Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

419 results about "Thermal hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal hydrolysis is a process used for treating industrial waste, municipal solid waste and sewage sludge.

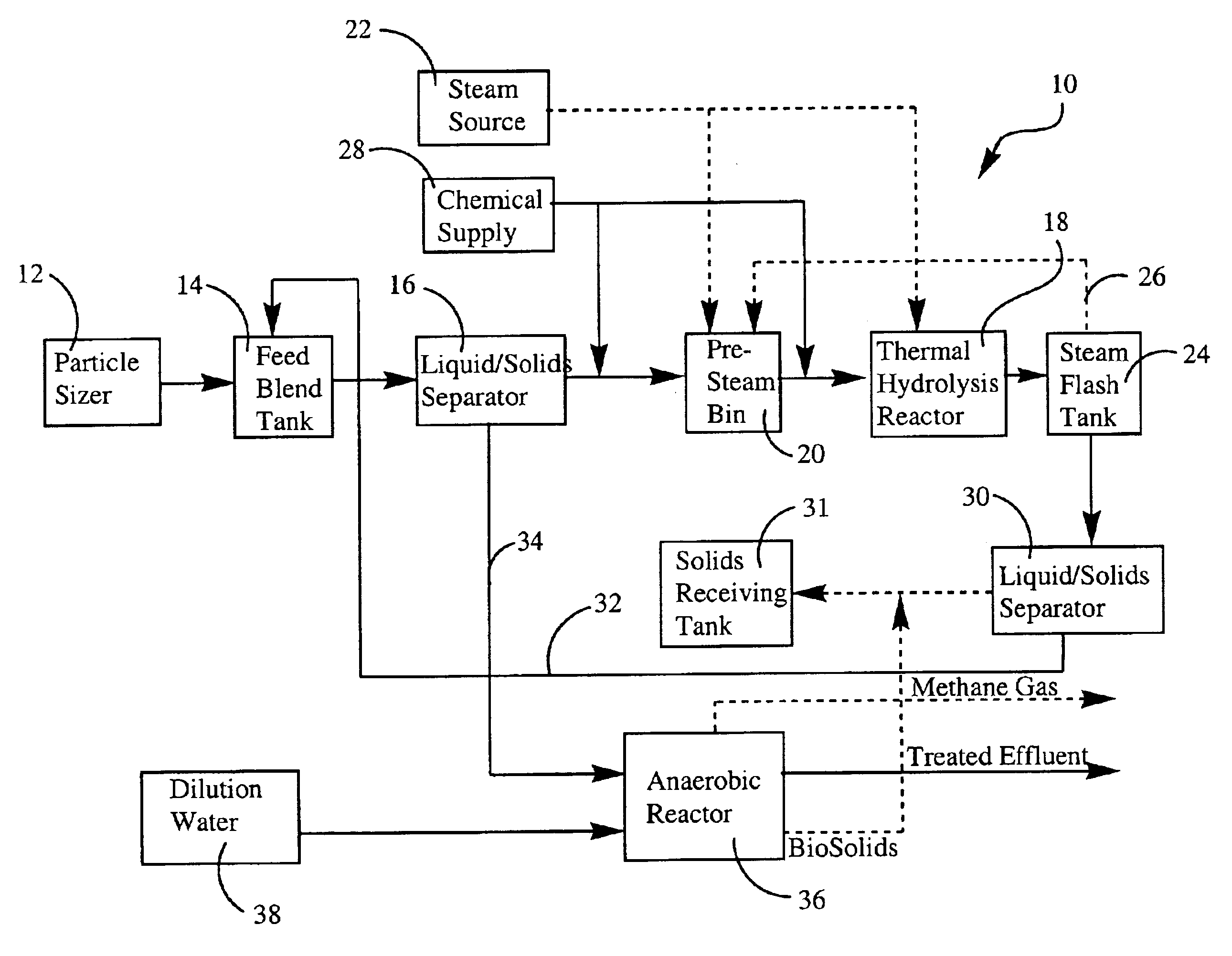

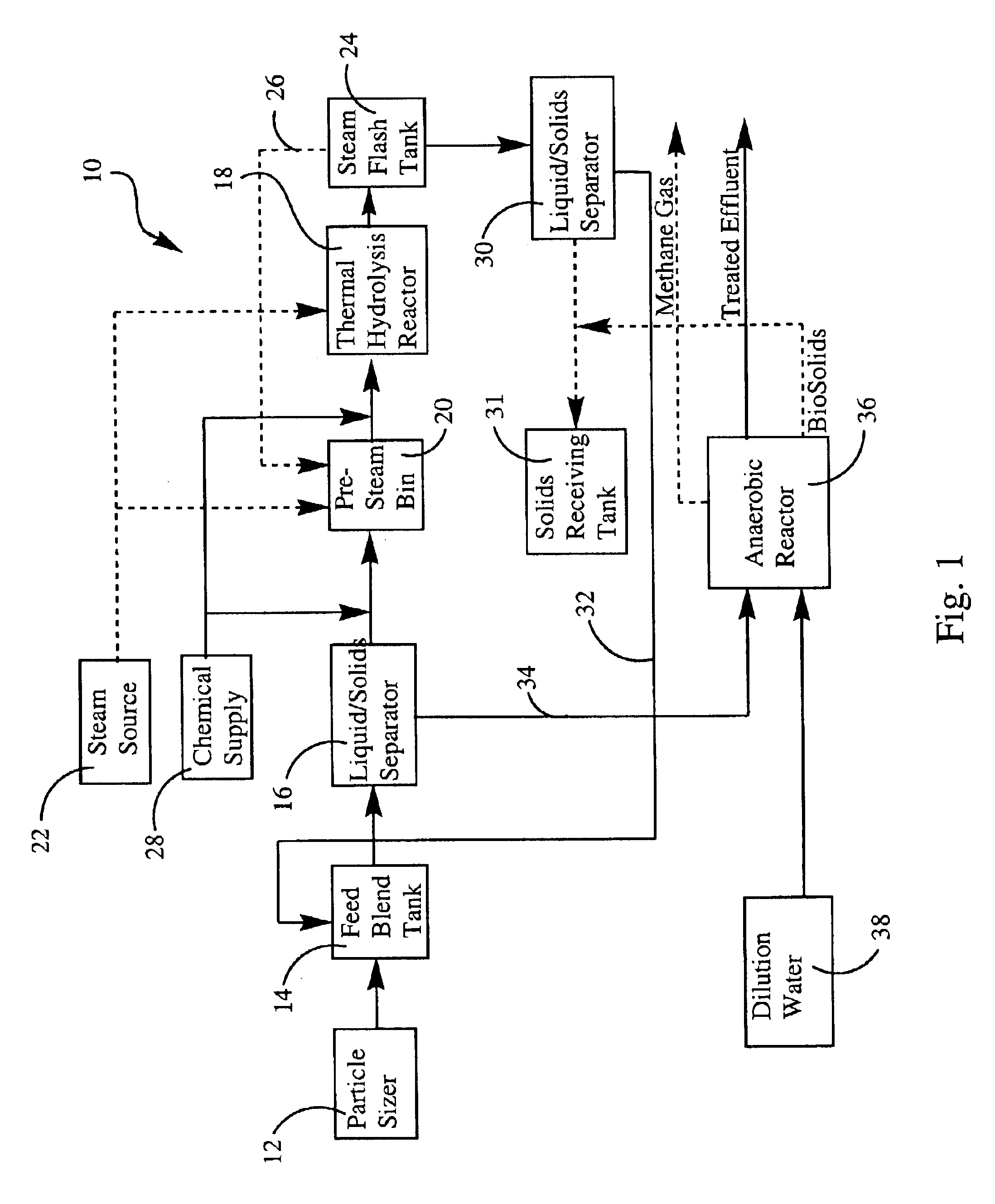

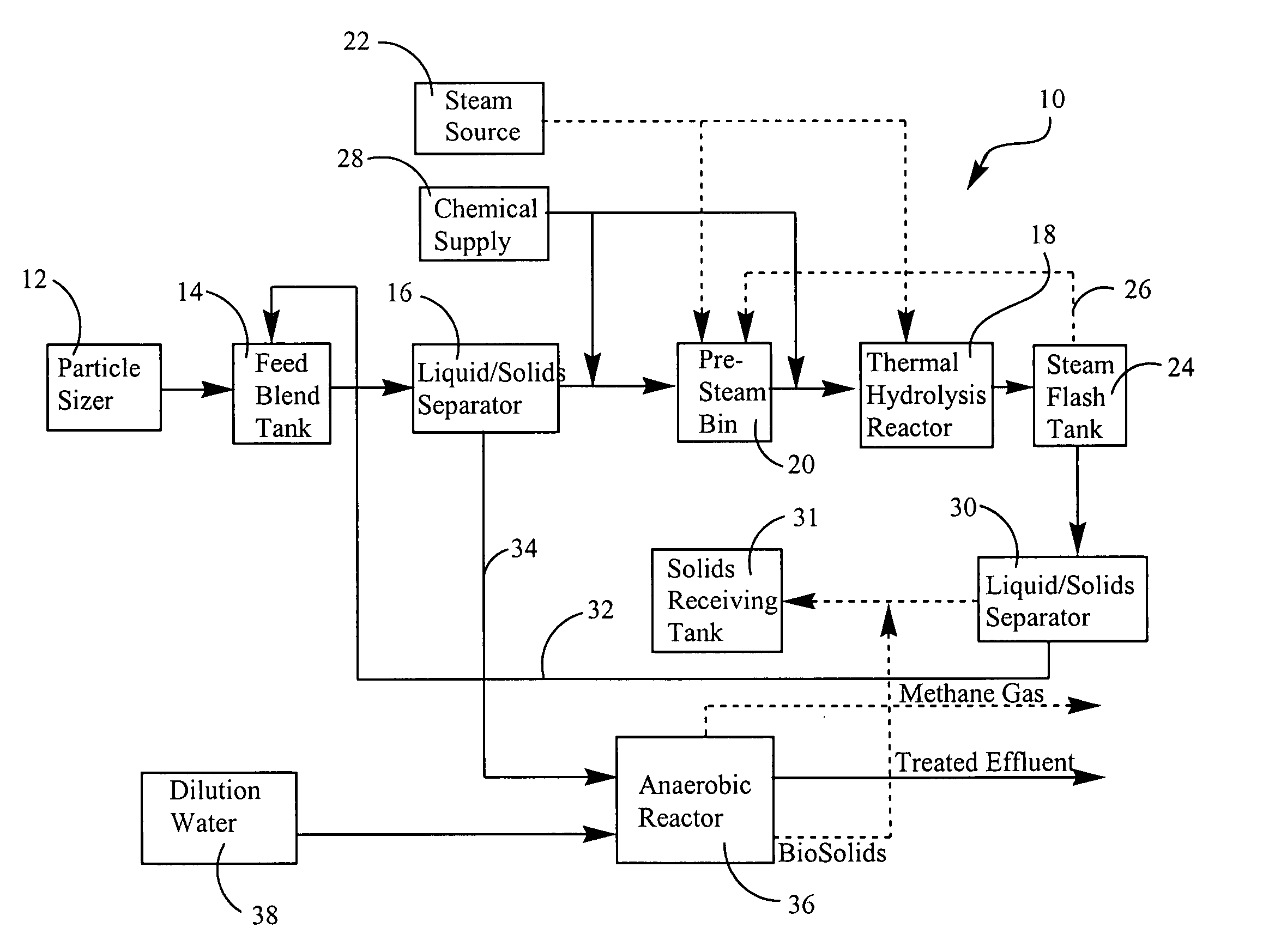

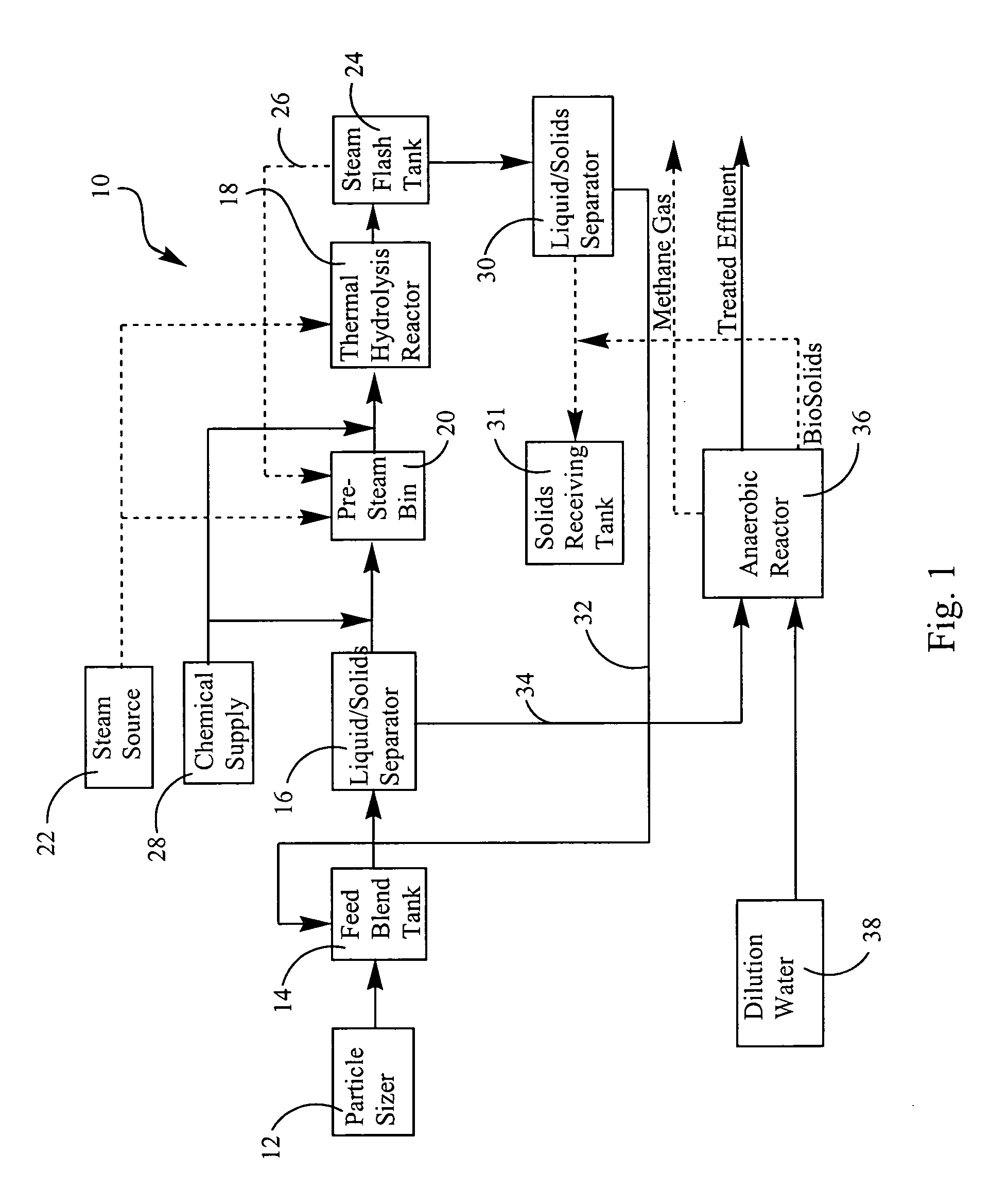

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

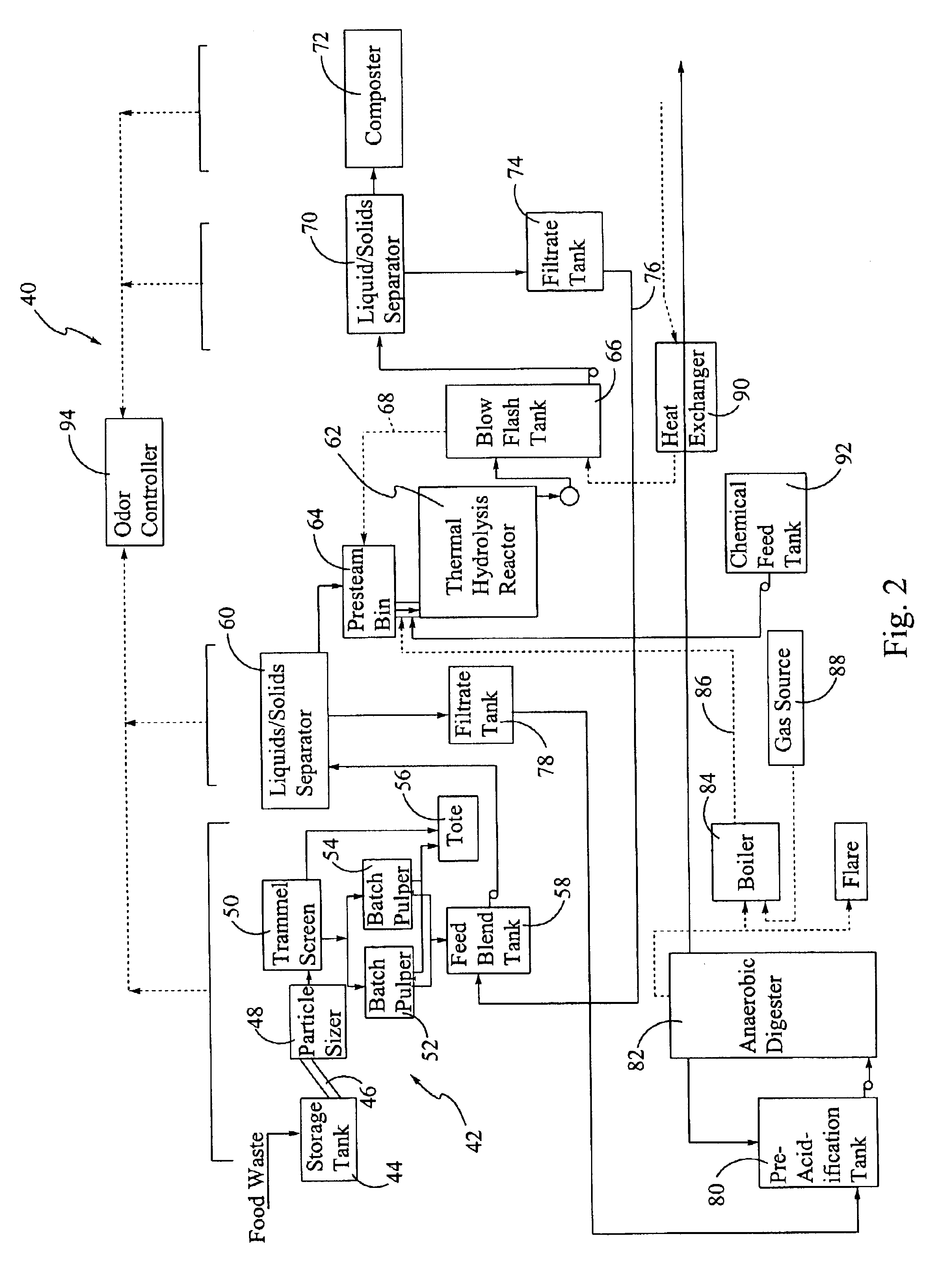

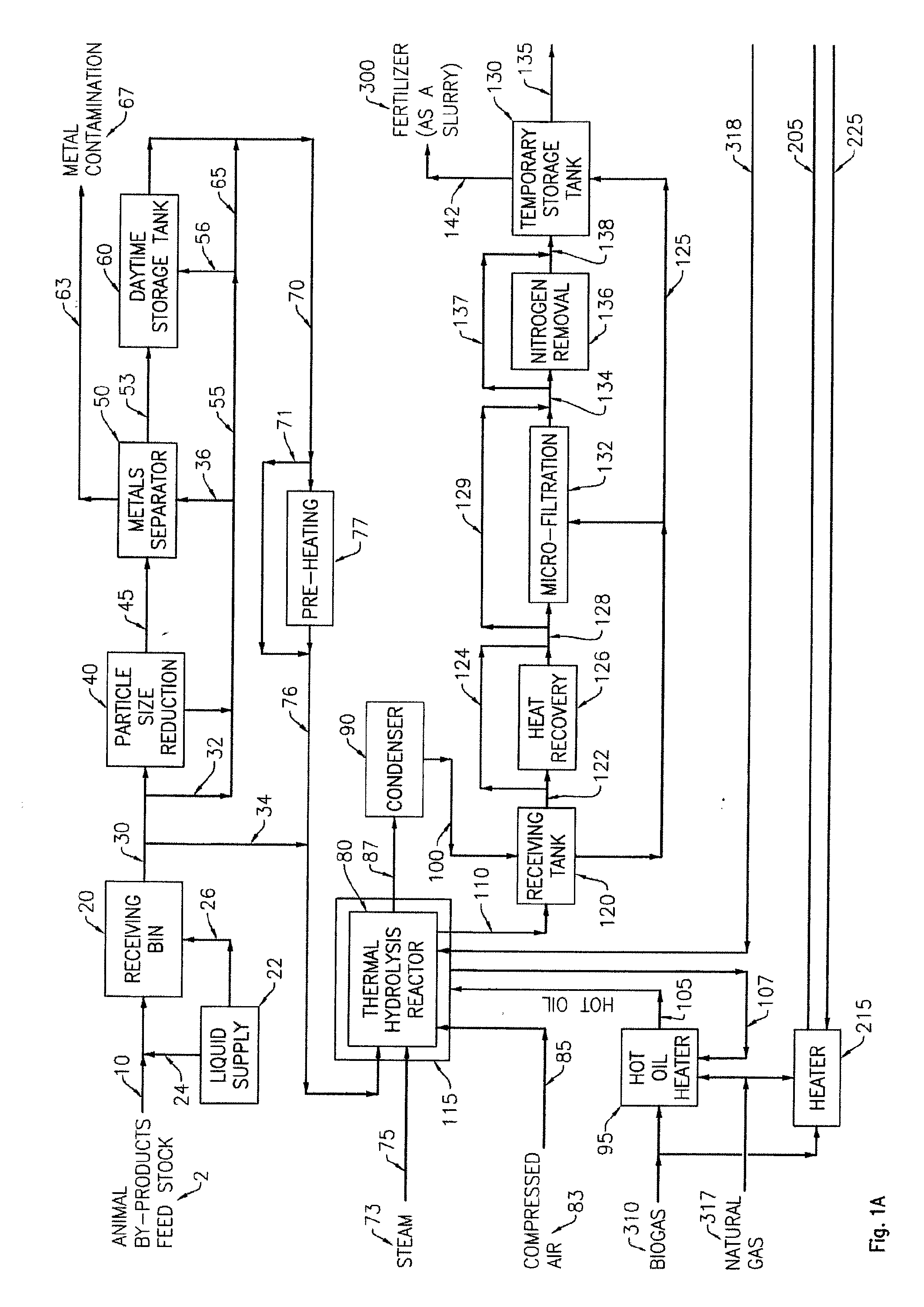

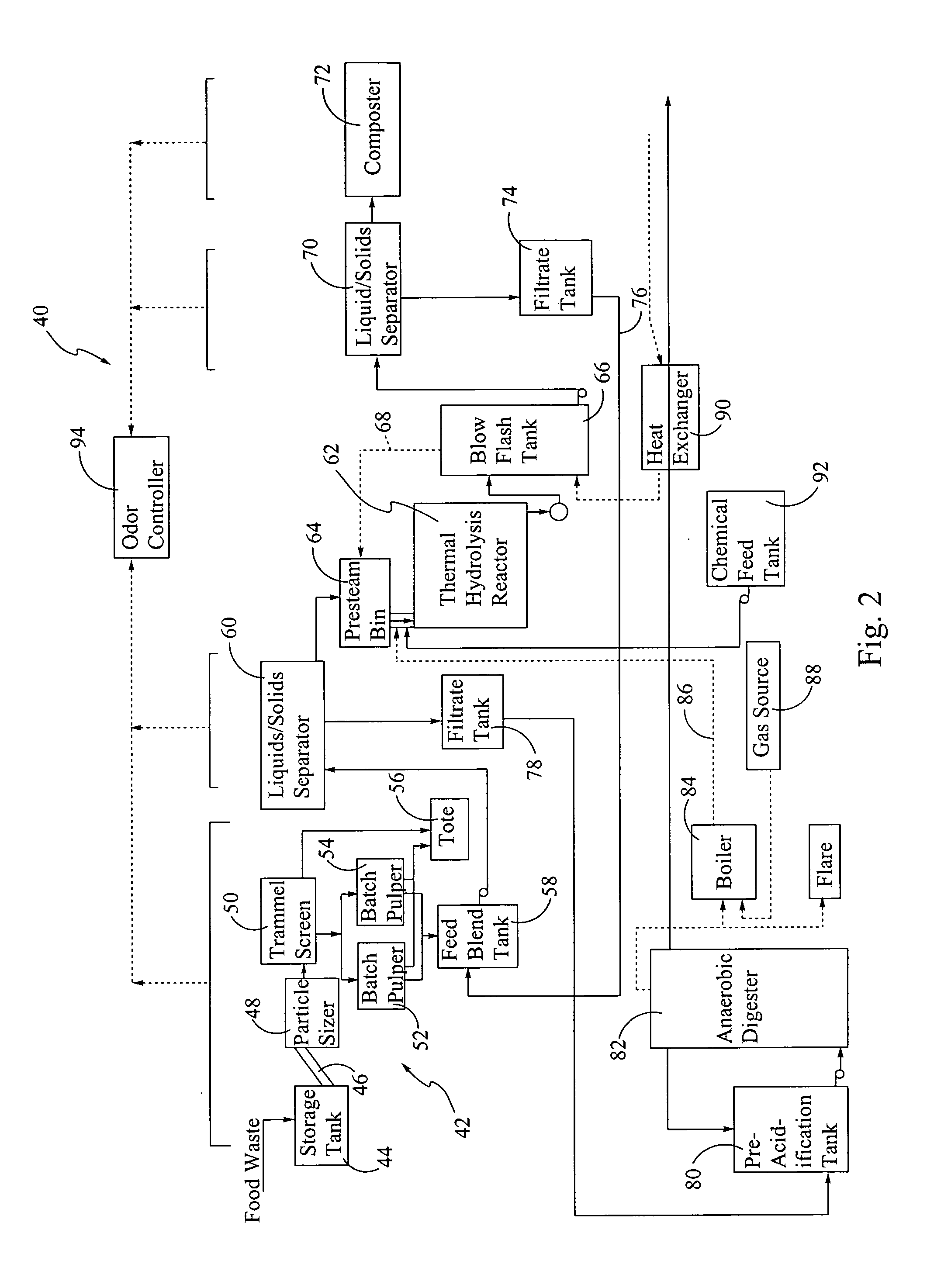

Apparatus and Process for Production of Biogas

ActiveUS20100021979A1Quick conversionDigesting retention timeBioreactor/fermenter combinationsBiological substance pretreatmentsHydrolysateSolid fraction

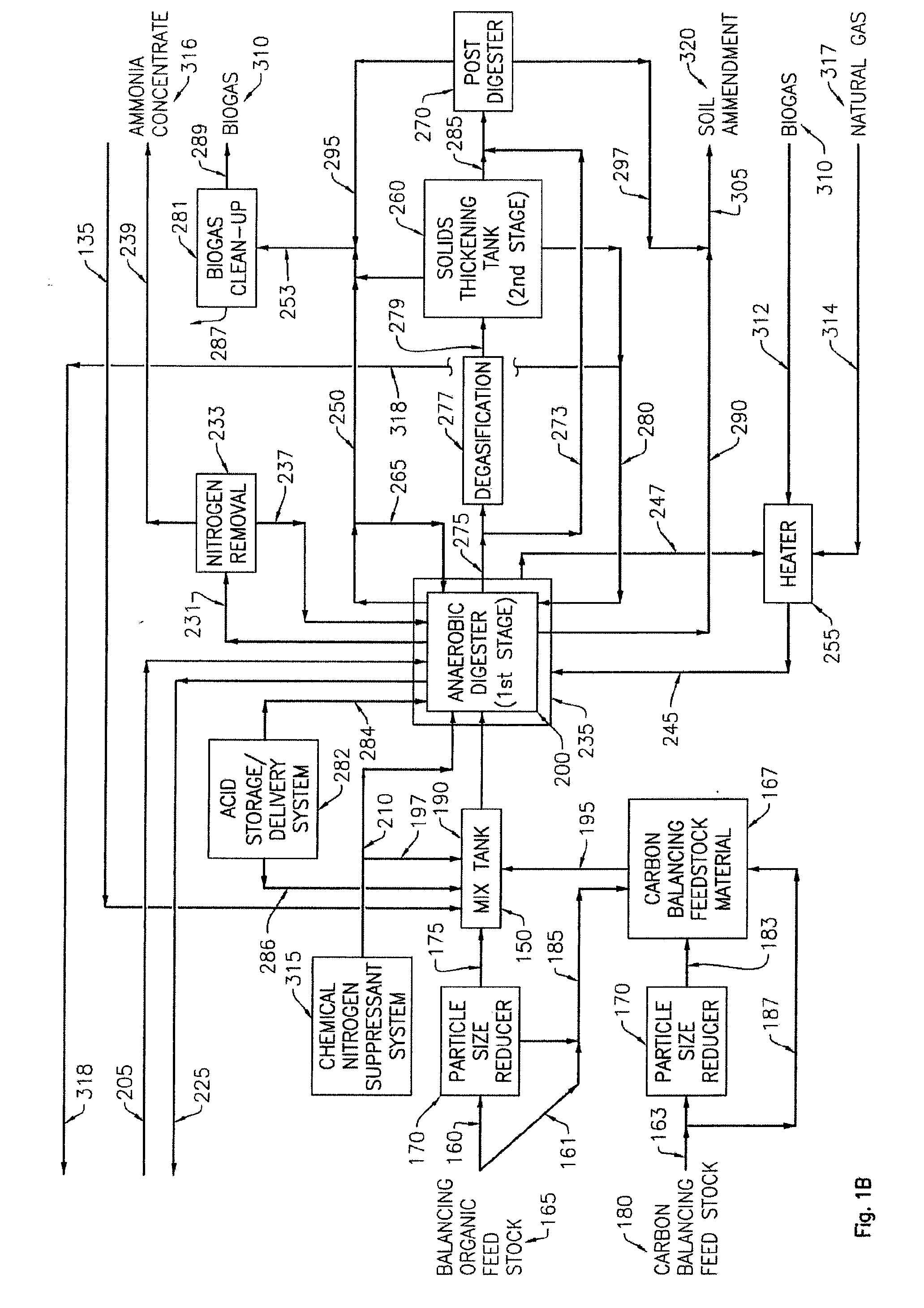

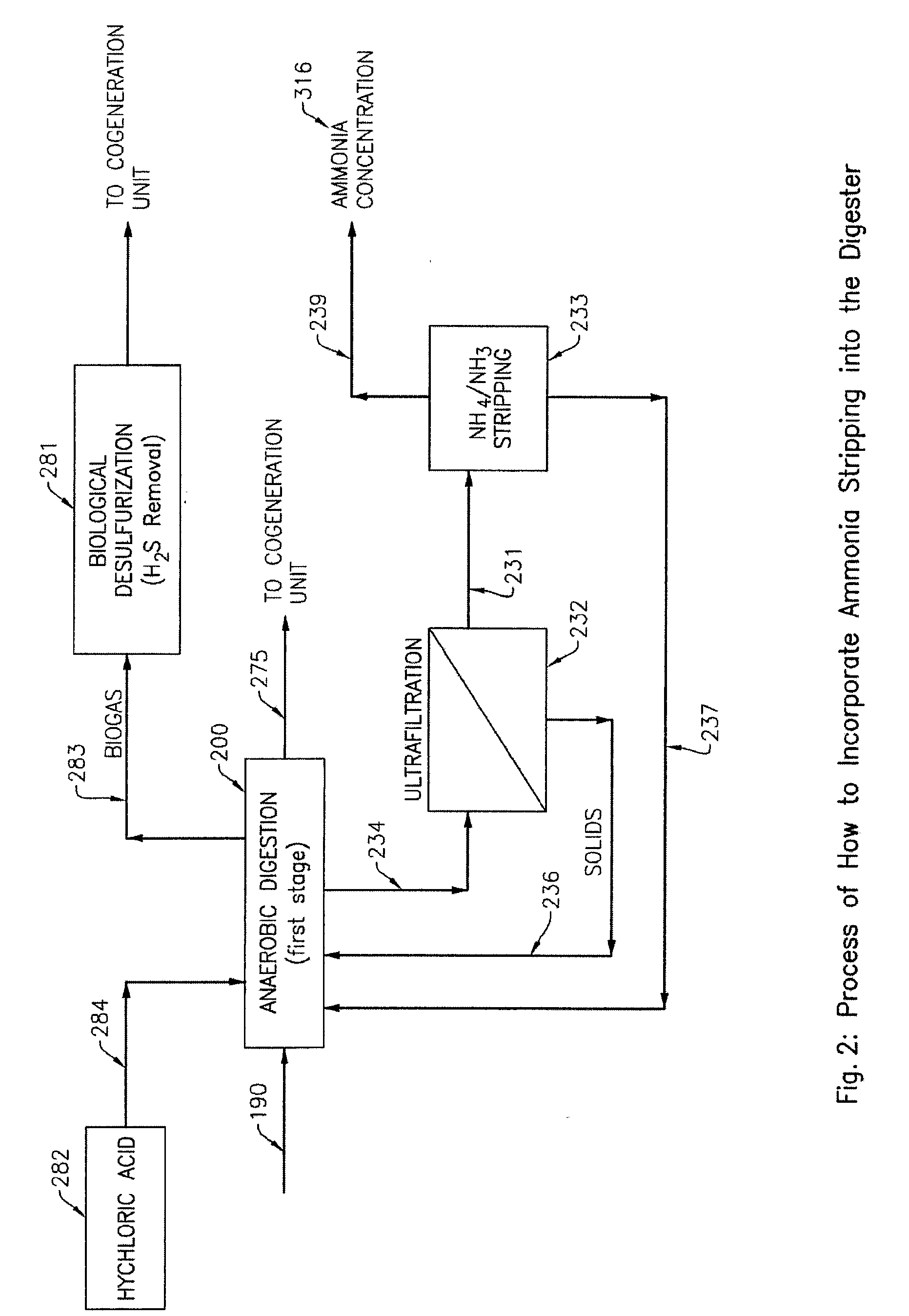

A process and an apparatus for the manufacture of biogas and a solids fraction from an organic waste feedstock is provided. The process involves thermal hydrolysis of the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours, to produce a hydrolysate. The hydrolysate undergoes anaerobic digestion at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce