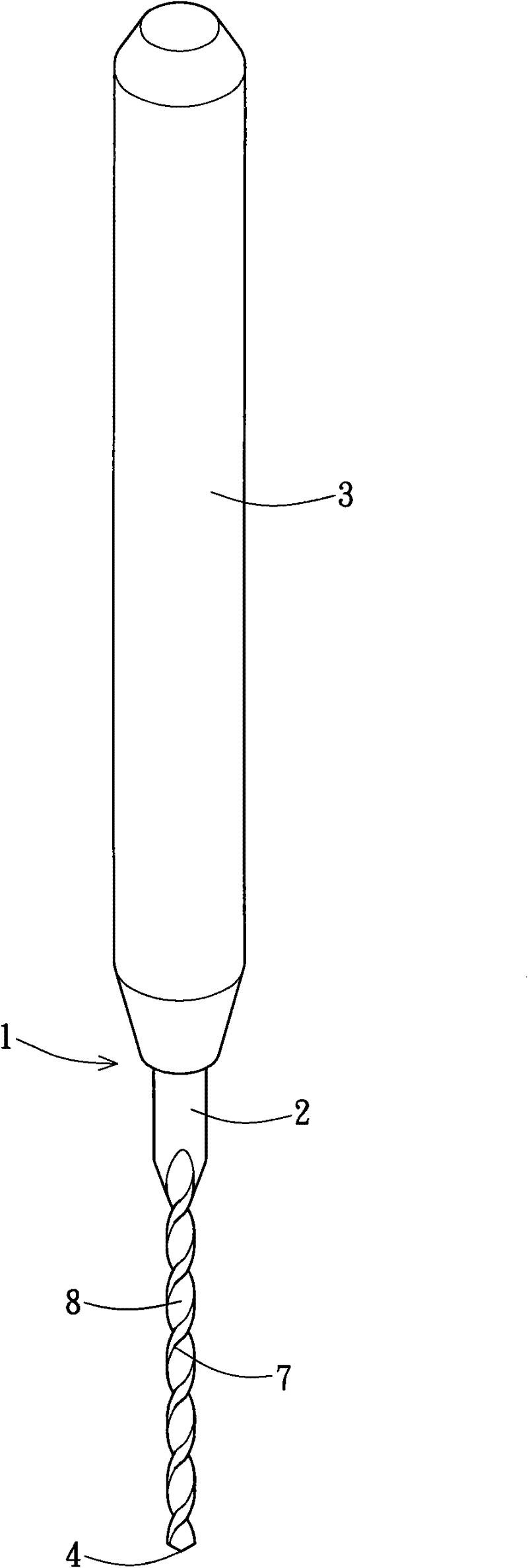

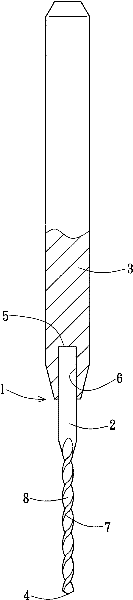

Powder sintering forming method for cutting tool and cutting body thereof

InactiveCN102189257AImprove machining accuracyImprove processing qualityTransportation and packagingTrepanning drillsDense bodyMilling cutter

The invention relates to a powder sintering forming method for a cutting tool and a cutting body thereof, which comprises the following steps of: manufacturing a cutting body workpiece with the same shape as the cutting body of a drill, a micro drill or a spiral end mill; performing injection coating forming at the periphery and one end of the cutting body workpiece to obtain a thermoplastic plastic mold body; rotatably withdrawing a cutting body forming mold cavity of the plastic mold body from the other end of the cutting body workpiece; injecting cutter material powder and a mixed binder thereof into the cutting body forming mold cavity, and injecting metal powder and a mixed binder thereof into a handle body forming mold cavity of a forming mold to prepare a cutting body powder dense body connected with a handle body powder dense body; extracting, degreasing to separate the binder, and heating to remove the plastic mold body; and sintering the cutting body powder dense body and the handle body powder dense body at a high temperature to prepare the cutting tool integrating the cutter material powder sintering cutting body with the metal powder sintering handle body.

Owner:钟淼芳

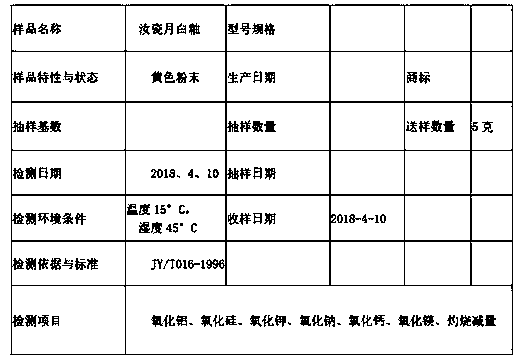

Moon white glaze Ru porcelain and preparation method thereof

The invention provides a moon white glaze Ru porcelain and a preparation method thereof. The moon white glaze Ru porcelain comprises a green body and a glaze, and the green body comprises, by mass, 20-35 parts of Fengxue soil, 30-65 parts of kaolin, 20-55 parts of Tanggou soil, 10-20 parts of black raw soil, 0.5-2 parts of white feldspar and 1-2.5 parts of sandstones; and the glaze comprises, by mass, 50-65 parts of white feldspar, 10-20 parts of red feldspar, 10-20 parts of calcite, 5-10 parts of black stones, 5-12 parts of agate, 0.5-1.2 parts of sheep bone ash and 3-10 parts of wollastonite. The preparation method comprises the following steps: preparing the green body, preparing the glaze, and coating the prepared green body with the prepared glaze. The porcelain formed by calcining the green body and the glaze has the advantages of excellent porcelain quality, dense body surface, delicate and elegant property, delicate shape, moist color and strong surface impression. The glaze layer is smooth regardless of the thickness of the body, and the porcelain has the characteristics of air ventilation, non-permeability, good taste-keeping function, moderate heat preservation, and goodreflection of the color, smell and taste of food materials.

Owner:王晟鸣

Persistent phosphorescent composite material

ActiveUS9284485B2Improve mechanical propertiesIncrease brightnessVisual indicationClockwork casesCeramic compositeDense body

The invention relates to a persistent phosphorescent ceramic composite material which is a sintered dense body comprising two or more phases, a first phase consisting of at least one metal oxide and a second phase consisting of a metal oxide containing at least one activating element in a reduced oxidation state. The invention furthermore relates to a method for the preparation of a phosphorescent ceramic composite material as defined in any of the previous claims, the method comprising the following steps: preparing a mixture of a metal oxide and a phosphor; fabricating a green body from the mixture; and heat treating the green body in a reducing atmosphere.

Owner:ROLEX SA

Method of producing a ceramic sintered body

InactiveUS20080246194A1Prevent oxidationAvoid corrosionFinal product manufactureCeramic shaping apparatusCeramic sinteringMetallurgy

A method of producing a laminated body having a ceramic porous body having a thickness of 300 μm or larger and a ceramic dense body having a thickness of 25 μm or smaller. A green body for the porous body and a green body for the dense body are laminated to obtain a laminate, which is then subjected to pressure molding by cold isostatic pressing to obtain a pressure molded body. The pressure molded body is sintered to obtain a laminated sintered body. By reducing the leakage rate of helium gas of the laminated sintered body to 10−6 Pa˜m3 / s or lower, the operational efficiency of the cell can be improved, and the deterioration of the cell can be prevented to improve an output after the cell is subjected to initiation and termination cycle tests of operation.

Owner:NGK INSULATORS LTD

Medical implant

ActiveCN103170013AHigh porosityReduce porositySurgeryTissue regenerationBiological propertyDense body

The invention relates to a medical implant with a compound structure. The medical implant is formed by compounding more than two medical implanted materials and is characterized in that various medical implanted materials have different biodegradation rates; the various medical implanted materials are embedded to each other and are in an interlaced compound structure to form a dense body; the medical implanted materials still keep respective biological properties and physical and mechanical properties; and each medical implanted material is a continuous structure body. The medical implant with the structure can provide multi-layered curative spaces for reparation of an implanting position and supply longer growth time for normal structures, that is, the implanting space gradually reserved by biodegradation of the medical implanted materials is in exchange of longer growth time for the normal structures, thereby being more suitable for the natural healing process of the implanting position of an impaired host.

