Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "Large range of control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent vehicle control method and apparatus

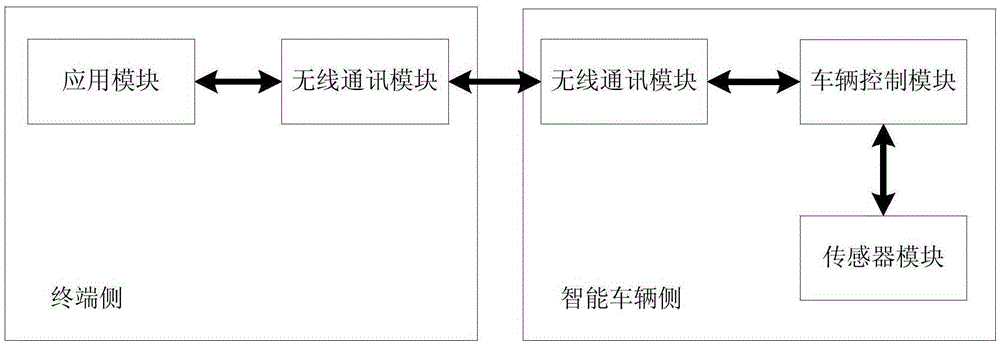

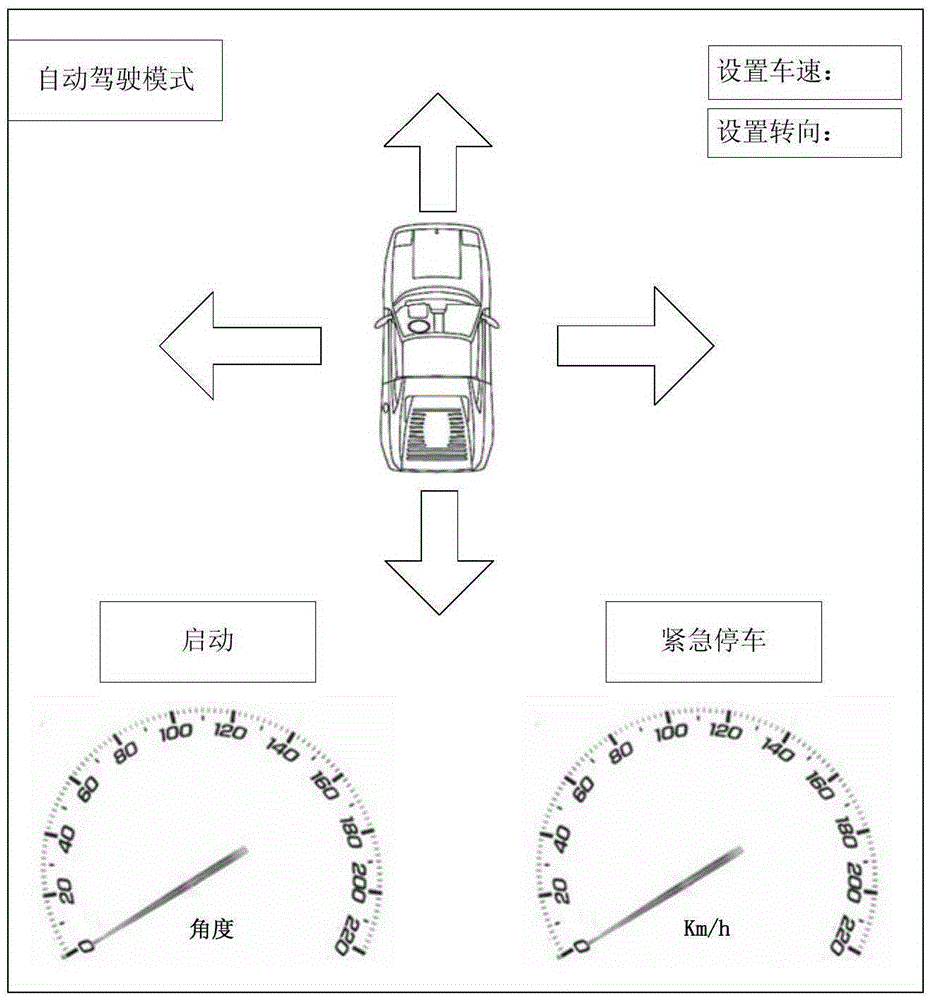

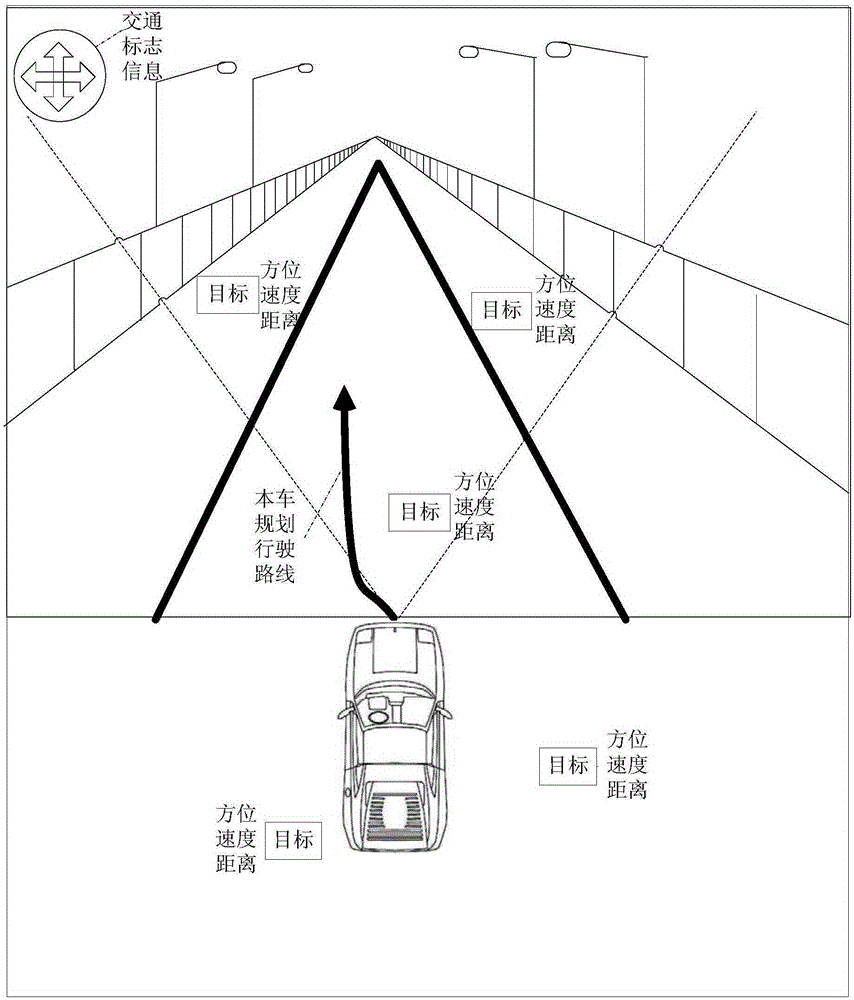

ActiveCN105261224ASmart controlLarge range of controlAnti-collision systemsComputer terminalComputer science

The invention, which belongs to the technical field of intelligent traffic, discloses an intelligent vehicle control method and apparatus. The method comprises: after a terminal receives current driving road situation information sent by an intelligent vehicle, an obstacle is displayed on a first display interface; a lane line and a traffic sign on the current driving road are displayed on the first display interface according to lane line information and traffic sign information contained in the road situation information; a driving route of the intelligent vehicle is planned based on the lane line information and state description information contained in the road situation information; and the driving route is sent to the intelligent vehicle, so that the intelligent vehicle can be driven based on the driving route. According to the invention, the intelligent vehicle can be controlled by the terminal independent of the intelligent vehicle and the driving route is planned and displayed, so that the intelligent vehicle can be driven based on the driving route. The control range is large and the control way is intelligent.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

