Alkali adding catalytic thermal hydrolysis treatment method for sludge

A treatment method and alkali catalysis technology are applied in the field of sludge addition alkali catalytic thermal hydrolysis treatment, which can solve the problems of difficult sludge increase, difficult separation and hydrolysis of organic matter and bound water, etc., so as to improve the sludge hydrolysis efficiency, steam The effect of lower usage and lower investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

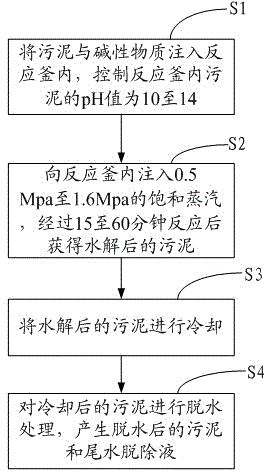

[0020] Such as figure 1 As shown, the present invention discloses a method for treating sludge with alkali-catalyzed thermal hydrolysis. In step S1, the sludge and alkaline substances are injected into the reaction kettle, and the pH value of the sludge in the reaction kettle is controlled to be 10 to 14 ; In step S2, inject saturated steam of 0.5 Mpa to 1.6 Mpa into the reactor, and obtain hydrolyzed sludge after 15 to 60 minutes of reaction.

[0021] In step S1, the water content of the sludge injected into the reactor may be 70% to 90%, or the water content of the sludge injected into the reactor is 75% to 85%.

[0022] As an embodiment of the present invention, in step S2, saturated steam of 1.0 Mpa to 1.5 Mpa is injected into the reactor, or saturated steam of 1.2 Mpa to 1.4 Mpa is injected into the reactor.

[0023] As another embodiment of the present invention, in the step S2, the temperature of the sludge in the reactor reaches 150 to 190 degrees Celsius; in the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com