Owner:CHONGQING RUNZE PHARM CO LTD

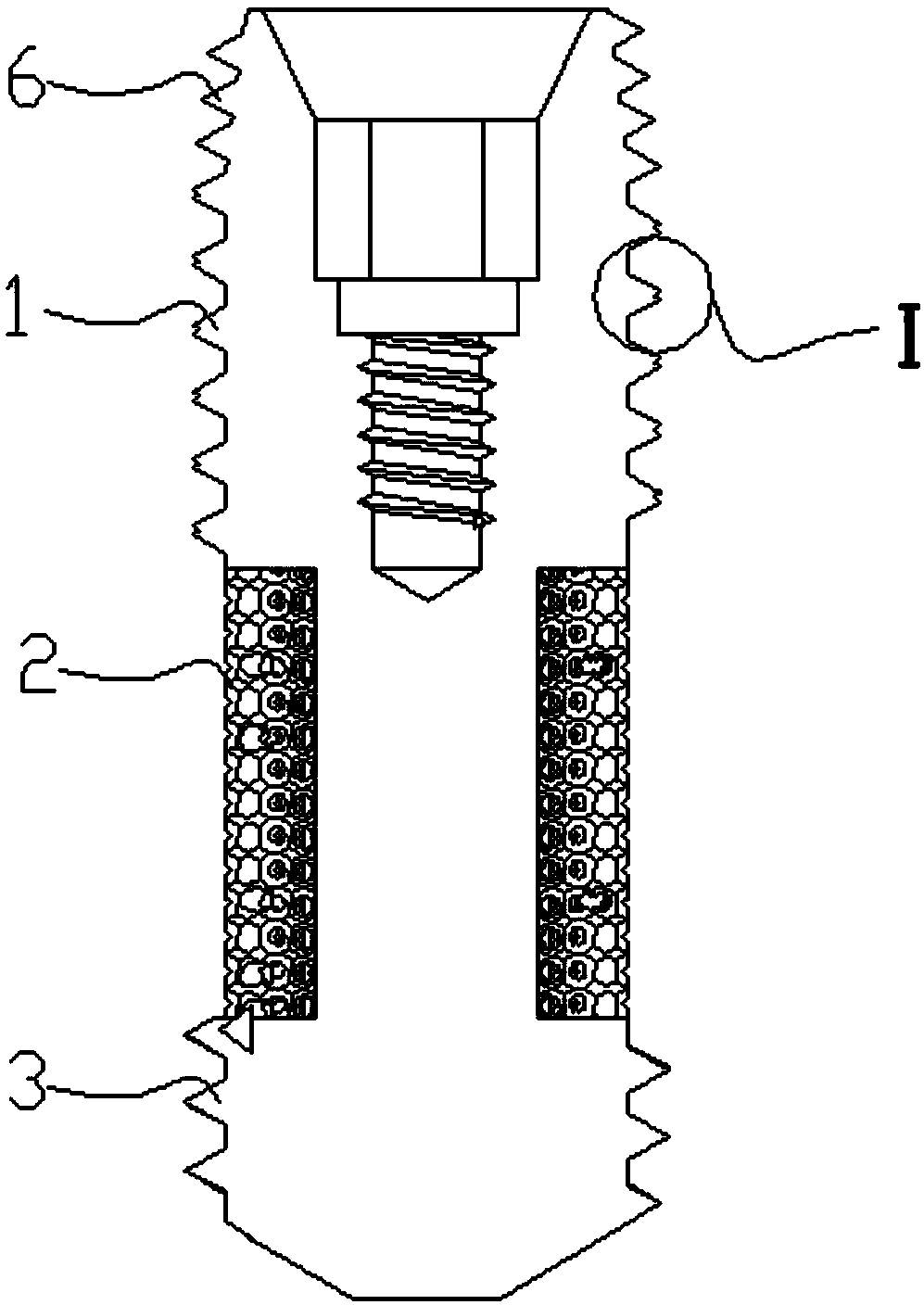

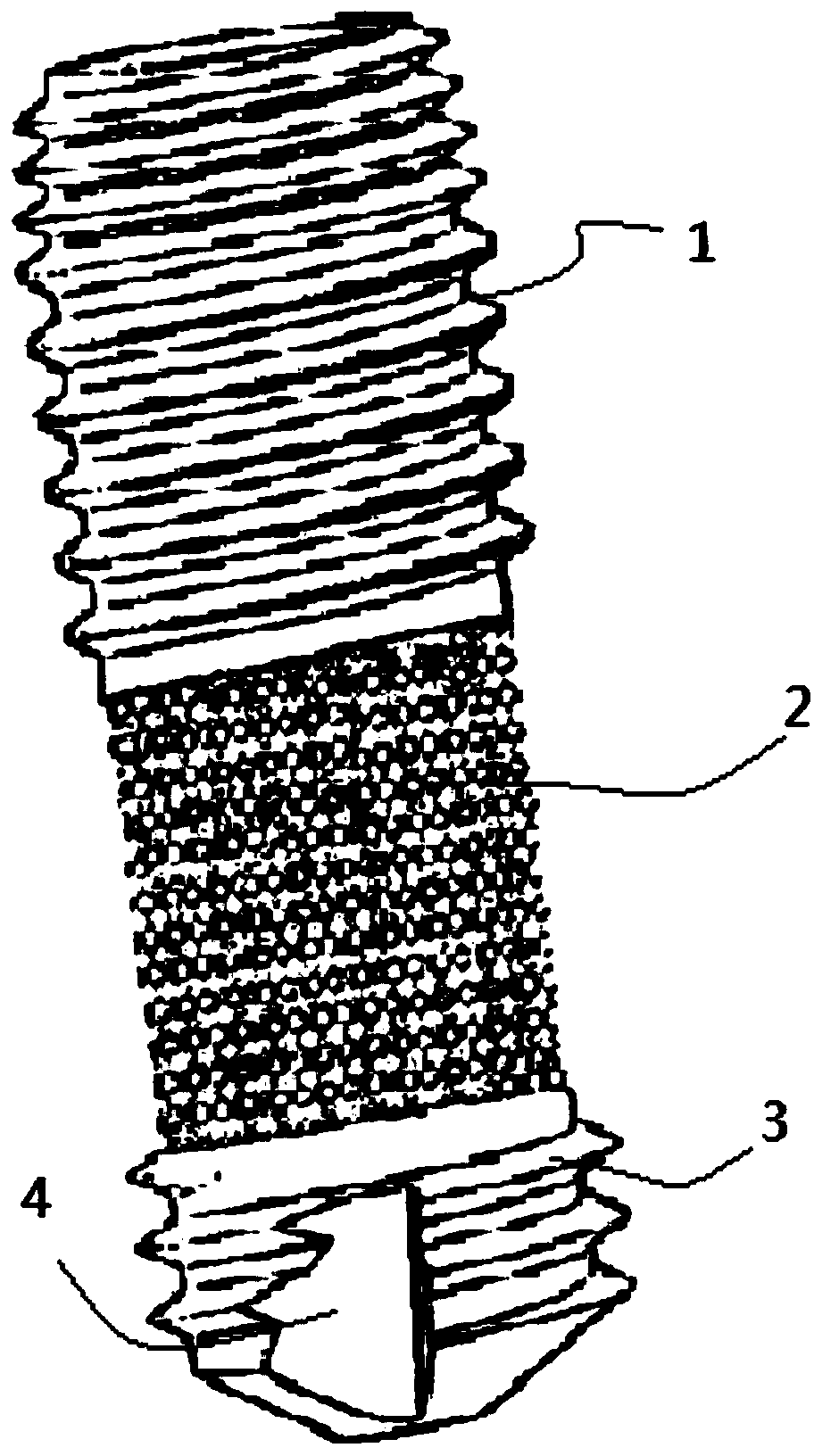

Porous structure titanium implant for dental implant

InactiveCN109223213AReduce the difficulty of implantationImproving Implantation EfficiencyDental implantsBone tissueDense body

The invention discloses a porous structure titanium implant suitable for dental implants. The porous structure titanium implant comprises an upper section, a middle section and a lower section. The upper section is a dense body, and the upper part of the outer layer of the upper section is provided with tapered threads inclined from the bottom to the inside; The lower part of the outer layer of the upper section is provided with a threaded tooth crest center concave to form a W-shaped sectional locking thread for increasing the initial stability of the implant. The inner core of the middle section is a dense body, the outer layer of the middle section is a communicating porous layer, and the porous layer provides a support for bone tissue growth and a bioactive coating. The lower section is a dense body, the outer layer of the lower section is provided with a self-tapping thread, and the end of the lower section is a flat end, and the end is provided with a cut with cutting function and intersects with the self-tapping thread. The invention effectively reduces the implantation difficulty, improves the implantation efficiency, the implantation success rate and the initial stabilityof the implantation.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

