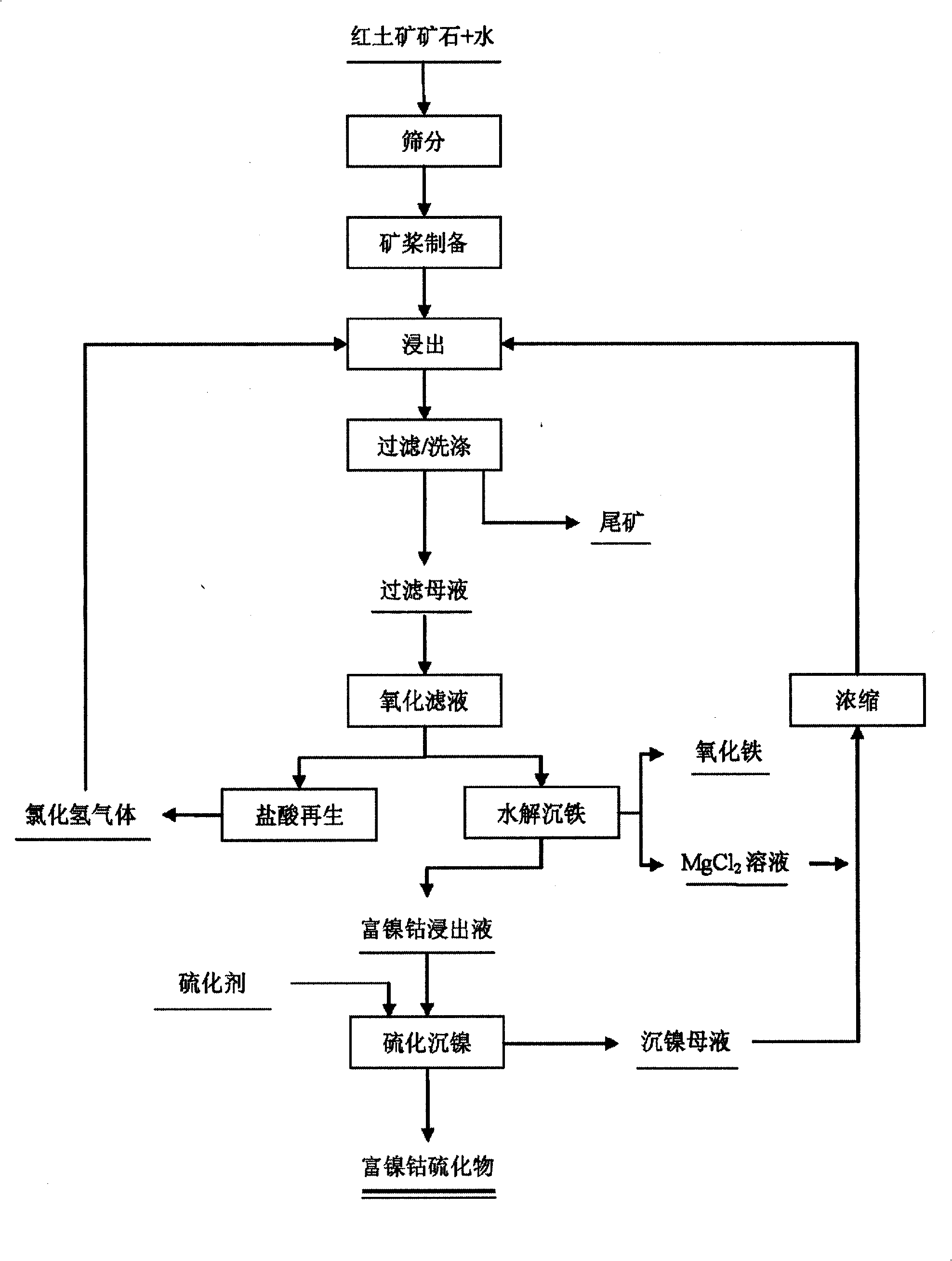

Method for comprehensive exploitation of low-ore grade laterite nickel mine

A laterite nickel ore, low-grade technology, applied in the field of non-ferrous metallurgy, can solve the problems of high energy consumption of hydrochloric acid regeneration, difficulty in separation and utilization of base metals, etc., and achieve the effects of improving recovery rate, increasing added value, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

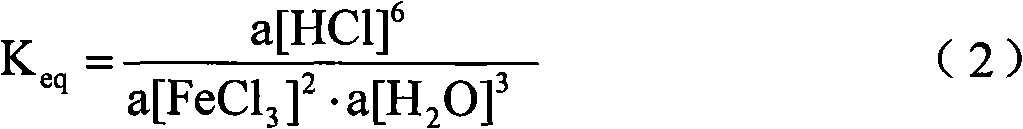

[0042] The laterite nickel ore is ball-milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching. The chloride leaching agent used is a mixed solution of magnesium chloride and hydrochloric acid, wherein the molar ratio of magnesium chloride to hydrochloric acid is 1:2, stirred and leached at 90°C, the time is controlled for 1 hour, and the leachate is analyzed after filtration, and the nickel leaching rate is determined to be 90.3 %, the cobalt leaching rate is 84.24%. Heat the leaching solution to 70°C, and feed in oxygen for 30 minutes. Keep the chloride ion in the system at 100g / L by heating, continue heating to 140-145°C, add a sufficient amount of deionized water every 10 minutes, vacuumize, control the time for 0.5 hours, and filter the precipitate. After analysis, 45.7% of ferric chloride was converted into precipitate. Return the regenerated hydrochloric acid to the leaching process for recycling. Na was added to the filtrate 2 S, ...

Embodiment 2

[0044] The laterite nickel ore is ball-milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching. The chloride leaching agent used is a mixed solution of magnesium chloride and hydrochloric acid, wherein the molar ratio of magnesium chloride to hydrochloric acid is 2:1, stirred and leached at 100°C, and the time is controlled for 2 hours. After filtering, the leachate is analyzed and the nickel leaching rate is determined to be 94.45%. %, the cobalt leaching rate is 89.73%. Heat the leaching solution to 80°C, add hydrogen peroxide, and control the time for 2 hours. Keep the chloride ion in the system at 300g / L by heating, continue heating to 145-150°C, add a sufficient amount of deionized water every 20 minutes, let in air to aid flow, control the time for 1 hour, and filter the precipitate. After analysis, 65.82% of the ferric chloride was transformed into precipitates, and the regenerated hydrochloric acid was returned to the leaching proces...

Embodiment 3

[0046] The laterite nickel ore is ball-milled and passed through a 50-mesh sieve, and a -50-mesh ore sample is taken for leaching. The chloride leaching agent used is a mixed solution of magnesium chloride and hydrochloric acid, wherein the molar ratio of magnesium chloride to hydrochloric acid is 5:2, stirred and leached at 90°C, and the time is controlled for 3 hours. After filtering, the leachate is analyzed and the nickel leaching rate is determined to be 97.64. %, the cobalt leaching rate is 90.55%. Heat the leaching solution to 90°C, add potassium permanganate and sodium chlorate, and control the time for 2 hours. Keep the chloride ion in the system at 350g / L by heating, continue heating to 155-160°C, add a sufficient amount of deionized water every 2 minutes, let in air to aid flow, control the time for 2 hours, and filter the precipitate. After analysis, 77.2% of ferric chloride was transformed into precipitates, and the regenerated hydrochloric acid was returned to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com