Method and device for continuously treating lead anode slime

A technology of lead anode slime and precious lead, applied in the field of lead anode slime treatment method and its device, can solve the problems of poor environmental protection, long production cycle, small production capacity, etc., reduce environmental pollution, strengthen smelting process, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

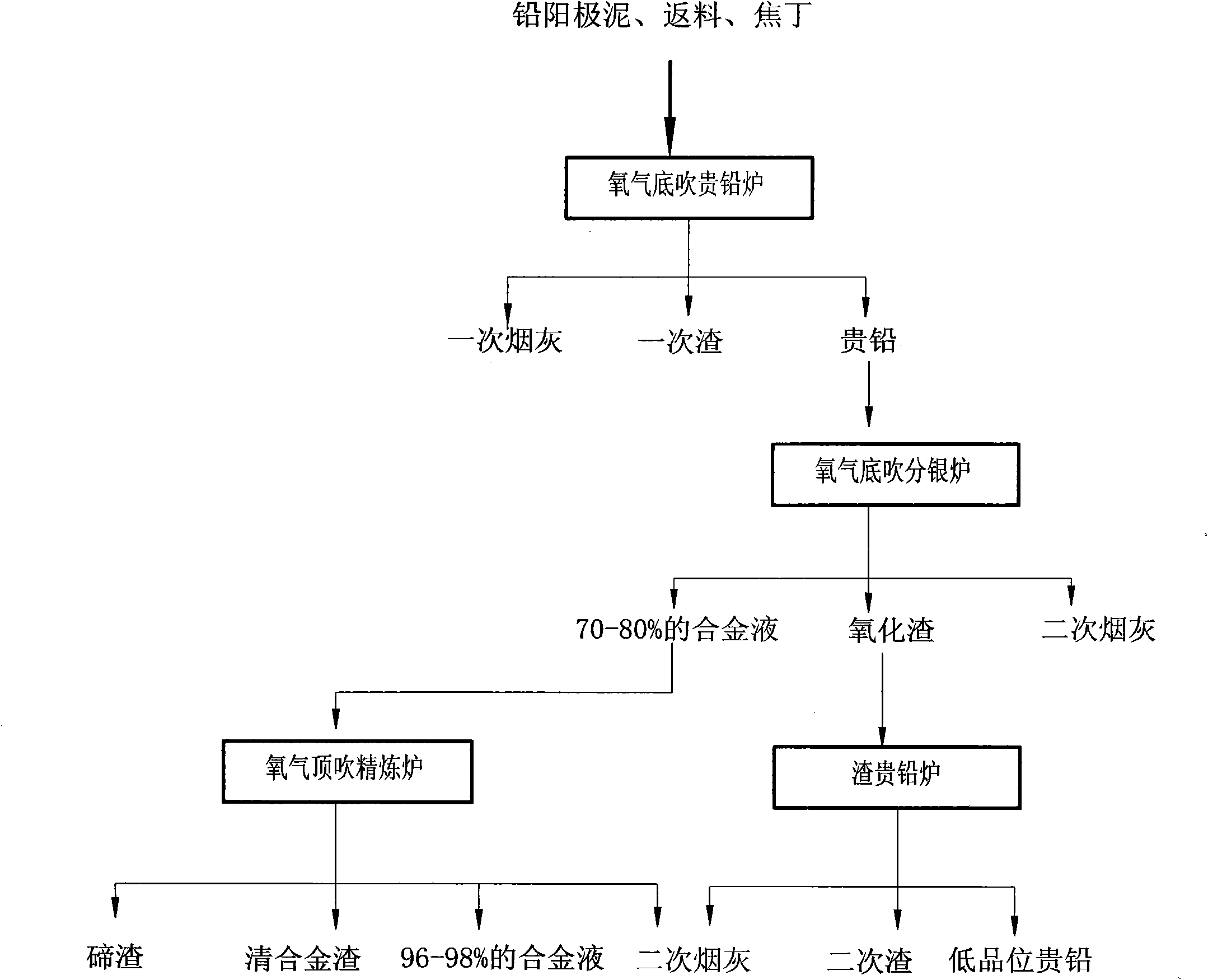

[0036] Example 1: Method and device for continuous processing of lead anode slime by molten pool smelting

[0037] Such as figure 1 , figure 2 , image 3 shown. figure 2 The winning number 1 is the grab crane, 2 is the hopper, 3 is the electronic belt scale or nuclear belt scale, 4 is the oxygen bottom-blown noble lead furnace, 5 is the feeding port, and 6 is the oxygen blowing pipe at the bottom of the oxygen bottom-blown noble lead furnace 7 is the natural gas burner hole, 8 is the slag outlet, 9 is the expensive lead outlet, 10 is the smoke outlet, 11 is the chute; 12 is the oxygen bottom blowing silver furnace, 13 is the smoke outlet, 14 is a feed inlet, 15 is the spray gun flange of the oxygen blowing pipe at the bottom of the silver-separating furnace, 16 is a natural gas burner, 17 is a slag outlet of the silver-separating furnace, and 18 is an alloy outlet siphoned out of the oxygen-separating furnace at the bottom; 19 20 is the oxygen top-blown refining furnace,...

Embodiment 2

[0057] Embodiment 2: A method for continuously processing lead anode slime by molten pool smelting, and the device is the same as that in Embodiment 1.

[0058] Lead anode slime, return material, and coke are batched according to the weight ratio of 100:0~10:2~5, and the mixed batching is carried out in the pit by using the grab truck 1, and the mixed materials are transported to the silo 2 by grab bucket truck , the material in the silo is measured by a nuclear belt scale or an electronic belt scale, and enters the oxygen bottom-blown precious lead furnace 4 for melting and oxidation and reduction reactions, and continuously and quantitatively feeds oxygen into the molten pool, the oxygen pressure is 0.8-1.0MPa, and the oxygen flow rate is 30 ~50m 3 / h, the oxidation-reduction reaction in the furnace is controlled by adjusting the oxygen in the oxygen bottom blowing noble lead furnace lance 6 and the amount of coke in the batching.

[0059] Negative pressure is maintained in...

Embodiment 3

[0066] Embodiment 3: basically the same as Embodiment 2, the difference is:

[0067] Lead anode slime, return material, and coke are batched according to the weight ratio of 100:10~20:3~6, and the mixed batching is carried out in the pit with the grab crane 1, and the mixed material is transported to the bin 2 with the grab bucket truck , the material in the silo is measured by a nuclear belt scale or an electronic belt scale, and enters the oxygen bottom-blown precious lead furnace 4 for melting and oxidation and reduction reactions, and continuously and quantitatively feeds oxygen into the molten pool, the oxygen pressure is 0.8-1.0MPa, and the oxygen flow rate is 25 ~45m 3 / h, the oxidation-reduction reaction in the furnace is controlled by adjusting the oxygen in the oxygen bottom blowing noble lead furnace lance 6 and the amount of coke in the batching.

[0068] Other steps are the same as in Example 2 and will not be repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com