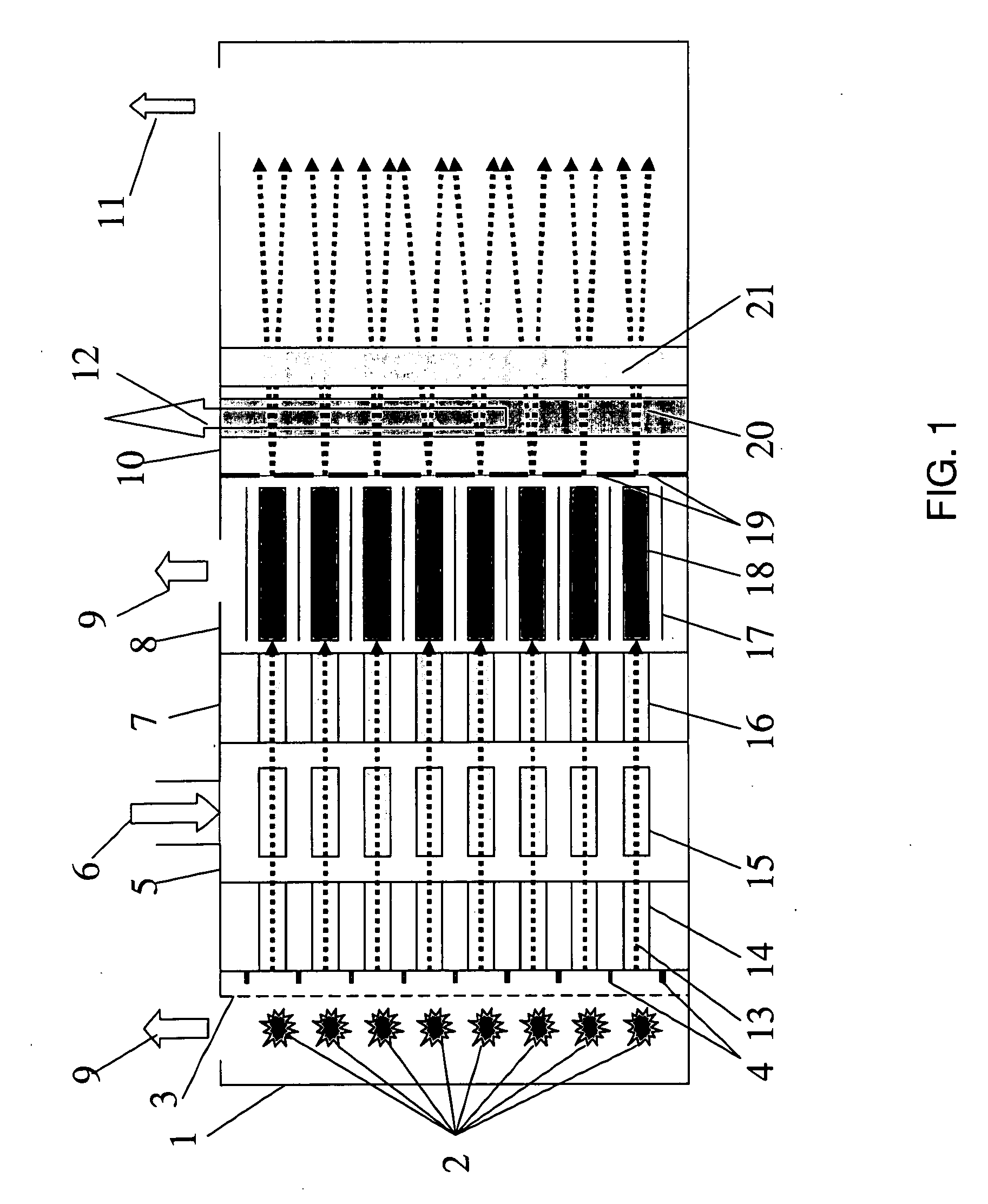

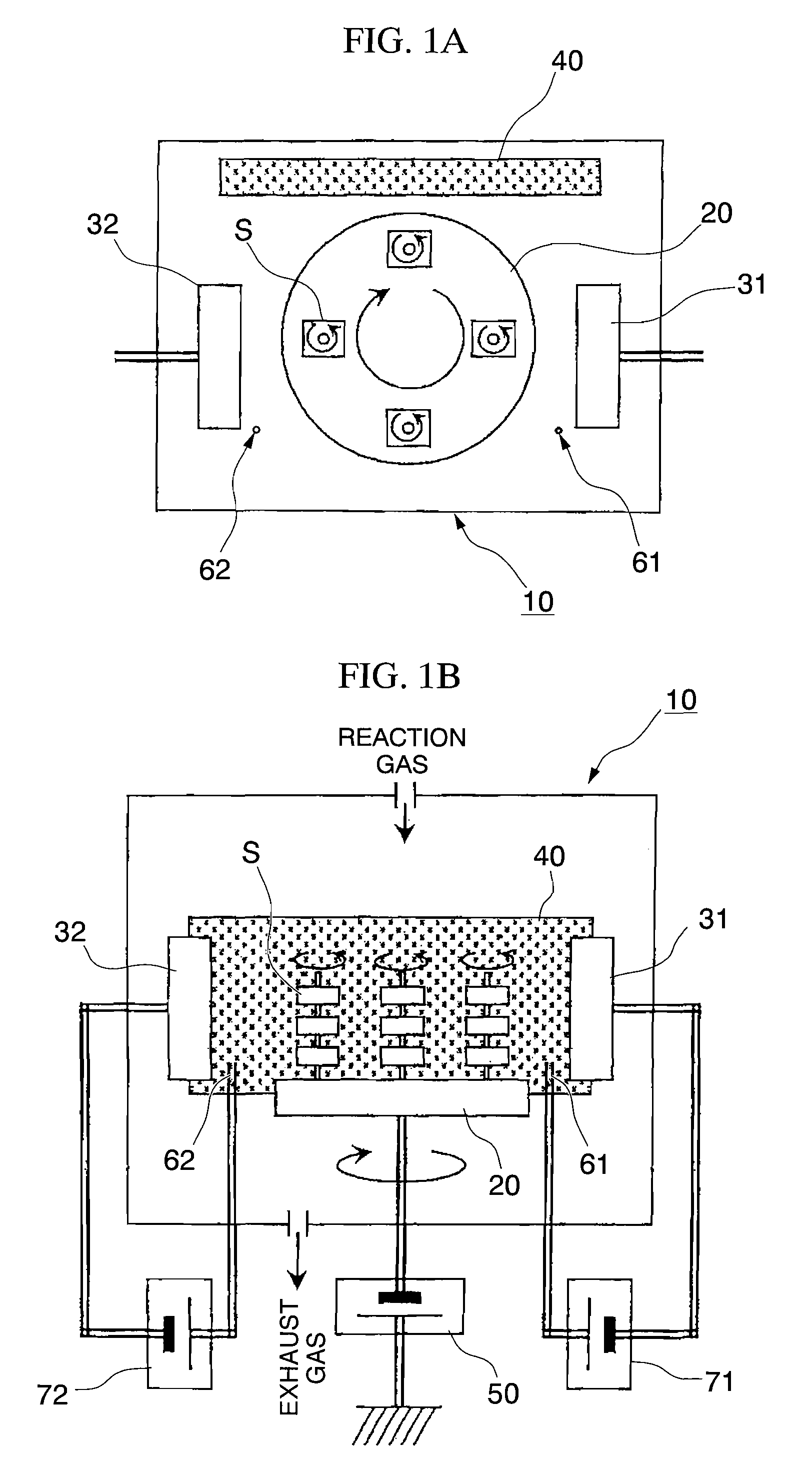

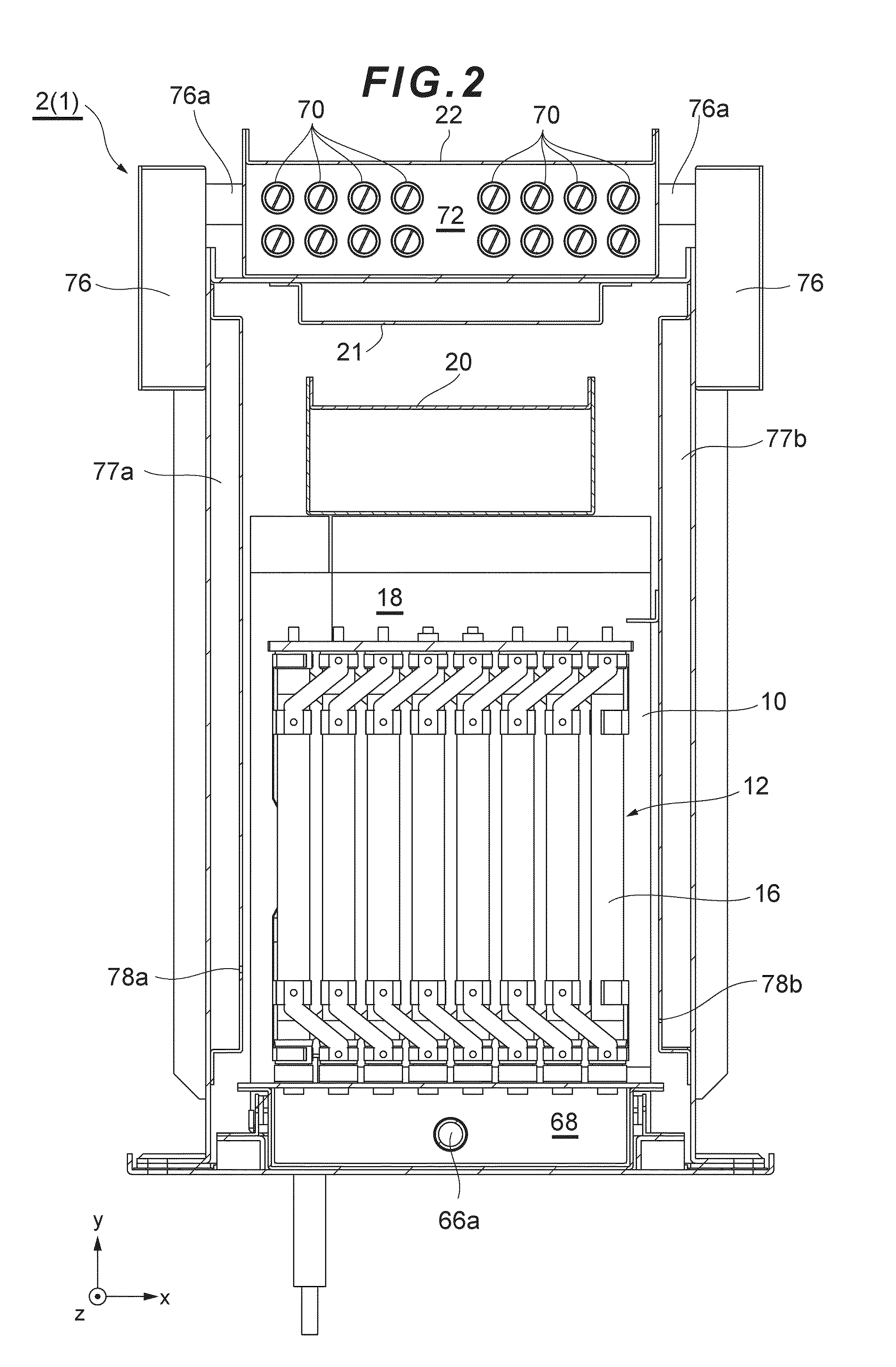

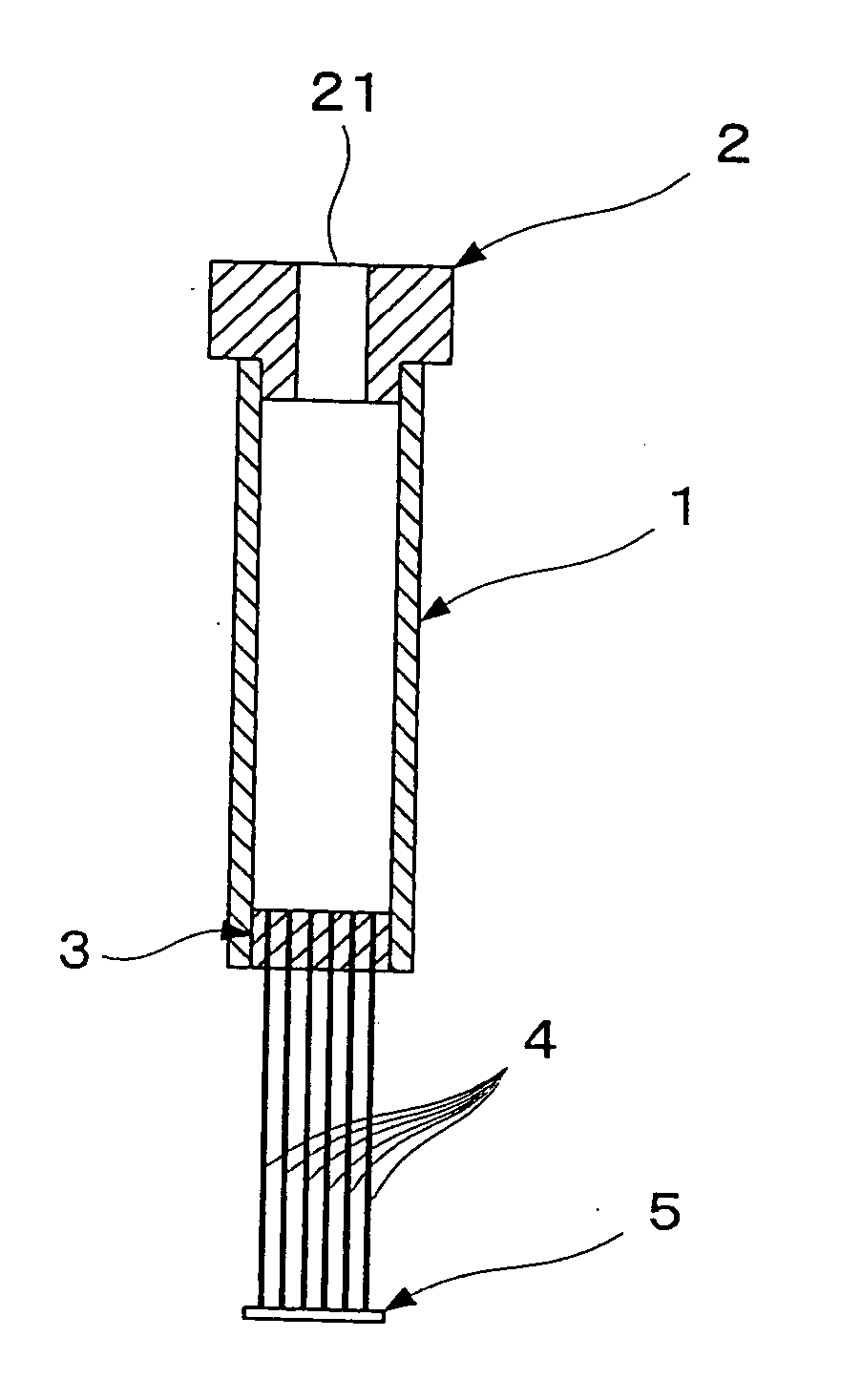

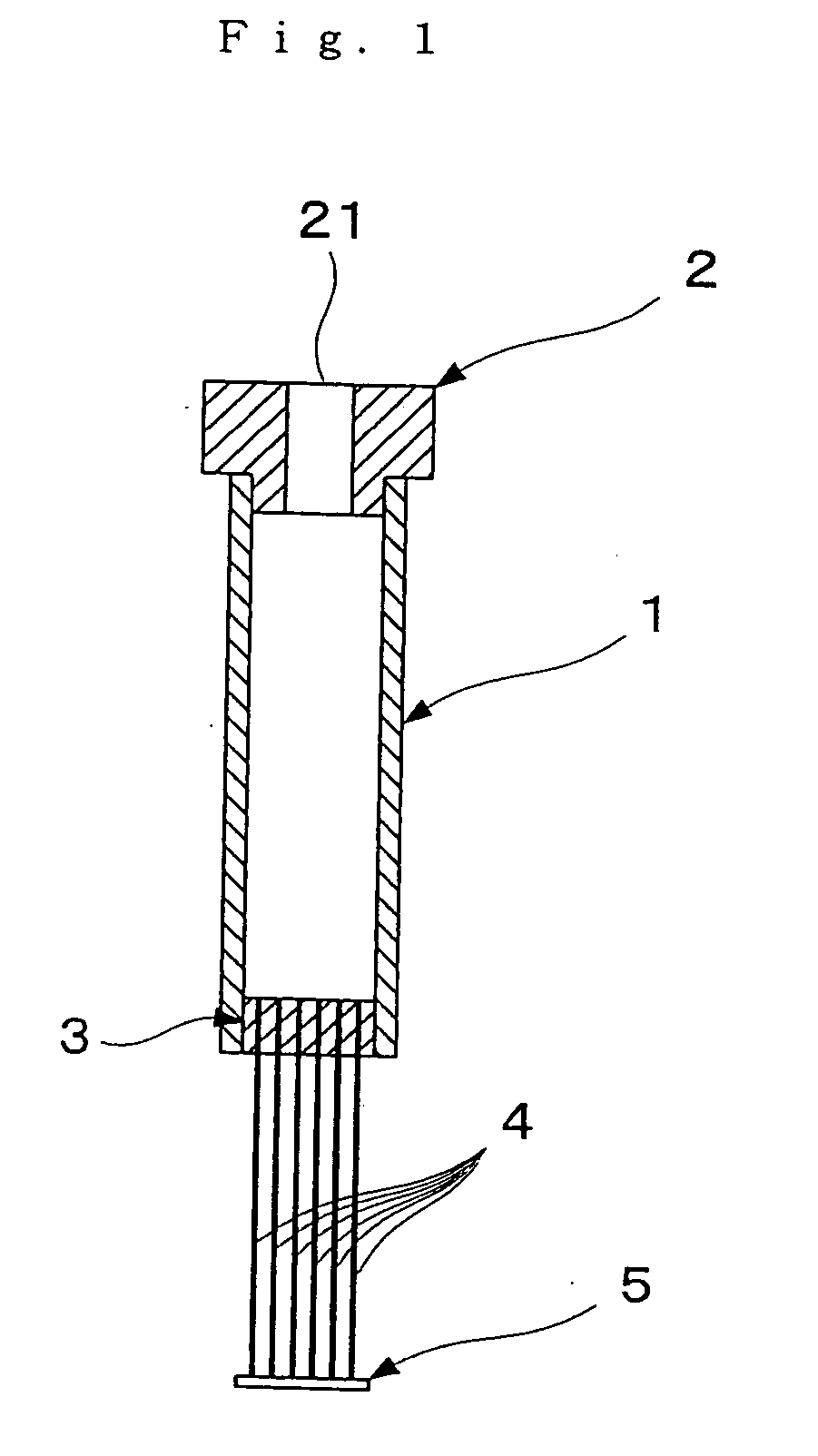

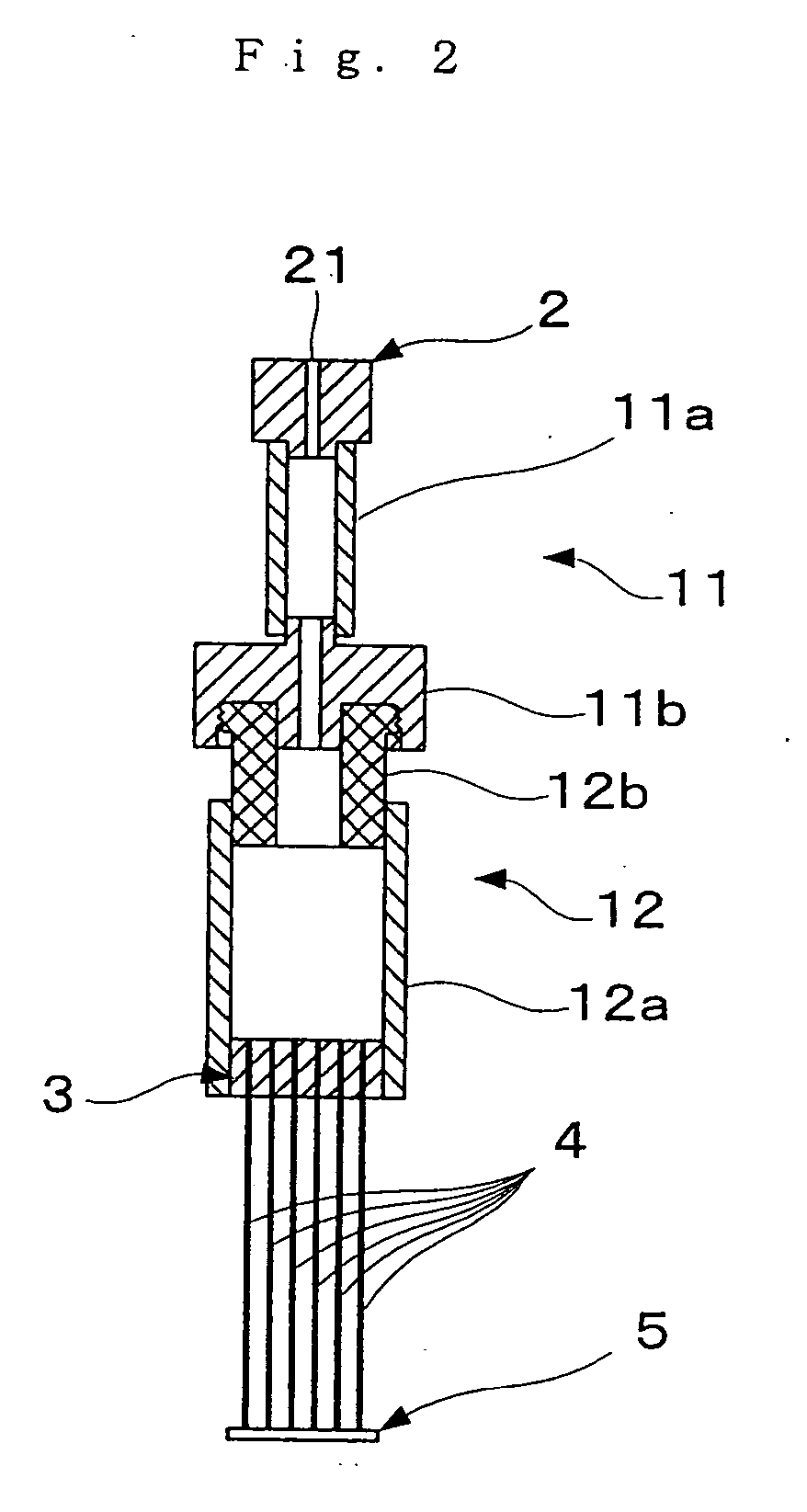

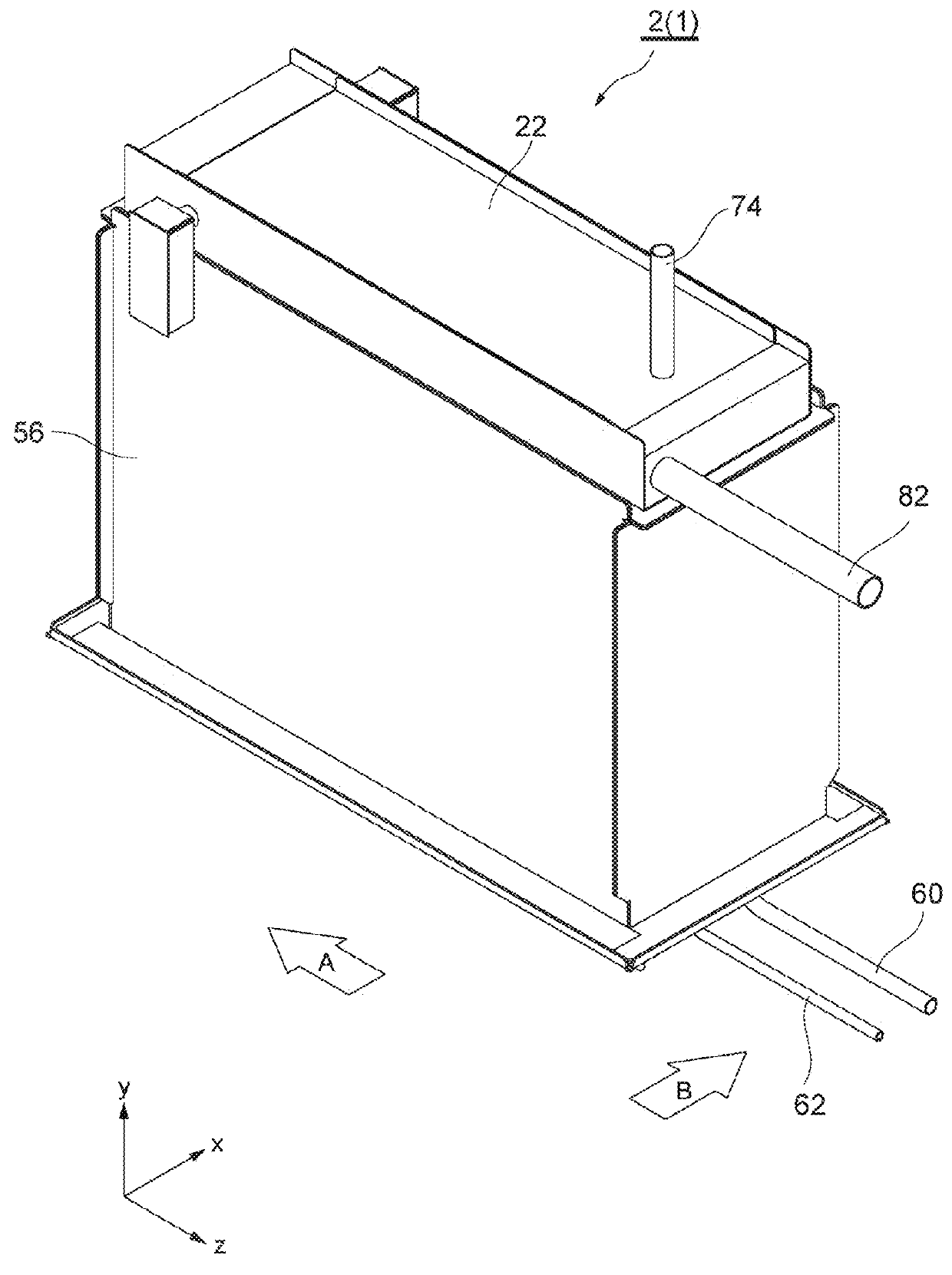

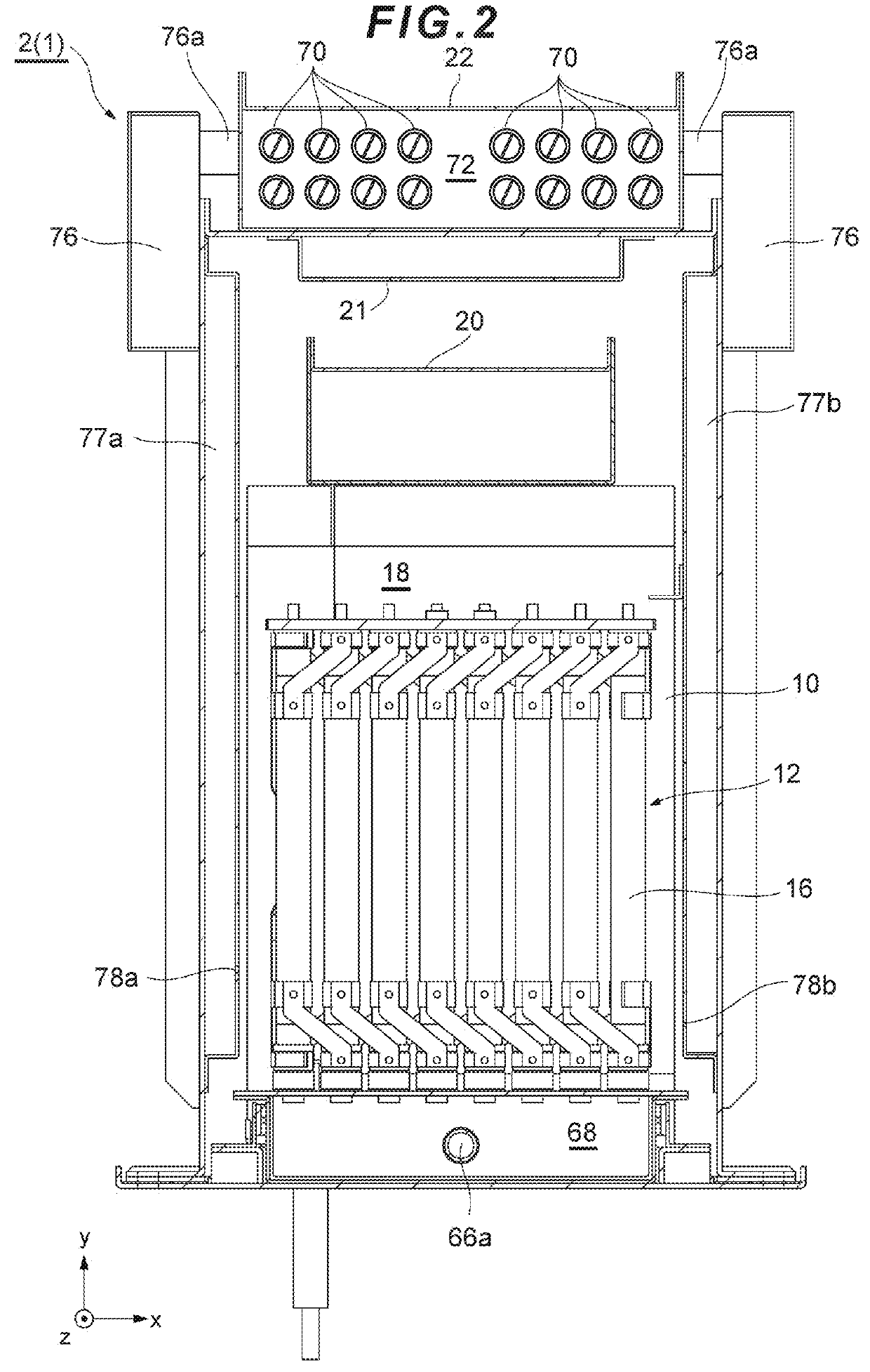

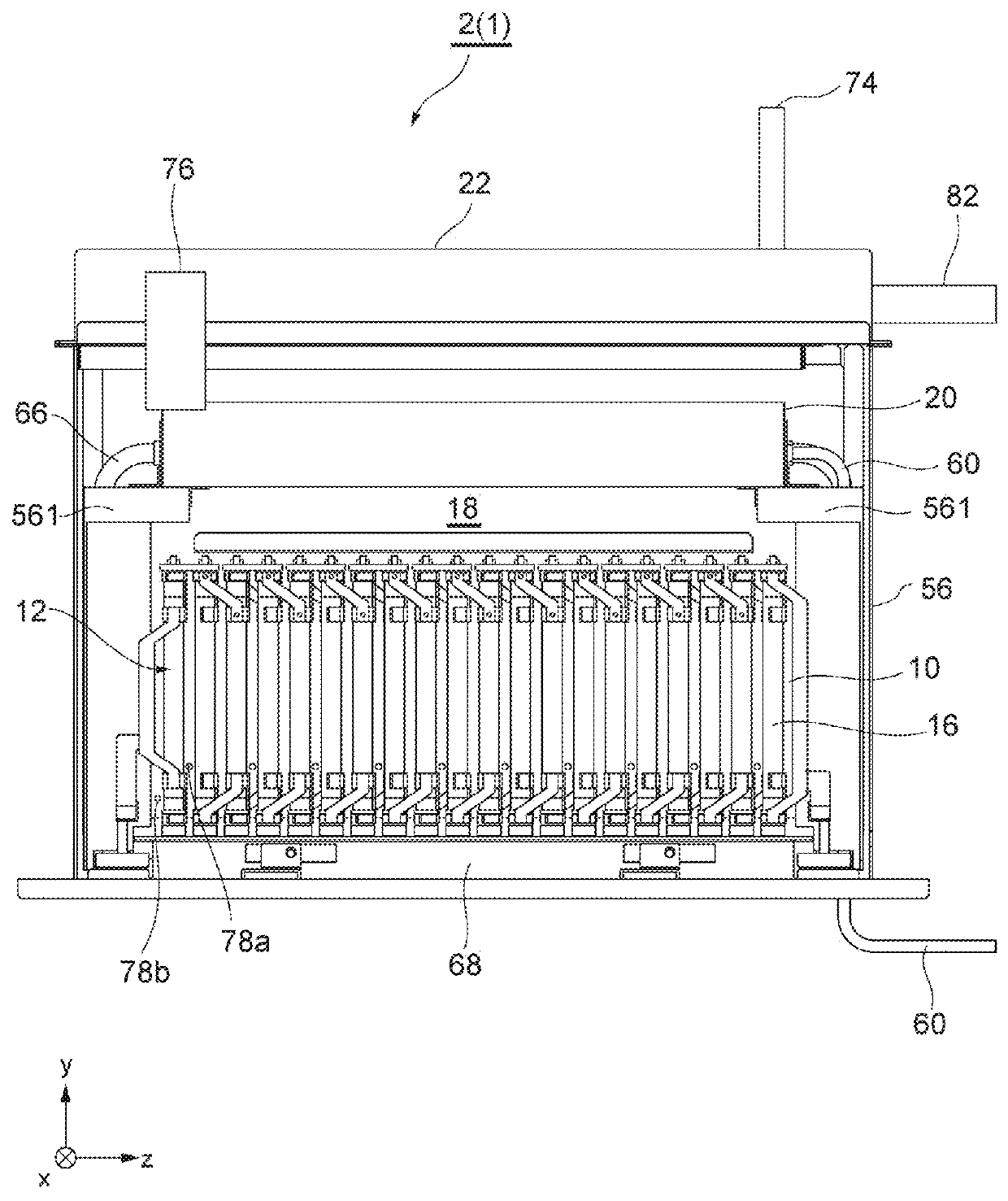

Solid oxide fuel cell device

ActiveUS20140227623A1High outputImprove power generation efficiencyFuel cells groupingFuel cell shape/formFuel cellsDense body

In a fuel cell unit 16 that constitutes a fuel cell module 2 of an SOFC device 1, a collector cap 86a is connected to an inner electrode layer 90 via a seal material 96 as an Ag seal portion. A glass