a biogas stream and a digestate. The digestate is separated into a solids fraction and a liquid fraction, and a portion of the solids fraction is recycled for further anaerobic digestion. The biogas stream, characterized as having a methane content from between 55 to 80% by volume, and the solids fraction, are recovered. The apparatus includes a receiving bin for receiving and supplying organic waste feedstock to a thermal hydrolysis reactor. The thermal hydrolysis reactor for processing the organic waste feedstock at a temperature from about 100 to about 220° C., a pressure from about 5 to about 20 bars, for a period of time from about 15 minutes to 4 hours to produce a hydrolysate. An anaerobic digester for processing the hydrolysate at a temperature from about 25 to 60° C., for a period of time from about 1 to 35 days to produce the biogas and a digestate, and a solids thickening tank for separating the digestate into the solid fraction, a liquid fraction and a secondary biogas fraction.

Owner:GEMINI CORP

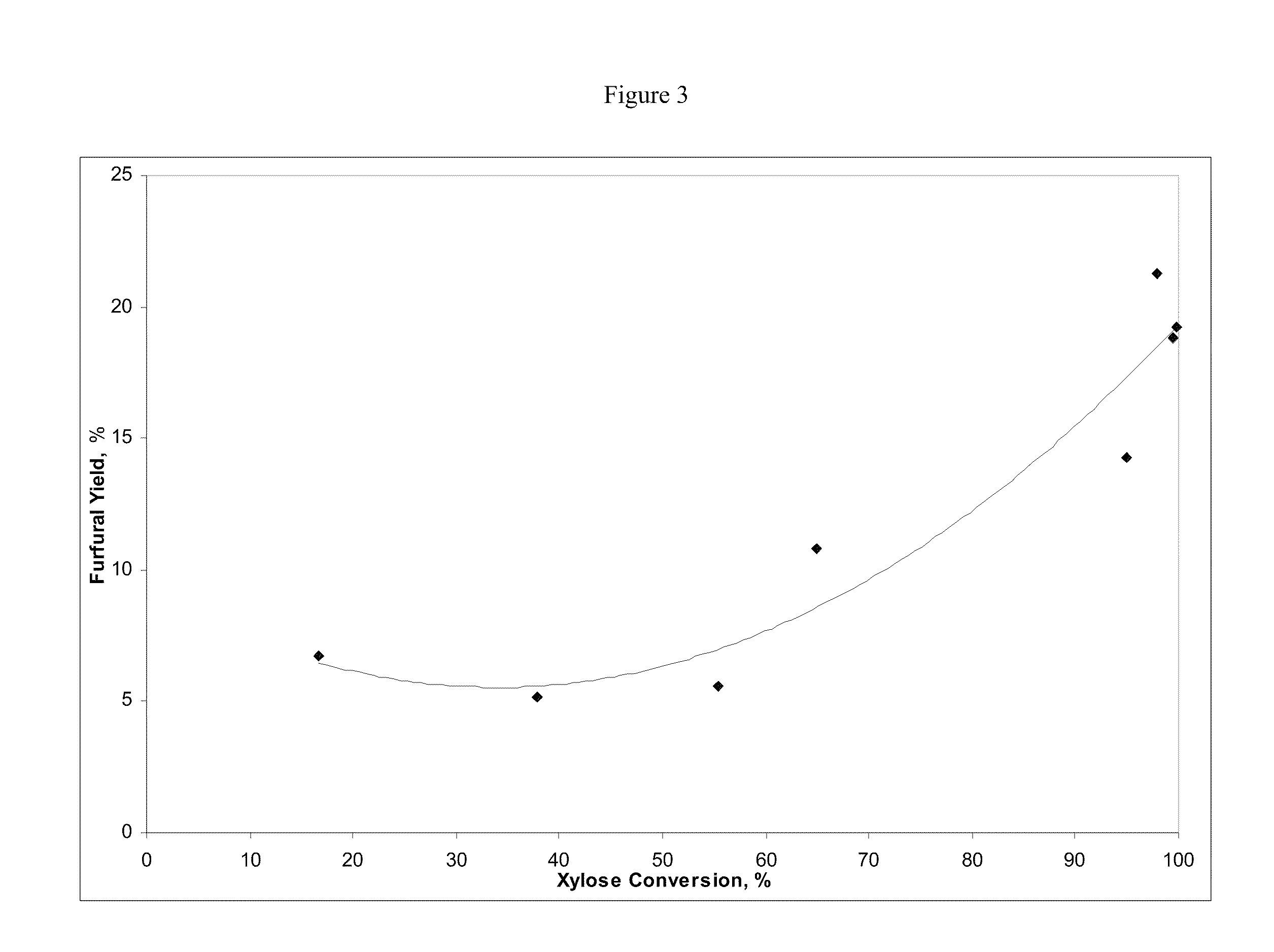

Solvo-thermal hydrolysis of xylose

ActiveUS20100048924A1Rapid coolingOrganic chemistryChemical/physical/physico-chemical processesSolventFurfural