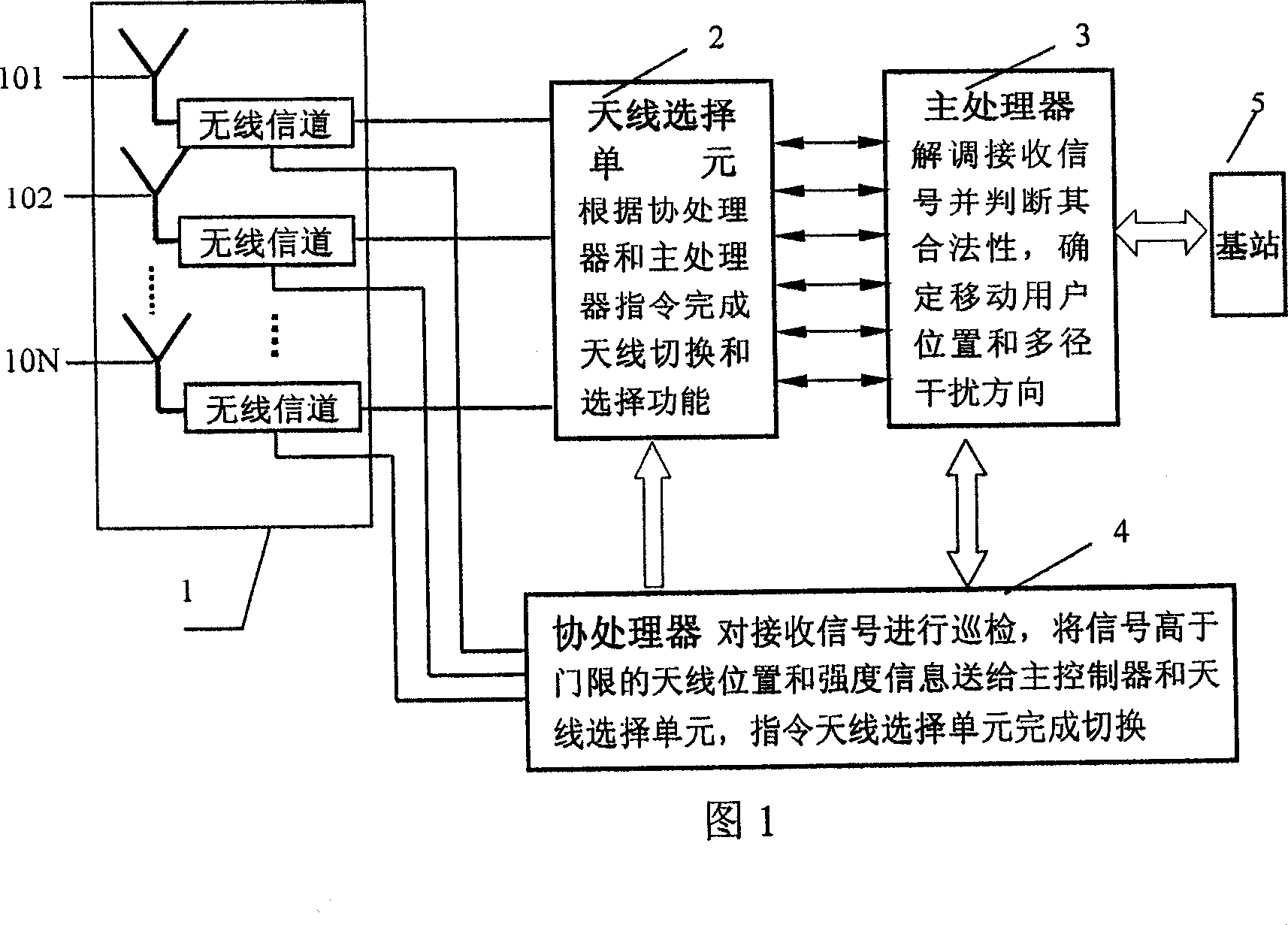

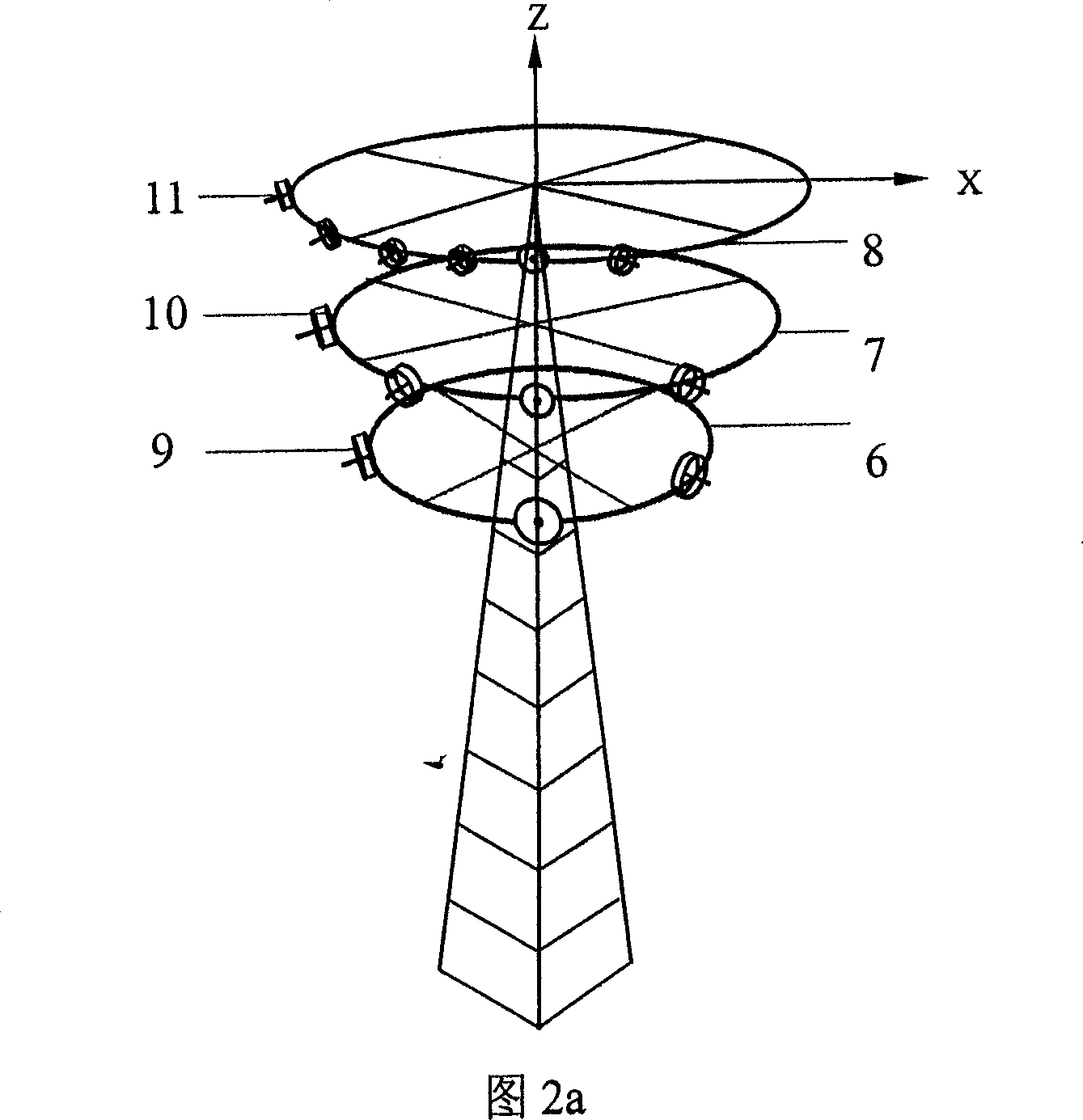

Method and device for implementing the multi-wave bundle intelligent antenna with the directional antenna

InactiveCN101056451AEasy to control and useSimple structureSpatial transmit diversityPolarisation/directional diversityDirectional antennaSmart antenna

A method and an apparatus for realizing a multibeam smart antenna by directional antennas in a mobile communication system, are provided. The method comprises performing space division on a base station service region by N directional antennas independent with one another to divide the base station service region into N cells, each cell satisfying a perdetermined electromagnetic radialization request; composing a delamination multibeam array by the N directional antennas based on the region to be covered by the base station, the directional antenna adjusting direction of the beam in advance to realize space division multiple access, the antenna for performing transmission and receiving of signals are controlled by a main processor unit, auxiliary processors and an antenna selection unit to position and track a mobile user. The apparatus includes a delamination antenna array composed of N directional antennas independent with one another, the antenna selection unit, auxiliary processors, a main processor; wherein the N directional antennas are connected with input ends of the auxiliary processors respectively, the auxiliary processors are connected with the antenna selection unit and the main processor respectively, the main processor is connected with the antenna selection unit and the base station. The invention has a high communication capacity and immunity.

