Preparation method of graded porous nickel-titanium alloy

A nickel-titanium alloy, hierarchical porous technology, applied in medical science, tissue regeneration, prosthesis, etc., to achieve good deformation synergy, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

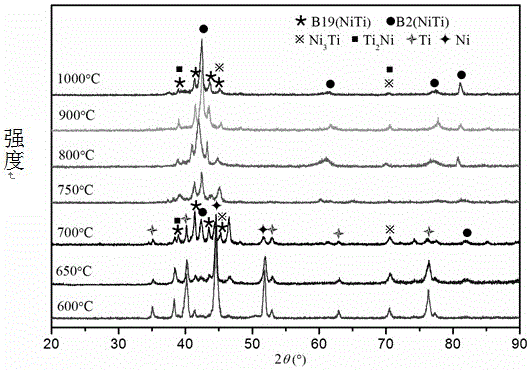

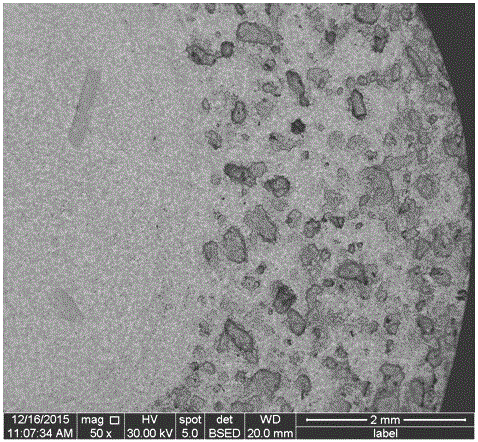

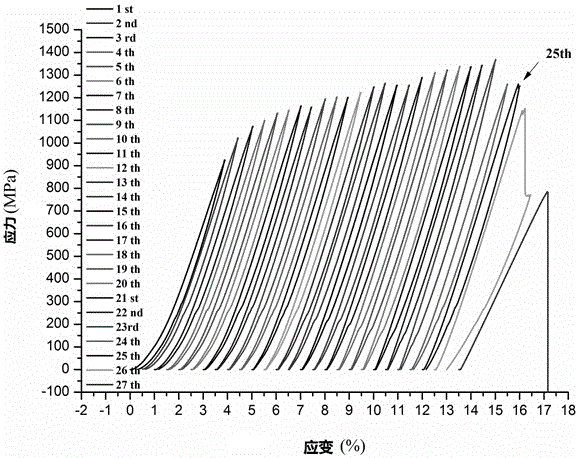

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the hierarchical porous nickel-titanium alloy described in this embodiment specifically comprises the following steps:

[0030] (1) According to the mass percentage of Ni58.8% and Ti41.20%, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 10 μm and the Ni metal powder with a purity of 99.5% and a particle size of 10 μm.

[0031] (2) Put the metal powder weighed in step (1) into the ball mill tank of a ball mill, evacuate to 6Pa, and then carry out ball milling and mixing for 20 hours to obtain mixed Ni-Ti metal powder.

[0032] (3) The mixed Ni-Ti metal powder obtained in step (2) is divided into two parts, and one part is divided into 80% by mass fraction of Ni-Ti powder and 20% by mass of NH 4 HCO 3 The powder (average particle size 300μm) was mixed in the mixer for 240min to obtain Ni-Ti-NH 4 HCO 3 Mix the powder (powder B), and mix the remaining part of Ni-Ti powder as powder A.

[0033](4) Put the po...

Embodiment 2

[0037] The preparation method of the hierarchical porous nickel-titanium alloy described in this embodiment specifically comprises the following steps:

[0038] (1) According to the mass percentage of Ni54.08% and Ti45.92%, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 300 μm and the Ni metal powder with a purity of 99.5% and a particle size of 300 μm.

[0039] (2) Put the metal powder weighed in step (1) into a ball mill tank, vacuumize to 6 Pa, and then perform ball milling and mixing for 40 hours to obtain mixed Ni-Ti metal powder.

[0040] (3) The mixed Ni-Ti metal powder obtained in step (2) is divided into three parts, and the first part is divided into 90% by mass fraction of Ni-Ti powder and 5% by mass of NH 4 HCO 3 The powder (average particle size 300 μm) was mixed in a mixer for 240 min to obtain Ni-Ti-NH 4 HCO 3 Mixed powder (powder A); the second part is 85% by mass fraction of Ni-Ti powder and 15% by mass of NH 4 HCO 3 ...

Embodiment 3

[0045] The preparation method of the hierarchical porous nickel-titanium alloy described in this embodiment specifically comprises the following steps:

[0046] (1) According to the mass percentage of Ni58.8% and Ti41.20%, respectively weigh the Ti metal powder with a purity of 99.9% and a particle size of 35 μm and the Ni metal powder with a purity of 99.5% and a particle size of 50 μm.

[0047] (2) Put the metal powder weighed in step (1) into the ball mill tank of a ball mill, vacuumize to 6Pa, and then carry out ball milling and mixing for 30 hours to obtain mixed Ni-Ti metal powder.

[0048] (3) The mixed Ni-Ti metal powder obtained in step (2) is divided into two parts, and one part is divided into 80% by mass fraction of Ni-Ti powder and 20% by mass of NH 4 HCO 3 The powder (average particle size 500μm) was mixed in the mixer for 240min to obtain Ni-Ti-NH 4 HCO 3 Mix the powder (powder A), and mix the remaining part of Ni-Ti powder as powder B.

[0049] (4) The powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com