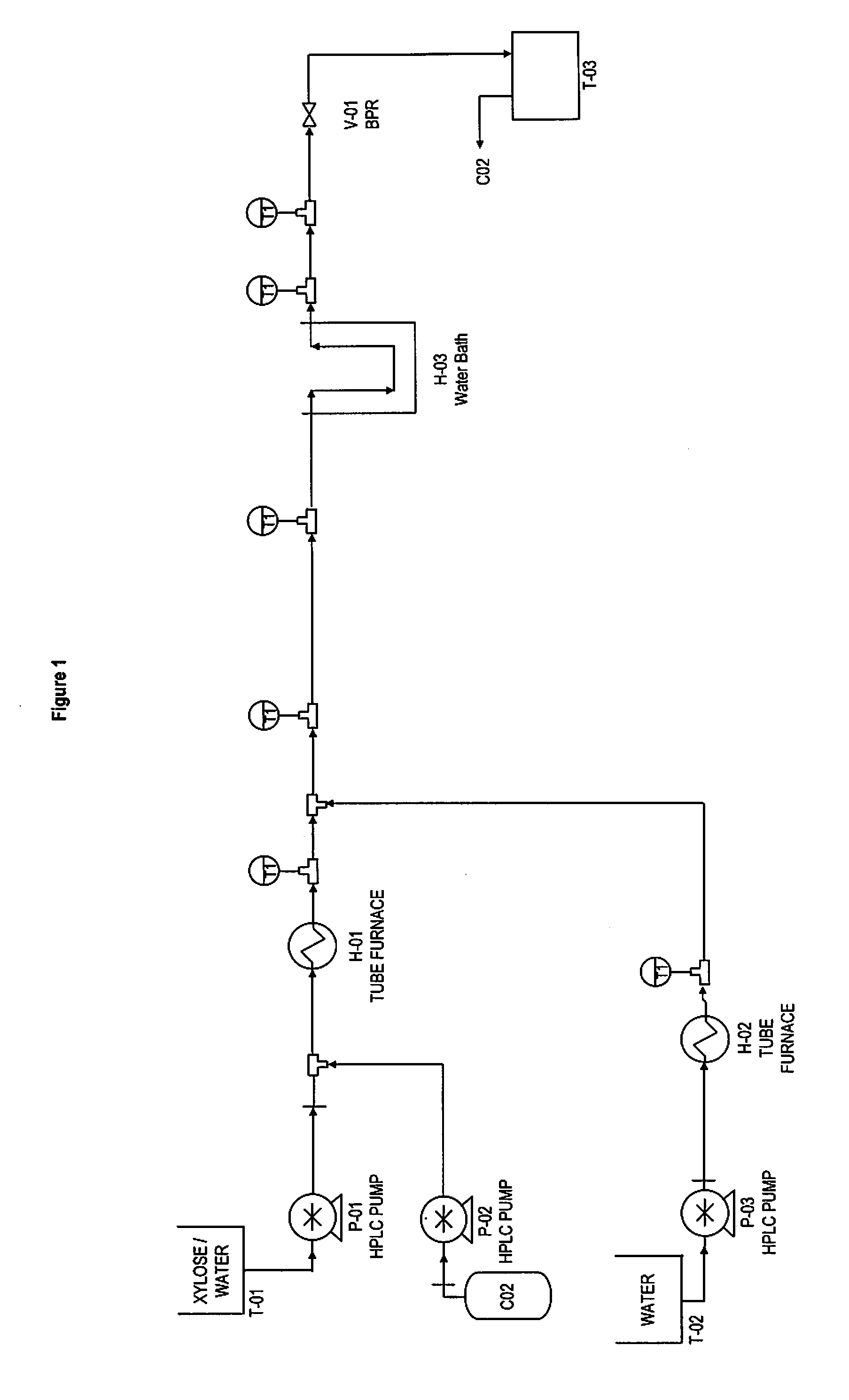

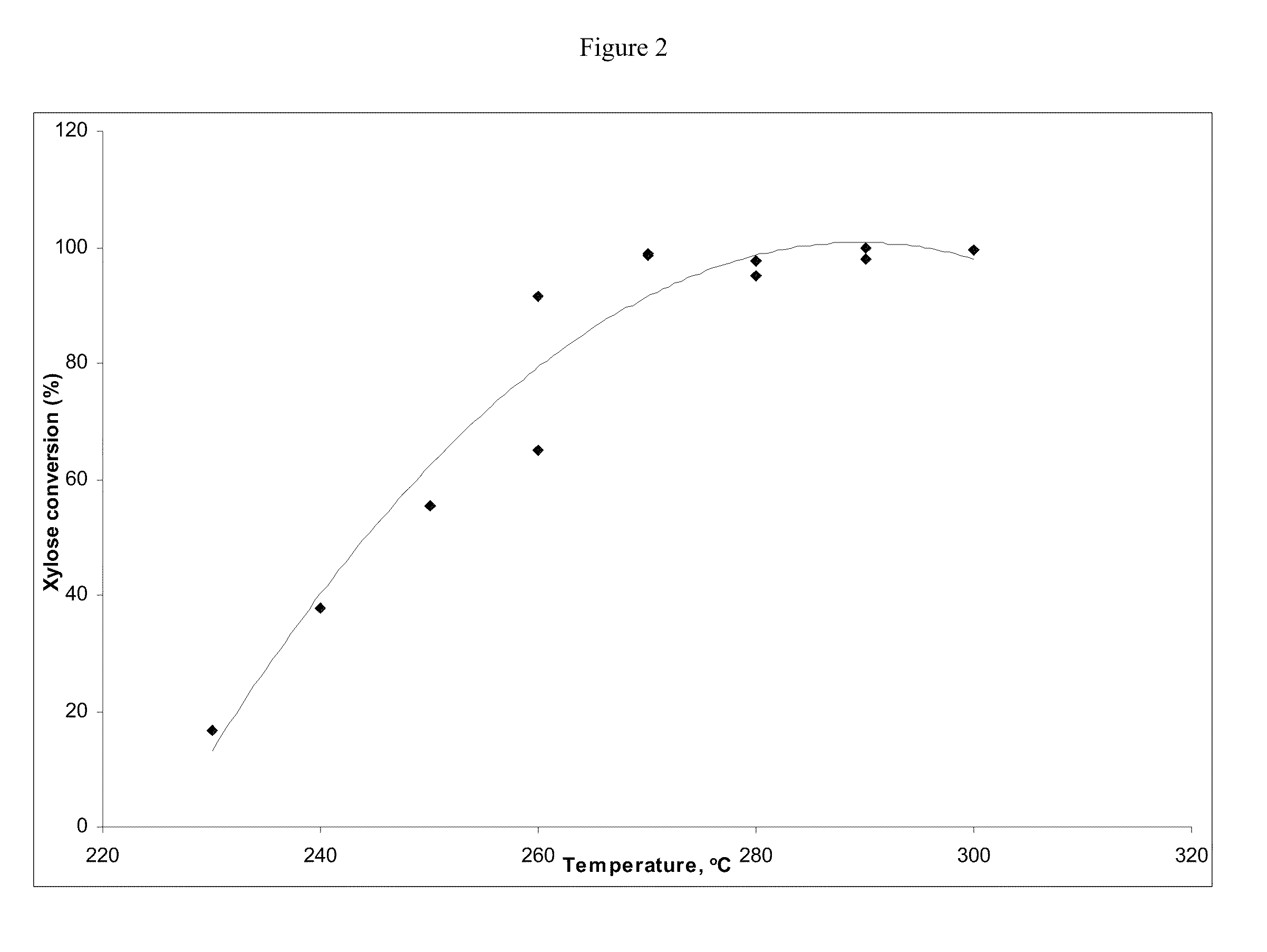

The invention relates to a process for producing furfural from xylose comprising: (a) mixing an aqueous xylose solution containing xylose oligosaccharides with sub-critical or near-critical water to form a mixture at a first temperature and a first pressure; (b) maintaining the mixture at the first temperature and the first pressure for a first time period; and (c) rapidly cooling the mixture to a second temperature and a second pressure, wherein furfural is produced by the process (d) process can also be carried out with or without mixing of carbon dioxide with aqueous xylose solution before it is mixed with sub-critical or near-critical water to form a mixture at a first temperature and pressure.

Owner:RENMATIX INC

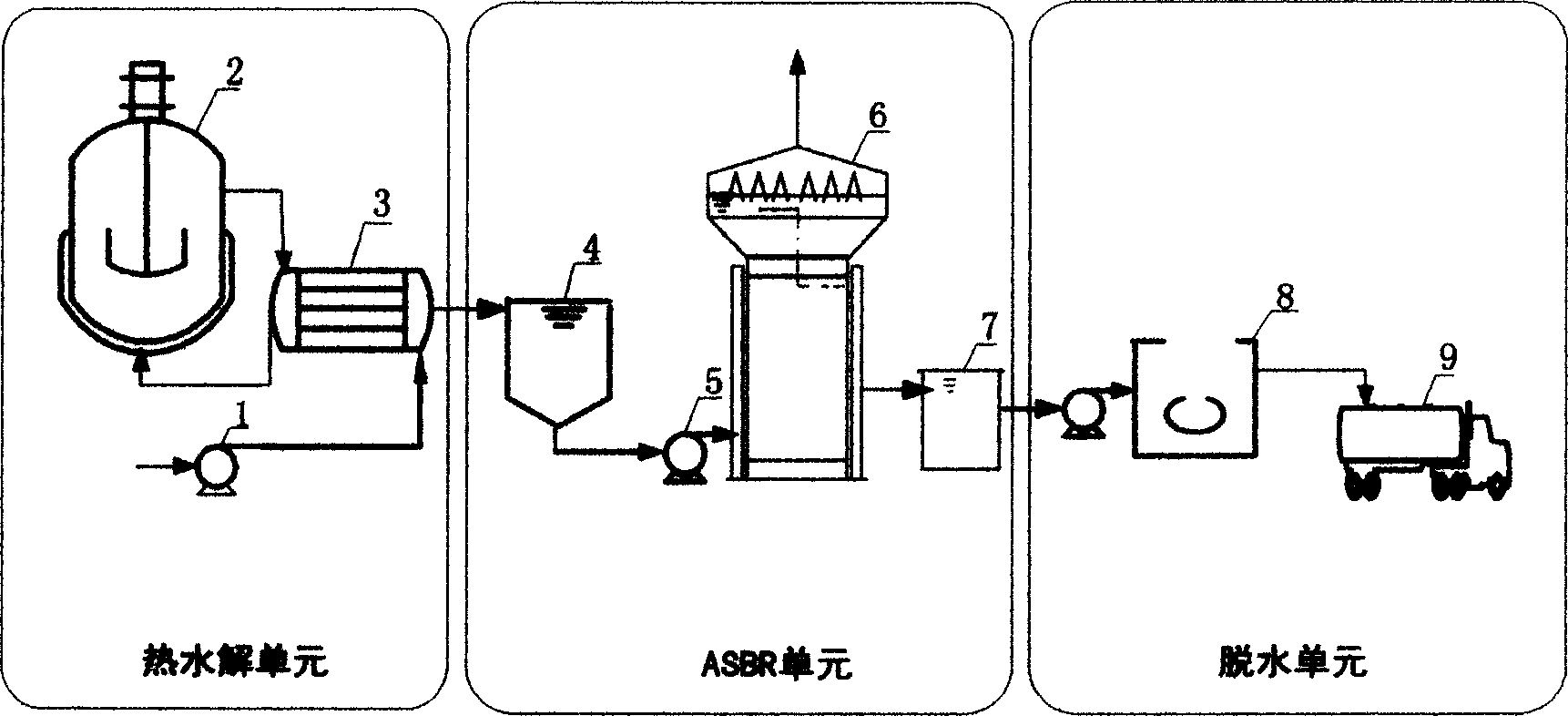

Process for treating excess sludge

ActiveCN1569699ARealize recycling of resourcesSmall volumeSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisMembrane bioreactorAnaerobic reactor

Disclosed is a method and equipment for treatment of polluted fluid, wherein ferrum family flocculating agents of a finite concentration are charged into the membrane bioreactor, in which they are subject to domestication and become compact biological ferrum sludge with improved property.

Owner:TSINGHUA UNIV

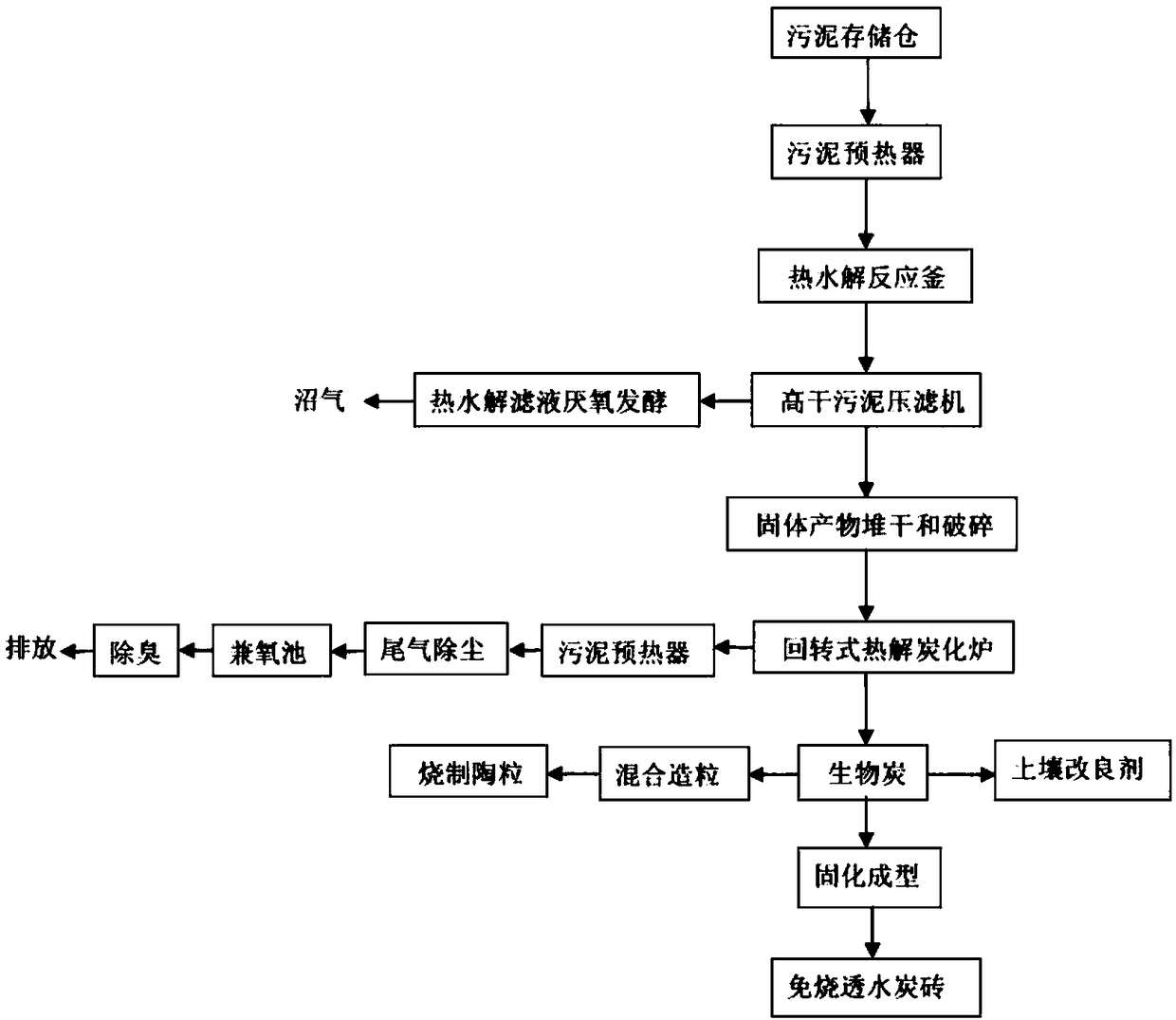

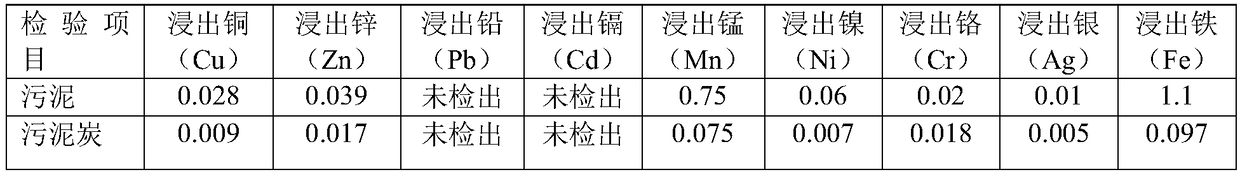

Resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization

InactiveCN108423959AImproved Anaerobic Digestion PerformanceImprove dehydration effectWater treatment parameter controlSpecific water treatment objectivesSludgeHigh energy

The invention discloses a resource utilization method of sludge based on thermal hydrolysis-pyrolysis carbonization. The method includes the steps of: (1) transporting dehydrated sludge to a sludge preheater; (2) sending the preheated sludge into a sludge thermal hydrolysis reaction kettle; (3) subjecting the thermal hydrolysis product to solid-liquid separation to obtain thermal hydrolysis filtrate and a solid product; (4) carrying out natural heap drying, crushing, activation and granulation on the solid product successively, then conveying the product to a rotary controllable pyrolysis carbonization furnace by a spiral conveyer, and conducting high-temperature rapid pyrolysis to obtain biochar, tar and high-temperature waste gas, introducing the high-temperature waste gas into the sludge preheater, and subjecting the biochar to resource comprehensive utilization; and (5) subjecting the thermal hydrolysis filtrate to anaerobic fermentation, and using the generated biogas as the fuelof the pyrolysis carbonization furnace. The method provided by the invention overcomes the problems of high energy consumption of the sludge carbonization process and nonstandard resource utilizationmethod of sludge biochar in sewage treatment plants at present, and realizes reduction, stabilization, harmless and resource comprehensive utilization of sludge in sewage treatment plants.

Owner:浙江合泽环境科技有限公司

Method for treating biomass and organic waste with the purpose of generating desired biologically based products

The present invention provides a method for treatment of lignocellulosic organic waste or biomass, by which the carbohydrates are rendered more available for subsequent hydrolysis, e.g. by means of addition of enzymes or direct fermentation to one or more desired products. The invention more specifically relates to a method comprising a combination of the following process steps: thermal hydrolysis, wet oxidation and wet explosion. The method according to the present invention can operate with undivided or only poorly divided substrate having a high dry matter concentration.