coating 30 (dense body) is filled up between the inner electrode layer 90 and an electrolyte layer 94 and the collector cap 86a to cover an upper end surface 96a of the seal material 96. As such, the fuel cell unit 16 includes the seal material 96 constituting as an Ag seal portion that separates a fuel gas from an oxidant gas, and a glass coating 30 at least partially formed to over at least either the fuel gas side surface of the seal material 96 or an the oxidant gas side surface of the seal material 96.

Owner:MORIMURA SOFC TECH CO LTD

Method for preparing four-axis carbon fiber robot shell

The invention discloses a method for preparing a four-axis carbon fiber robot shell. The method is characterized by comprising the steps of a, selecting a die; b, preheating the die; c, applying a release agent; d, conducting cladding to obtain a dense body; e, conducting die assembly for vulcanization; f, conducting cooling and die releasing; g, spraying an undercoat; and h, spraying a finishing coat. By the adoption of the method, operation is easy, industrial production is facilitated, and the produced robot shell has the advantages of being light, high in strength, high in fatigue resistance, high in chemical resistance and the like.

Owner:赵静

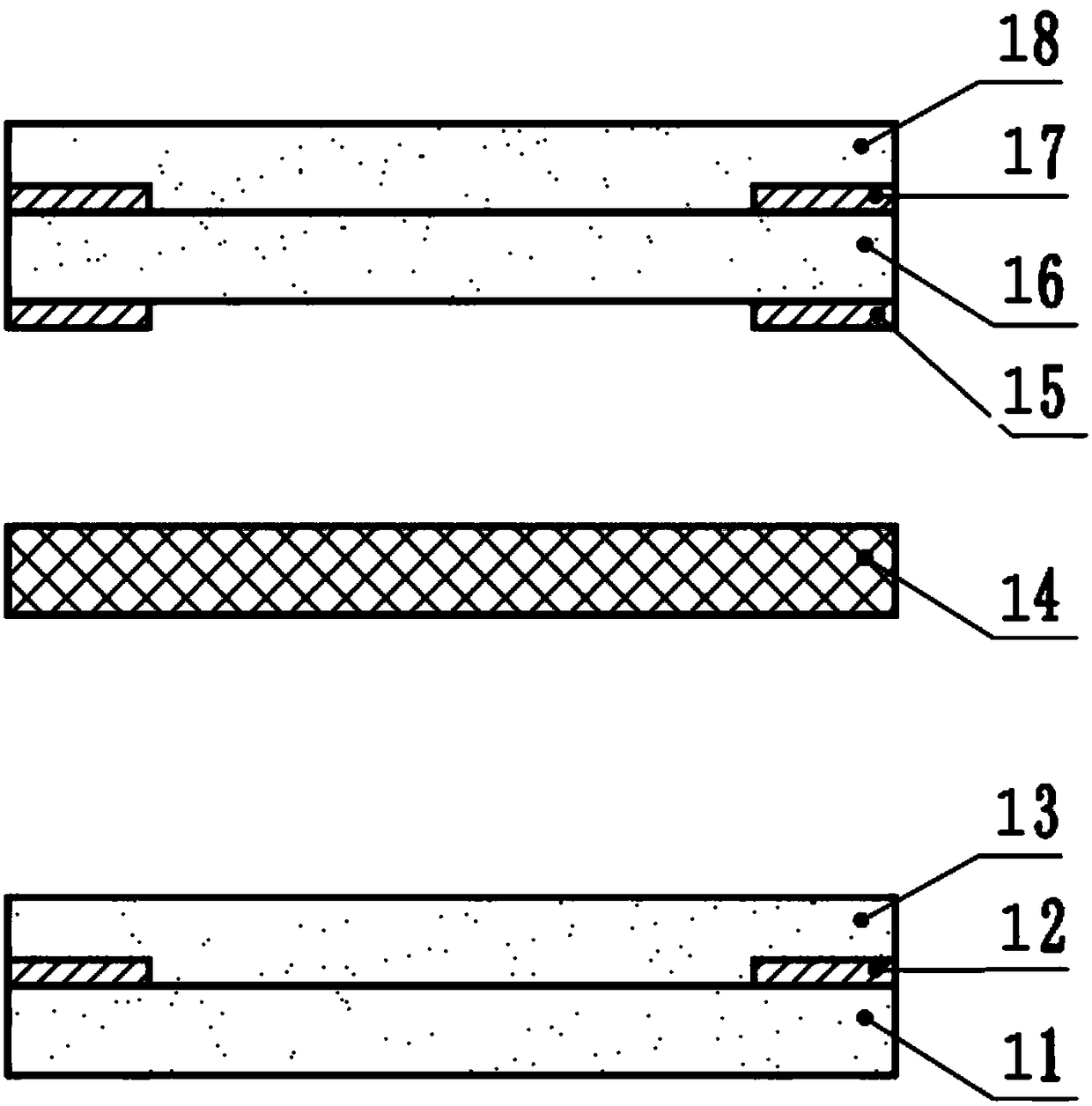

Chip oxygen sensor and preparation method thereof

PendingCN108254430AUniform printingGuaranteed yieldMaterial analysis by electric/magnetic meansPlatinumDense body

