Nano-grade ZnO loaded magnetic biological carbon composite photocatalyst and preparation method thereof

A nano-scale, bio-carbon technology, applied in the field of adsorption materials, can solve the problem of difficult separation and recovery of photocatalysts, and achieve the effect of strong absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

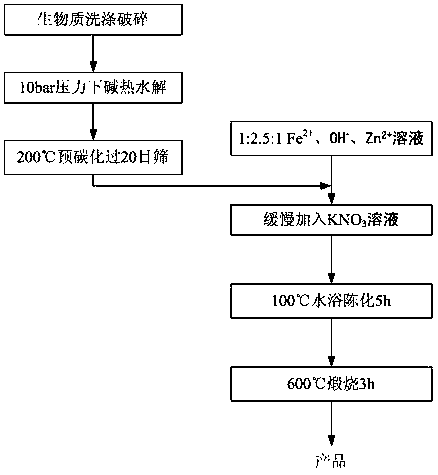

[0032] like figure 1 As shown, a preparation method of magnetic bio-carbon composite photocatalyst loaded with nano-scale ZnO, 500g coconut shells are washed and dried, then broken to a width of 3-4cm and put into 2L of clear water, and flake KOH is added until the water The pH value is between 11-12, and then placed in a small autoclave to maintain a temperature of 200 o Around C, the pressure is 10 6 pa thermal hydrolysis reaction for 30min, stop heating and naturally cool to room temperature, remove the coconut shell and dry in the sun. Put the washed, dried and crushed coconut shells into clean water and then add KOH to a high pH value. The strong alkalinity of KOH is used to activate and hydrolyze the coconut shells at the same time, so that the coconut shells are hydrolyzed in a strong alkali high temperature environment.

[0033] The dried coconut shells were placed in a muffle furnace, and nitrogen gas was continuously fed into it at 20 o The heating rate of C / min ...

Embodiment 2

[0038] The basic principle of Example 2 is the same as that of Example 1. Take 300g of sawdust or bamboo chips and put them into 2.5L of clear water after washing and drying. Add KOH until the pH value of the water is 11, and then place it in a small high-pressure reactor to maintain the temperature. for 190 o C, the pressure is 8*10 5 Pa hydrolysis reaction for 25min, stop heating and cool to room temperature naturally, remove sawdust or bamboo chips and dry in the sun.

[0039] Place the dried wood chips or bamboo chips in a muffle furnace, and continuously feed nitrogen to 15 o The heating rate of C / min raises the temperature to 180 o Stop heating after C, keep the temperature for 25 minutes, then stop heating, cool naturally to room temperature to obtain pre-carbonized coconut shells, smash the pre-carbonized coconut shells through a 10-mesh sieve.

[0040] Respectively get 0.1mol / L ferrous sulfate heptahydrate solution 80ml, 0.25mol / L potassium hydroxide solution 80ml,...

Embodiment 3

[0044] The basic principle of this example is the same as that of Example 1. Take 400g of cotton stalks or straws, wash and dry them, cut them to 2-3cm, put them into 3L of clean water, add KOH until the pH of the water is 11.5, and then place them in a small high-pressure Keep the temperature in the reactor at 180 o C, the pressure is 9*10 5 Pa hydrolysis reaction for 20min, stop heating and cool to room temperature naturally, remove cotton stalks or straws and dry in the sun.

[0045] Place the dried cotton stalks or straws in a muffle furnace, and continuously feed nitrogen to 22 o The heating rate of C / min raises the temperature to 190 o Stop heating after C, keep the temperature for 20 minutes, stop heating, cool naturally to room temperature to obtain pre-carbonized coconut shells, smash the pre-carbonized coconut shells through a 15-mesh sieve.

[0046] Take 120ml of 0.1mol / L ferrous chloride solution, 90ml of 0.25mol / L potassium hydroxide solution, and 120ml of 0.1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com