Owner:CAMBI BIOETHANOL APS

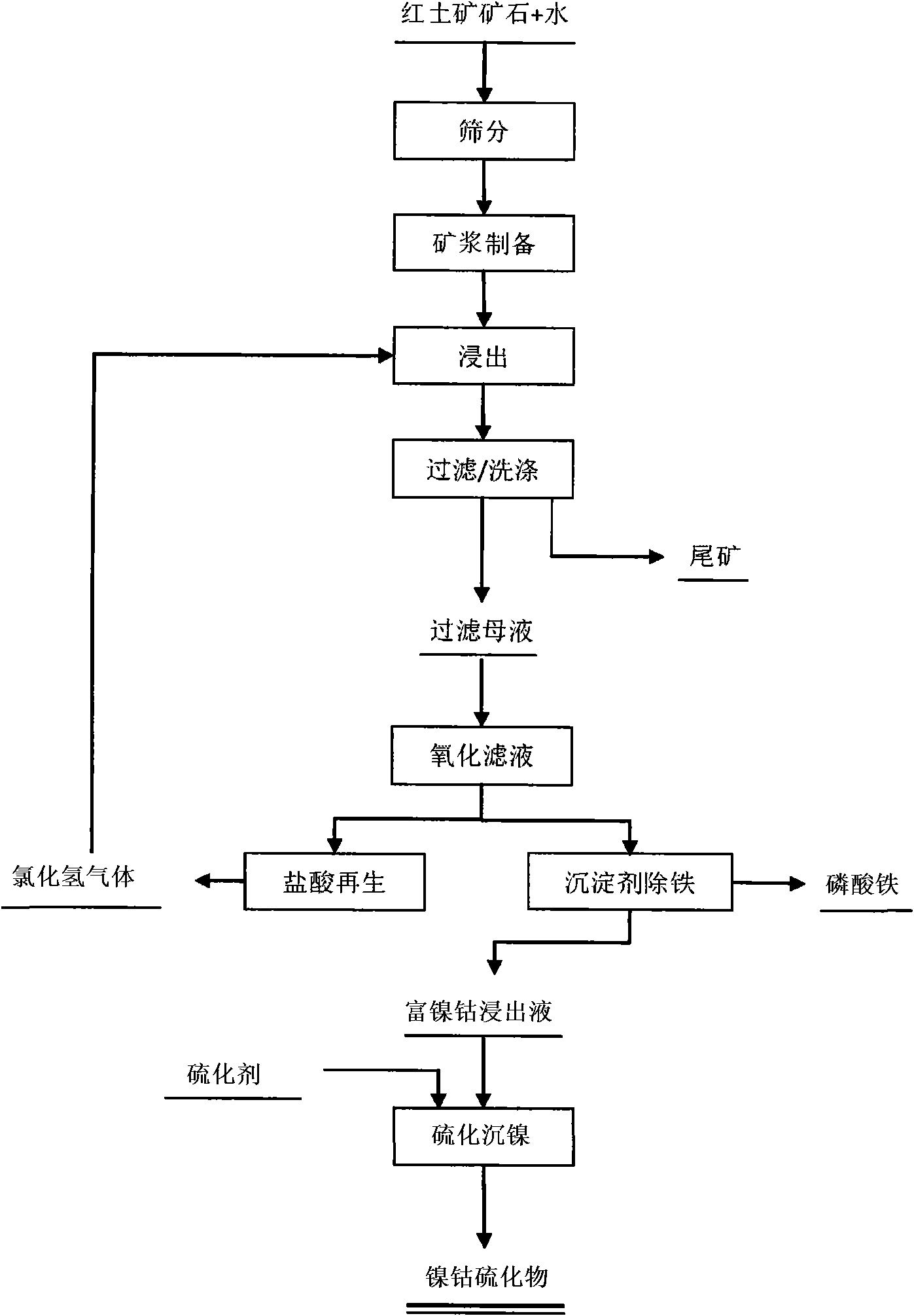

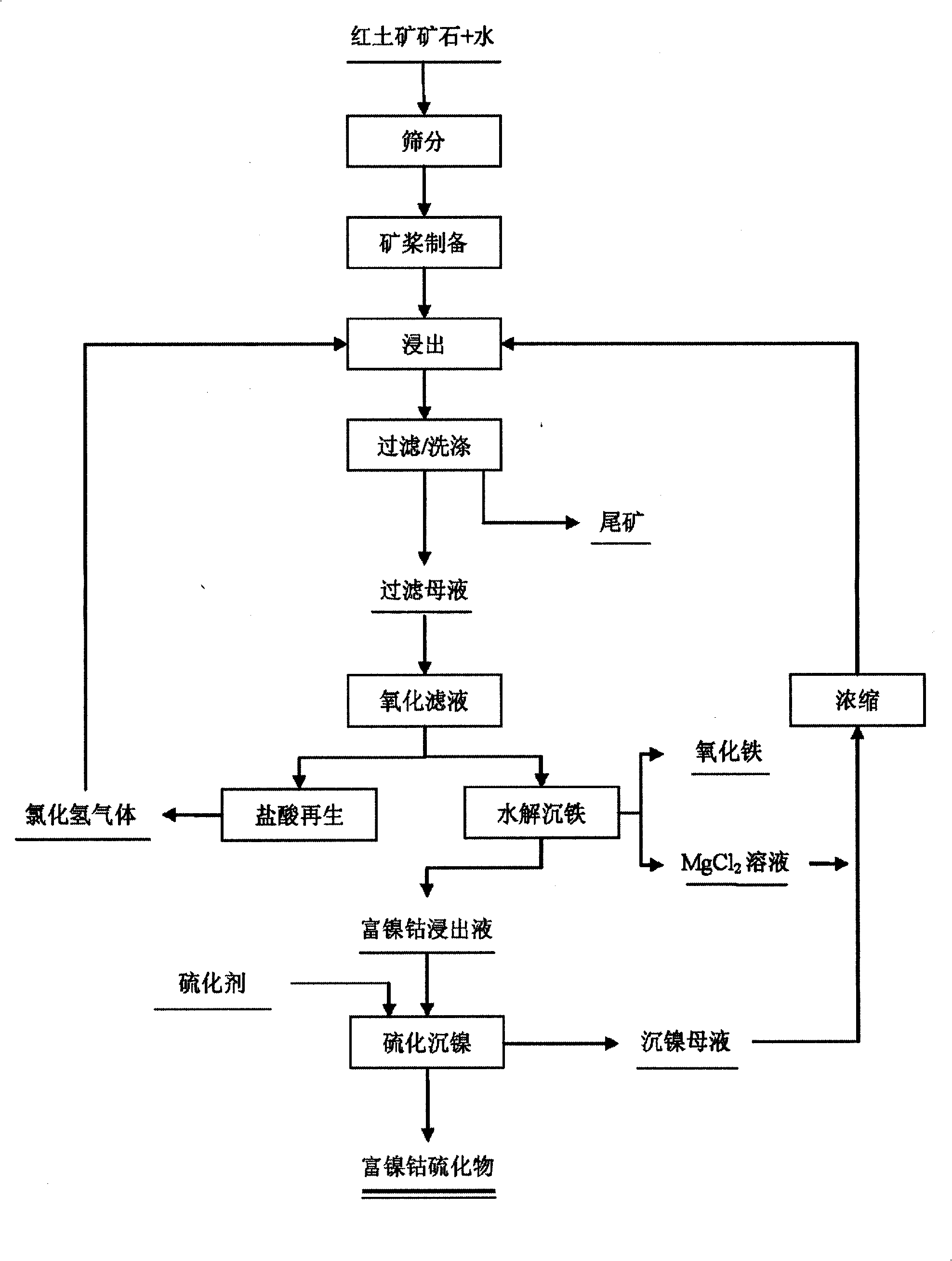

Method for removing iron and enriching nickel cobalt through precipitation of laterite type nickel ores

InactiveCN101575676AEasy to separateLow costProcess efficiency improvementPregnant leach solutionLaterite

The invention relates to a method for removing iron and enriching nickel cobalt through precipitation of laterite type nickel ores, which is characterized in that: performing ball milling on the laterite type nickel ores, sieving the laterite type nickel ores through 50 mesh sieves, sampling a 50 mesh ore sample, using a hydrochloric acid to leach out the 50 mesh ore sample, driving the Fe concentration in lixivium to between 0.01 and 6 mol / L, and adding an oxidant and a precipitator into a solution, wherein the concentration of the oxidant and the precipitator is between 0.01 and 9 mol / L; using 0.01 to 6 mol / L of aqueous alkali to control the pH value of the system to between 0.1 and 6.0, performing reaction on the system in a stirring reactor at the temperature of between 20 and 90 DEG C for 1 minute to 24 hours, obtaining deposit after solid-liquid separation, regenerating the hydrochloric acid during iron removal through precipitation, returning the regenerated hydrochloric acid to the leaching procedure for recycling; and adding a sulfidizer into filtrate for sulfidization and precipitation, and finally realizing the effective enrichment of nickel and cobalt. The invention discards the conventional pyrohydrolysis or high-temperature roasting method, reduces the energy consumption of removal of iron and regeneration of the hydrochloric acid, and has the advantages of simple technological process, high recovery rate of nickel cobalt, good byproduct quality, stability, low cost and the like.

Owner:CENT SOUTH UNIV

Deep dehydration device and deep dehydration method for organic materials

InactiveCN104628233ASave energyEasy to dehydrateSludge treatmentEnergy based wastewater treatmentSludgeOrganic matter

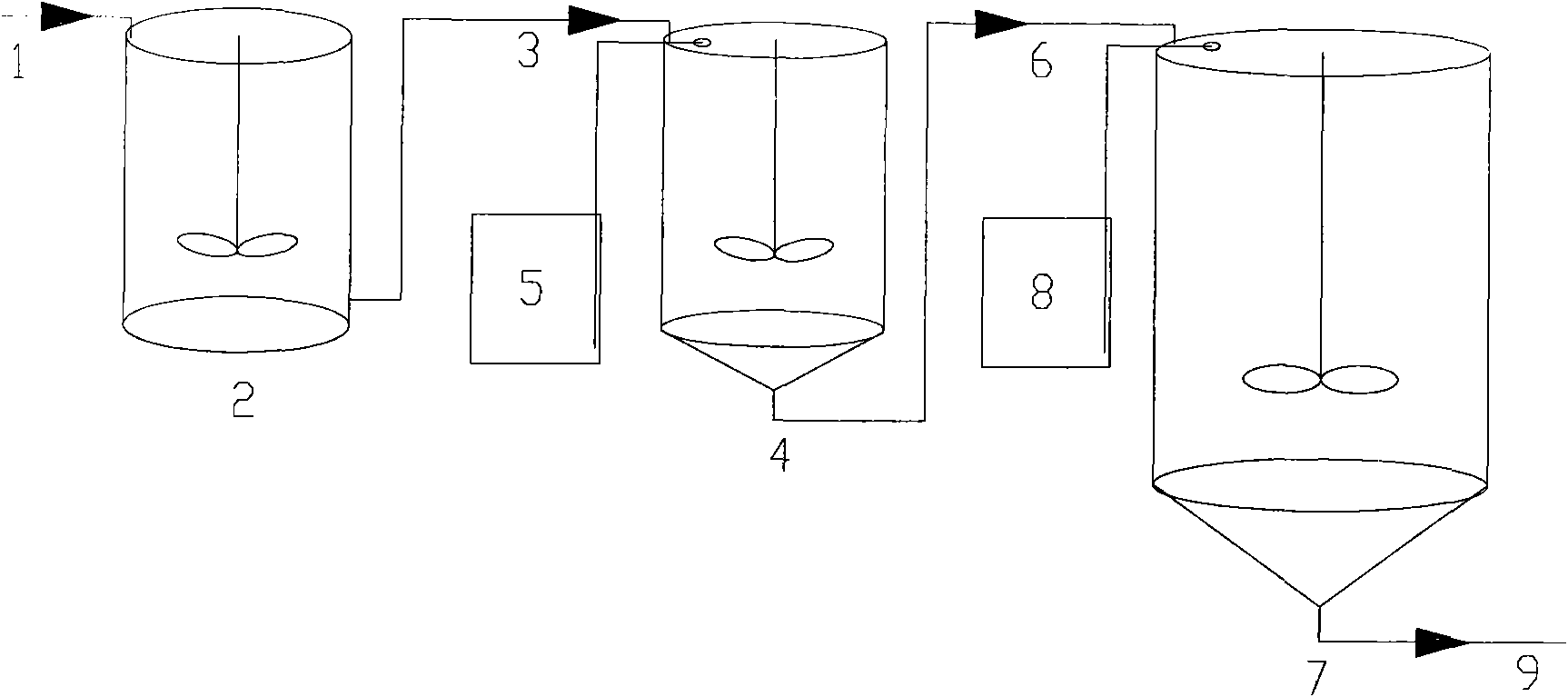

The invention relates to a deep dehydration device and deep dehydration method for organic materials and belongs to the field of sludge treatment. The deep dehydration device and the deep dehydration method are used for realizing the deep dehydration of organic granular materials. The deep dehydration method for the organic materials comprises the following steps: (a) carrying out pretreatment: stirring the organic granular materials, and adjusting the additive, moisture content and temperature of the organic granular materials; (b) carrying out thermal hydrolysis: putting the organic granular materials pretreated in the step (a) into a hydrolysis tank, carrying out thermal hydrolysis on the organic granular materials so as to destroy sticky organic substances outside granules of sludge or mud materials and liberate biochemical water organic matters contained in the granules, and thus, hydrolyzing the biochemical water organic matters contained in the granules; (c) carrying out thermal oxidation: putting a thermal hydrolysis product obtained in the step (b) into an oxidation tank, and carrying out thermal oxidation on the thermal hydrolysis product so as to release biochemical water; (d) carrying out solid-liquid separation: dehydrating a product obtained in the step (c), wherein after dehydration, a solid substance can be directly recovered as a solid organic fertilizer, and a liquid substance can be concentrated and oxidized as a liquid organic fertilizer.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

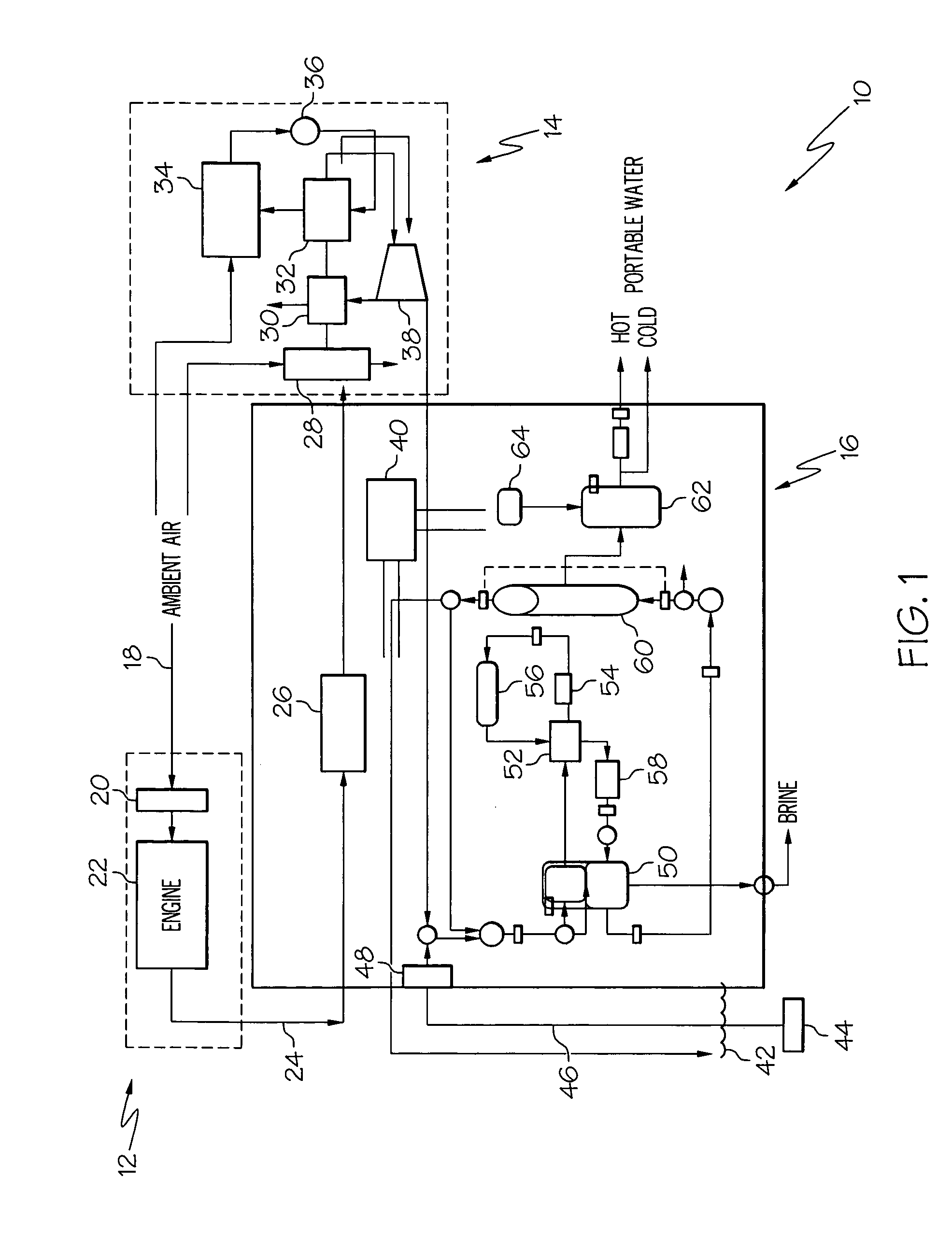

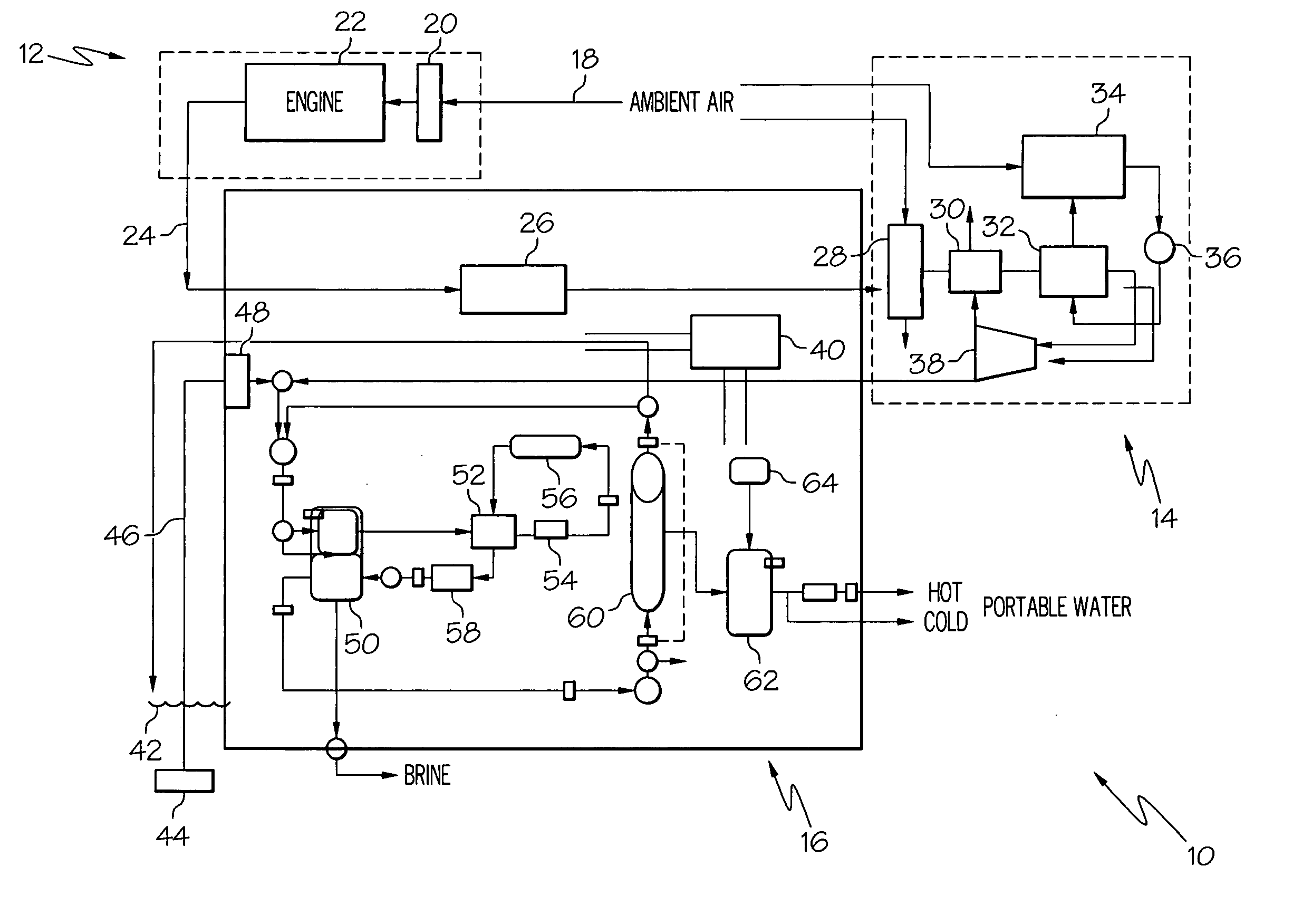

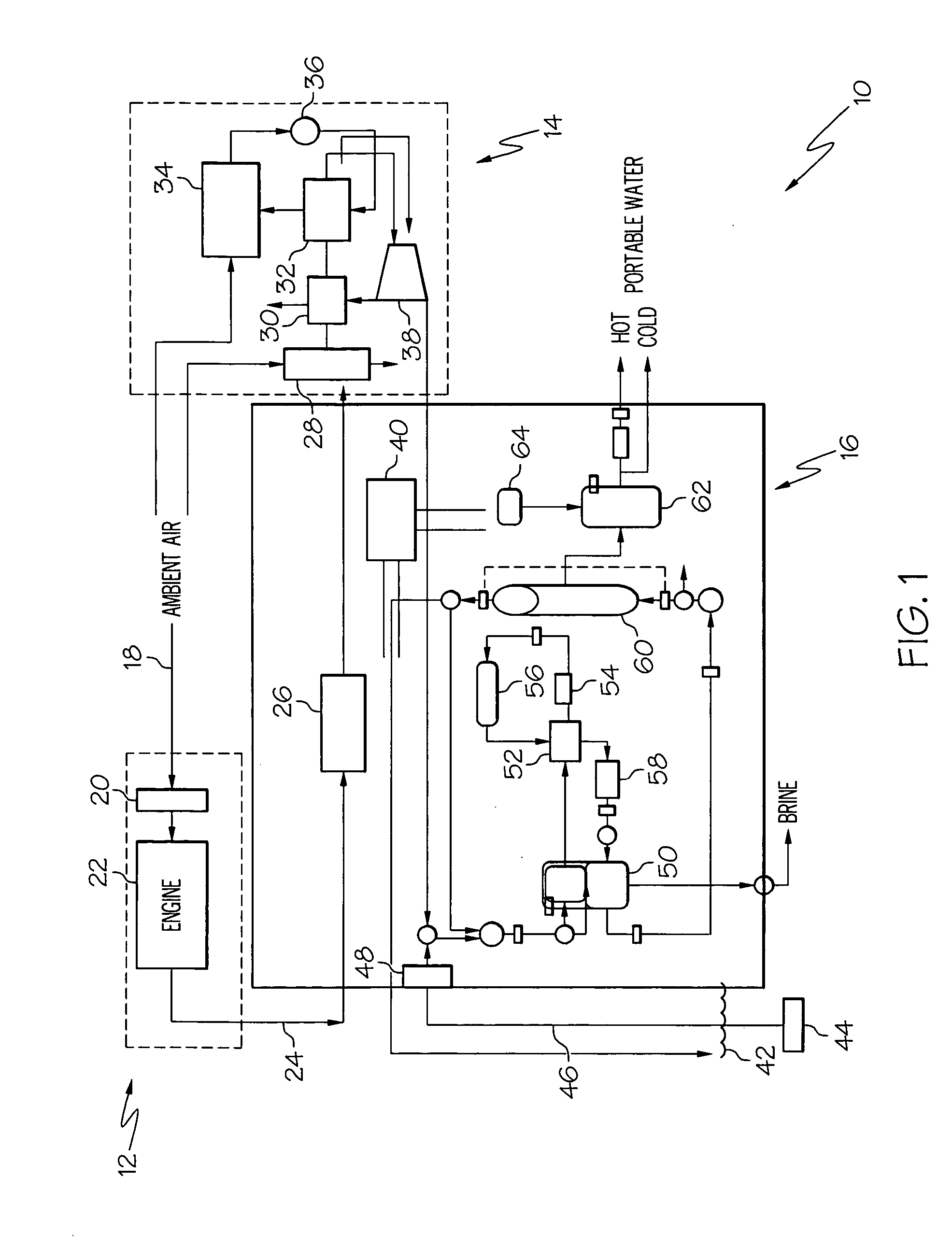

Water purification system and modes of operation

InactiveUS7537702B2Dispersed particle filtrationGeneral water supply conservationRadioactive agentPotable water

A water purification system comprising a thermal hydrolysis catalytic reactor, an adsorbent media bed and a reverse osmosis unit is provided. The water purification system may provide potable water from non-potable water, such as non-potable water contaminated with chemical warfare agents, biological warfare agents, radioactive agents and / or Toxic Industrial Chemicals (TICs). Methods for providing potable water using the water purification system of the present invention are also provided.