The invention discloses a preparation method of a chip oxygen sensor and the chip oxygen sensor prepared by the method. The preparation method comprises the following steps: preparing a ceramic substrate sintered into a dense body to serve as a support body; sequentially printing a first insulating layer and drying the printed first insulating layer at one side of the ceramic substrate through a thick film printing mode, printing a heating electrode and drying the printed heating electrode and printing a second insulating layer and drying the printed second insulating layer at the other side of the ceramic substrate or on the second insulating layer through the thick film printing mode; sequentially printing a third insulating layer and drying the printed third insulating layer, printing afirst porous platinum electrode and drying the printed first porous platinum electrode, printing a reference layer and drying the printed reference layer, printing a second porous platinum electrodeand drying the printed second porous platinum electrode and printing a porous protection layer and drying the printed porous protection layer; and sintering the printed ceramic substrate at high temperature so as to be molded. The chip oxygen sensor disclosed by the invention has no need of being thermally pressed and is simple in process, less in deformation and cracks and high in finished product yield.

Owner:卢忠勇 +1

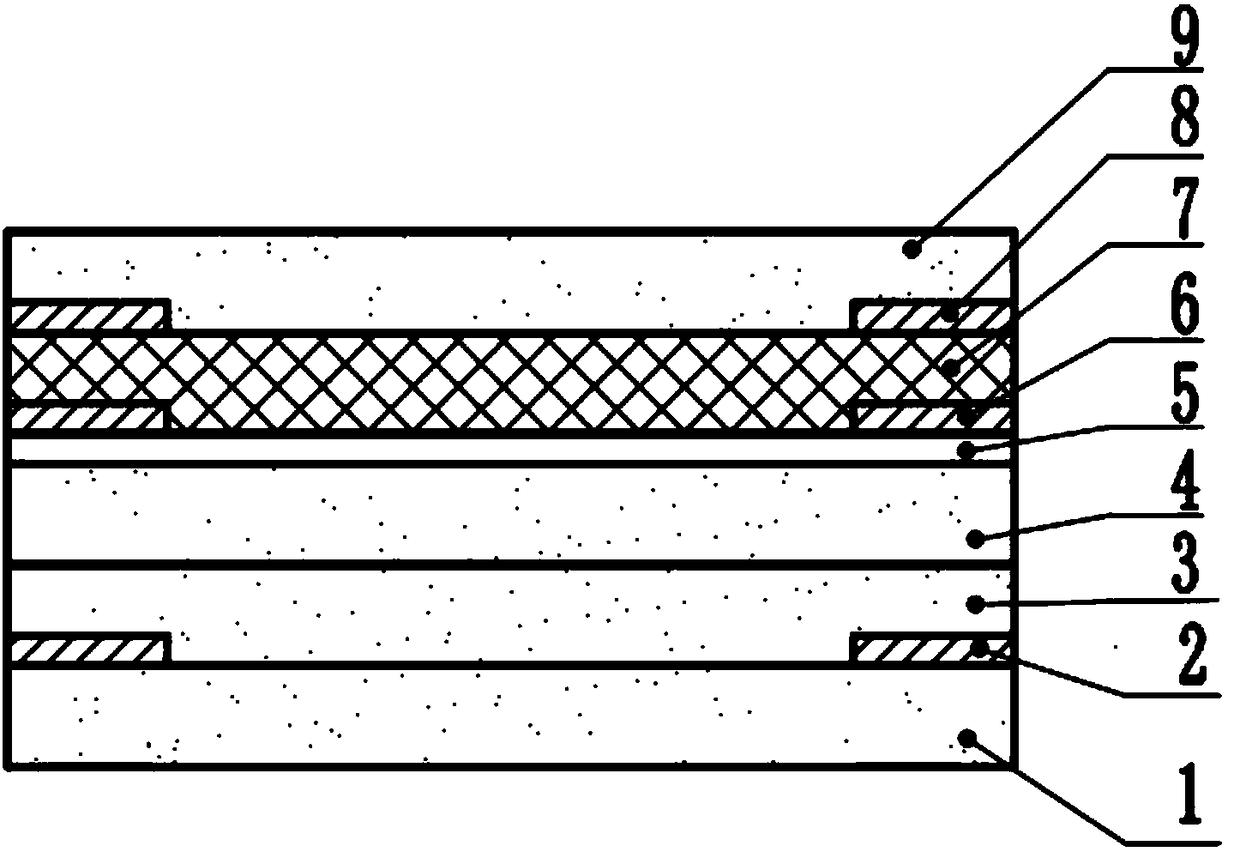

Multilayer substrate

ActiveUS20190394874A1Reduce warpageHigh bonding strengthPorous dielectricsPrinted circuits stress/warp reductionMetallurgyDense body

A multilayer substrate that includes a first ceramic layer that is a dense body, a second ceramic layer that has open pores, and a resin layer adjacent the second ceramic layer, wherein a material of the resin layer is present in the open pores of the second ceramic layer.

Owner:MURATA MFG CO LTD

Methods of culturing, storing, and inducing differentiation in cells, instrument for use in the methods, method of using the instrument, and medical biomaterial

InactiveUS20070020756A1Loss of function of cell can be suppressedLoss of the functions of the cells during storage can be suppressedBioreactor/fermenter combinationsBiological substance pretreatmentsDense bodyCentrifugal force

The present invention provides methods of culturing or storing cells for a prolonged period while suppressing a loss of functions of the cells during storage, by applying centrifugal force or pressure such as hydraulic pressure to the cells to form compact bodies, particularly aggregates, in which a state of high contact or a high contact frequency is maintained between the cells, and then culturing, storing or inducing differentiation in the cells in this aggregate state.

Owner:TOYOBO CO LTD +1

Hot isostatic pressure preparation method of high-density grained titanium alloy

InactiveCN104694774ASolve the problem that it is difficult to sinter dense and the mechanical properties of the alloy are lowGood mechanical propertiesHigh densityDense body

The invention discloses a hot isostatic pressure preparation method of a high-density grained titanium alloy, so as to solve the problems that the titanium alloy prepared by the conventional powder metallurgic method at present is lower in density and coarser in microscopic structure. The method comprises steps of titanium alloy mixed powder preparation, cold isostatic pressure molding, dense body sintering, hot isostatic pressure densifying, demolding, and the like. The density of the prepared titanium alloy can be up to 100%; and the prepared titanium alloy is characterized by a fine grain size, an excellent mechanical property, and a high specific strength. The prepared titanium alloy is able to meet the requirements to a high-density and high-performance titanium alloy in the fields of aviation and aerospace. The hot isostatic pressure preparation method of the high-density grained titanium alloy is reasonable in design; the hot isostatic pressure preparation method of the high-density grained titanium alloy is able to solve the problems mentioned above; and the hot isostatic pressure preparation method of the high-density grained titanium alloy is of a great significance in preparing titanium alloys.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

