Ceramic coating film composite and preparation method thereof

A composition and ceramic coating technology, applied in the direction of coating, etc., can solve the problems of inconvenient processing of special-shaped workpieces, environmental pollution, deformation of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

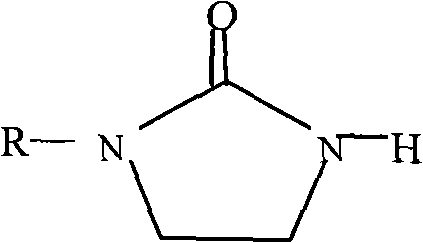

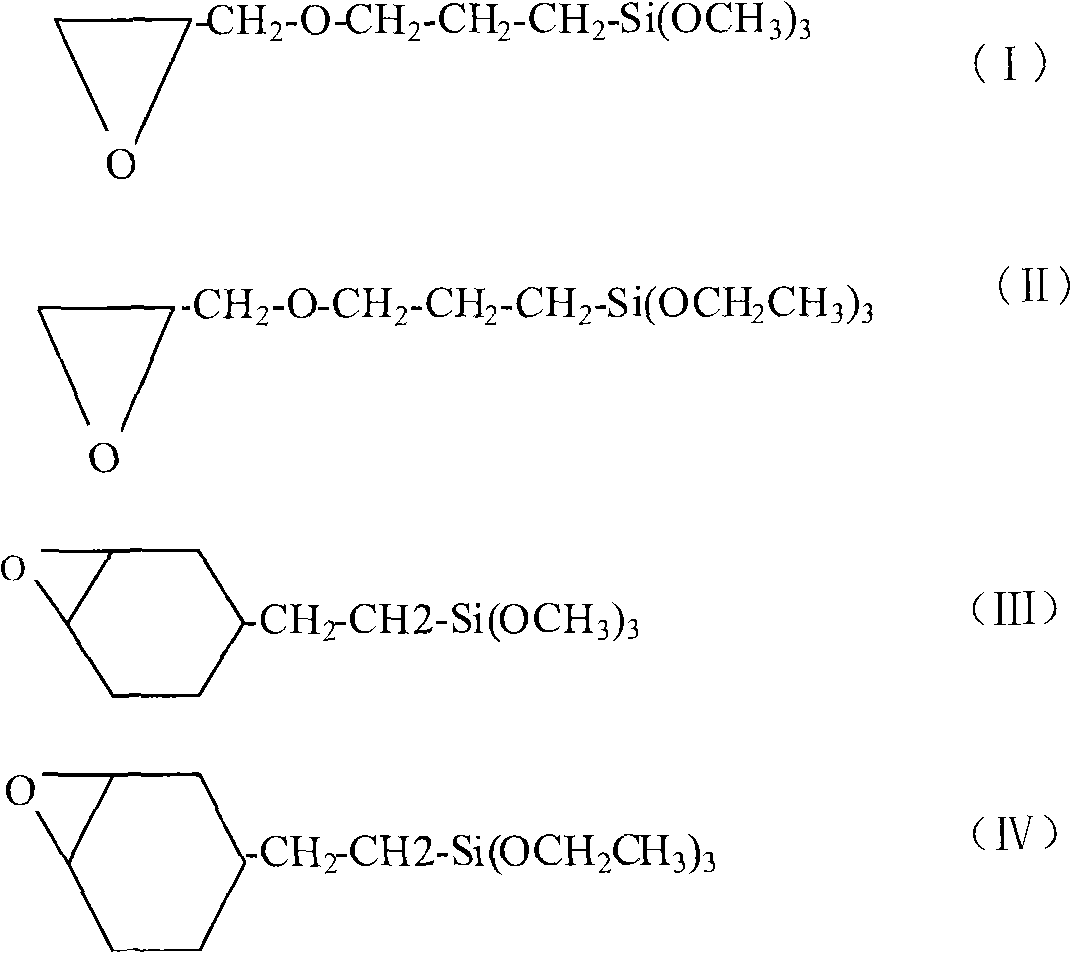

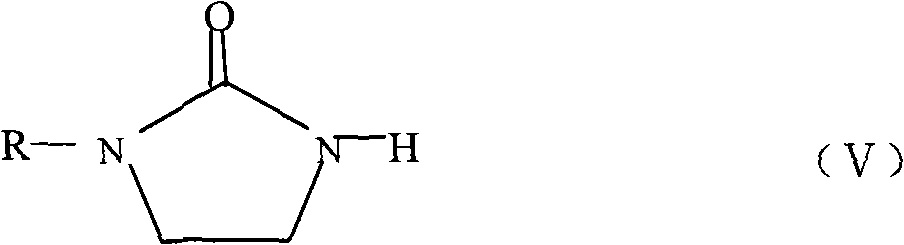

[0084] Preparation of Adhesion Promoters

[0085] In the present invention, when preparing the adhesion promoter, the molar ratio of the silane coupling agent and the compound containing the imidazolidinone ring can be theoretically calculated (equivalent ratio = 1: 1), but in order to ensure that the imidazolidinone ring When connected to the coupling agent, an excess of the coupling agent is often adopted. Generally, the molar ratio of the coupling agent / imidazolidinone-containing compound can be set at 1 / 0.9 to 1 / 0.5, usually at 1 / 0.8, The coupling agent that fails to connect the imidazolidinone ring will become one of the effective components of the B component, which will be hydrolyzed to form silanol, and then polycondensed to form a coating film composition.

[0086] The above reaction for preparing the adhesion promoter can be carried out in a four-necked flask with a stirring bar, a condenser and a thermometer, and the whole reaction process is protected by nitrogen...

Embodiment

[0129] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0130] Evaluation method of coating film adhesion

[0131] (i) Initial adhesion, according to GB / T9286-1998, using a 2mm scratcher and 3M 6100 tape for testing;

[0132] (ii) Secondary adhesion, place the test plate in boiled pure water, take it out after boiling for 4 hours, let it dry for 10 minutes, and test according to the same standard as (i).

Embodiment 1-3

[0144] A component is the same as that in Comparative Example 1-2, the difference is that different amounts of adhesion promoters have been added in the B component, and the adhesion promoter is composed of β-(3,4-epoxycyclohexyl) Prepared from ethyltrimethoxysilane and N-hydroxyethyl-2-imidazolidinone (V-1) at a molar ratio of 1 / 0.8.

[0145] The same paint ratio, curing conditions and plate making method as in Comparative Example 1-2. The test results of the adhesion of the comparative example and the embodiment are shown in Table 2 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com