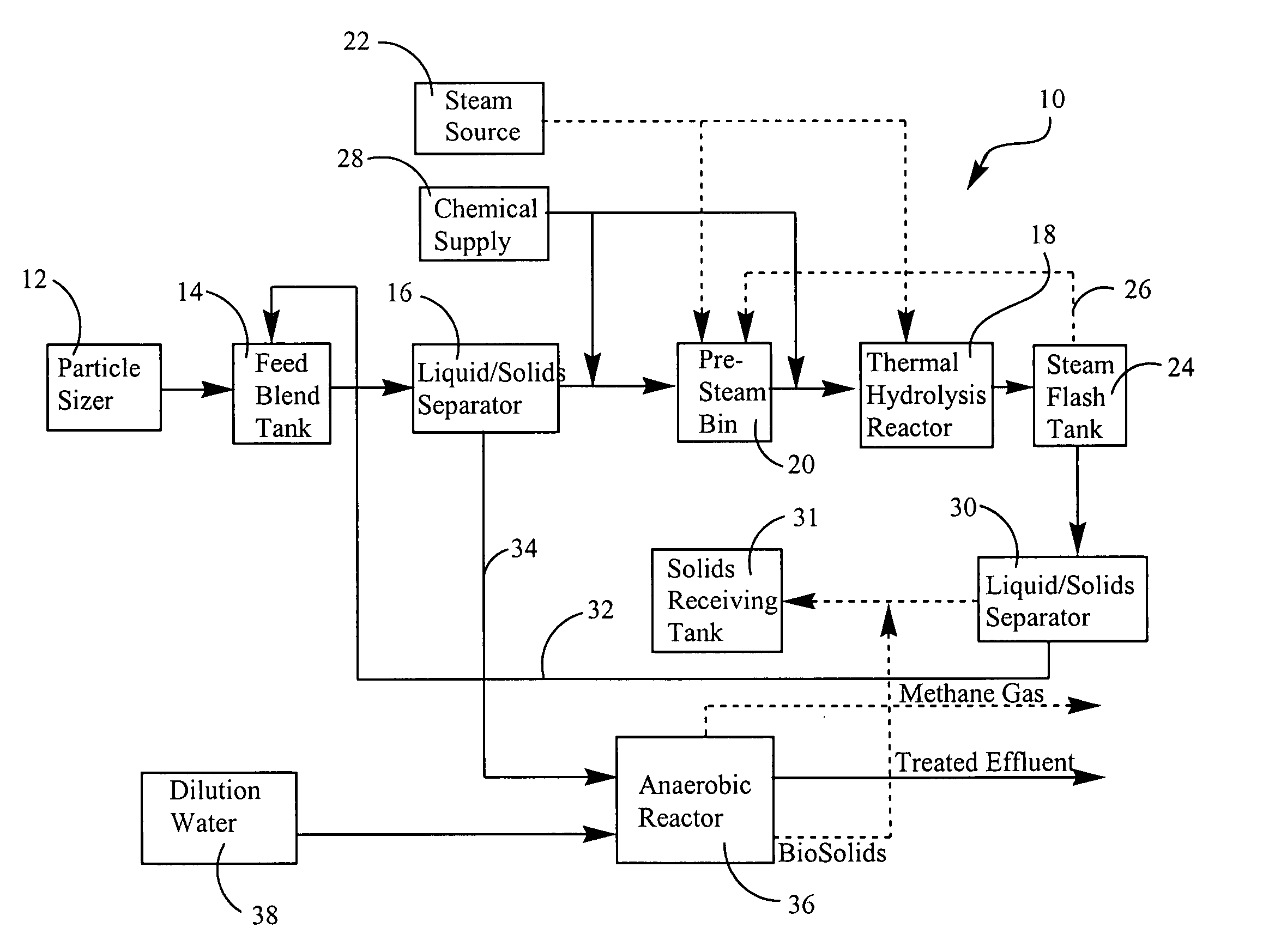

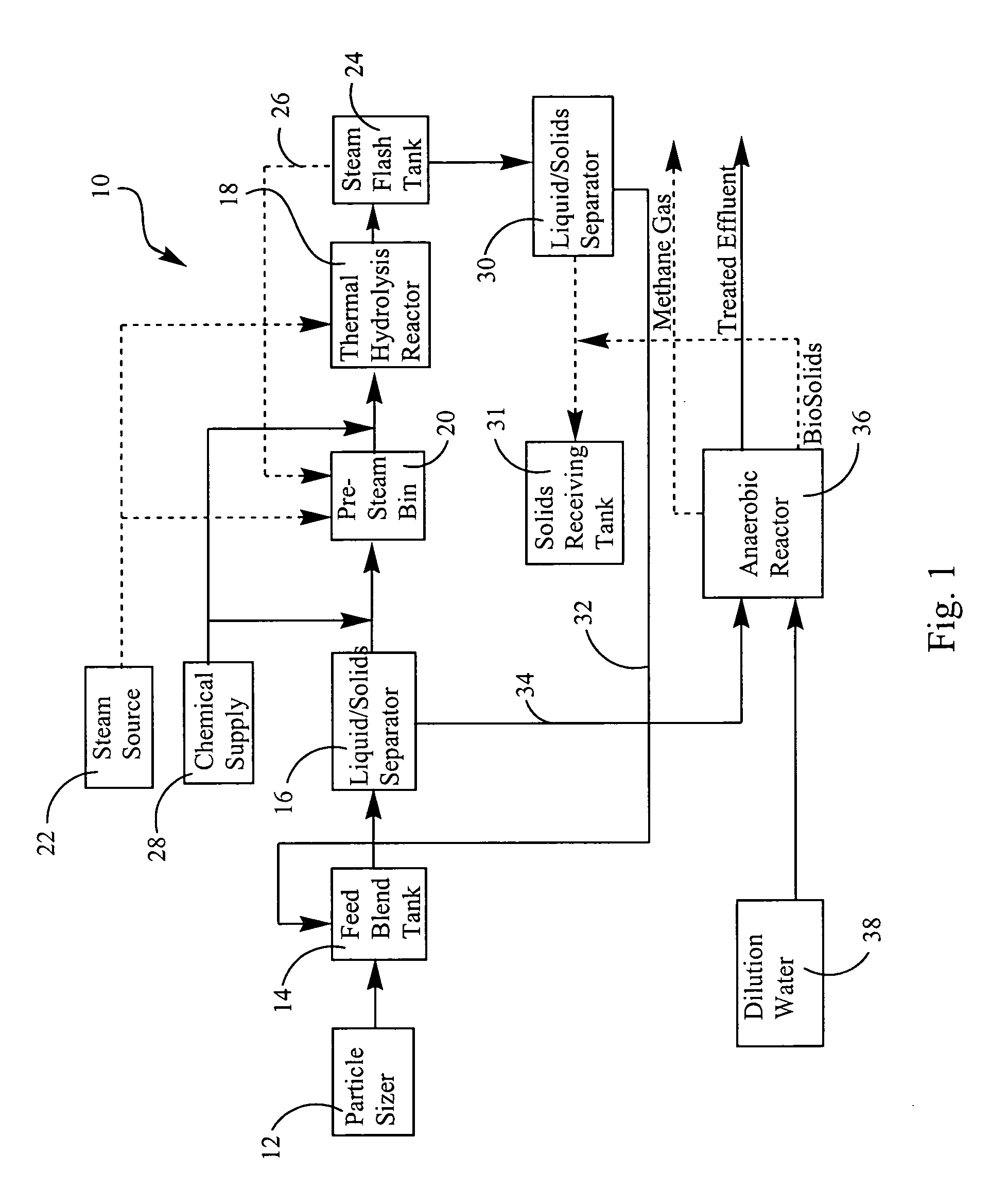

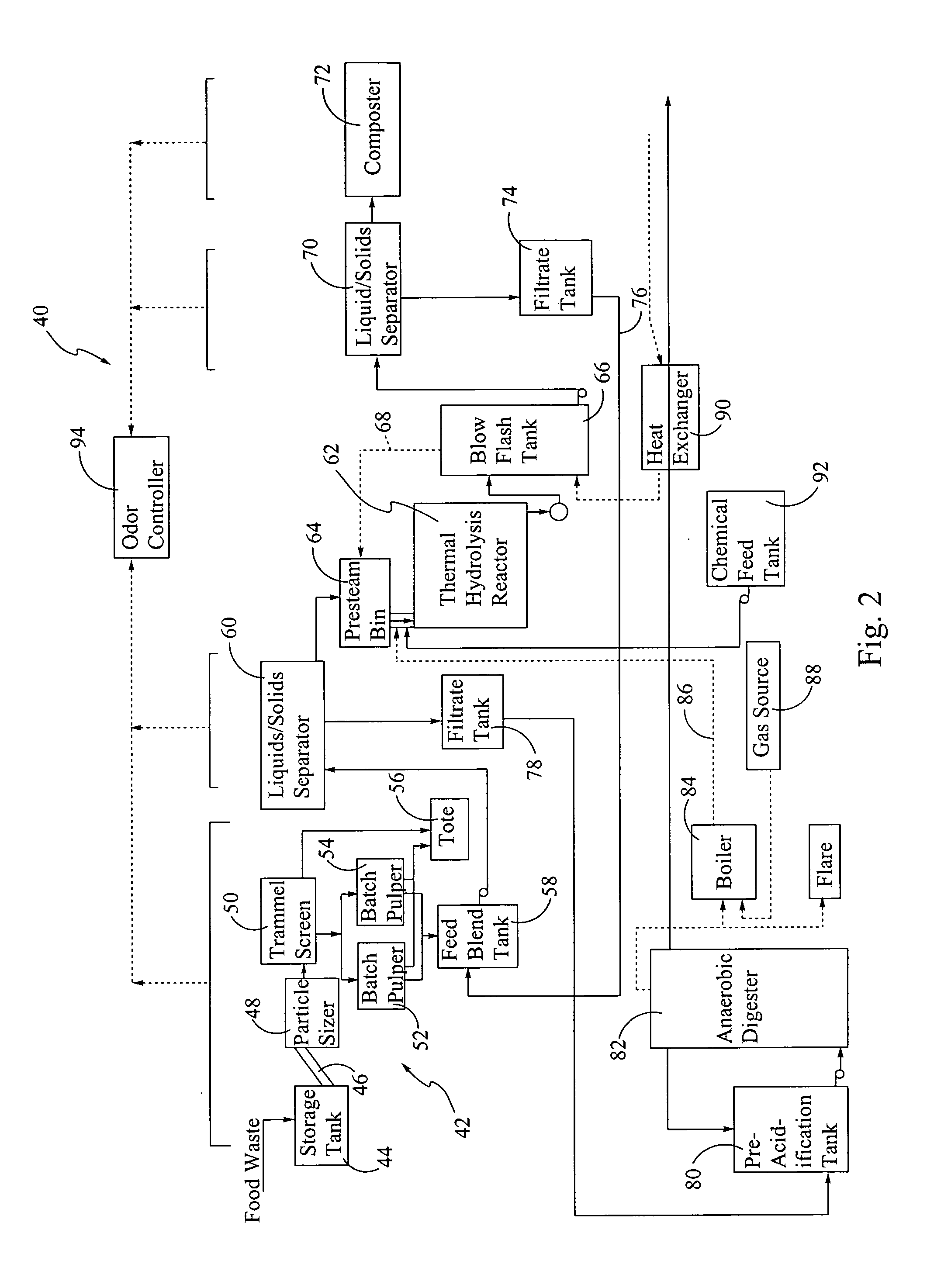

Method and apparatus for the treatment of particulate biodegradable organic waste

a biodegradable organic waste and treatment method technology, applied in biological water/sewage treatment, biological sludge treatment, multi-stage water/sewage treatment, etc., can solve the problems of inefficient inefficient yokoyama process, and insufficient solubilization or liquid removal, etc., to achieve more efficient anaerobic digestion, reduce the volume of particulate biodegradable organic waste, and save volume requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0032] The following examples are provided for illustrative purposes only and are not intended to limit the scope of the invention.

[0033] A number of bench tests were conducted to evaluate the efficacy of hydrolyzation under various operating conditions and anaerobic digestion of the solubilized organics under different operating conditions. The feed stocks used in the examples below were taken from food waste obtained from Korean restaurants in the Seattle metropolitan area. Approximately 80 gallons of food waste was collected from three Korean restaurants and maintained in cold storage. Two heavy-duty household (“garbage”) grinders were used to grind the particulate waste to approximately 3 / 16″ or less sized particles. After the food waste was ground, it was put into two 50-gallon coated steel drums designated as Sample A and Sample B. Sample A was used for the first 9 hydrolysis treatability tests (cooks 1-9) and Sample B was used for cooks 10-19, which are descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com