Owner:HONEYWELL INT INC

Water purification system and modes of operation

InactiveUS20060226081A1Dispersed particle filtrationGeneral water supply conservationRadioactive agentPotable water

A water purification system comprising a thermal hydrolysis catalytic reactor, an adsorbent media bed and a reverse osmosis unit is provided. The water purification system may provide potable water from non-potable water, such as non-potable water contaminated with chemical warfare agents, biological warfare agents, radioactive agents and / or Toxic Industrial Chemicals (TICs). Methods for providing potable water using the water purification system of the present invention are also provided.

Owner:HONEYWELL INT INC

Method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis

InactiveCN101524699AImproved Anaerobic Digestion PerformanceShortened hydrolysis efficiencySolid waste disposalBiological sludge treatmentMicrowaveRoom temperature

The invention relates to a method for improving anaerobic digestion performance of sludge by utilizing microwave alkaline thermal hydrolysis, and the method belongs to the technical field of solid waste treatment. Alkaline solution is firstly added in the sludge with the solid concentration of 7 percent-10 percent for controlling the pH value of the sludge, the mixing is carried out after adding the alkaline solution, the alkalified sludge is placed in a pressure-bearing reactor, the heating is carried out in a microwave field with the frequency of 2450MHz, the sludge heated by microwave is cooled to the room temperature, and the anaerobic digestion treatment is carried out on the sludge after the cooling. More than 60 percent of organic matters in the sludge which is treated by the method are converted to liquid phase; during anaerobic digestion, the conversion efficiency of the organic matters of the sludge is improved, thereby being an effective means for realizing the whole process pollution control, the energy conservation and the emission reduction of sewage treatment.

Owner:TSINGHUA UNIV

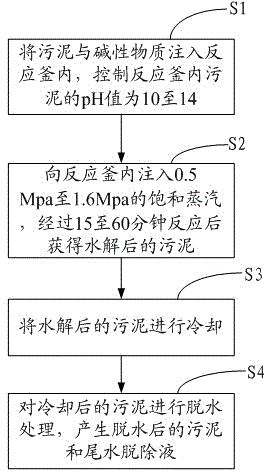

Alkali adding catalytic thermal hydrolysis treatment method for sludge

InactiveCN102718384AImprove hydrolysis efficiencyQuick breakSludge treatment by pyrolysisSludgeHydrolysis

The invention provides an alkali adding catalytic thermal hydrolysis treatment method for sludge. The method comprises the following steps of: A, injecting the sludge and an alkali substance into a reaction kettle, and controlling the pH value of the sludge in the reaction kettle to be 10-14; and B, injecting saturated steam of 0.5 to 1.6MPa into the reaction kettle, and reacting for 15 to 60 minutes to obtain hydrolyzed sludge. The method has the advantages that the hydrolysis efficiency of the sludge is improved by adopting a method of adding the alkali substance into the sludge, and quick crushing of sludge cells and quick hydrolysis of organic substances are facilitated in an alkali environment and under a heating condition. Because the hydrolysis efficiency of the sludge is improved by adding the alkali substance into the sludge, the saturated steam of 0.5 to 1.6MPa can be injected into the reaction kettle; the pressure of the saturated steam declines, so that the design pressure of the reaction kettle declines, and the investment cost is greatly reduced; because the pressure of the saturated steam declines, the investment for matched equipment such as a boiler is greatly reduced; and the consumption of the steam declines, so that the energy consumption is reduced, and the operating cost for treating the sludge is greatly reduces.

Owner:SHENZHEN ECO SOLUTION TECH CORP

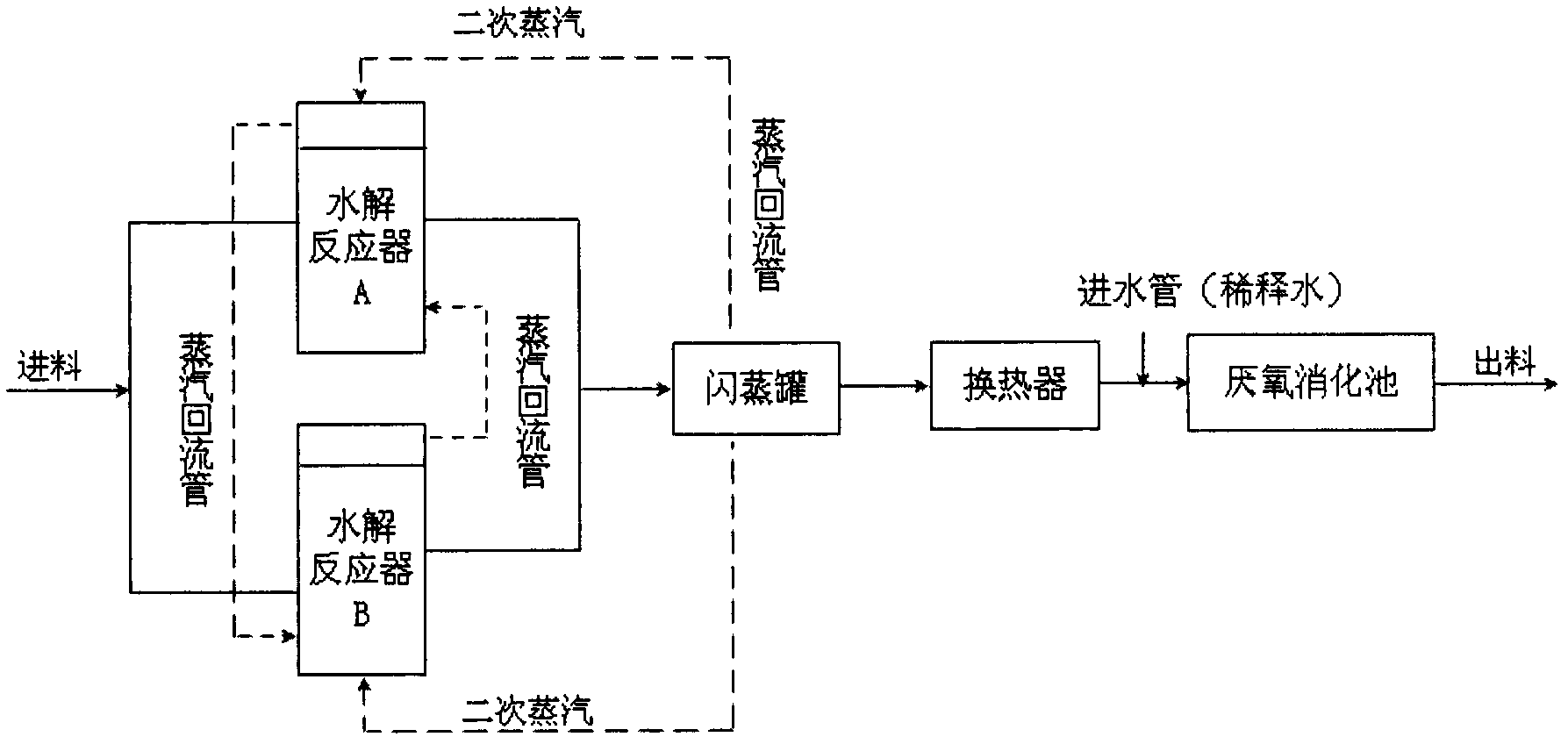

Sludge pyrolytic digestion process for efficiently recovering heat energy and equipment thereof

InactiveCN102424508AImproved Anaerobic Digestion PerformanceImprove anaerobic biodegradabilitySludge treatment by pyrolysisByproduct vaporizationDigestionPre treatment

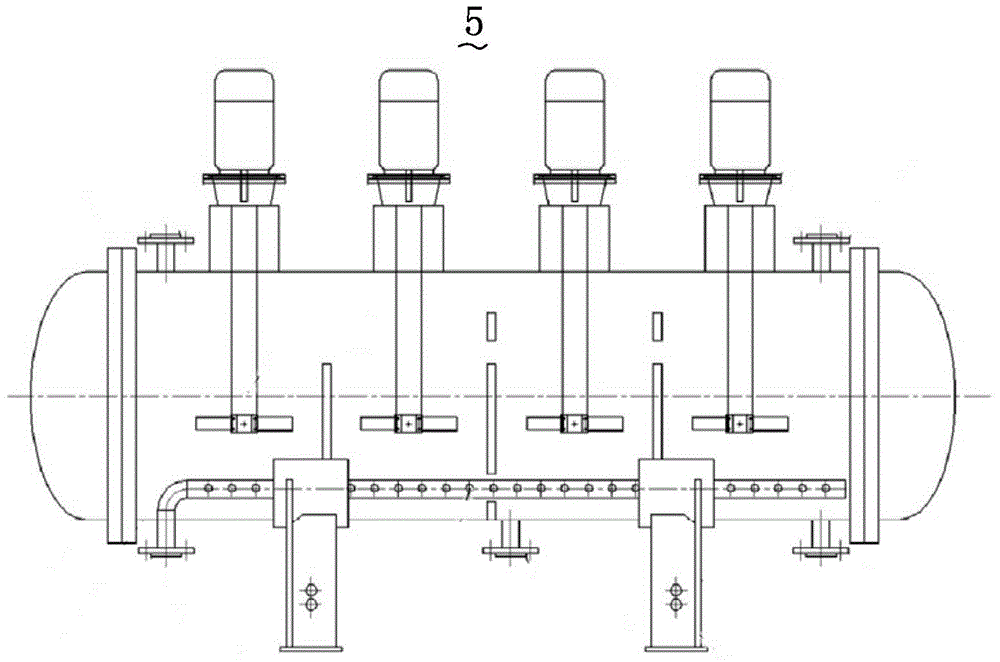

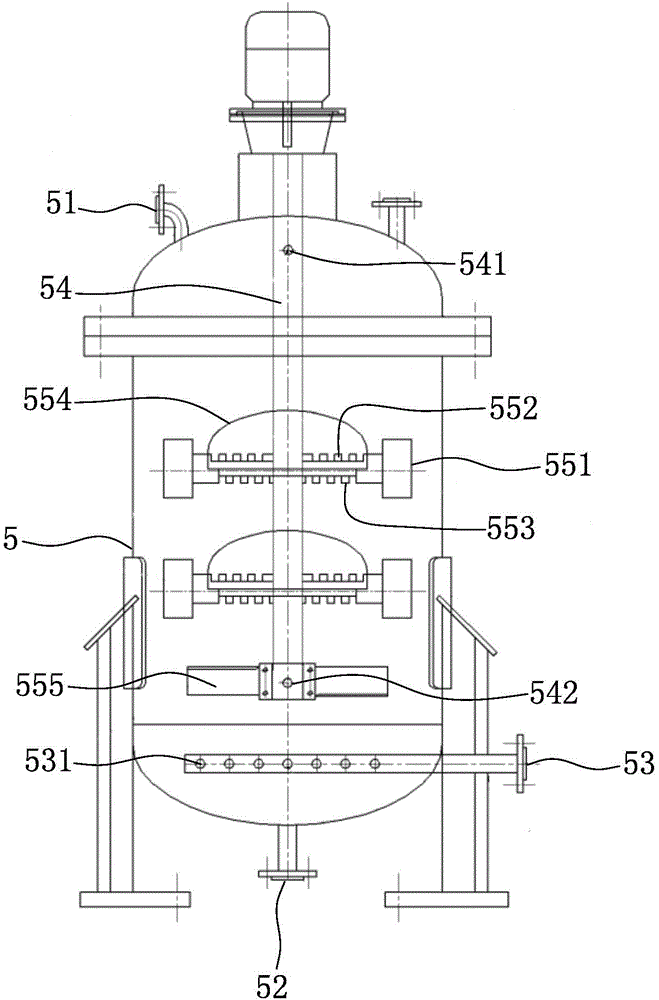

The invention discloses a sludge pyrolytic digestion process for efficiently recovering heat energy and equipment thereof. The process comprises the following steps of using excess active sludge as raw materials, heating and pressurizing a hydrolyzing reactor with heated steam, performing pyrohydrolysis for 30-90 min at 150-180 DEG C and 0.5-0.7 Mpa; after the completion of the reaction, back flowing the heated steam to the other group of hydrolyzing reactor to perform preheating, blowing the sludge into a flash tank when the pressure is dropped at 0.2-0.3 Mpa, further releasing the steam and back flowing to another hydrolyzing reactor; further diluting the sludge discharged from the flash tank to a moisture content of 88-92% after being cooled to 50-55 DEG C by a heat exchanger, and finally entering an anaerobic digestion pond to perform high temperature anaerobic digestion reaction, wherein the temperature in the pond is controlled at 50 DEG C to 58 DEG C. The process provided by the invention can be used for increasing the feed concentration and shortening the staying time; after the adoption of pyrohydrolysis pretreatment, the treatment capability of the anaerobic digestion system is increased by 2-3 times and the content of methane reaches 65%. Moreover, a plurality of pyrohydrolysis reactors connected in parallel are further adopted in the invention, the heated steam can be efficiently reused through a heat energy recovering system, so that the energy consumption is reduced.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

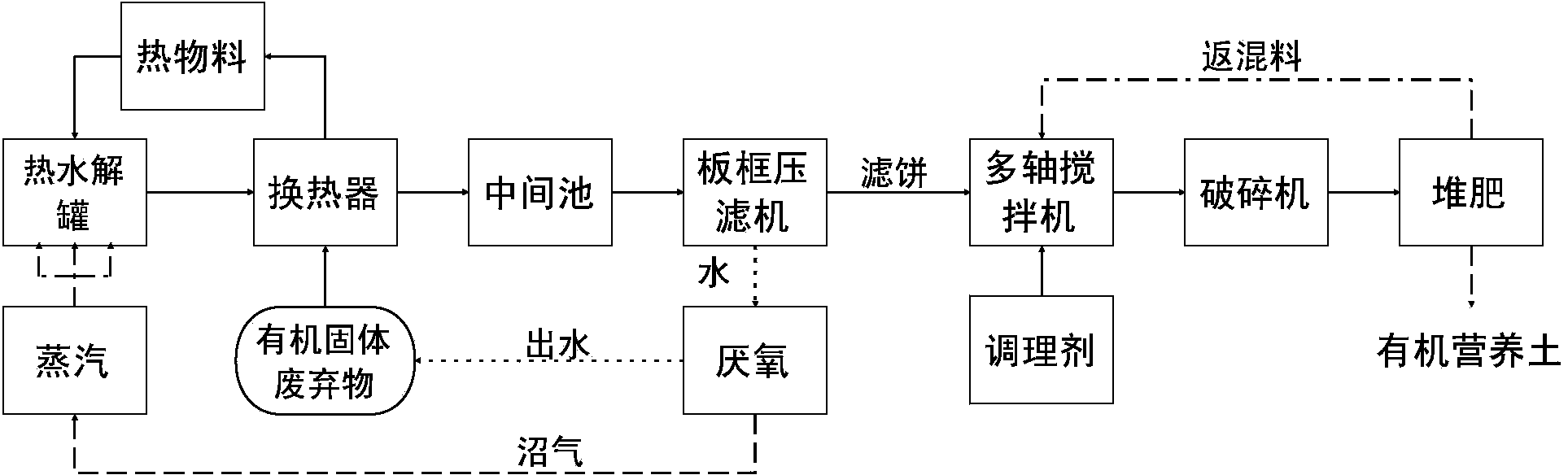

Thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes

ActiveCN104177145ASpeed up fermentationImprove dehydration effectBio-organic fraction processingClimate change adaptationOxygenFilter press

The invention discloses a thermal hydrolysis and high-temperature aerobic composting treatment process of organic solid wastes. The process comprises the following steps: preheating the organic solid wastes with the solid content of 10%-15% by virtue of a heat exchanger, performing thermal hydrolysis on hot steam with pressure of 0.4-1.0MPa and temperature of 150-190 DEG C, dehydrating the treated materials in a plate-and-frame filter press to form filter cakes with the water content of 35%-50%, adding proper conditioners and back-mixing materials into the filter cakes, and finally performing high-temperature aerobic composting treatment in a composting system to form organic nutritional soil. Compared with a conventional composting system, the process has the characteristics that the conditioner consumption is greatly reduced, the composting speed is relatively high, the composting effect is relatively good, and the treating capacity of the composting system is increased by 2-3 times.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

Energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate

InactiveCN105396862ALow viscosityImprove liquiditySolid waste disposalWaste based fuelTemperature controlEnergy regeneration

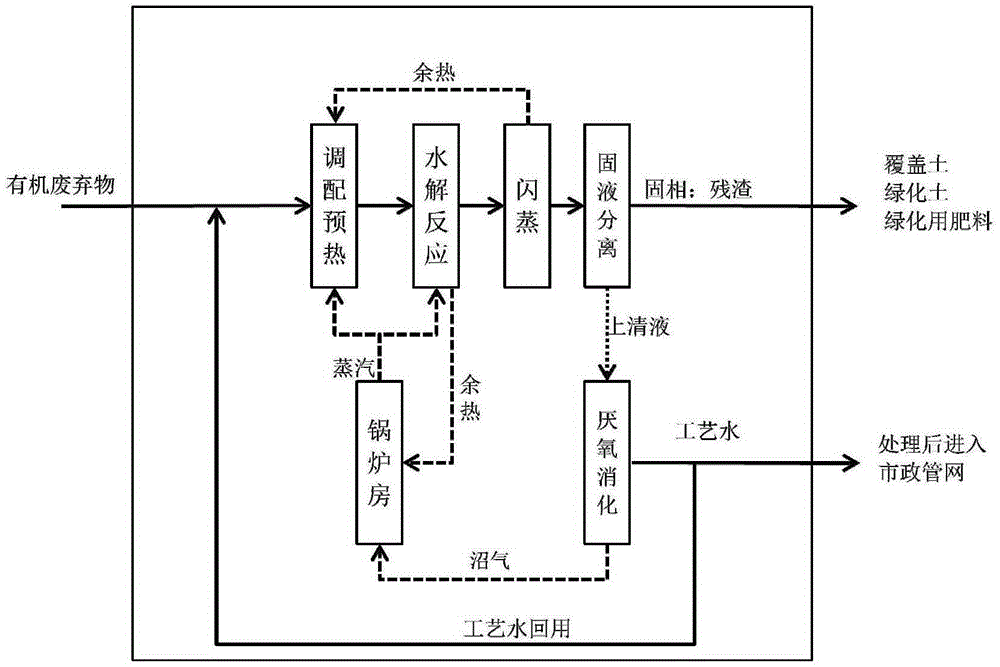

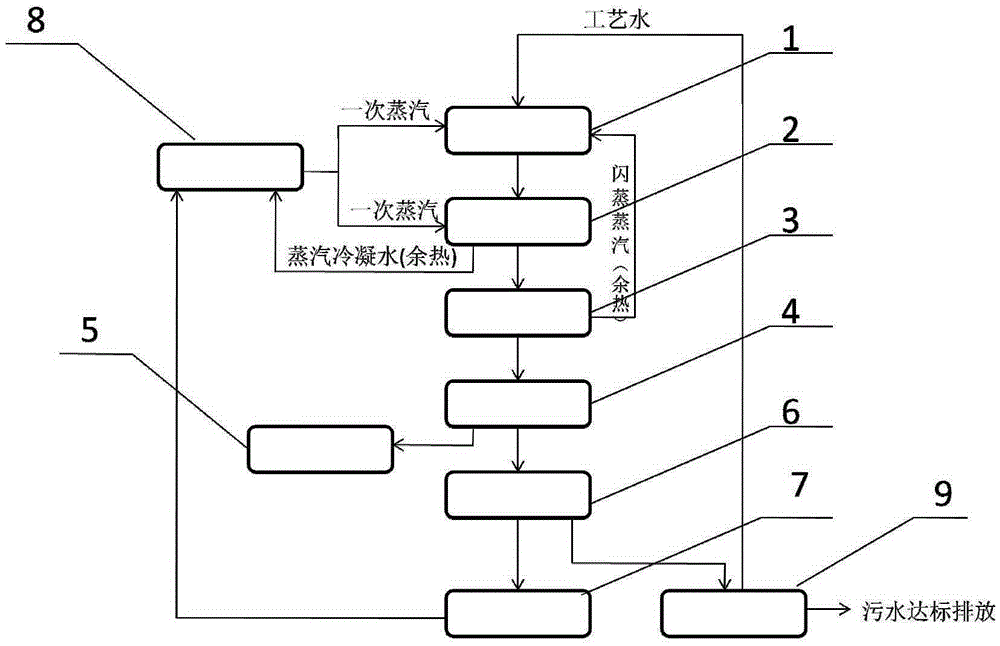

The invention relates to an energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate. Solid organic waste mainly comprises kitchen waste and sludge. The energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate comprises the following steps that (1) after the organic waste, water and alkali hydrolysis agents are proportioned and mixed in a proportioning and preheating tank, heating is conducted, so that the temperature of the materials in the tank is increased to 30-99 DEG C; (2) the materials in the proportioning and preheating tank are sent into a reaction kettle through a pump for the temperature rise reaction, and finally the temperature of the materials is controlled between 100 DEG C and 140 DEG C, and the reaction continues to be conducted for 90-120 minutes; (3) the materials after the hydrolysis reaction are conveyed into a flash evaporation tank for pressure relief and cooling, so that the temperature of the materials is decreased to 50-100 DEG C; (4) clarified liquid and solid are obtained after solid-liquid separation; and (5) the liquid obtained after solid-liquid separation is delivered into an anaerobic digestion system for anaerobic digestion treatment, and thus marsh gas is generated. By the adoption of the energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate, toxin removal, stabilization, minimization and energy regeneration of the organic waste can be achieved at a time.