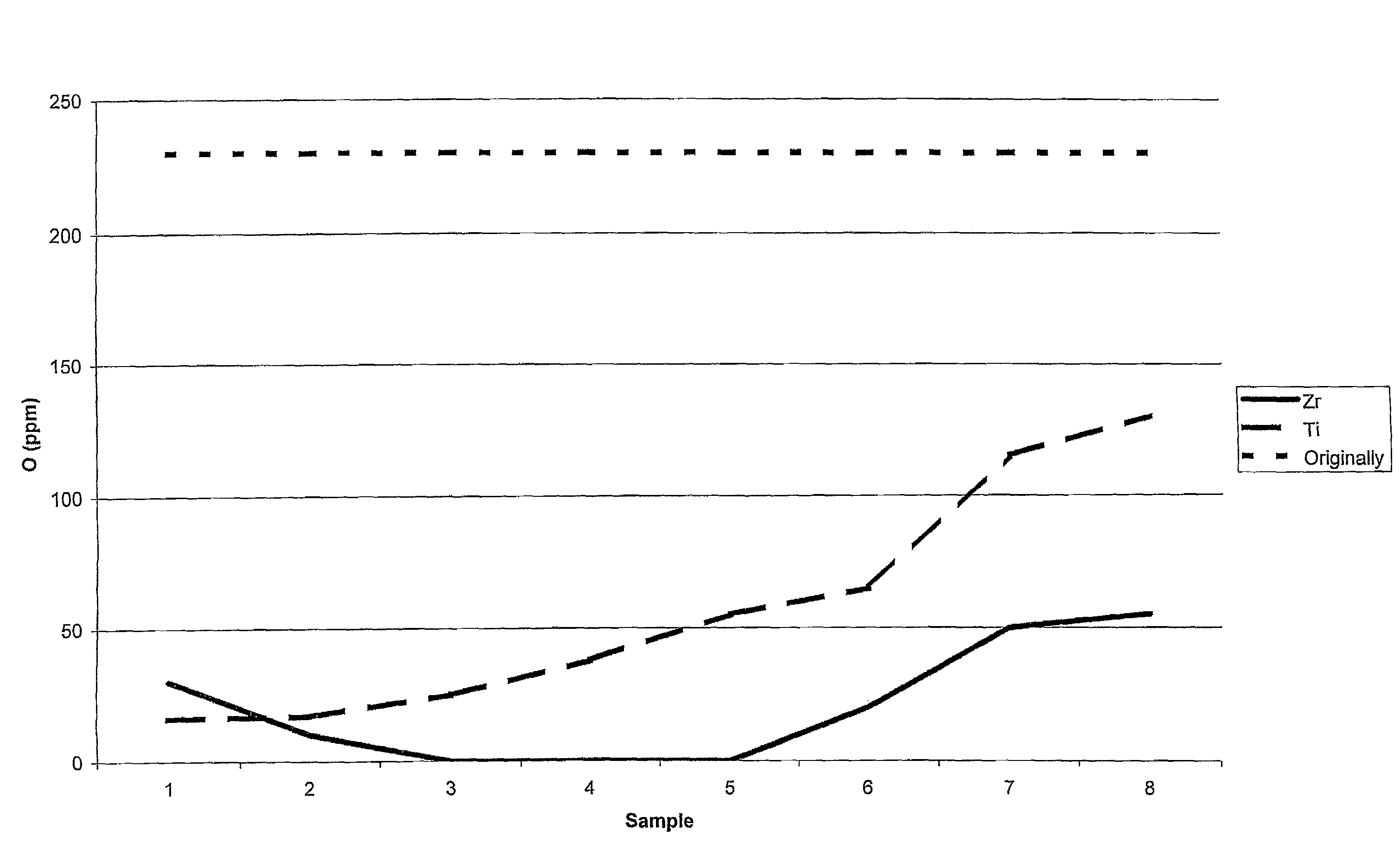

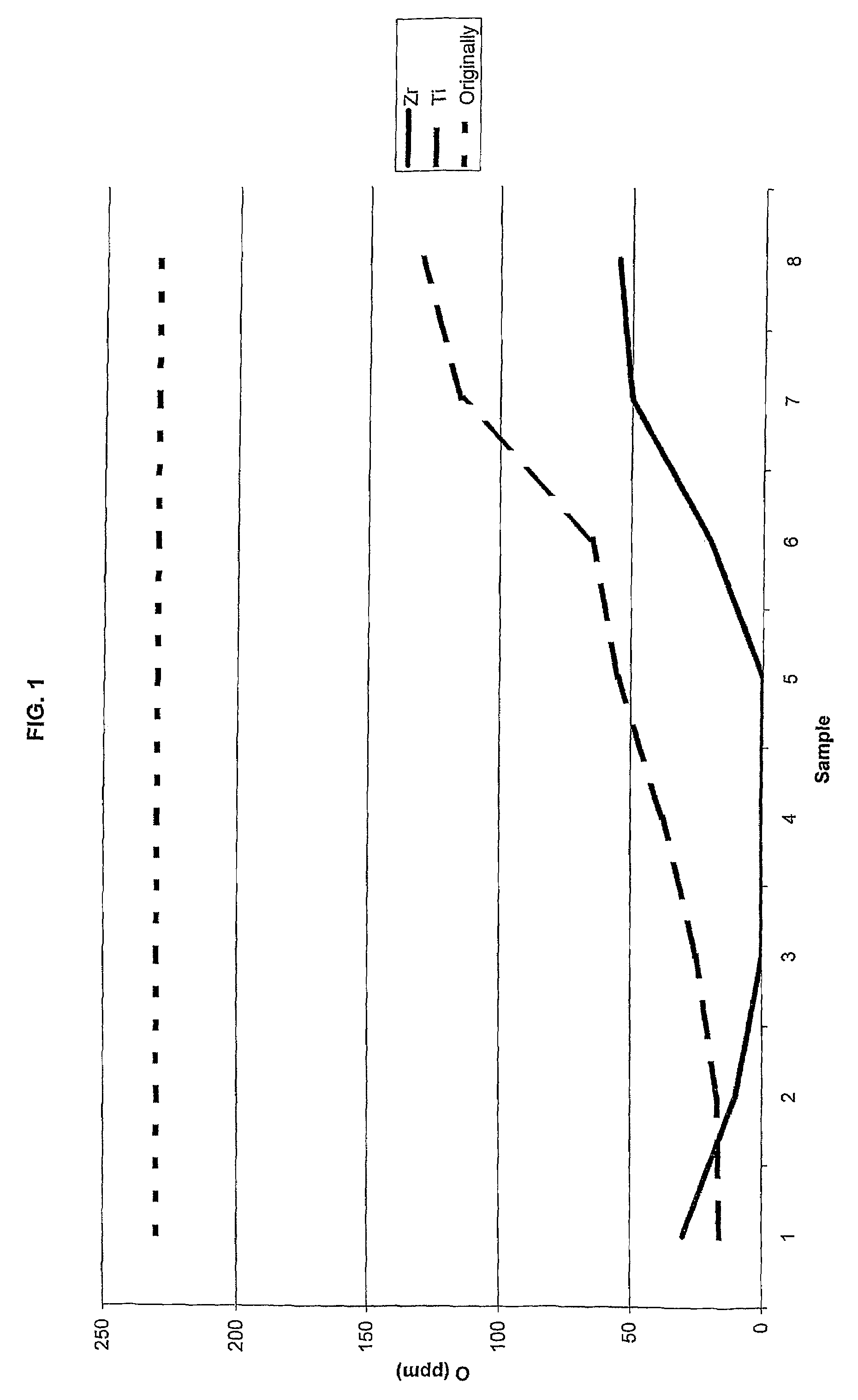

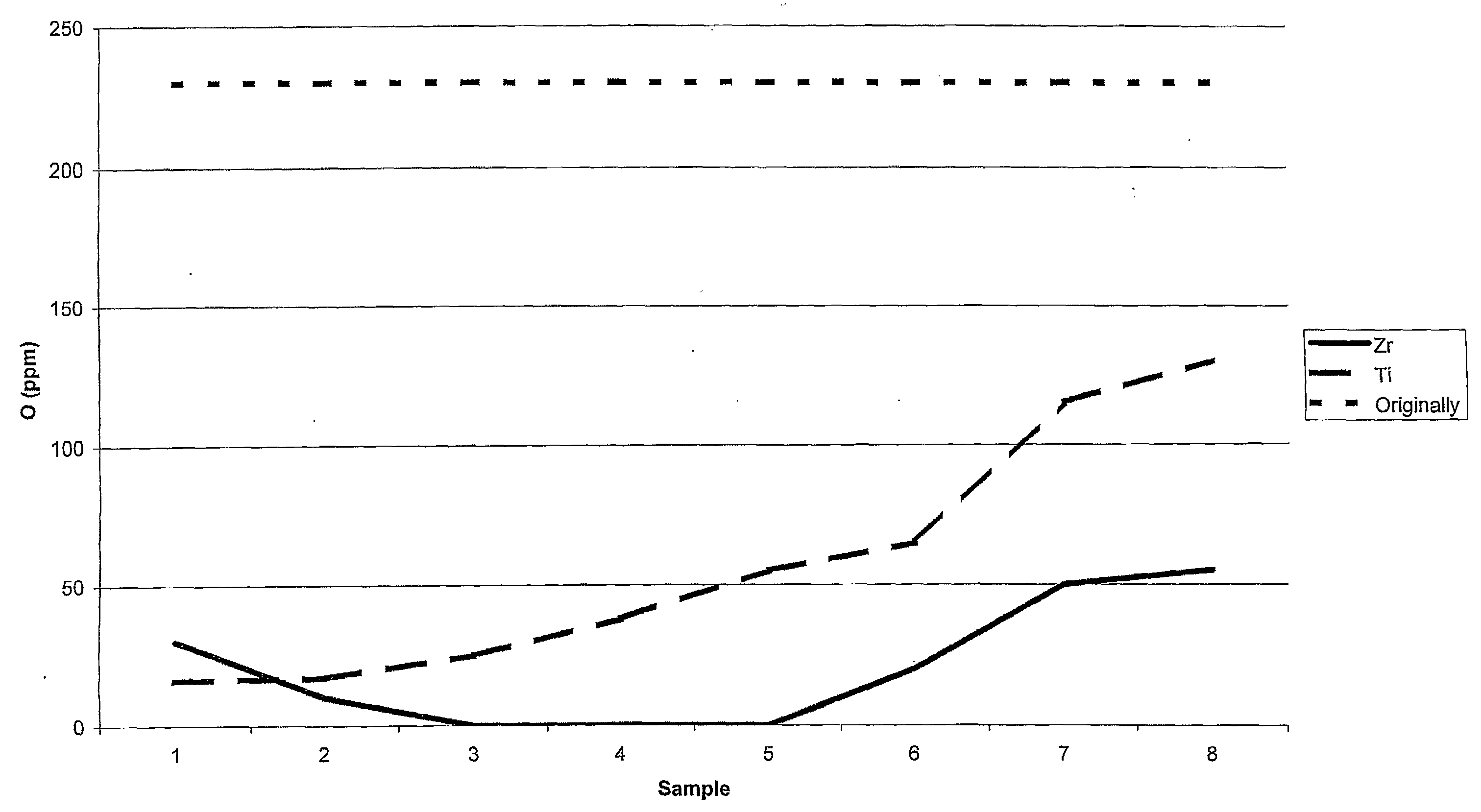

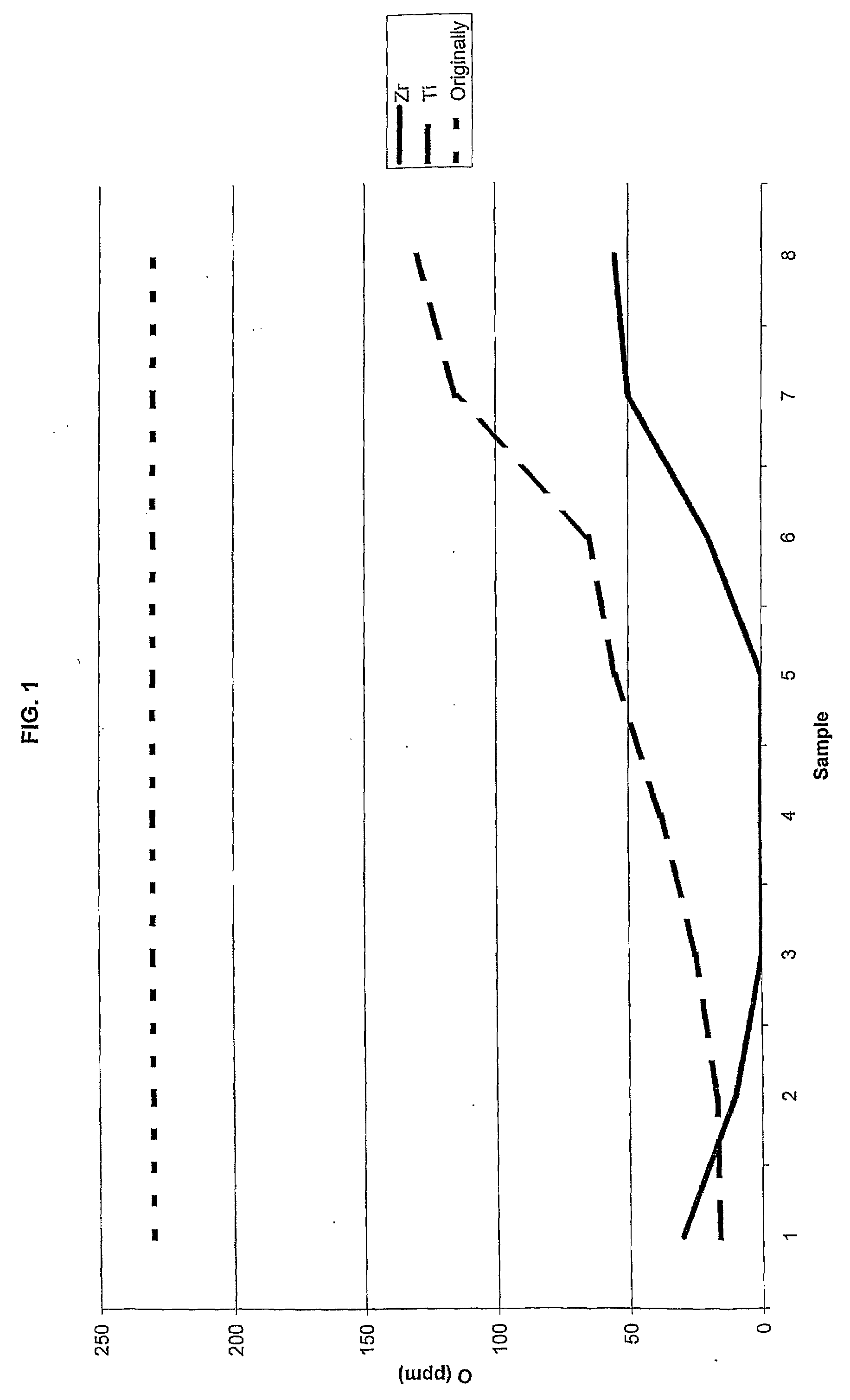

Method of controlling the oxygen content of a powder

ActiveUS7931855B2Low oxygenLimit inclusionMetal-working apparatusThin material handlingHydrogen atmosphereDense body

