Internal pressure type fiber-reinforced filter membrane and preparation method thereof

A fiber-reinforced, internal-pressure technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor adhesion between support and membrane filaments, and improve water flux and filtration accuracy High and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

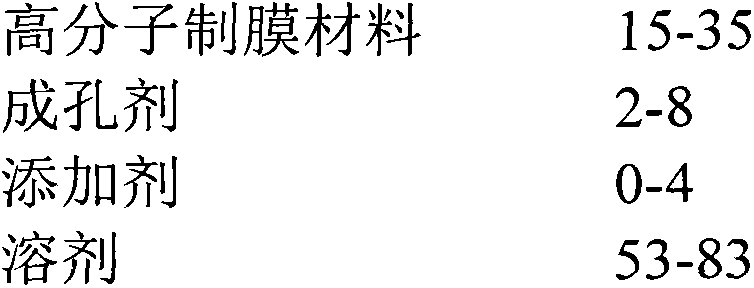

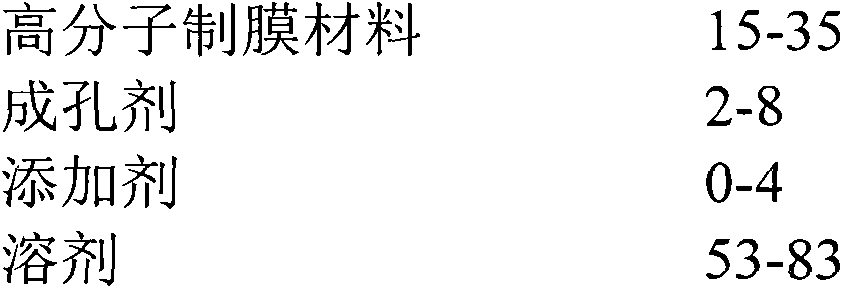

[0037] 1) Weigh 180g PVDF, 30g PVP-K30, 10g LiCl, and 780g DMF respectively and place them in a spinning kettle, and uniformly mix, dissolve, and defoam at a temperature of 60°C to obtain a PVDF casting with a mass concentration of 18%. Membrane fluid;

[0038] 2) Weigh 300g of DMF and 700g of water to make internal coagulation core liquid;

[0039] 3) Weigh 200g DMF and 800g water respectively to make external coagulation solution;

[0040] 4) The polyester fiber with a fineness of 30dtex is pulled out from the spool at a speed of 8m / min after being twisted twice and passed through the guide wheel of a braiding machine with 32 spindles to guide the braiding point, and braided into a hollow braided tube. The tube passes through the outermost channel of the three-channel spinneret through the tension control device;

[0041] 5) Pressurize the spinning kettle so that the casting solution passes through the filter and the melt pump in turn, and then enters the middle channel of...

Embodiment 2

[0046] 1) Weigh 150g PVC, 20g PEG200, 10g Tween 80, and 820g DMAC respectively in a spinning kettle, uniformly mix, dissolve, and defoam at a temperature of 80°C to obtain a PVC casting with a mass concentration of 15%. Membrane fluid;

[0047] 2) Weigh 100g of DMAC and 900g of water respectively to make the inner coagulation core liquid;

[0048] 3) take by weighing 1000g water as the external coagulation liquid;

[0049] 4) crochet the polyamide fiber with a fineness of 75dtex into a hollow braided tube after twisting three times, and pass the braided tube through the outermost channel of the three-channel spinneret through the tension control device;

[0050] 5) Pressurize the spinning kettle so that the casting solution passes through the filter and the melt pump in turn, and then enters the middle channel of the three-channel spinneret;

[0051] 6) pressurize the core liquid tank, so that the core liquid is ejected from the innermost channel of the three-channel spinner...

Embodiment 3

[0055] 1) Weigh 200g PAN, 30g PEG6000, and 770g DMF respectively and place them in a spinning kettle, uniformly mix, dissolve, and defoam at a temperature of 90°C to obtain a PAN casting solution with a mass concentration of 20%;

[0056] 2) Weigh 1000g of water to make the inner coagulation core liquid;

[0057] 3) Weigh 300g DMF and 700g water respectively to make external coagulation solution;

[0058] 4) Winding the glass fiber with a fineness of 400dtex after 5 times of twisting to form a hollow braided tube, passing the braided tube through the outermost channel of the three-channel spinneret through the tension control device;

[0059] 5) Pressurize the spinning kettle so that the casting solution passes through the filter and the melt pump in turn, and then enters the middle channel of the three-channel spinneret;

[0060] 6) pressurize the core liquid tank, so that the core liquid is sprayed from the innermost channel of the three-channel spinneret through the core l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com