Owner:天津市裕川环境科技有限公司

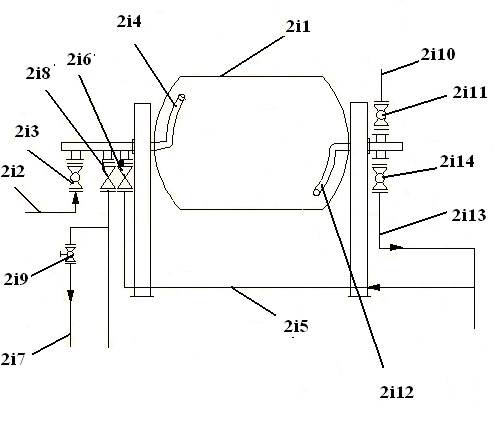

Device and method for realizing thermal-hydrolysis fermentation treatment in rotation way

ActiveCN102515454ASpeed up the thermal hydrolysis processShort thermal hydrolysis cycleWaste based fuelBiological sludge treatmentSlagHigh pressure

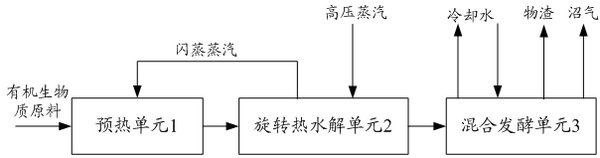

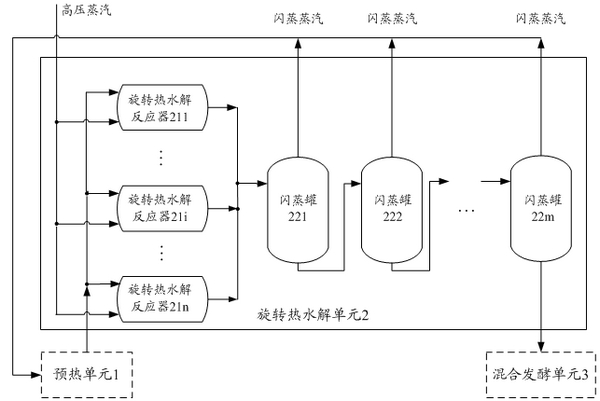

The invention provides a device and a method for realizing thermal-hydrolysis fermentation treatment in a rotation way. The device provided by the invention comprises a preheating unit, a rotary thermal-hydrolysis unit and a mixing fermentation unit. The method provided by the invention comprises the following steps that 1, an organic biomass raw material is preheated by flash-off steam in a preheating tank until a temperature of the organic biomass raw material is less than or equal to 105 DEG C, and then is orderly fed into all rotary thermal-hydrolysis reactors; 2, orderly through all the rotary thermal-hydrolysis reactors, the preheated organic biomass raw material is mixed with high pressure steam in a rotation way and is subjected to thermal hydrolysis; 3, organic biomass obtained by the thermal hydrolysis is subjected to flash evaporation in a flash evaporation tank; and 4, a digestive juice and the organic biomass subjected to flash evaporation are mixed and cooled and the cooled mixture is further cooled by a heat exchanger, wherein the organic biomass subjected to flash evaporation is digested by the digestive juice and produces biogas and slag. The device and the methodprovided by the invention have the characteristics of high heat exchange efficiency, short thermal-hydrolysis period and low energy consumption, and can be widely utilized for the field of organic biomass treatment.

Owner:HUBEI GUOXIN TIANHUI ENERGY

Processing method for cephalosporin dreg

ActiveCN103146761AEasy to handleDeal with economical and thoroughWaste based fuelSludge processingActivated sludgeResource utilization

The invention discloses a processing method for cephalosporin dreg. The processing method comprises the following process steps of: (A) thermal alkaline hydrolysis and separation treatment: uniformly mixing cephalosporin dreg, water and alkali, carrying out constant-temperature alkaline hydrolysis reaction, and carrying out solid-liquid separation at a certain temperature after the constant-temperature alkaline hydrolysis reaction, so as to obtain sediments to be standby; and (B) anaerobic digestion treatment: inoculating anaerobic activated sludge into an anaerobic fermentation tank, mixing the sediments obtained in the step (A) with excess sludge produced by utilizing wastewater biological treatment, injecting the mixture into the fermentation tank, carrying out constant-temperature stirring, and carrying out biogas residue discharging and feeding during fermentation. According to the processing method for the cephalosporin dreg, drug residues in the cephalosporin dreg can be completely removed, the problem that the anaerobic fermentation of single cephalosporin dreg cannot be effectively sustained is solved, and the reduction and innocent treatment to the cephalosporin dreg are realized; and biogas residues produced during the processing process can be used for preparing raw materials of organic fertilizers, the produced sewage gas can be used as clean fuels, and safe and effective disposition and resource utilization to the cephalosporin dreg are realized.

Owner:河北华药环境保护研究所有限公司

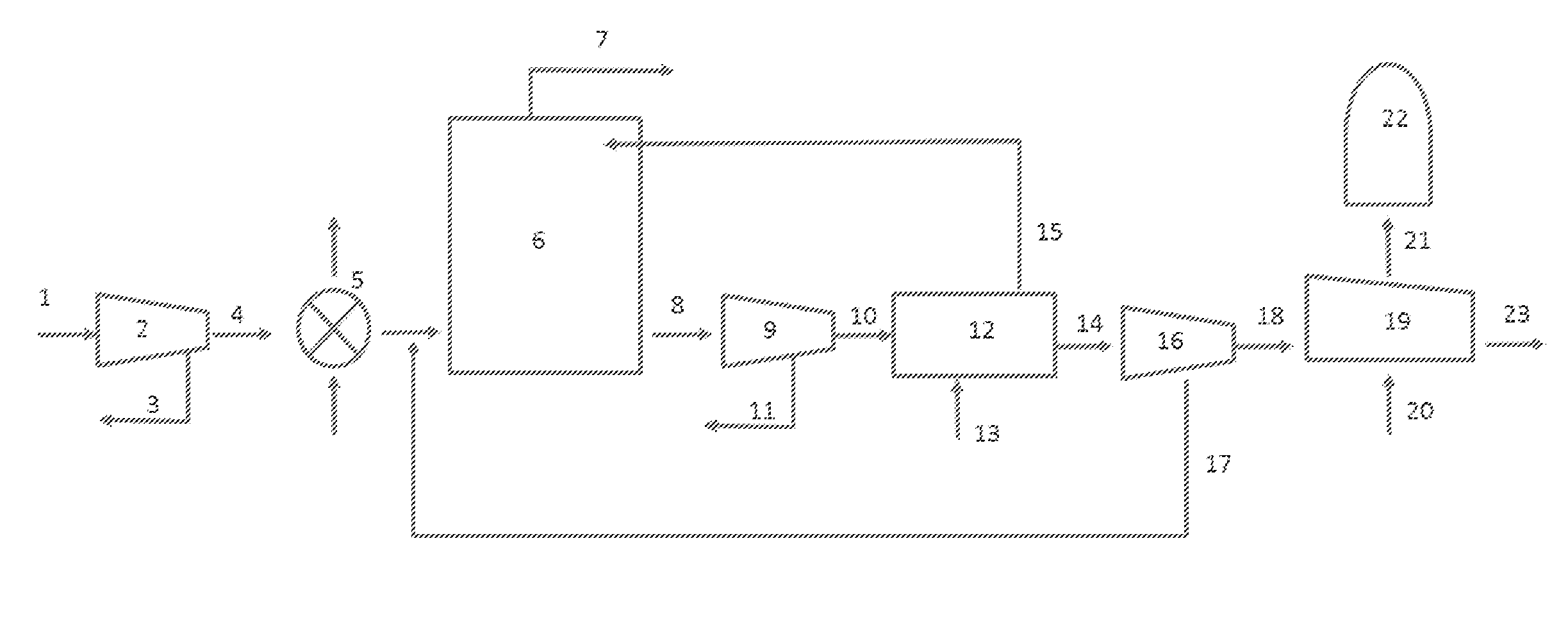

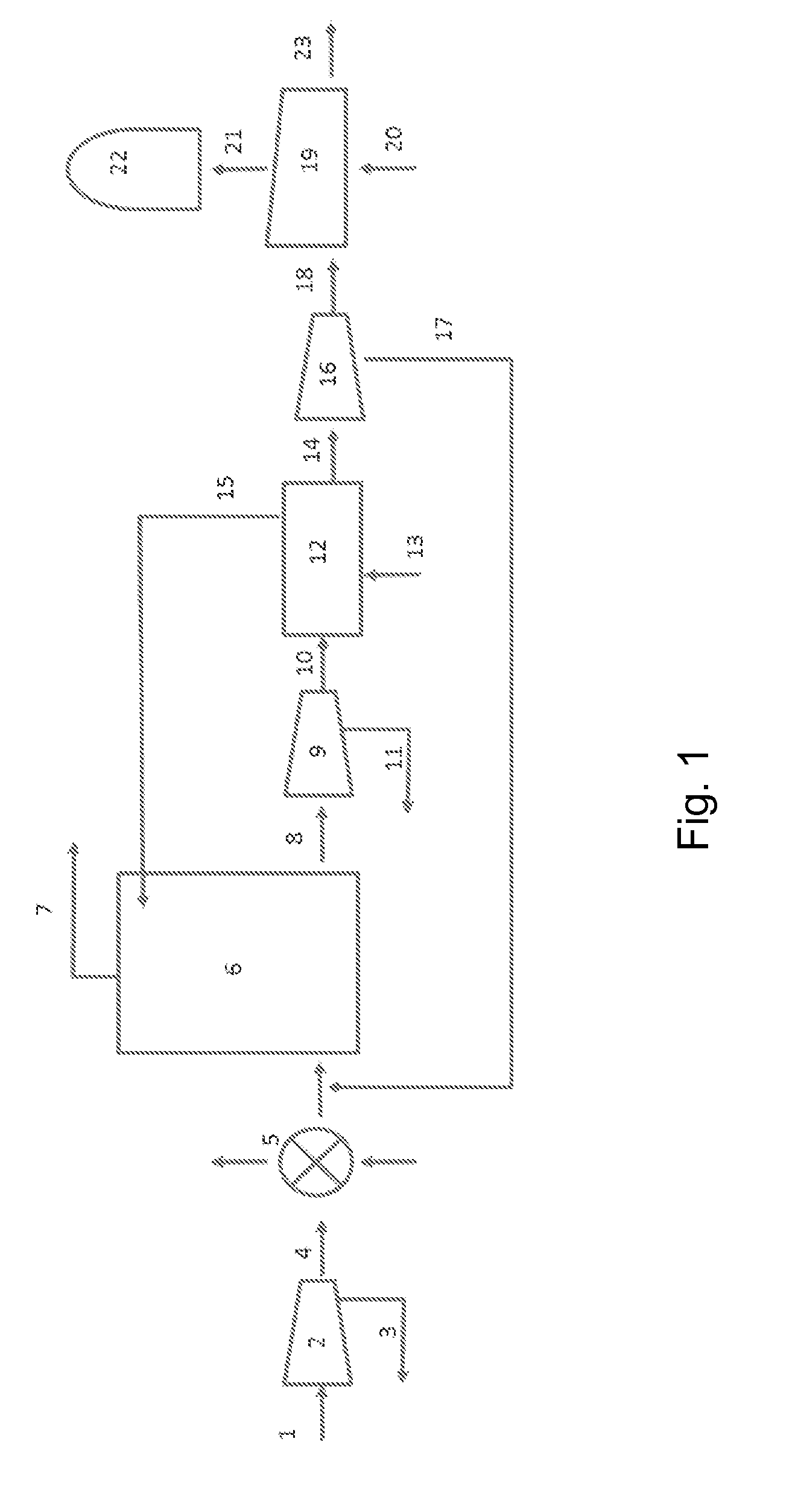

Method and device for thermal biological breakdown and dewatering of biomass

InactiveUS20140251902A1Sludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEvaporationPressure reduction

A method is described for thermal biological breakdown and dewatering of biomass, which is characterised in that it comprises the following steps:lead the biological residue material (8) from a digesting tank (6) to a dewatering device (9) and dewater the material to typically 15-25% dry matter,lead the dewatered material (10) to a device (12) and carry out a thermal hydrolysis at typically 145-170° C. for typically 10-40 minutes,subject the hydrolysed biomass (14) to a quick pressure reduction that results in a steam explosion in the biomass,dewater the thermally hydrolysed and steam exploded hot biomass (14), at typically 85-105° C. in a closed dewatering unit (16), typically a centrifuge, to typically 35-60% dry matter,cool the dewatered biomass (18) in a cooler (19), preferably an air-cooler and dewater the biomass further by evaporation to typically 40-75% dry matter,lead the liquid phase (17) from the dewatering unit (16), which contains considerable amounts of hydrolysed organic matter and heat upstream of the digesting tank (6) for increased production of biogas.Also described is a device to carry out the method.

Owner:CAMBI TECH AS

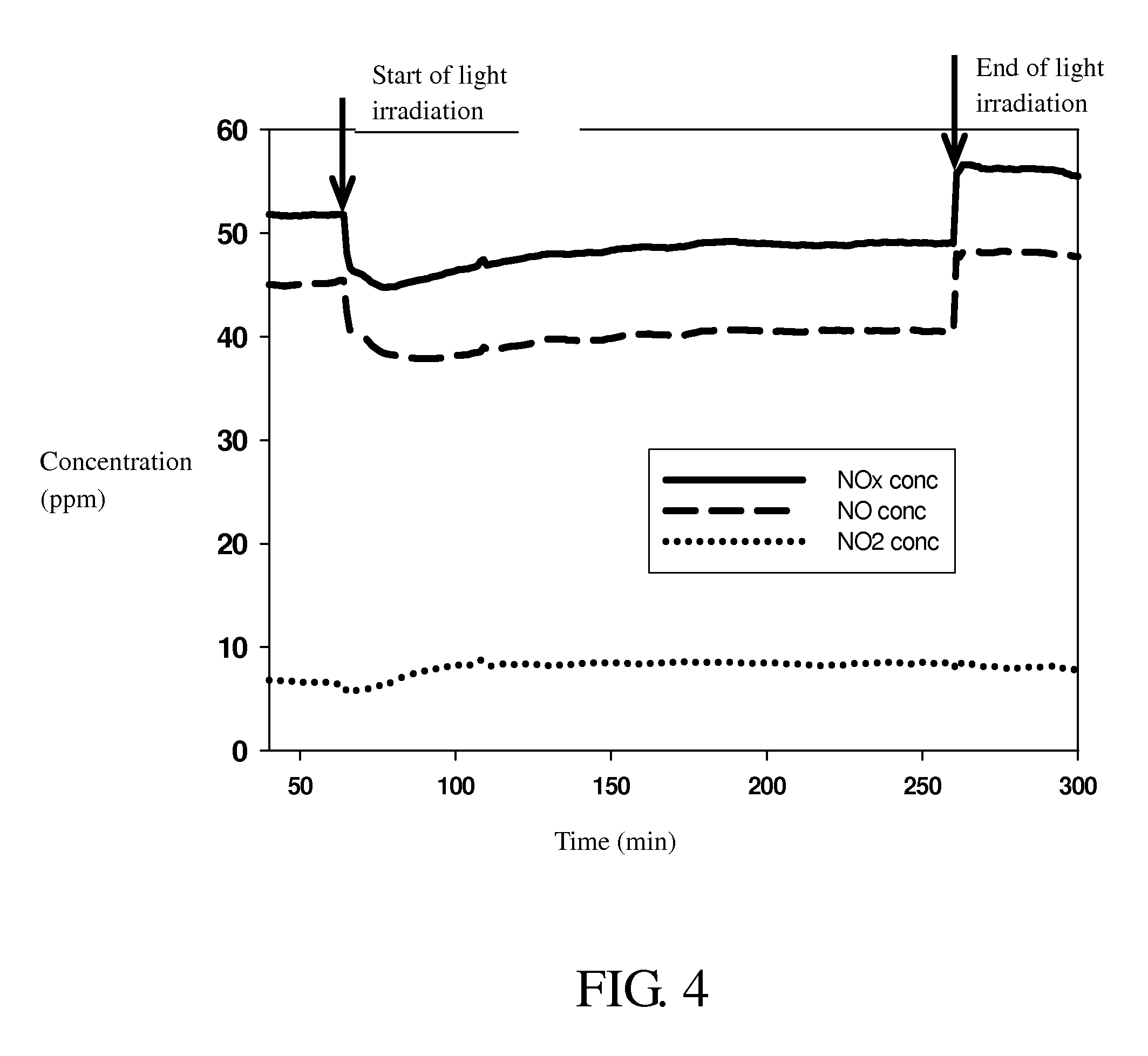

Optical Fiber Photocatalytic Reactor And Process For The Decomposition Of Nitrogen Oxide Using Said Reactor

An optical fiber photocatalytic reactor is provided. The reactor comprises a reaction zone and multiple fibers located in the reaction zone. The fiber comprises a photocatalyst that is coated onto its surface via a thermal hydrolysis method. The adhesion between the fiber and the photocatalyst thereon is strong, and thus, the delamination of the photocatalyst film on the fiber can be prevented. Moreover, the optical fiber photocatalytic reactor is useful for the decomposition of nitrogen oxide which is one of air's most harmful contaminants. The present invention exhibits a high conversion of nitrogen oxide.