Owner:LANZHOU UNIV ELECTRONICS TECH DEV APPL RES INST

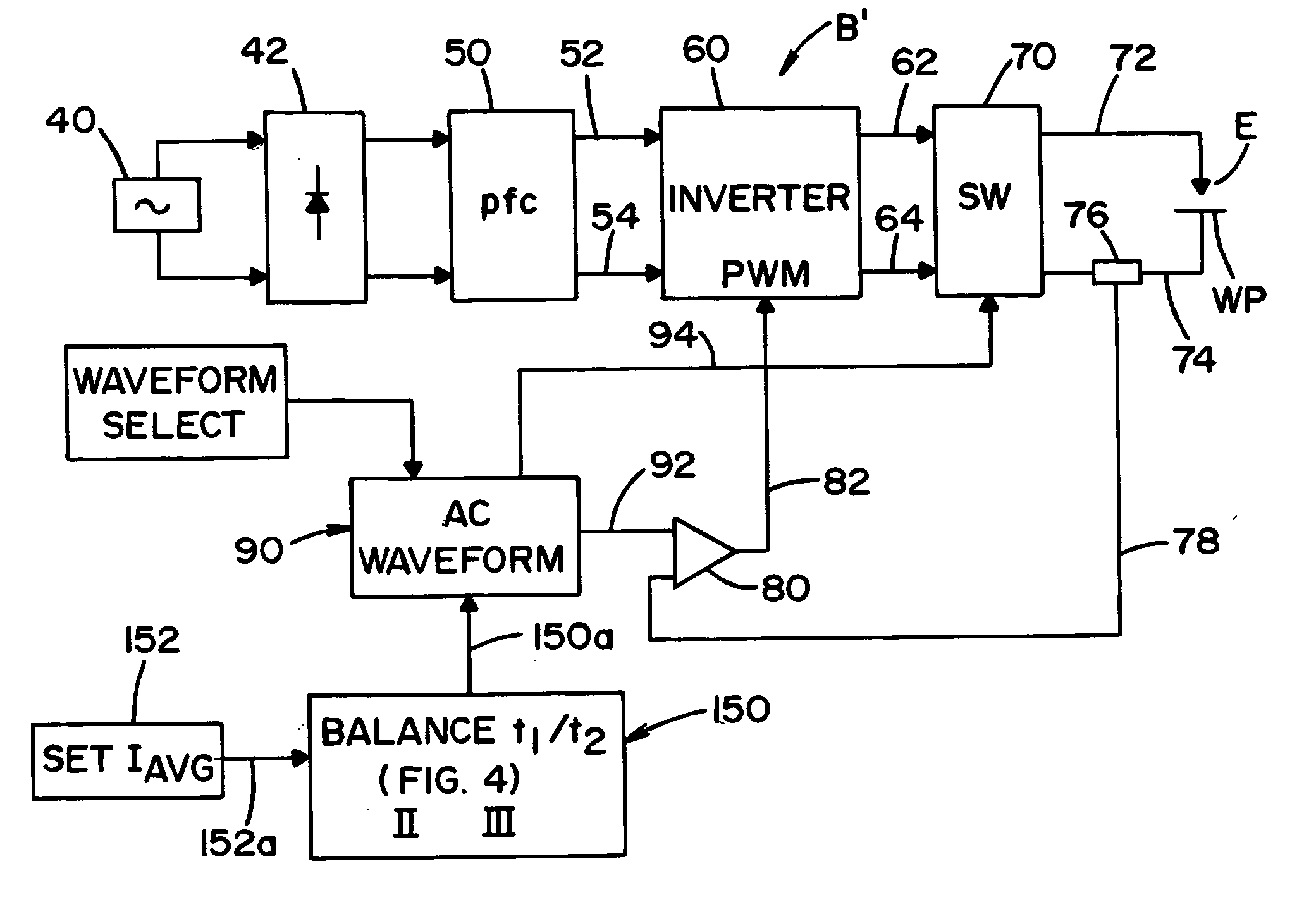

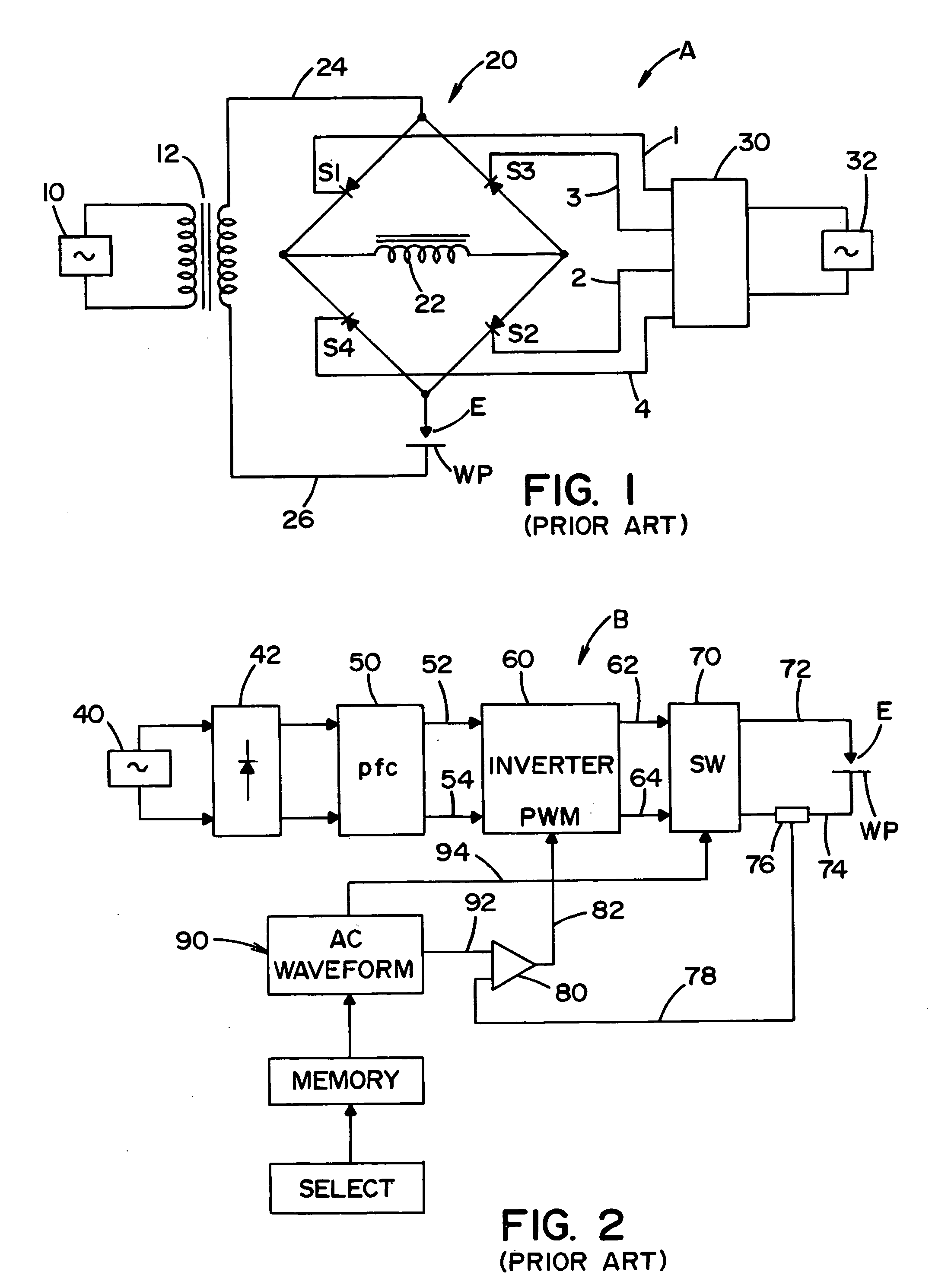

Synergic TIG welding system

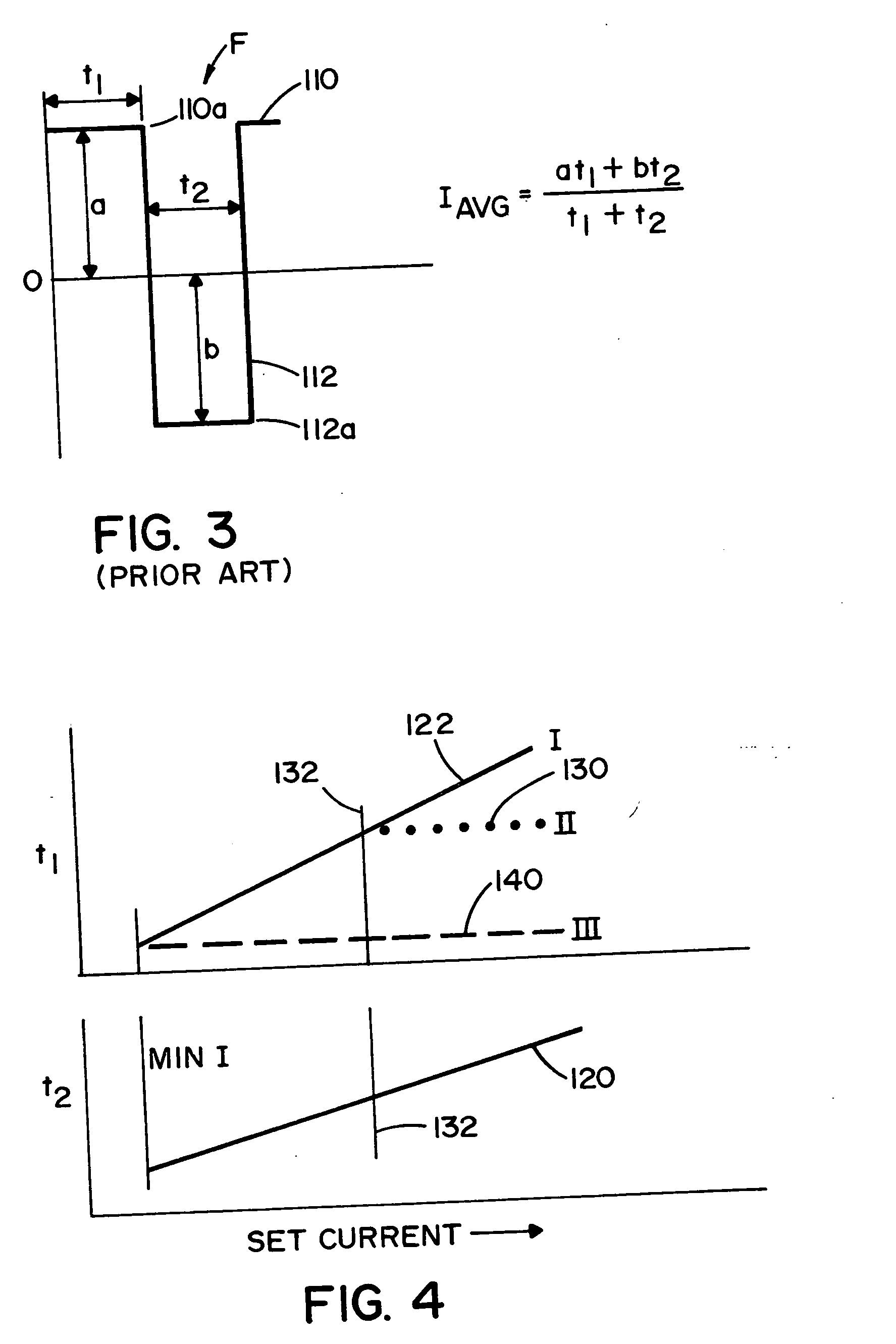

ActiveUS20070164007A1High frequencyReduce noiseArc welding apparatusLinear relationshipPositive current

There is provided an improved TIG welder comprising a power source for performing an AC TIG welding process across an electrode and a workpiece with a controller for creating an AC waveform. The controller having a synergic input device with an input for receiving a signal level representing a desired set current for the welding process and an output signal determining an aspect of the waveform and representing a non-linear relationship between peak positive current and peak negative current for certain desired set welding currents.