A method of reducing the oxygen content of a powder is provided. A canister is prepared with a getter, filled with the powder to be densified, sealed and evacuated. The canister is subjected to a hydrogen atmosphere at an elevated temperature whereby hydrogen diffuses into the canister through the walls thereof. The hydrogen forms moisture when reacted with the oxygen of the powder and the moisture in the reacted with the getter in order to remove oxygen from the powder to the getter. The atmosphere outside the canister is then altered to an inert atmosphere or vacuum, whereby hydrogen diffuses out of the canister. A dense body having a controlled amount of oxygen can thereafter be produced by conventional powder metallurgy techniques.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +2

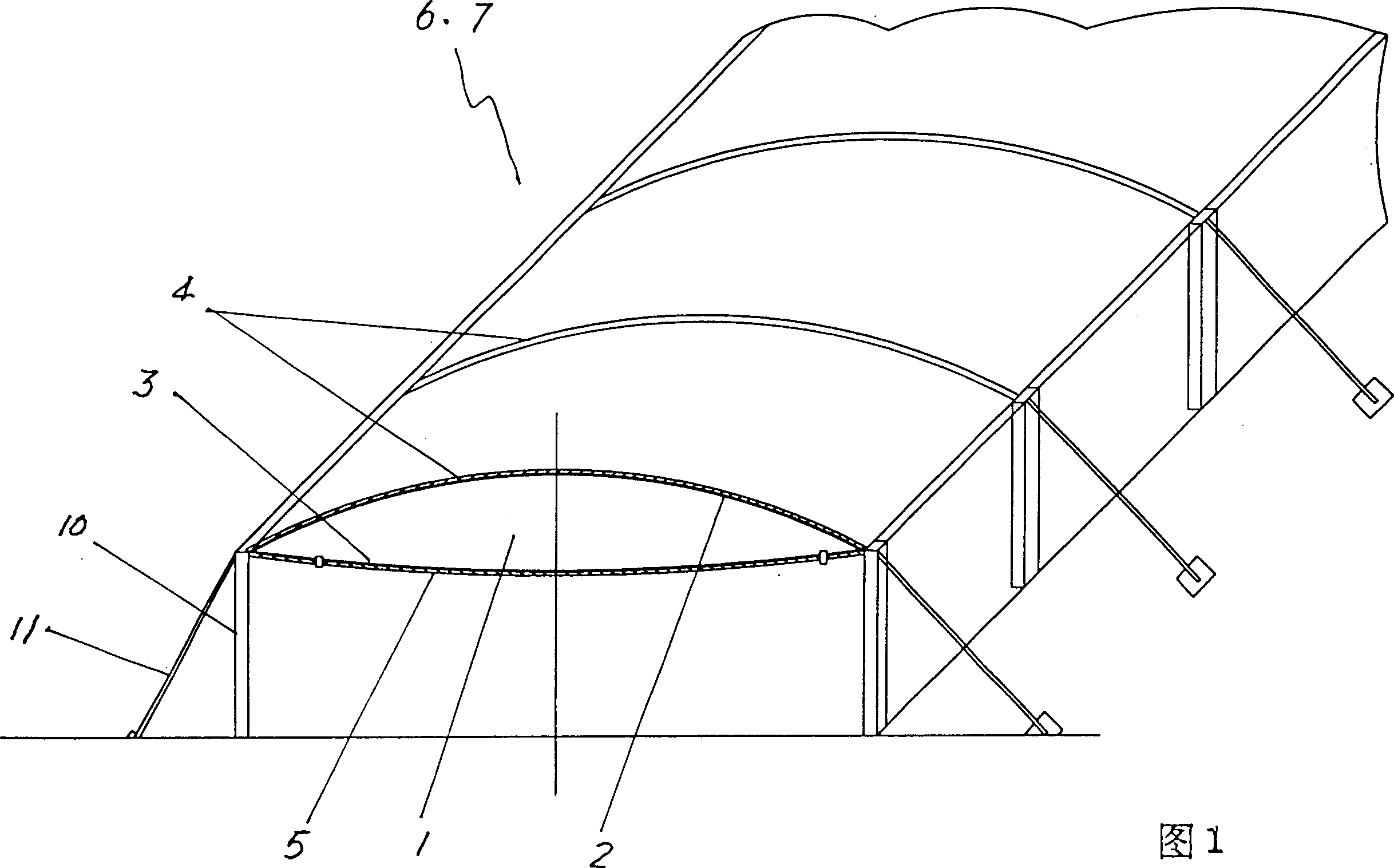

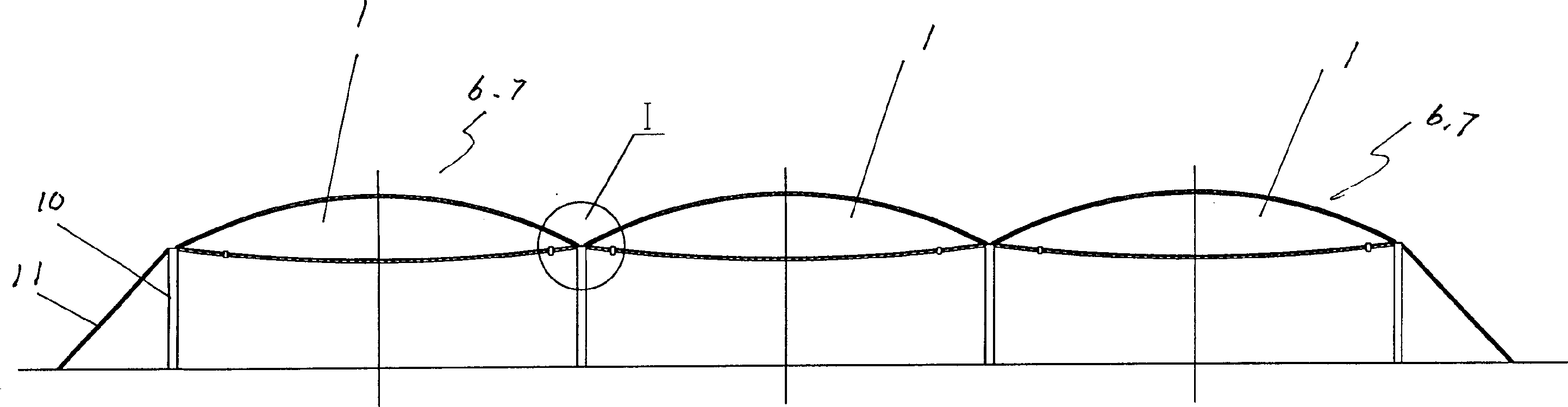

Inflated building structure body

An inflatable building structure, which is an airtight closed body composed of an outer membrane and an inner membrane, on which an inflation and deflation valve is installed, and the cross section of the airtight body formed by the outer and inner membranes Thick, gradually thinning towards both ends to the shape of the inner and outer joints; outside the outer diaphragm and the inner diaphragm of the inflatable airtight body, there are respectively longitudinal or vertical and horizontal tensioned stay ropes; the present invention can withstand relatively large High pressure, large size, can be used in inflatable roofs, inflatable greenhouses, inflatable walls, inflatable bridges, inflatable tents, etc. of buildings. It is easy to assemble and disassemble, and easy to relocate in different places.

Owner:北京时空通用科贸有限公司

Solid oxide fuel cell device

ActiveUS9252435B2Prevent degradationImprove efficiencyFuel cells groupingFuel cell shape/formFuel cellsDense body

In a fuel cell unit 16 that constitutes a fuel cell module 2 of an SOFC device 1, a collector cap 86a is connected to an inner electrode layer 90 via a seal material 96 as an Ag seal portion. A glass coating 30 (dense body) is filled up between the inner electrode layer 90 and an electrolyte layer 94 and the collector cap 86a to cover an upper end surface 96a of the seal material 96. As such, the fuel cell unit 16 includes the seal material 96 constituting as an Ag seal portion that separates a fuel gas from an oxidant gas, and a glass coating 30 at least partially formed to over at least either the fuel gas side surface of the seal material 96 or an the oxidant gas side surface of the seal material 96.

Owner:MORIMURA SOFC TECH CO LTD

Member for nuclear reactors

Provided is a member for nuclear reactors capable of being stably used without swelling or creep deformation even if directly exposed to neutrons with no additional improvements in nuclear reactor operation conditions or devices. A member for nuclear reactors comprises a core section comprising an aggregate of graphite particulates and a covering layer comprising a dense body of ceramic covering the core section. Because graphite that is affected by neutron irradiation is used in a state of aggregation of particulates and is not mutually connected, the shape and dimensions of the member for nuclear reactors is not affected even if there is swelling, creep deformation, or the like. Moreover, this member for nuclear reactors has a covering layer comprising a dense body of ceramic covering the core section. Because the covering layer comprising the dense body is more durable than graphite with respect to neutron irradiation, the shape and dimensions of the member for nuclear reactors are unlikely to be affected.

Owner:IBIDEN CO LTD

Method of Controlling the Oxygen Content of a Powder

ActiveUS20080268275A1Low oxygenLimit inclusionMetal-working apparatusThin material handlingHydrogen atmosphereDense body

A method of reducing the oxygen content of a powder is provided. A canister is prepared with a getter, filled with the powder to be densified, sealed and evacuated. The canister is subjected to a hydrogen atmosphere at an elevated temperature whereby hydrogen diffuses into the canister through the walls thereof. The hydroge forms moisture when reacted with the oxygen of the powder and the moisture in the reacted with the getter in order to remove oxygen from the powder to the getter. The atmosphere outside the canister is then altered to an inert atmosphere or vacuum, whereby hydrogen diffuses out of the canister. A dense body having a controlled amount of oxygen can thereafter be produced by conventional powder metallurgy techniques.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com