Owner:NAT TAIWAN UNIV

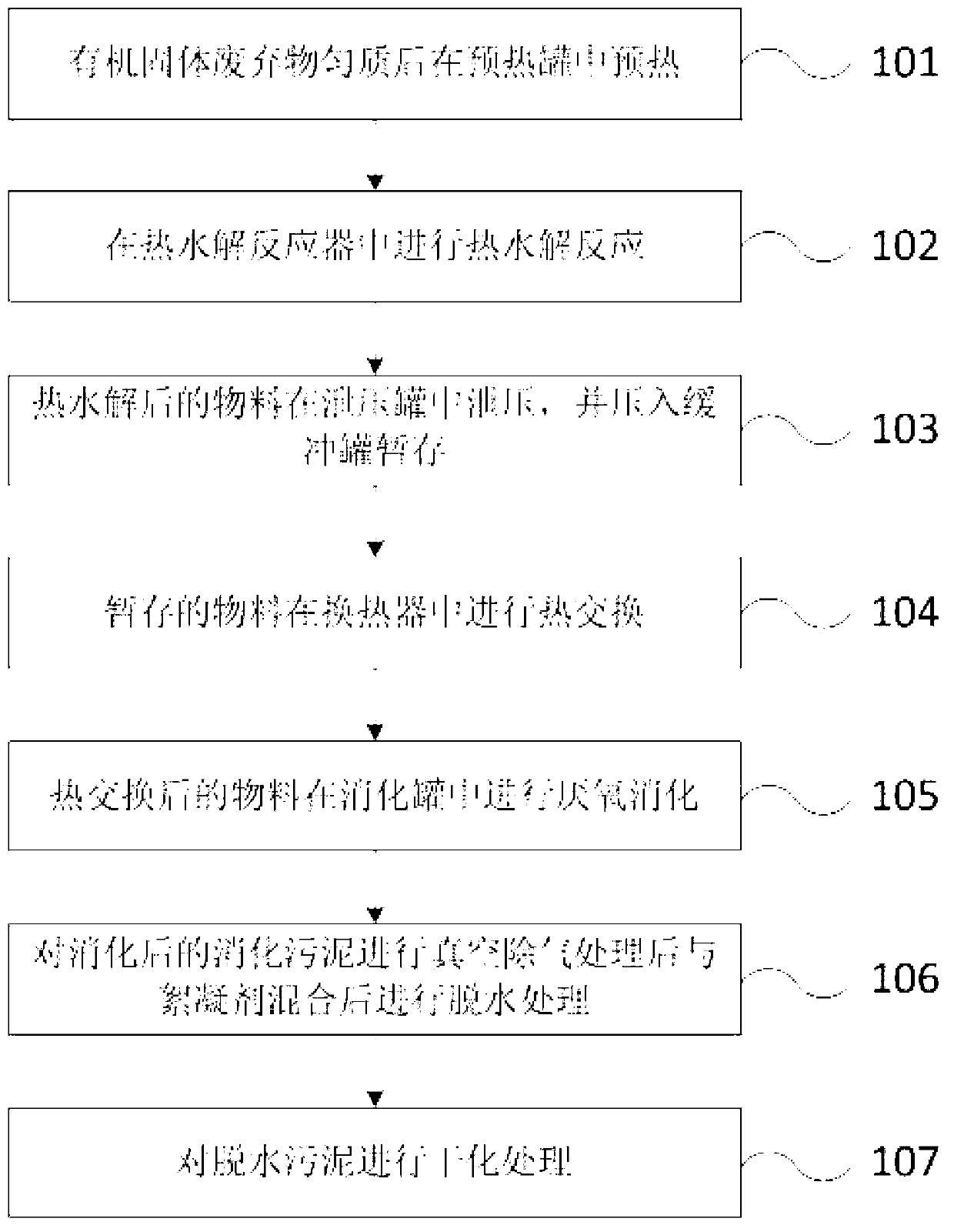

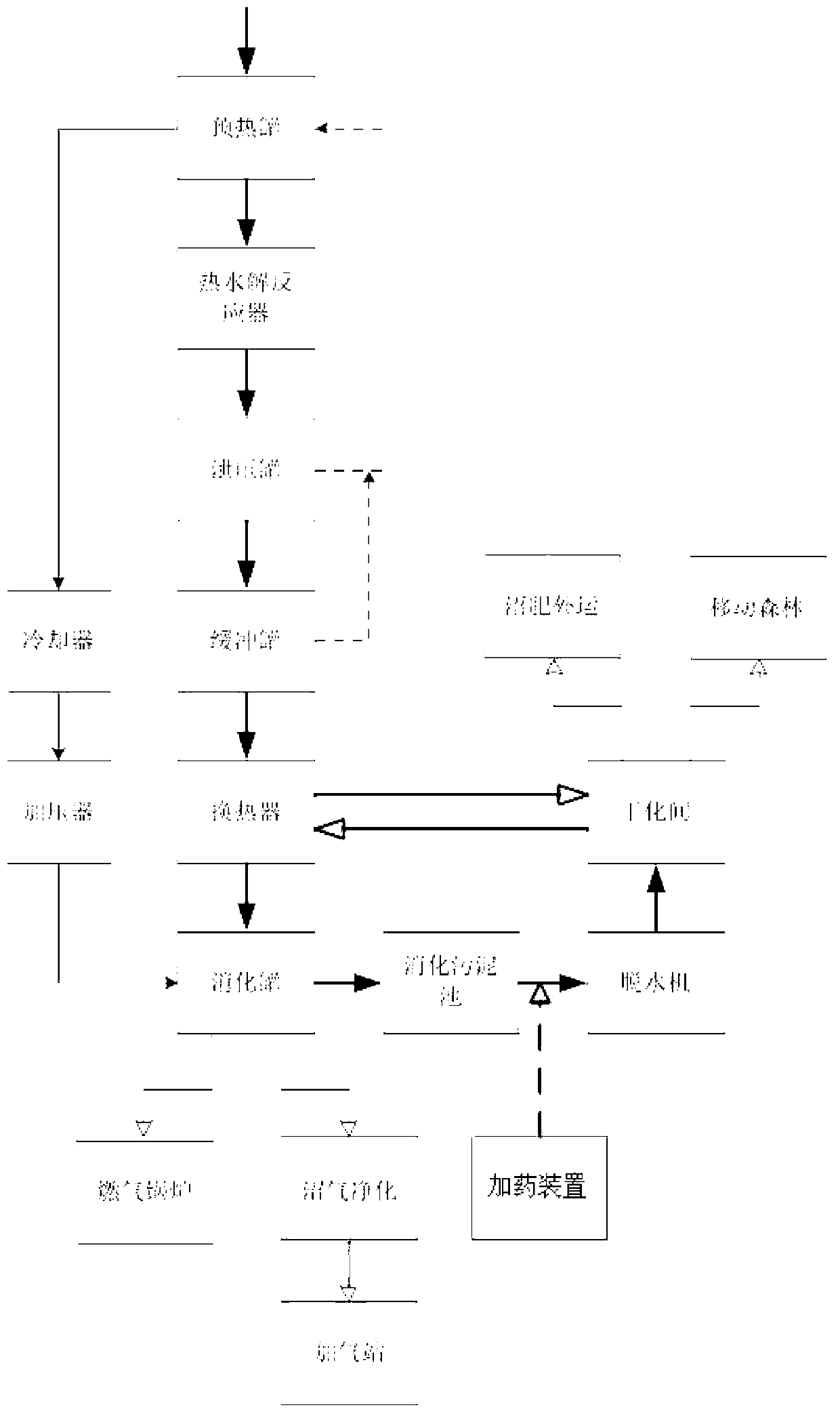

Treatment method of organic solid waste

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

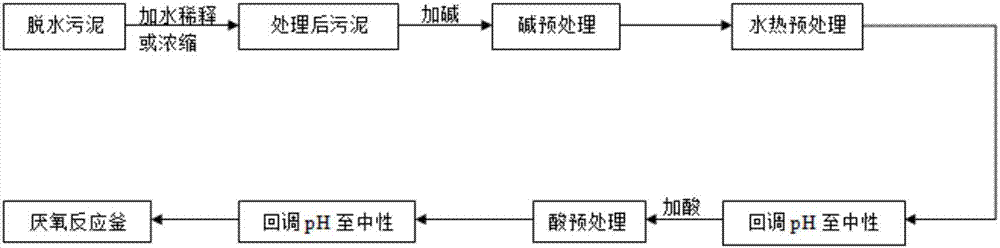

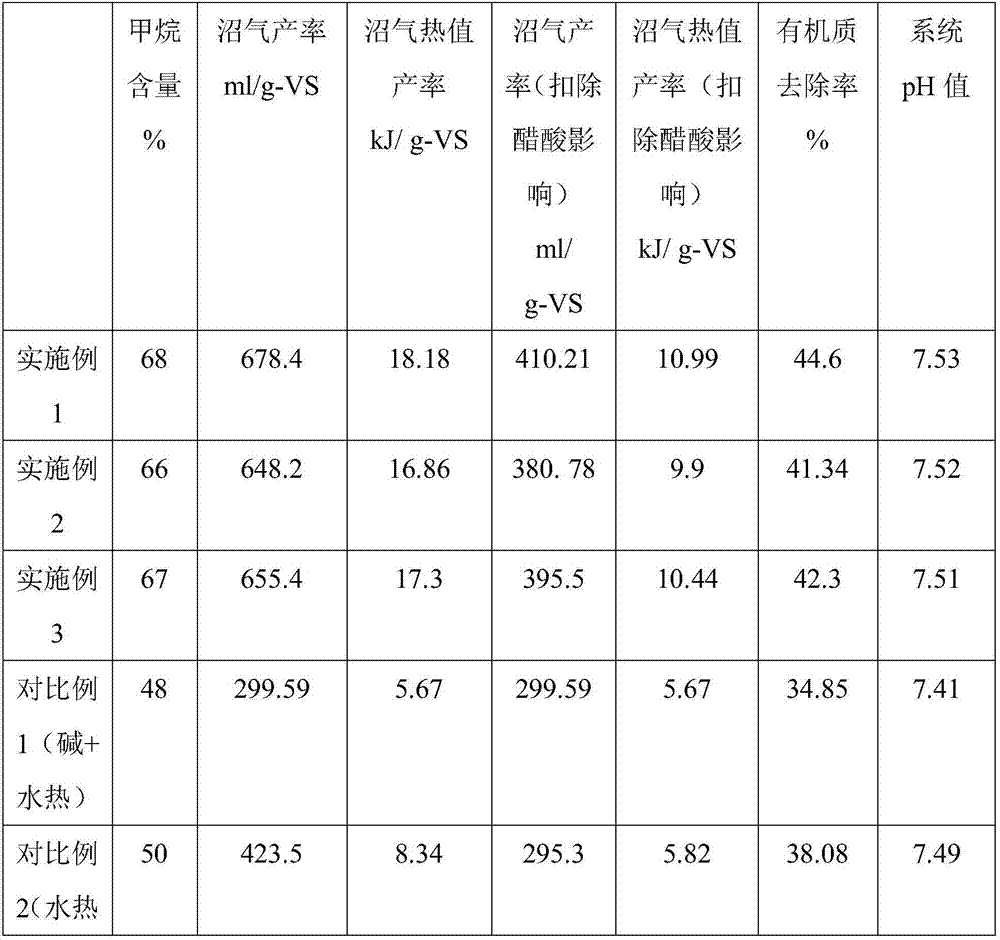

Sludge anaerobic-digestion method based on combined pretreatment of thermal hydrolysis and chemical tempering

ActiveCN107382003AImprove the gas production rate of anaerobic digestionIncrease gas production in anaerobic digestionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSystem stabilityPre treatment

The invention discloses a sludge anaerobic-digestion method based on combined pretreatment of thermal hydrolysis and chemical tempering. The sludge anaerobic-digestion method comprises the following steps: (1) adding water into sludge to dilute or concentrate, adding an alkaline substance, stirring, adjusting pH value to be alkaline and then standing; (2) carrying out thermal hydrolysis reaction on the sludge obtained in the step (1), adding a first acid substance after hydrothermal reaction, stirring, adjusting the pH value to be neutral, then adding a second acid substance, stirring, adjusting the pH value to be acid, finally adding the alkaline substance, stirring and adjusting the pH value to be neutral; and (3) carrying out anaerobic-digestion treatment on the sludge obtained in the step (2). The sludge anaerobic-digestion method disclosed by the invention has the advantages that the gas producing rate of anaerobic digestion of the sludge can be obviously increased, the gas producing amount and the produced-methane content of anaerobic digestion of the sludge are increased, sludge stabilization and the system stability condition are good, the energy consumption is low, the economic applicability is strong, the application bottleneck of anaerobic digestion of the sludge is broken through, and the sludge anaerobic-digestion method can better realize harmless, recycling and reducing treatment for the sludge when being used for treating municipal sludge.

Owner:SOUTHEAST UNIV

Method and apparatus for treatmet of sludge

InactiveUS20100255562A1Rapidly and efficientlyImprove efficiencyBio-organic fraction processingExcrement fertilisersEutrophicationCell membrane

Disclosed are an enhanced apparatus and a method for treating organic sludge, which is constructed so that concentrated sludge is first dewatered with a dewatering device in order to to lower percentage of moisture content of the sludge, which is included in foul water or wastewater sludge such as sewage, food waste, and livestock excretion, etc. thereby causing eutrophication; dewatered sludge is passed through a thermal hydrolysis reactor to decompose a polymer formed spontaneously in the dewatered sludge and cell membrane of an organism; since microorganisms discharge absorbed phosphorus, at least one selected from magnesium, potassium, zinc, calcium carbonate, phosphoric acid and calcium is poured in order to remove phosphorus, nitrogen and various material contained in a solution generated during dewatering by crystallization into struvite, and is passed through a crystallization reactor to crystallize into struvite and then remove it; a is remaining solution after crystallization is fed back to a step prior to the biological reactor or the digester.

Owner:KANG SEOK WOONG

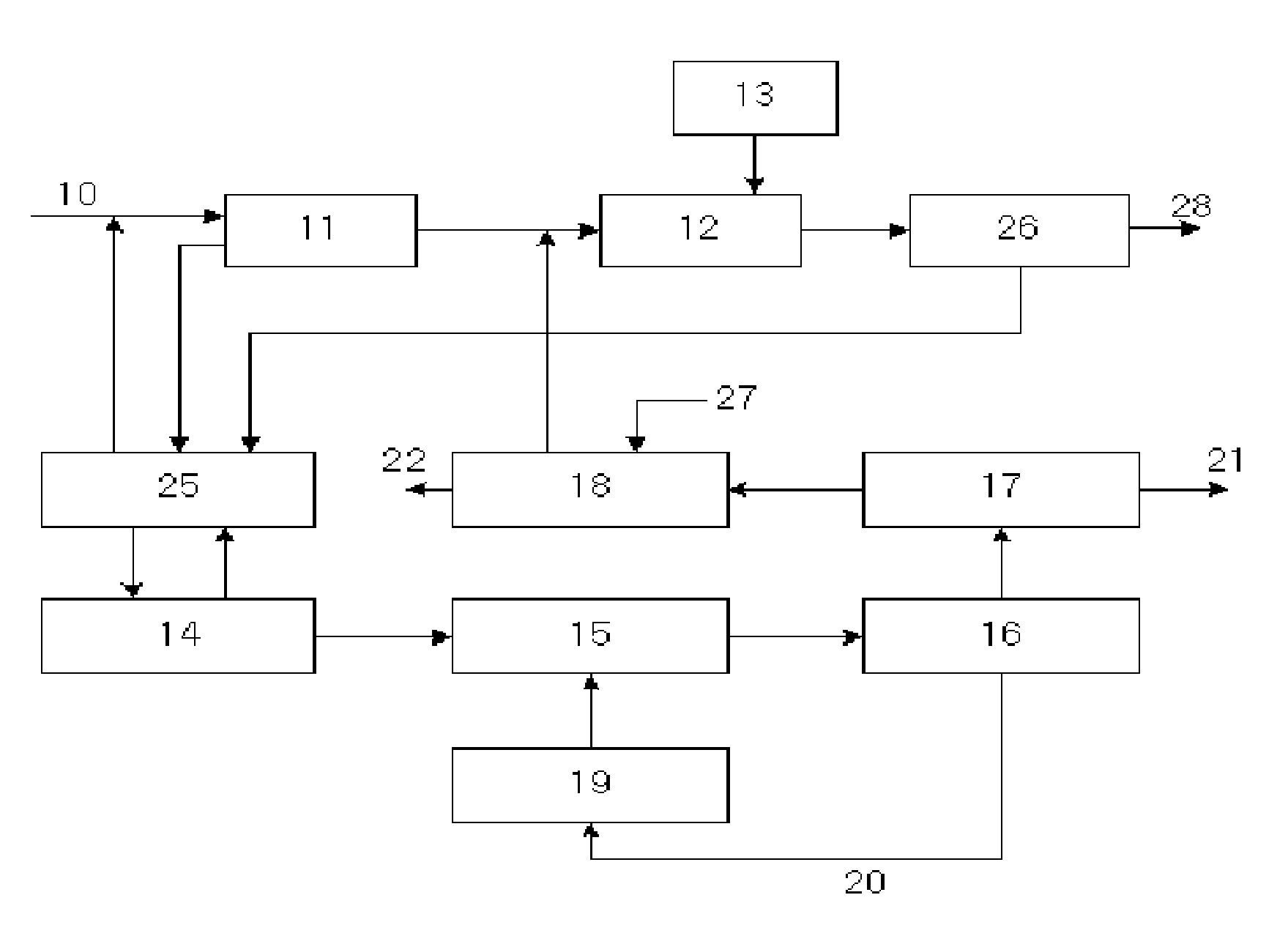

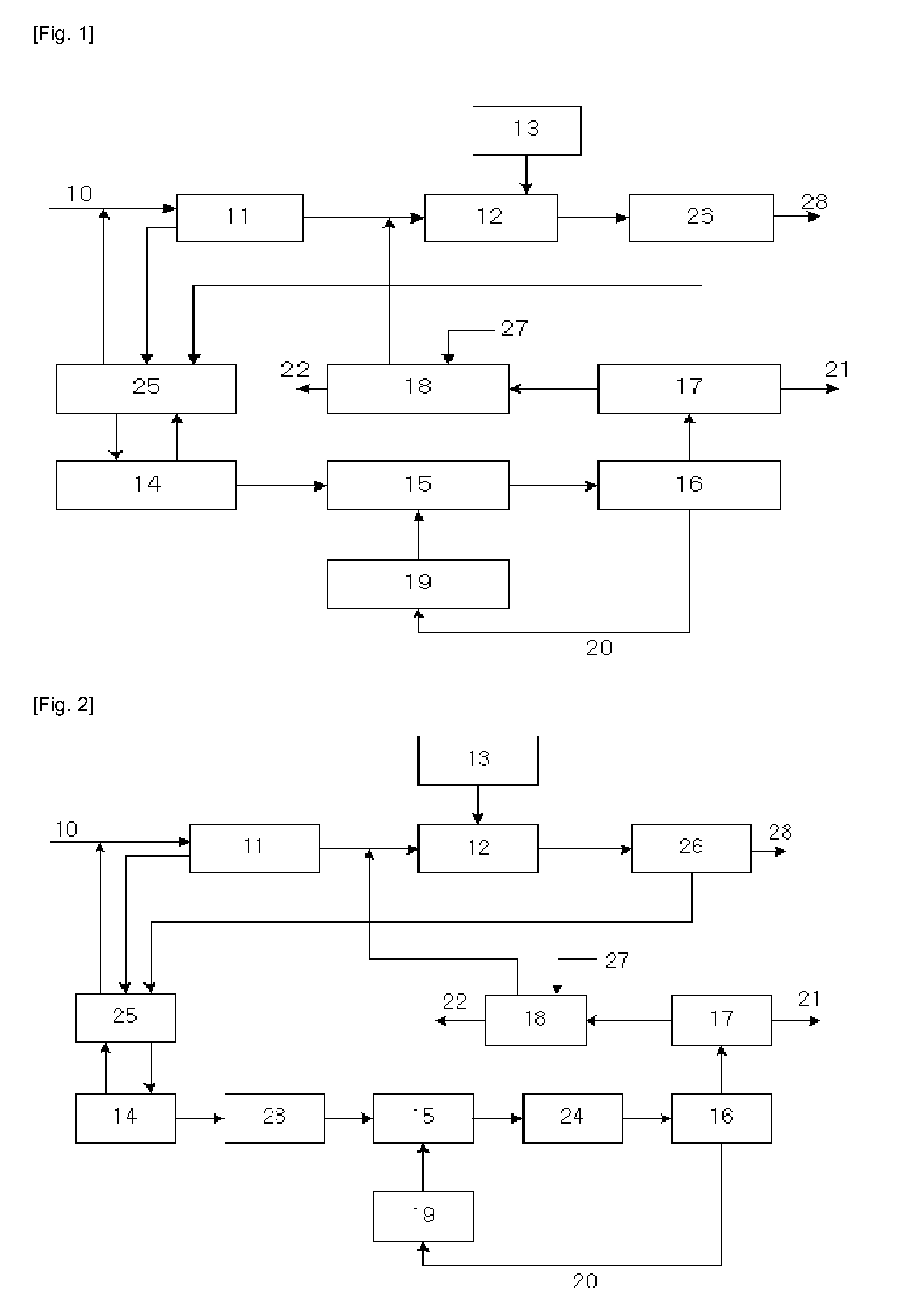

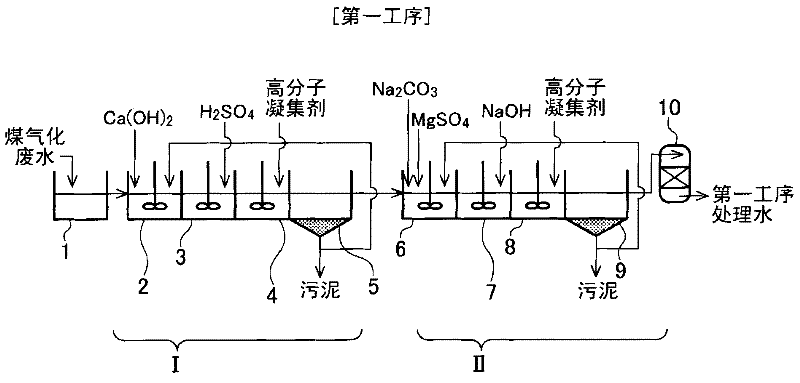

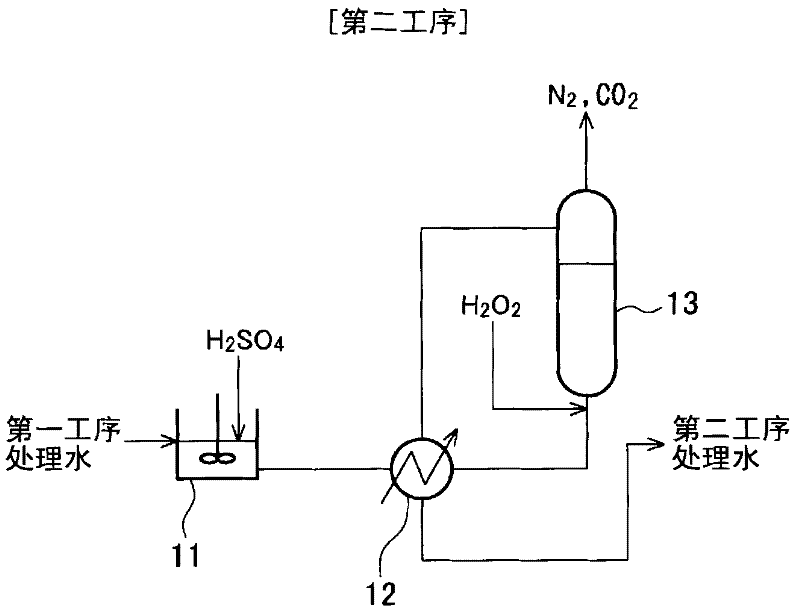

Method of treating coal gasification wastewater

InactiveCN102348648AImprove water qualitySludge treatment by oxidationWater contaminantsCoal gasification wastewaterReduction treatment