Owner:LINCOLN GLOBAL INC

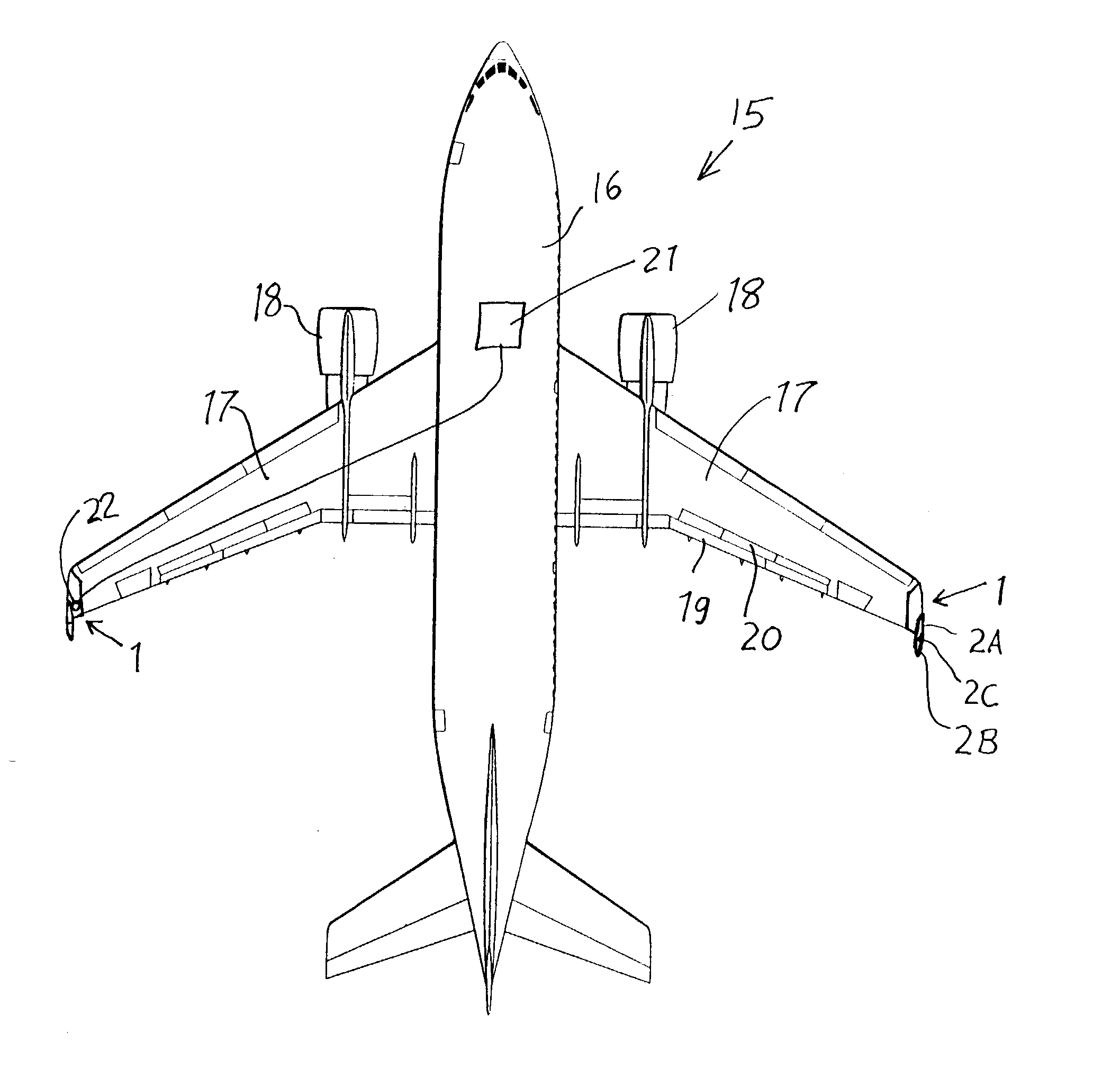

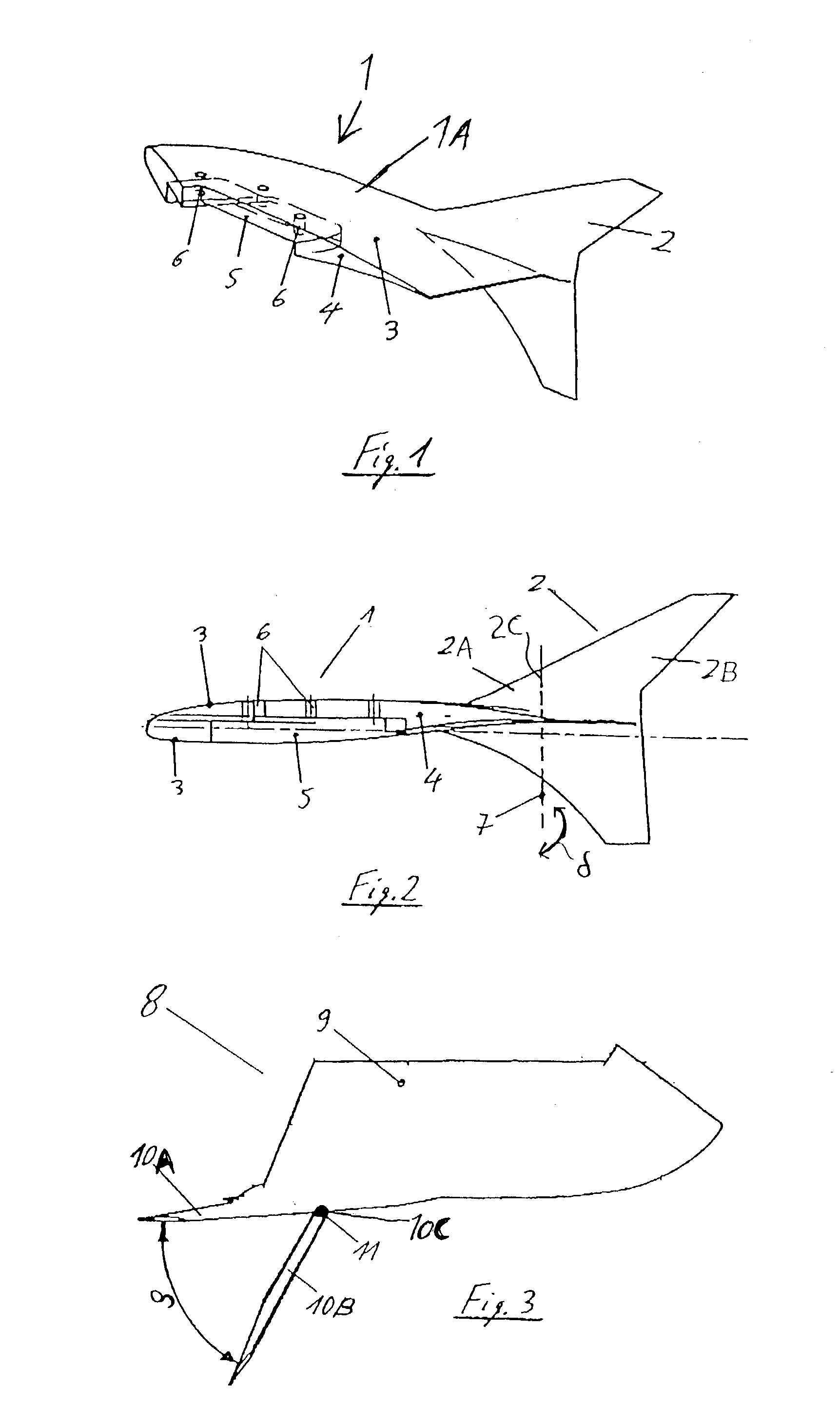

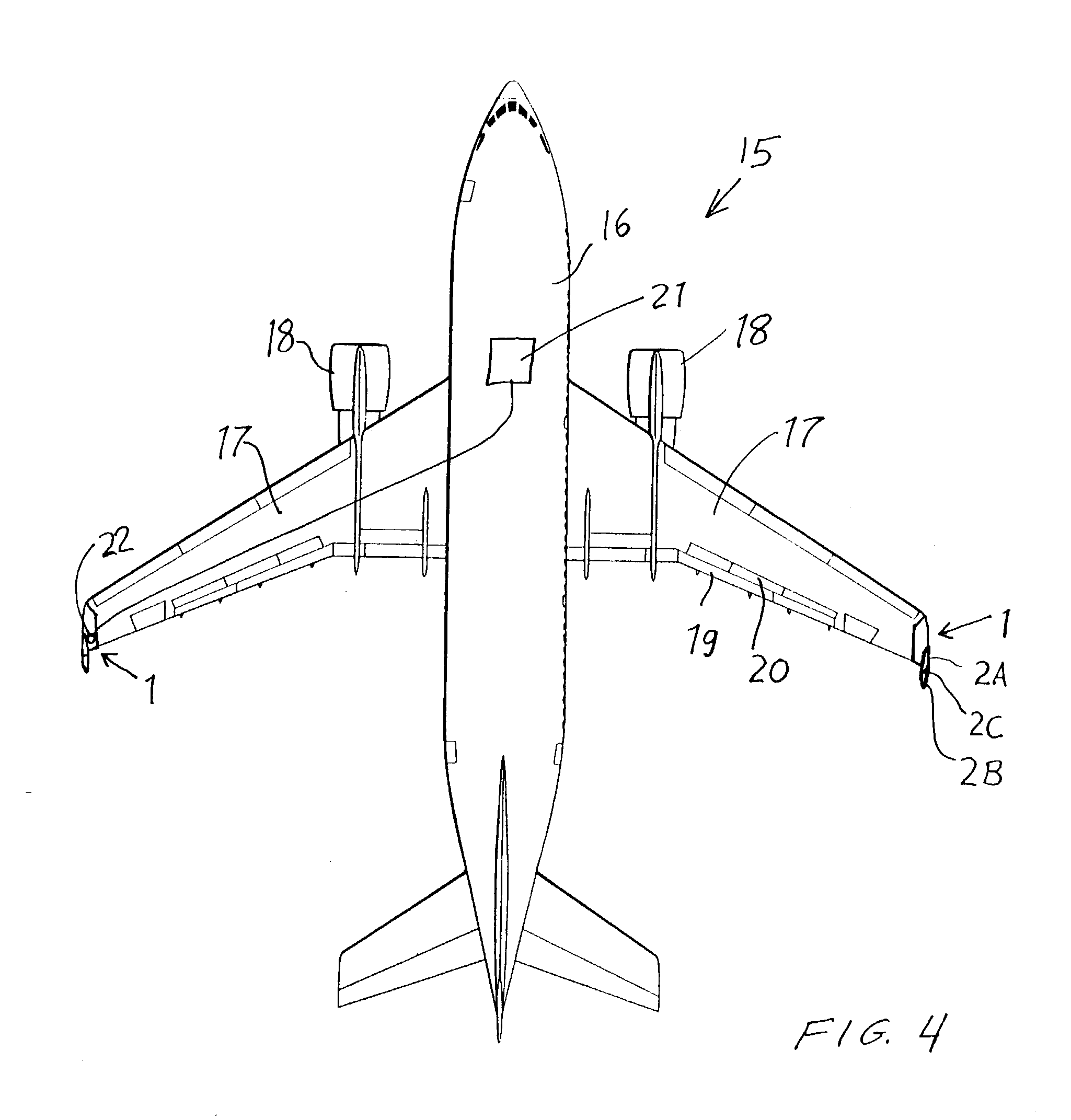

Method and device for steepening a landing approach of an aircraft

ActiveUS20030106961A1Coefficient is alteredHigh trafficInfluencers by generating vorticesAircraft stabilisationFlight vehicleAirplane

Owner:AIRBUS OPERATIONS GMBH

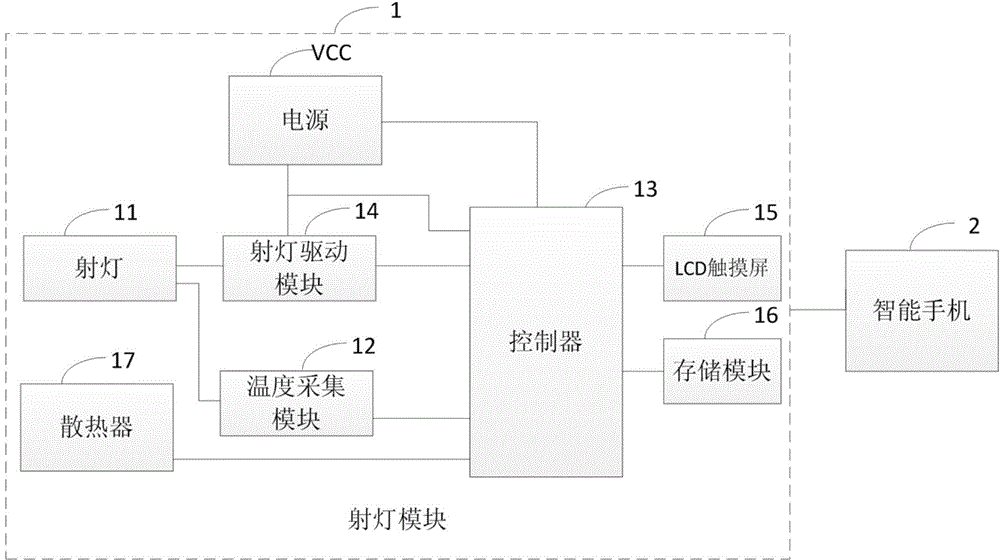

Intelligent control system of off-road vehicle spotlight

InactiveCN104869728AReduce power consumptionImprove luminous efficiencyElectric light circuit arrangementEnergy saving control techniquesBuggy vehicleIntelligent control system

The invention relates to an intelligent control system of an off-road vehicle spotlight, and provides an intelligent control system of an off-road vehicle spotlight, so as to solve problems that at present, control on an off-road vehicle spotlight is mainly realized through keys in a vehicle, and that operation is not convenient in practical use procedures. The control system comprises a spotlight module and an intelligent terminal connected with the spotlight module in a communication manner. The spotlight module comprises a spotlight, a spotlight driving module, a power supply, and a controller. The technical scheme can adjust functions and parameters of an off-road vehicle spotlight in real time through a touch screen. In addition, the system can control operating states of the off-road vehicle spotlight through the intelligent terminal, and control range is increased, and convenience is improved.

