Preparation method for sulfur-containing phosphate fertilizer

A technology of phosphate fertilizer and phosphoric acid, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of uneven mixing of reactors, explosion hazards of elemental sulfur dust, etc., and achieve good dispersion effect and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

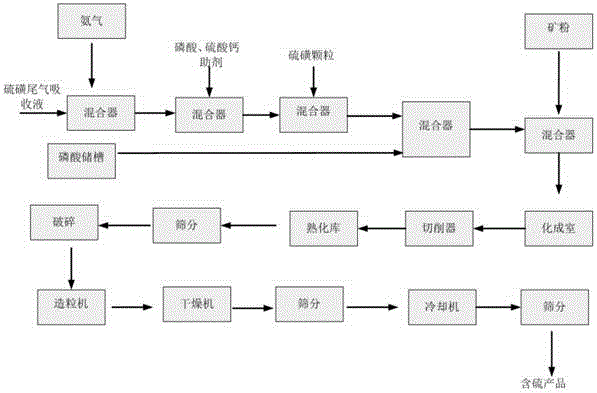

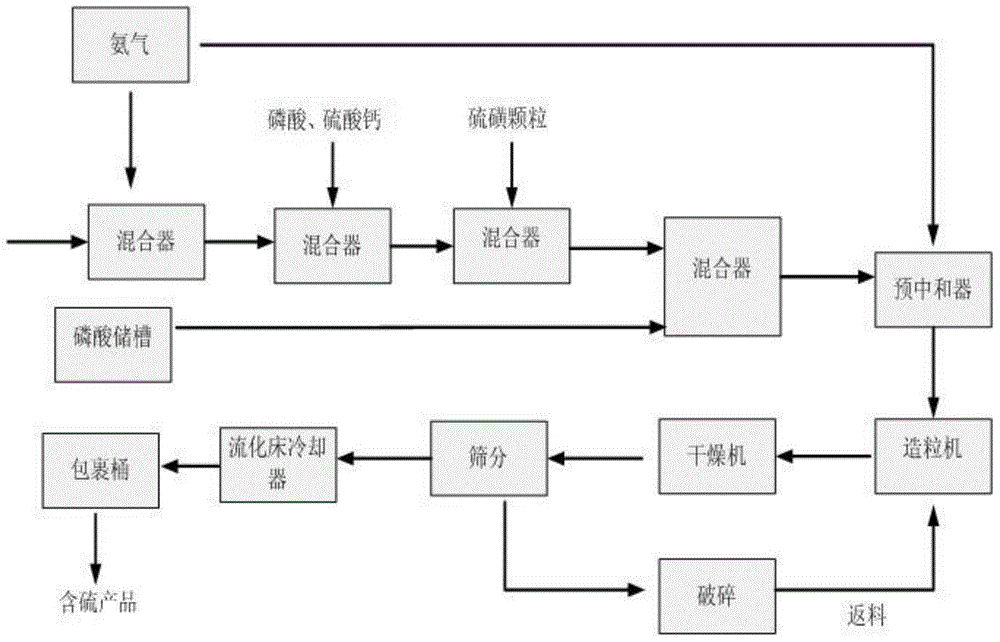

[0024] Production of monoammonium thiophosphate, such as figure 1 Shown:

[0025] The first step: firstly take the sulfuric acid tail gas absorption liquid, add phosphoric acid and 150 microns of calcium sulfate to make the sulfate radical content 0.5%, the calcium content 0.1%, and the phosphorus pentoxide 8%. Grind sulfur into sulfur powder with a fineness of 180 microns. According to the demand for sulfur in the product (the ratio of elemental sulfur or sulfate), mix the sulfur powder with the sulfuric acid tail gas absorption liquid mixed with additives in a proportion of 50%. Mix and stir evenly, and then introduce 15% of phosphoric acid mass into phosphoric acid.

[0026] The second step: producing monoammonium thiophosphate granules. The applied reactor is a tubular reactor. The above-mentioned phosphoric acid is introduced into the tubular reactor, and ammonia gas is passed through, the mixture is reacted at 120°C, and monoammonium phosphate (diammonium phosphate ca...

Embodiment 2

[0030] Production of monoammonium thiophosphate, such as figure 1 Shown:

[0031] Step 1: first take the sulfuric acid tail gas absorption liquid, add phosphoric acid and 150 microns of calcium sulfate to make the sulfate radical content 1.0%, the calcium content 0.2%, and the phosphorus pentoxide 10%. Grind sulfur into sulfur powder with a fineness of 180 microns. According to the demand for sulfur in the product (the ratio of elemental sulfur or sulfate), mix the sulfur powder with the sulfuric acid tail gas absorption liquid mixed with additives in a proportion of 30%. Mix and stir evenly, and then introduce 10% of phosphoric acid mass into phosphoric acid.

[0032] Second step: operate according to the second step of Example 1 to obtain the product, and the analysis results are shown in 2.

[0033] Table 2, analysis results of sulfur and phosphate fertilizers

[0034] Indicator name Total N / (%) Effective P 2 o 5 / (%) Total S / (%) h 2 O / (%) Compres...

Embodiment 3

[0036] Production of monoammonium thiophosphate, such as figure 1 Shown:

[0037] Step 1: first take the sulfuric acid tail gas absorption liquid, add phosphoric acid and 150 microns of calcium sulfate to make the sulfate radical content 1.5%, the calcium content 0.3%, and the phosphorus pentoxide 12%. Grind sulfur into sulfur powder with a fineness of 180 microns. According to the demand for sulfur in the product (the ratio of elemental sulfur or sulfate), mix and stir the sulfur powder at 10% with the sulfuric acid tail gas absorption liquid mixed with additives. uniform, and then introduced into phosphoric acid by 20% of the mass of phosphoric acid.

[0038] Second step: operate according to the second step of Example 1 to obtain the product, and the analysis results are shown in 3.

[0039] Table 3, analysis results of sulfur and phosphate fertilizers

[0040] Indicator name Total N / (%) Effective P 2 o 5 / (%) Total S / (%) h 2 O / (%) Compressive str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com