Owner:KURITA WATER INDUSTRIES LTD

Method and device for treating organic solid waste

ActiveCN104148357AAvoid unfit problemsImprove efficiencySolid waste disposalAcid hydrolysisCompound (substance)

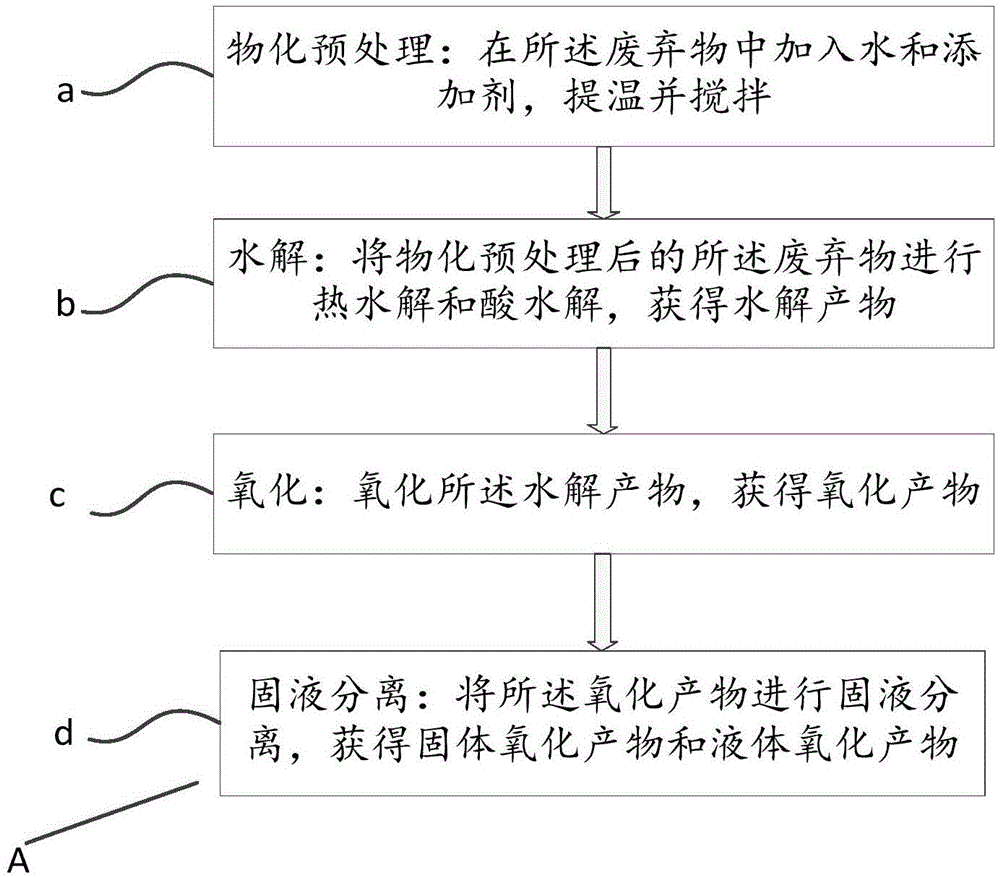

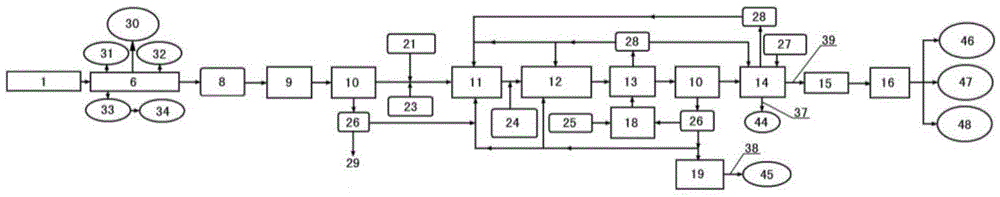

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely carrying out thermal hydrolysis and acid hydrolysis on the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; and (d) carrying out solid-liquid separation namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

Sludge pyrohydrolysis method and sludge pyrohydrolysis system

InactiveCN104355511AEfficient removalShorten digestion timeSpecific water treatment objectivesSludge treatment by pyrolysisDigestion TreatmentSewage

The invention relates to a sludge pyrohydrolysis method and a sludge pyrohydrolysis system, belongs to the field of treatment of a sewage plant, and particularly relates to the field of treatment of sludge of a sewage treatment product. To solve the problem that most of organic matters are not removed with an existing method, the invention provides the sludge pyrohydrolysis method and the sludge pyrohydrolysis system. The method comprises the processes of sludge slurrying, sludge pyrohydrolysis, sludge decompressed flash, sludge digestion, and centrifugal dewatering, wherein the process of sludge slurrying adopts a pump stirring mode, the temperature in a slurrying tank is kept at 97 DEG C; saturated steam heats a pyrohydrolysis tank to rapidly rise the temperature to be 165-190 DEG C in the process of sludge pyrohydrolysis, the pyrohydrolysis process lasts for 90 min, wherein the time for sludge charge is 15 min, the time for sludge discharge is 15 min, the steam is introduced for about 15 min, the pyrohydrolysis reaction is about 30 min, and the air is exhausted for 15 min; in the flash process, the pressure of a flash tank is kept at 0.1-0.3 MPa and the balance temperature is 102 DEG C; the time for sludge digestion is 15 days. The method and the system use the modes of pyrohydrolysis and flash, the organic matters in the sludge are effectively removed, meanwhile, the time for sludge digestion is shortened, and the sludge treatment efficiency is improved.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

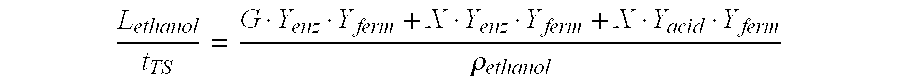

Energy reclaiming sludge reduction method

InactiveCN101880118AImprove solubilityImproved Anaerobic Digestion PerformanceBiological substance pretreatmentsGas production bioreactorsAcetic acidReduction treatment

The invention provides an energy reclaiming sludge reduction method in order to overcome the defects that the conventional sludge reduction technology has high running cost, long treatment period and the like. Thermal hydrolysis serving as pretreatment is coupled with two-phase anaerobic digestion to perform reduction treatment on the excess sludge. Ethanol type zymophyte is cultured and domesticated by using the excess sludge after the thermal hydrolysis pretreatment as matrix, an acid generating phase is controlled at an ethanol type fermentation stage, ethanol type fermentation products mainly comprise ethanol, acetic acid and hydrogen, and the ethanol type fermentation products after entering a methane generating phase can be easily utilized by methane generating bacteria and transformed into methane. The method can effectively improve the sludge reduction effect, and can reclaim clean energy such as hydrogen, methane and the like.

Owner:王鹤立

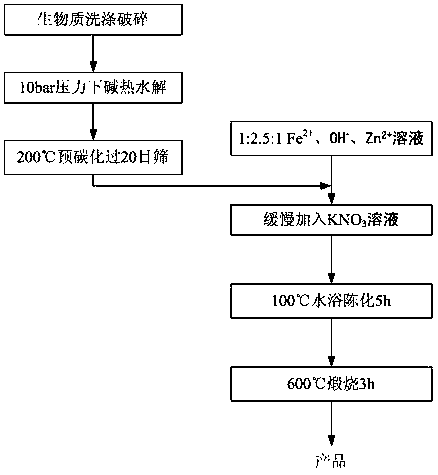

Nano-grade ZnO loaded magnetic biological carbon composite photocatalyst and preparation method thereof

ActiveCN108311153ASolve separation and recyclingHas a reducing effectWater/sewage treatment by irradiationWater treatment compoundsWater bathsCarbon composites

The invention provides a nano-grade ZnO loaded magnetic biological carbon composite photocatalyst and a preparation method thereof. The preparation method comprises the following steps: step 1: carrying out thermal hydrolysis on a biomass under an alkaline condition to extract plant fibers; after drying, carrying out pre-carbonization treatment; mashing and sieving with a sieve with the size of 10to 20 meshes; step 2: mixing a ferrous salt solution and a potassium hydroxide solution; adding soluble zinc salt; step 3: adding the sieved plant fibers into the solution formed by step 2; uniformlymixing and adding a potassium nitrate solution; after sufficiently stirring, treating a mixture in a water bath; continuously stirring and ageing until black gel is formed, so as to obtain a black gel solution; step 4: after washing and drying the black gel solution, generating dry gel; calcining the dry gel and continuously introducing inert gas; after washing and drying, obtaining the nano-grade ZnO loaded magnetic biological carbon composite photocatalyst. According to the nano-grade ZnO loaded magnetic biological carbon composite photocatalyst, magnetic biological carbon is used as a carrier of the photocatalyst, and the problem that the photocatalyst in chromium-containing sewage treatment is difficult to separate and recycle is solved.

Owner:湖南大辰环保股份有限公司

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS20050274668A1Lower the volumeSave volumeBio-organic fraction processingBiological substance pretreatmentsParticulatesSaturated water vapor

A method for treating particulate biodegradable organic waste includes adjusting the pH as necessary to provide an acidic pH prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

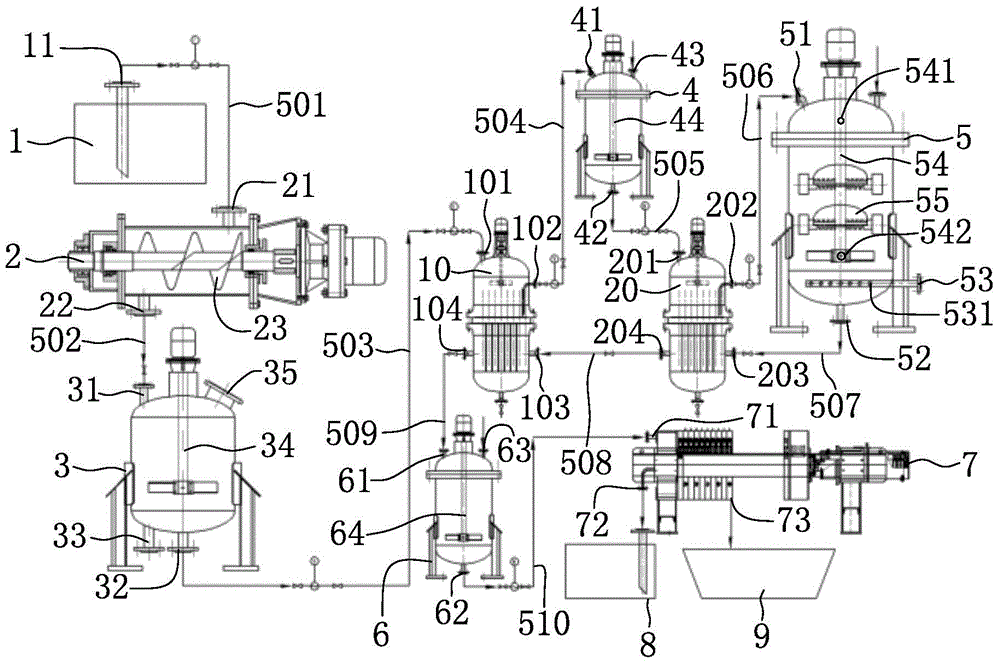

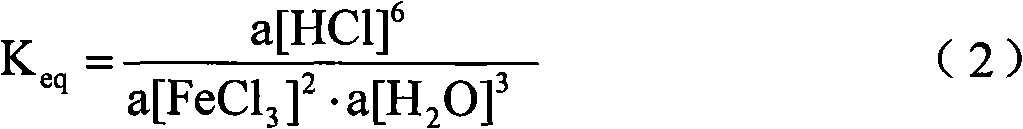

Method for comprehensive exploitation of low-ore grade laterite nickel mine

ActiveCN101403035ASimple processReduce manufacturing costIron oxides/hydroxidesProcess efficiency improvementLateriteHydrolysis

The invention discloses a method for comprehensively developing low-grade nickeliferous laterite ore. The main technique comprises the steps of the preparation of minerals, chlorination and leaching, the oxidation of leachate, the regeneration of hydrochloric acid and the hydrolysis of settled iron, solid-liquid separation, sulfuration and sediment and the recycling of chloride and the like; the method is characterized in that the nickeliferous laterite ore is leached out by hydrochloric acid and the chloride at normal pressure and iron in the nickeliferous laterite ore is leached out as much as possible; leached ferrous ions are oxidized into ferric ion; the regeneration of hydrochloric acid and hydrolysis of settled iron are realized synchronously under the condition of normal pressure and the temperature of 140 to 180 DEG C; the collection of the regenerated hydrochloric acid prompts the hydrolysis reaction to be complete so as to obtain iron oxide red of byproduct; and after solid-liquid separation, filtrate enriched with nickel and cobalt carries out sulfuration and sediment and chloride solution is recycled. The invention discards the method of pyrohydrolysis or high-temperature roasting in the traditional technique, reduces the energy consumption of removal of iron and the regeneration of hydrochloric acid, improves the leaching rate of the nickel and cobalt and simultaneously develops and utilizes base metal in the ore reasonably so as to increase the additional value of the technique.

Owner:CENT SOUTH UNIV

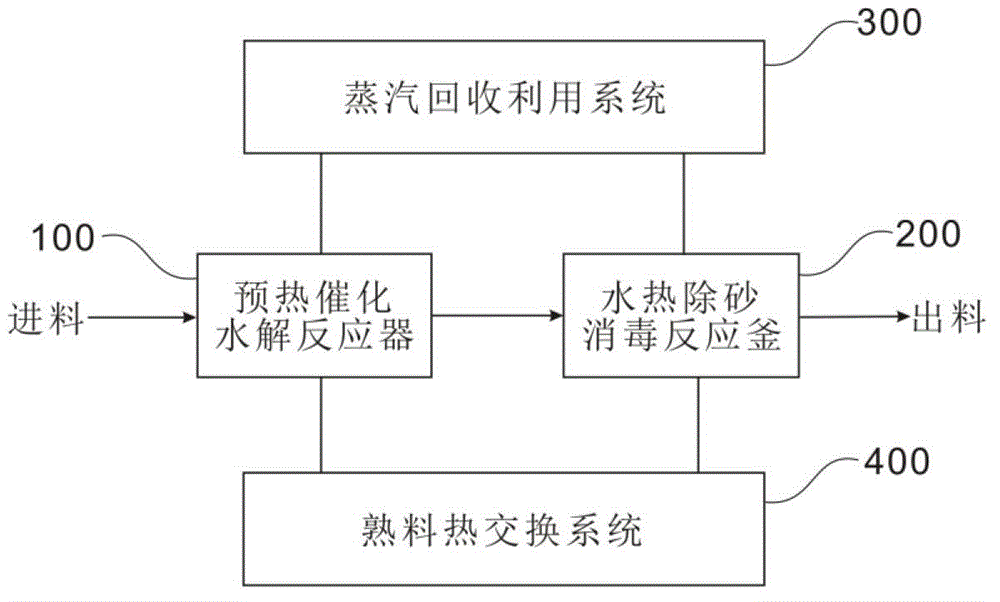

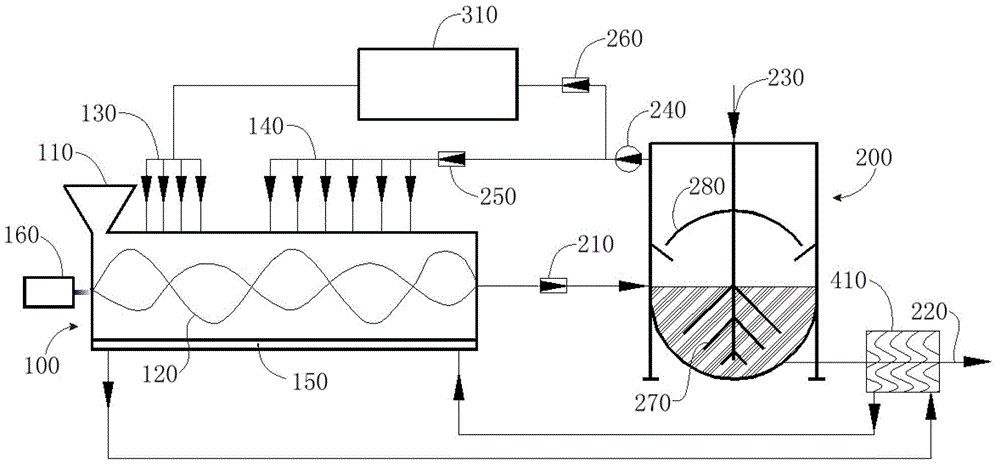

Device and method for desanding and disinfecting pretreatment of municipal sludge

ActiveCN102718377ALow viscosityReduce adhesionSludge treatment by thermal conditioningSludge treatment by pyrolysisEnergy recoveryPre treatment

The invention provides a device and a method for performing desanding and disinfecting pretreatment on municipal sludge with high sand content (solid containing rate is 8%-30%). The device comprises a preheating catalytic hydrolysis reactor, a hydrothermal desanding and disinfecting reaction kettle, a clinker heat exchange system and a steam recycling system. The pretreatment can be performed on the material through the preheating catalytic hydrolysis reactor to remarkably reduce viscosity of the materials, promote organic matter in the material to be hydrolyzed and easily separate the sludgefrom micro sand. In order to improve the energy utilization rate of a system, energy of the follow-up hydrothermal desanding and disinfecting reaction kettle is recycled to serve as a heat source required by the preheating catalytic hydrolysis reactor. According to the method, the organic matter can achieve high-efficiency hydrolyzing conversion without using a flash evaporation process needed bya conventional thermal hydrolysis process. The method can be used to improve flowability, dewatering and desanding performance and follow-up anaerobic digestion performance of the material and can serve as a pretreatment system of a dewatering drying or anaerobic digestion process.

Owner:上海同济普兰德生物质能股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com