Owner:杨键 +1

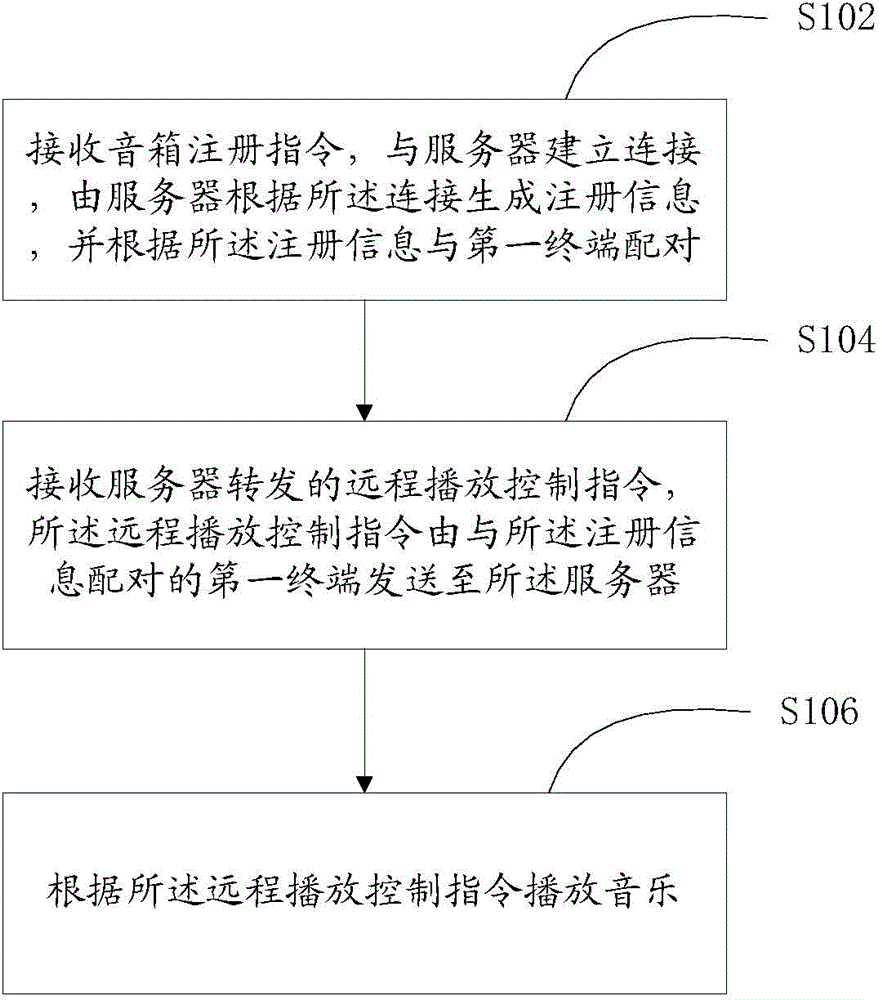

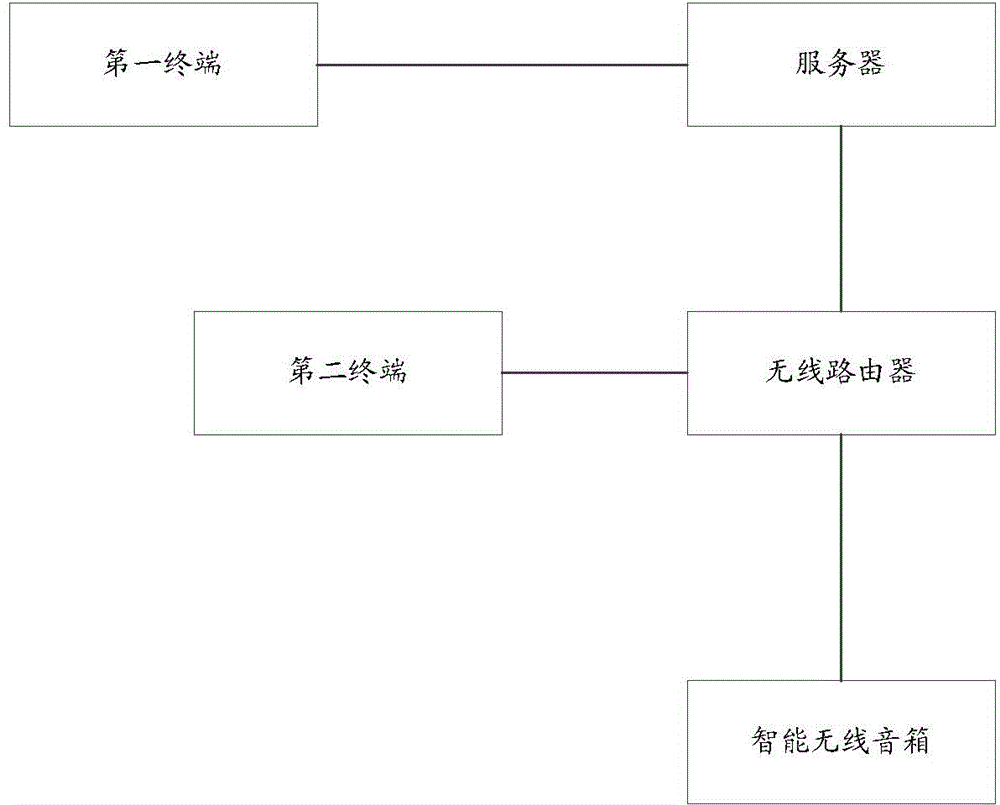

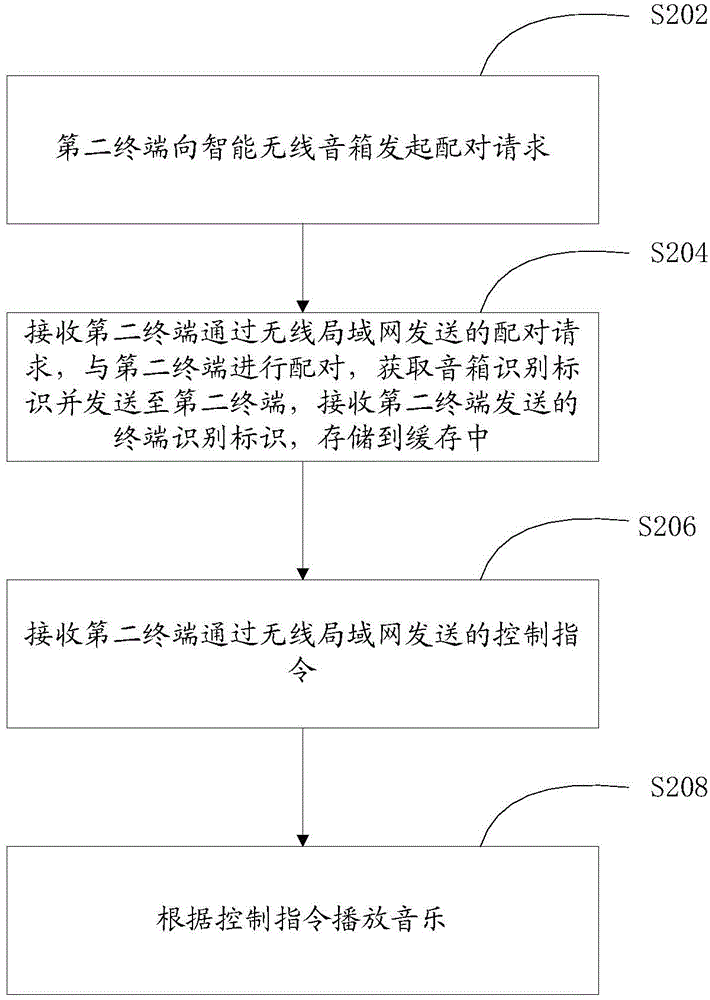

Remote play control method and apparatus of wireless sound box

The embodiment of the invention discloses a remote play control method of a wireless sound box. The method is characterized by including the steps: receiving a sound box register instruction, establishing a connection with a server, generating by the server register information on the basis of the connection, and matching the server with a first terminal on the basis of the register information; receiving a remote play control instruction forwarded by the server, the remote play control instruction sent to the server by the first terminal that matches the register information; and playing music according to the remote play control instruction. The invention also discloses a remote play control apparatus of a wireless sound box. Through adoption of the method and the apparatus, the control range of a smart wireless sound box is increased, and the operation convenience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

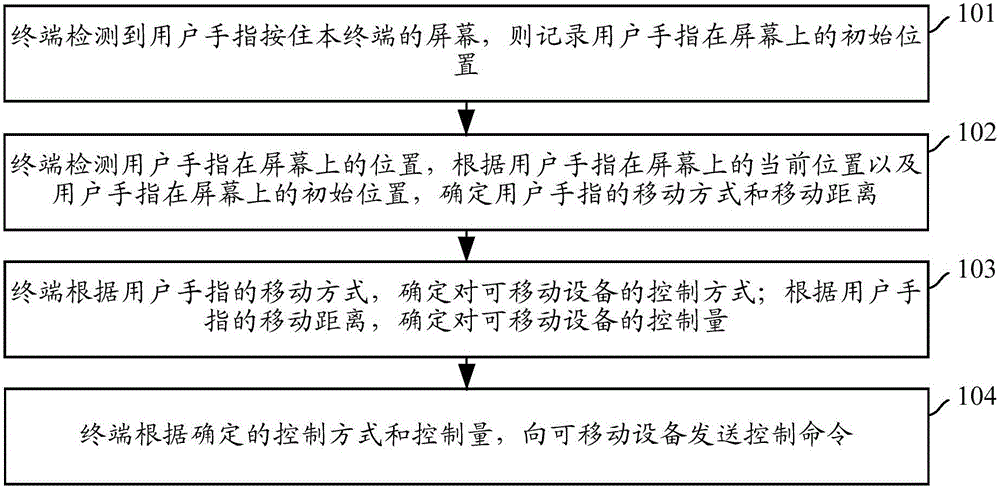

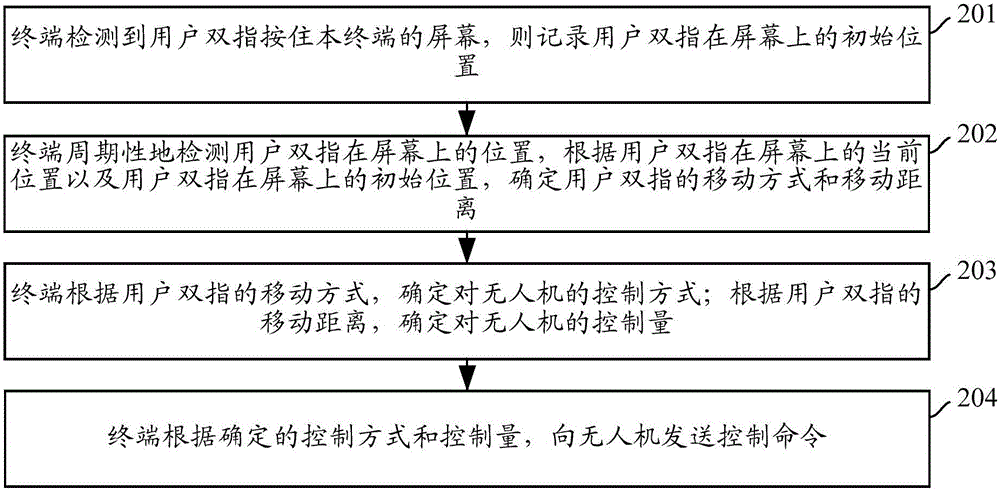

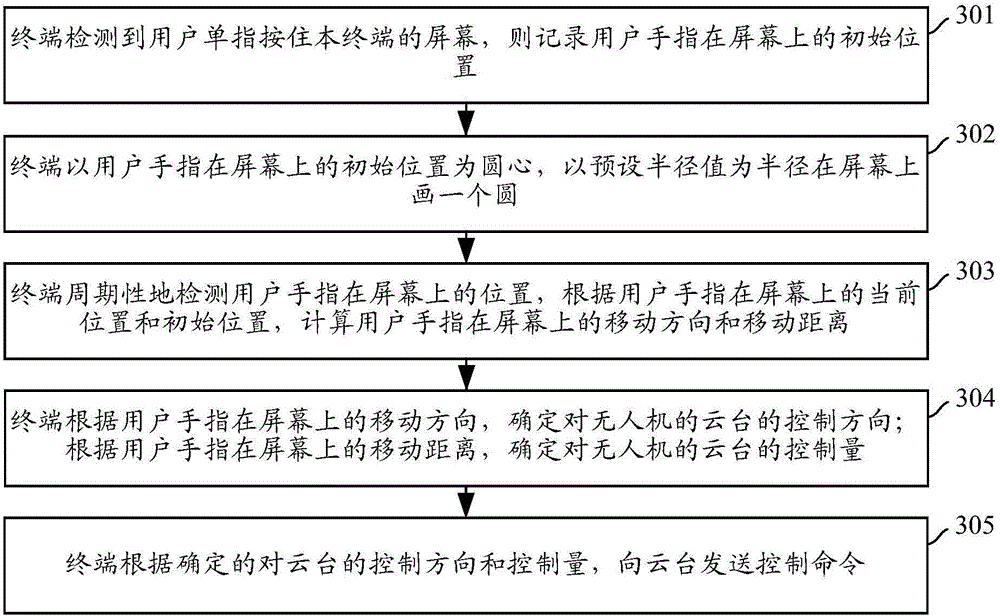

Control method and device for mobile equipment

ActiveCN105700812ARealize complex controlLarge range of controlPosition/course control in three dimensionsInput/output processes for data processingComputer terminalMobile device

The invention provides a control method and device for mobile equipment. The method comprises the steps that when a terminal detects that a screen of the terminal is pressed by a finger of a user, the initial position of the finger of the user on the screen is recorded; the terminal detects the position of the finger of the user on the screen, and a moving mode and a moving distance of the finger of the user are determined according to the current position of the finger of the user on the screen and the initial position of the finger of the user on the screen; the terminal determines a control mode on the mobile equipment according to the moving mode of the finger of the user; the control amount on the mobile equipment is determined according to the moving distance of the finger of the user; the terminal sends a control command to the mobile equipment according to the determined control mode and the determined control amount. By means of the control method and device for the mobile equipment, the control range on the mobile equipment is widened.

