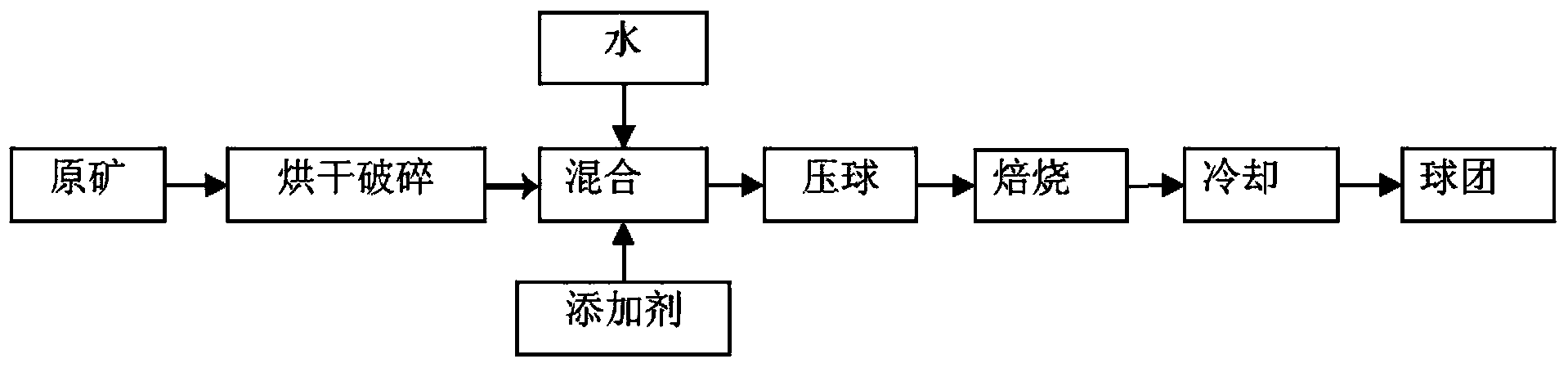

Process for briquetting oxidation pellets from laterite nickel ore

A technology of lateritic nickel ore and oxidized pellets, which is applied in the field of metallurgy to achieve the effects of reducing thermal and electrical energy consumption, increasing added value, and requiring low material particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take the laterite nickel ore, the total water content of the laterite nickel ore is 36.6%, the specific chemical composition: TFe: 39.4Wt%; FeO: 1.44Wt%; Ni: 1.23Wt%; CaO: 0.35Wt%; MgO: 5.34Wt %; SiO2: 10.09Wt%; Al2O3: 5.60Wt%; S: 0.01Wt%, trace P percentage content;

[0027] (2) Dry the laterite nickel ore to a moisture content of 15%, and crush it to a particle size below 3mm;

[0028] (3) Put 2% sodium sulfate and 8% limestone into the crushed laterite nickel ore and mix them;