Owner:POWERVISION ROBOT INC

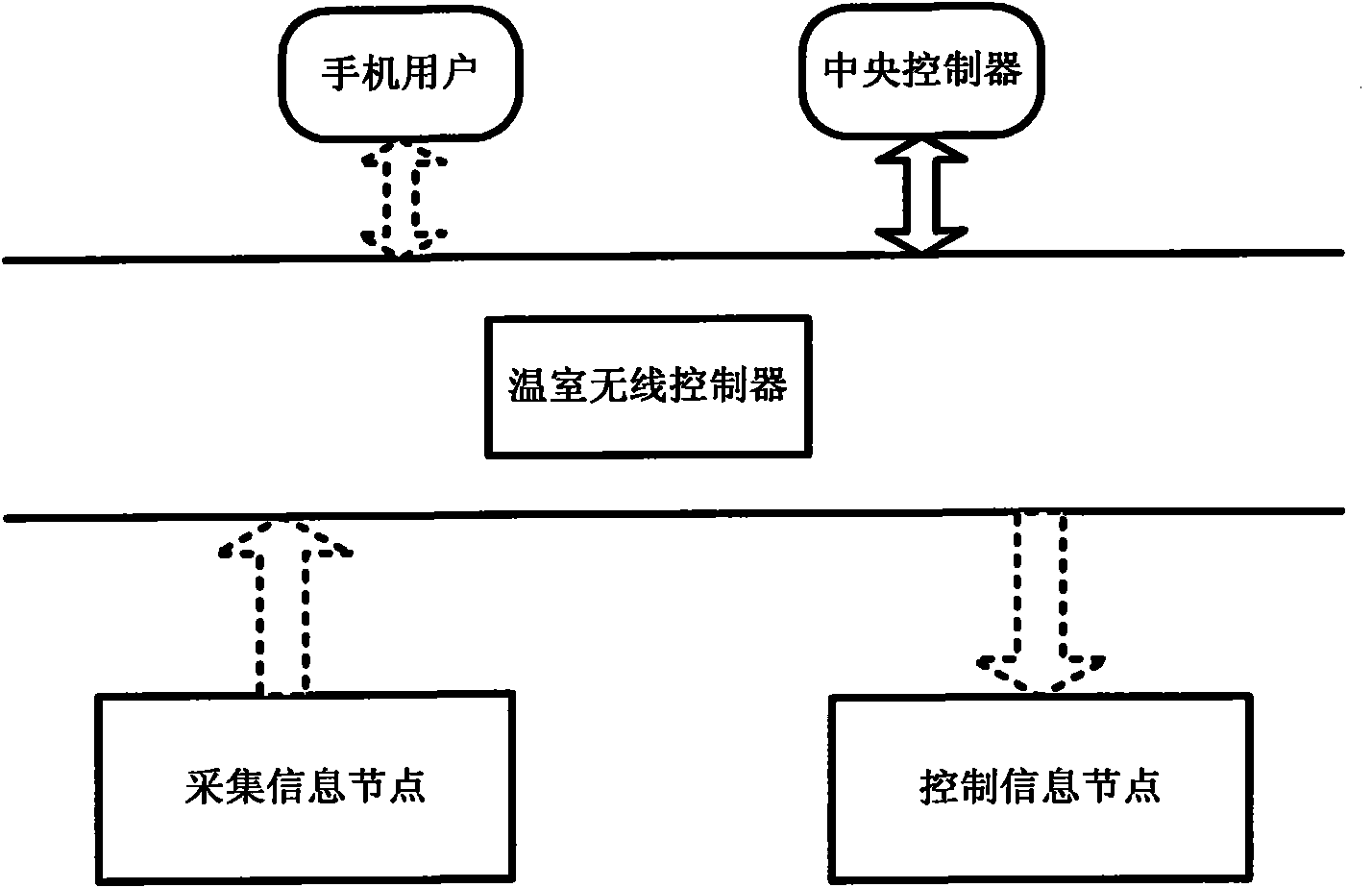

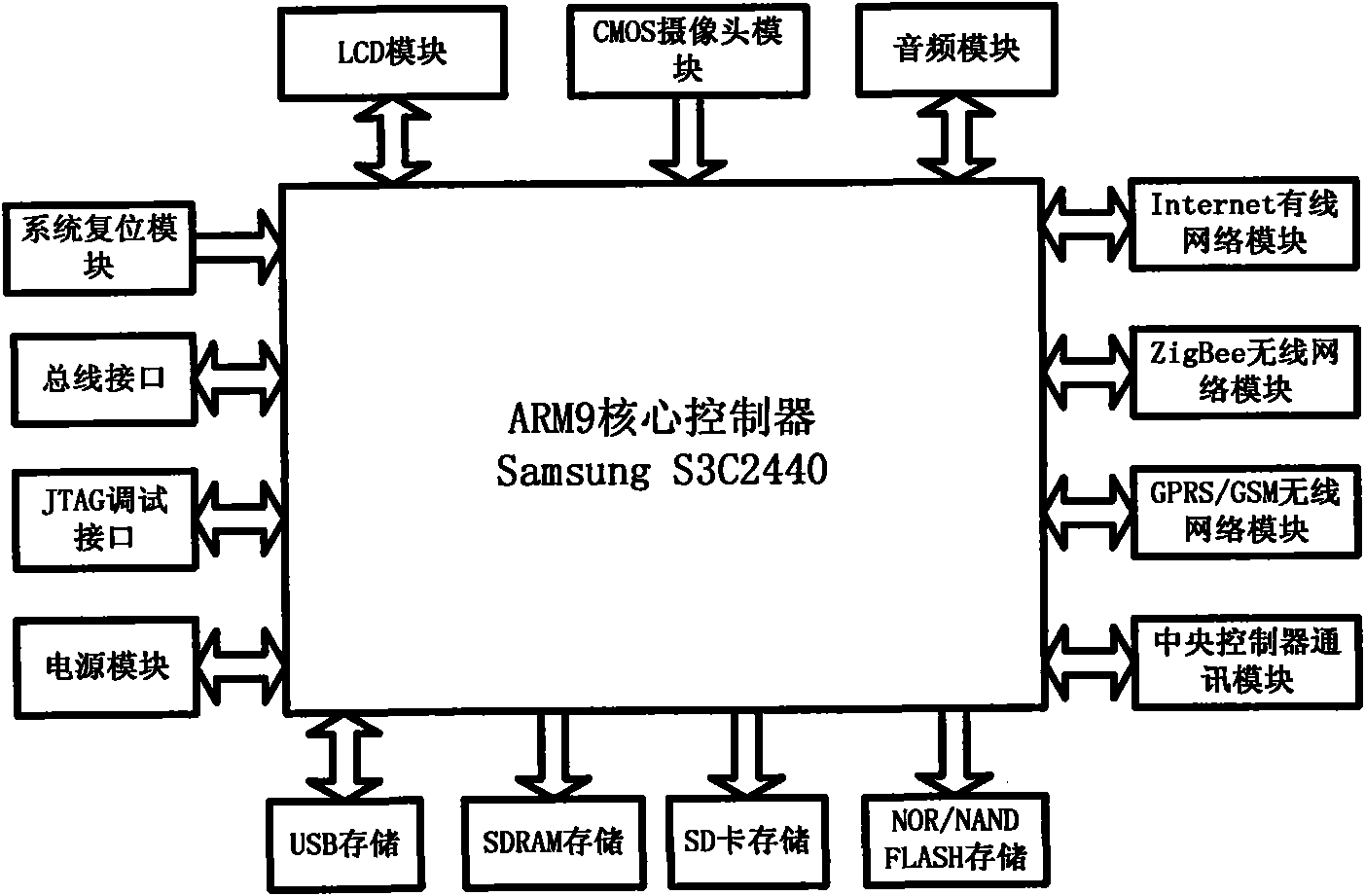

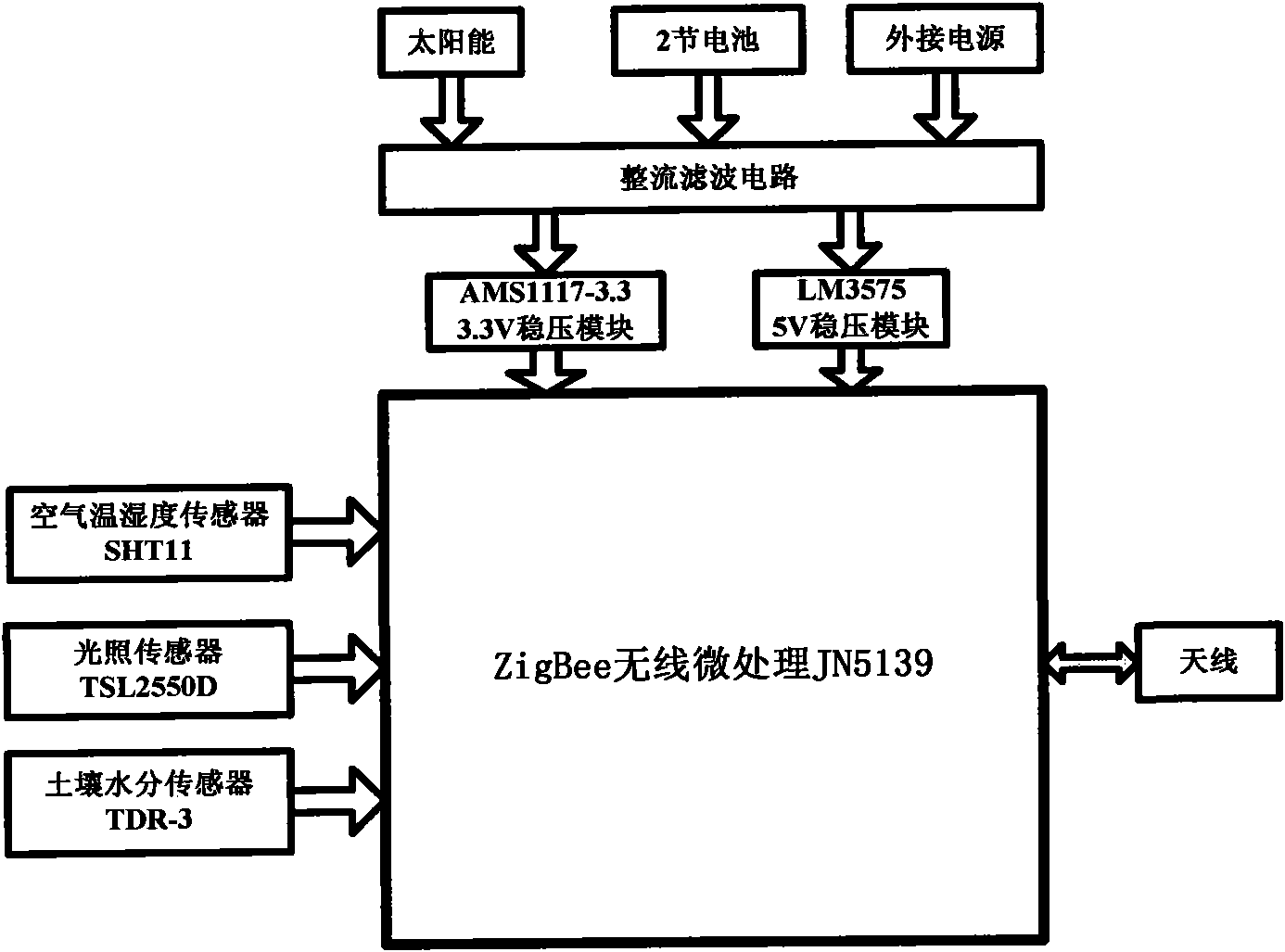

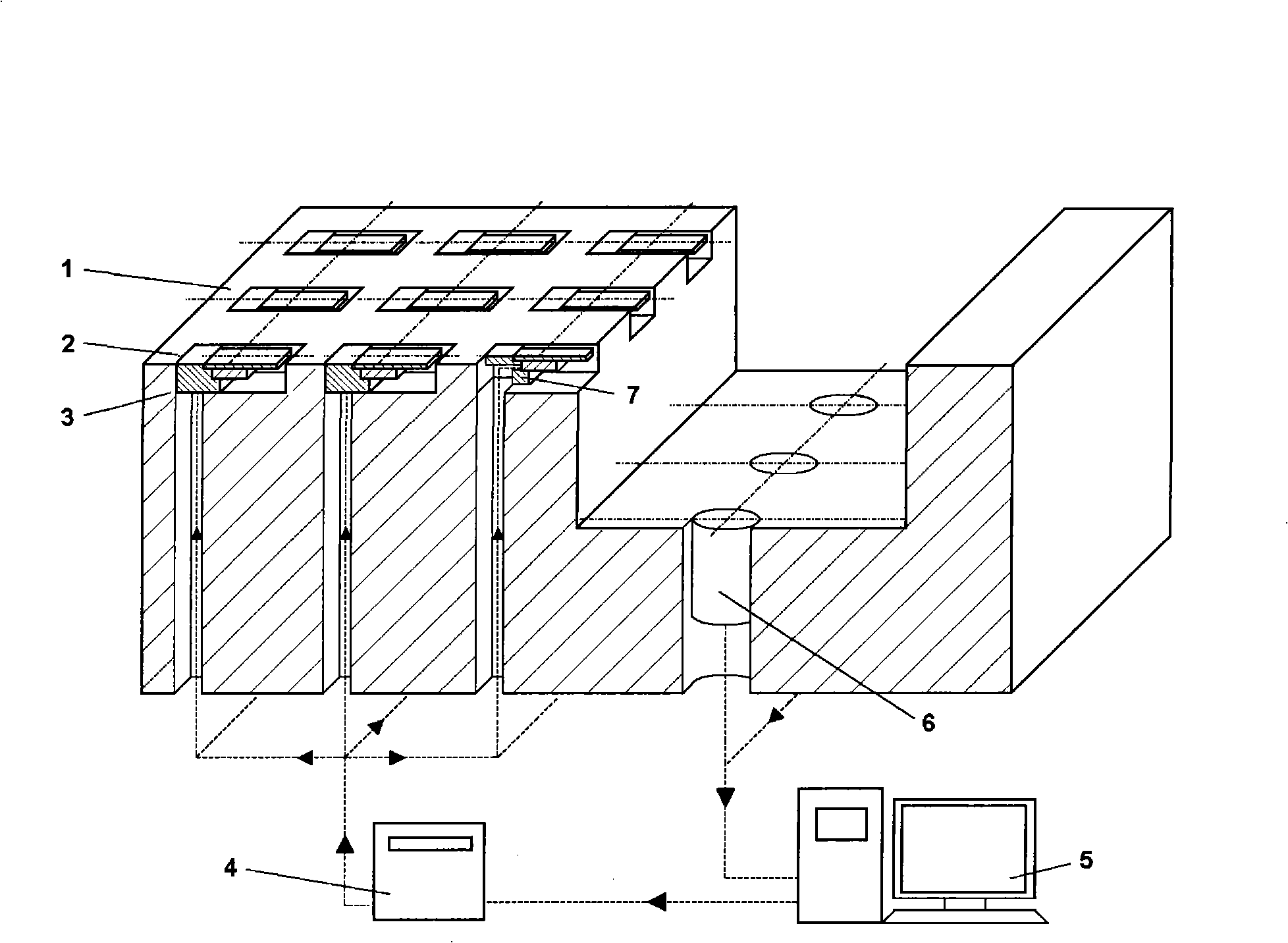

Greenhouse dripping and irrigating locale monitoring system based on wireless embedded technology

InactiveCN101833323AAvoid layout difficultiesLow costNetwork topologiesProgramme total factory controlEmbedded technologyWireless control

The invention discloses a greenhouse dripping and irrigating locale monitoring system based on a wireless embedded technology. A wireless capturing information node, a greenhouse locale wireless controller and a wireless control information node are formed into a star-shaped monitoring network; the wireless capturing information node transmits an environment parameter to the greenhouse locale wireless controller; the greenhouse locale wireless controller immediately displays and transmits a control order to the wireless control information node; and the wireless control information node drives a valve to move after receiving the control order. The greenhouse locale wireless controller transmits data to a mobile phone user through the GPRS / GSM network, and transmits the data to a central controller through various modes such as the Internet, the USB and the bus. The system abundantly makes full use of the advantages of a ZigBee short distance free wireless network and a GPRS / GSM long distance billing network, is more efficient with the embedded technology, greatly improves the monitoring function of the greenhouse locale, improves the irrigating efficiency, increases the crop yield, increases the yield for the user, and is suitable for the popularization and the application in large range.

Owner:ZHEJIANG UNIV

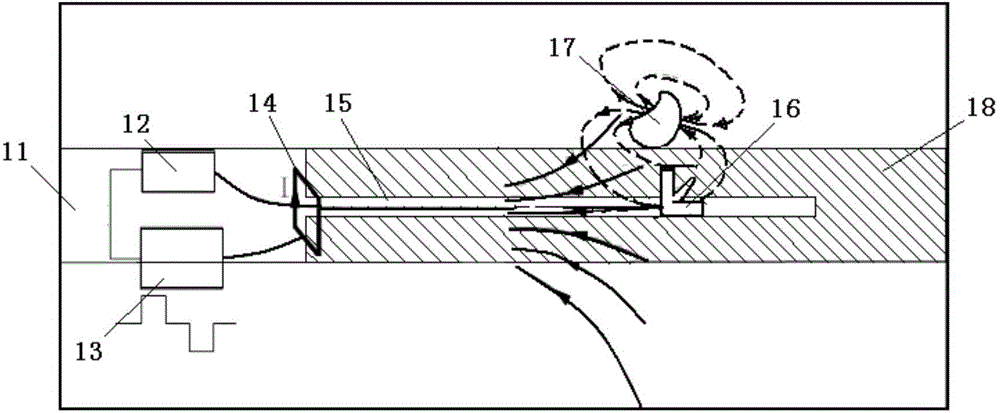

Three-dimensional cavity resonance pulsating pressure and aerodynamic noise inhibition device

InactiveCN101264798AImprove carrying capacityEasy to achieve precise controlAir-flow influencersControl signalCavity resonance

The invention relates to a fluctuating pressure and pneumatic noise suppression device for three-dimensional cavity resonates, belonging to flow control technical field, comprising an aligned array groove, an actuating reed, a piezoelectric ceramic piece, an installing seat, a special high voltage power supply for piezoelectric ceramic, a dynamic pressure transducer and a computer with an A / D acquisition card. The dynamic pressure transducer is arranged under the cavity, and is connected with the computer with A / D acquisition card by the through hole under the cavity. The actuating reed is arranged in the aligned array groove. The piezoelectric ceramic piece is pasted on the bottom of the reed to be the excitation element. The piezoelectric ceramic piece is connected with the special high voltage power supply for piezoelectric ceramic. The piezoelectric ceramic piece produces extensional deformation under the control signal excitation, and drives the actuating reed to vibrate, the oscillation frequency of the shear layer is changed, the cavity resonates is broken down, and the cavity pneumatic noise is suppressed. The fluctuating pressure and pneumatic noise suppression device for three-dimensional cavity resonates has the advantages of wide adjustable range, realizing the accurate control of the phased array for the three-dimensional space of the cavity by the real time feedback of the fluctuating pressure of cavity.