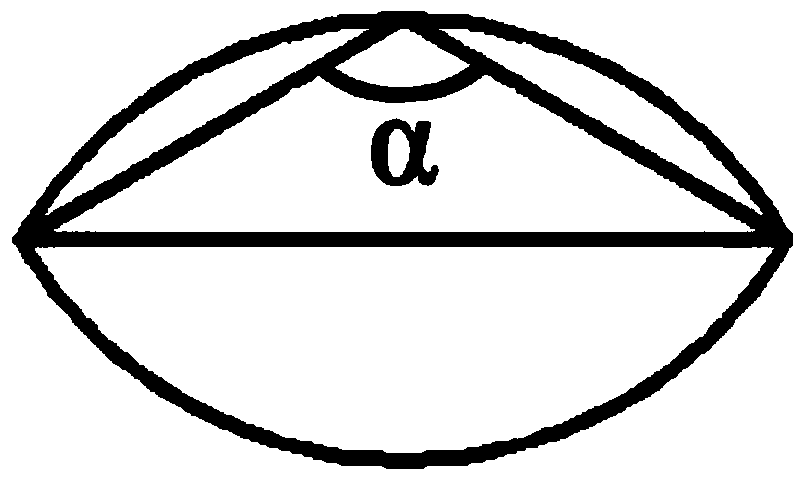

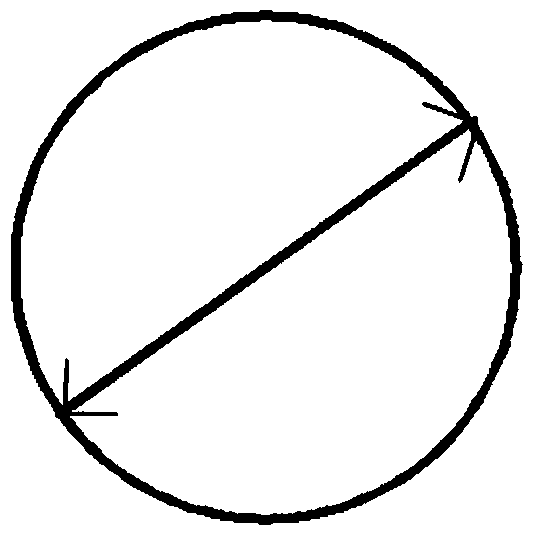

[0029] (4) Press the mixed material into balls on the roller press machine, such as image 3 Shown: the pressed raw ball is a biconvex ball with a diameter of 10-20mm, such as figure 2 Shown: the angle α between the top of the convex surface and the edge is greater than 110 degrees, and the water content of the raw ball is 10-13%;

[0030] (5) Transport the green pellets to the shaft furnace for drying and roasting with waste heat according to the conventional process, and obtain the ...

Embodiment 2

[0032] (1) Use laterite nickel ore with a total water content of 36%, specific chemical composition: TFe: 20.13Wt%; FeO: 1.8Wt%; Ni: 1.66Wt%; CaO: 0.28Wt%; MgO: 9.21Wt%; SiO2: 27.07Wt%; Al2O3: 3.85Wt%; S: 0.006Wt%, trace P percentage;

[0033] (2) Drying the laterite nickel ore to a moisture content of 17%, and crushing to a particle size below 3mm;

[0034] (3) Put 4wt% sodium sulfate and 20wt% limestone into laterite nickel ore and mix;

[0035] (4) Press the mixture into balls on the roller press machine, such as image 3 Shown: The pressed green ball is a double convex ball with a diameter of 10-20mm, such as figure 2 Shown: The angle between the top of the convex surface and the edge is greater than 110 degrees, and the moisture content of the raw ball is 12-14%;

[0036] (5) Transport the green pellets to the shaft furnace for drying and roasting according to the conventional process to obtain finished oxidized pellets with an average compressive strength of more tha...

Embodiment 3

[0038] (1) Use laterite nickel ore with a total water content of 34%, specific chemical composition: TFe: 13.98Wt%; FeO: 1.08Wt%; Ni: 1.25Wt%; CaO: 0.28Wt%; MgO: 18.11%; SiO2: 30.08 Wt%; Al2O3: 1.28Wt%; the percentages of S and P are traces, and the test is carried out;

[0039] (2) Dry the laterite nickel ore to a moisture content of 17%, and crush the particle size to less than 3mm;

[0040] (3) 3wt% sodium sulfate and 15wt% limestone are mixed with laterite nickel ore;

[0041] (4) Press the mixture into balls on the roller press machine, such as image 3 Shown: the pressed green ball is a biconvex ball with a diameter of 10-20, such as figure 2 Shown: the angle α between the top of the convex surface and the edge is greater than 110 degrees, and the water content of the raw ball is 12-15%;

[0042] (5) Transport the raw pellets to the shaft furnace for drying and roasting according to the conventional process, and obtain the finished oxidized pellets with a compressive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com