Owner:SHANGHAI JIAO TONG UNIV

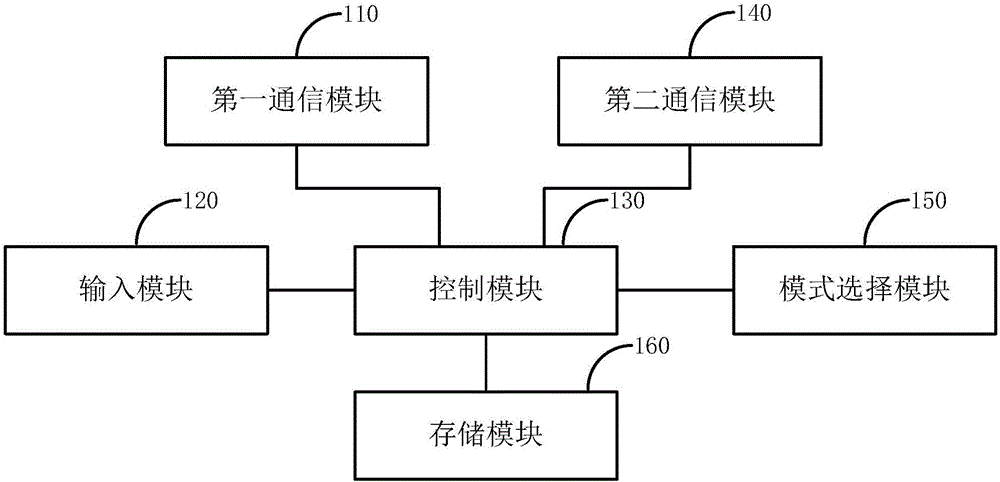

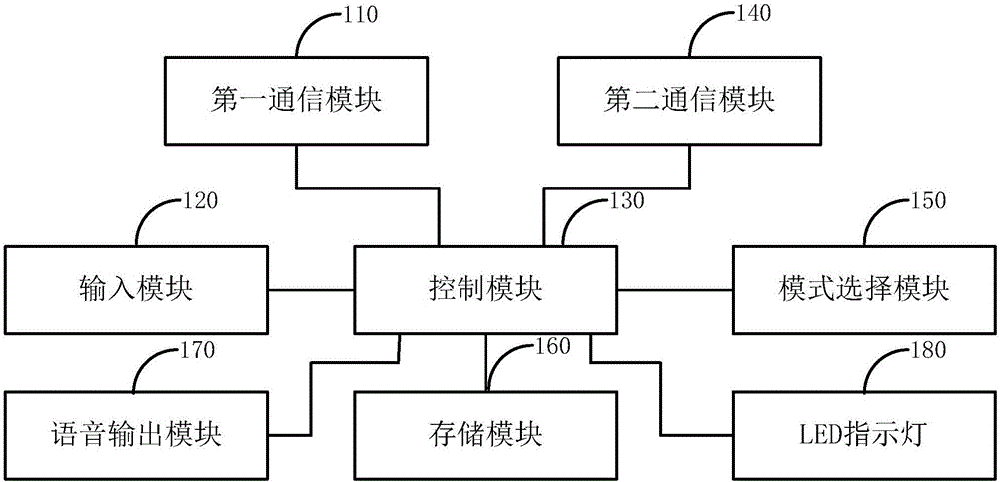

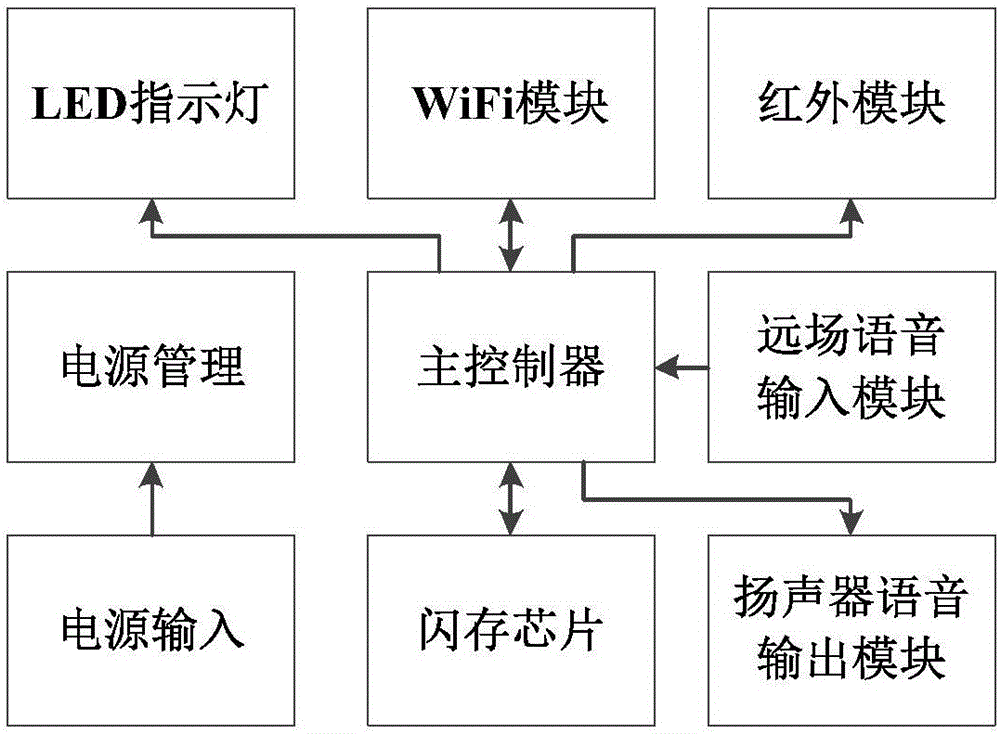

Intelligent center control auxiliary unit equipment and method and system for achieving intelligent control

InactiveCN106681292AExpand pickup rangeLarge range of controlTransmission systemsProgramme total factory controlIntelligent controlReal-time computing

The invention discloses intelligent center control auxiliary unit equipment and a method and system for achieving intelligent control. The intelligent center control auxiliary unit equipment comprises a first communication module, an input module, a control module and a second communication module. The first communication module is used for being in charge of communication between a control module and a server and / or communication between the control module and intelligent center control host equipment. The input module is used for acquiring a user instruction. The control module is used for controlling the first communication module to send the user instruction to the server or the intelligent center control host equipment, receiving a control instruction sent by the server or the intelligent center control host equipment to a target intelligent household appliance through the first communication module and sending the control instruction to the second communication module. The second communication module is used for sending the control instruction to the corresponding target intelligent household appliance. The intelligent center control auxiliary unit equipment and the intelligent center control host equipment are matched for use, and the pickup range and the control range of the intelligent center control host equipment can be widened.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

Method for detecting radial water cut abnormal body in underground coal mine drilled hole

ActiveCN104090306AExtended Radial Control RangeLow densityElectric/magnetic detection for well-loggingWater cutCoal

A method for detecting a radial water cut abnormal body in an underground coal mine drilled hole comprises the following steps that firstly, a detection hole is drilled in a roadway under the shaft , an emission wire frame is arranged at the position of a hole opening of the detection hole, and an emission receiving device is arranged; secondly, a three-component receiving probe in the detection hole is fixed in a plurality of design measuring points according to the same angle, and meanwhile an inclination measuring device is utilized for recording direction angles, inclined angles and transverse rolling angles of the positions of the measuring points; thirdly, measuring information of all measuring points is respectively recorded, and an abnormal response is judged; fourthly, the position of an emission device is moved, or the angle of the emission device is changed, and the second step and the third step are repeated; fifthly, collected data are processed, and information of the position of the low-resistance abnormal body around the drilled hole is obtained. According to the method, the positioning function of the low-resistance abnormal body in the radial direction of the drilled hole can be provided, the control range of the drilled hole is expanded, the head-on advanced detection precision of the roadway is enhanced, a water contained construction object existing possibly can be pointed out, and the next-step drilling direction can be pointed out.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

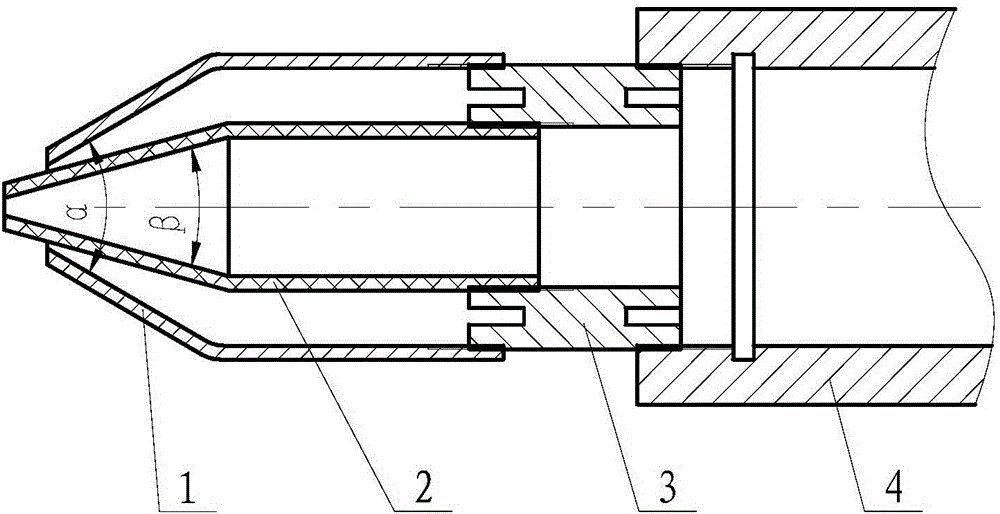

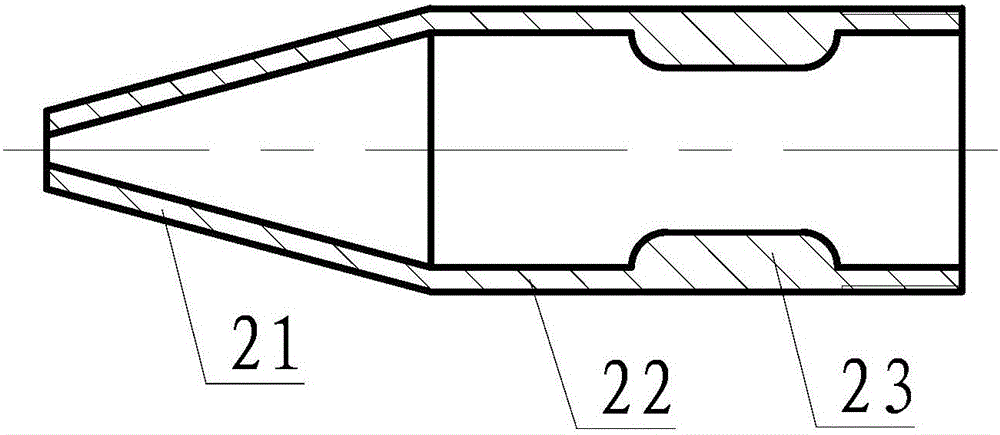

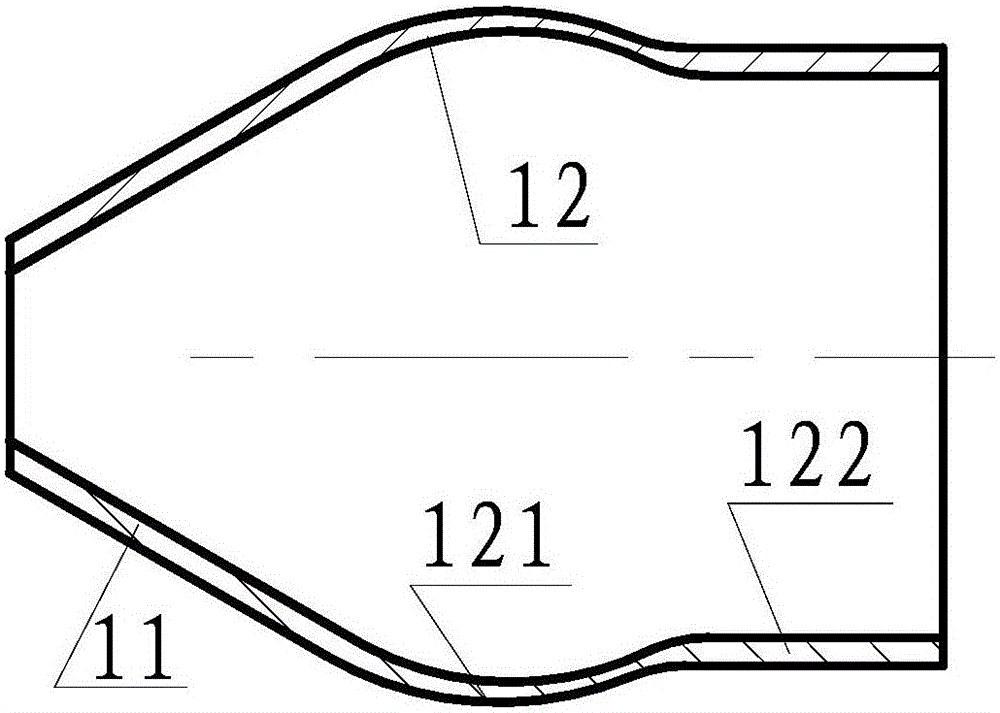

Micro sprinkler with sprinkling modes variable

The invention discloses a micro sprinkler with sprinkling modes variable. The micro sprinkler comprises an atomizing nozzle, a rectifying nozzle, a connecting sleeve and a main pipeline. The connecting sleeve is connected with the main pipeline through threads. The rectifying nozzle is assembled on the inner side of the connecting sleeve through threaded connection. The atomizing nozzle is assembled on the outer side of the connecting sleeve through threaded connection. The rectifying nozzle and the atomizing nozzle are concentrically installed. The rectifying nozzle is located in the atomizing nozzle. The amplification segment of the rectifying nozzle is a gradually-shrunk conical pipe made of elastic materials. The diameter of an outlet of the rectifying nozzle changes together with working pressure. By adjusting the outlet modes of the micro sprinkler through the working pressure, switching operation between a spraying state and a far-distance large-flow sprinkling state can be achieved.

Owner:JIANGSU UNIV

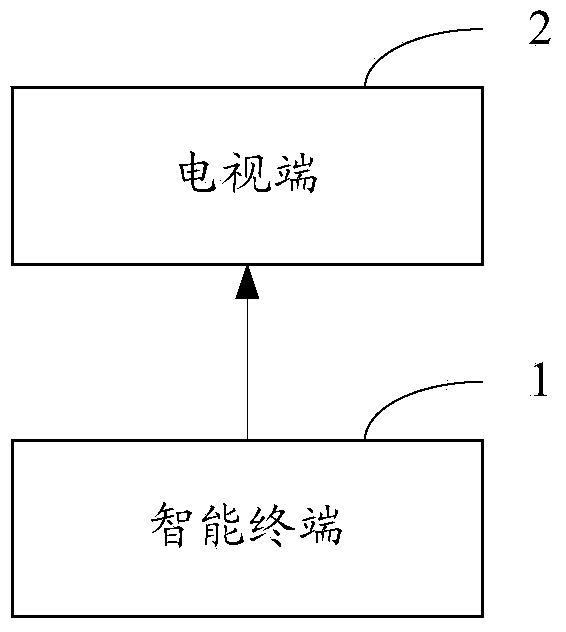

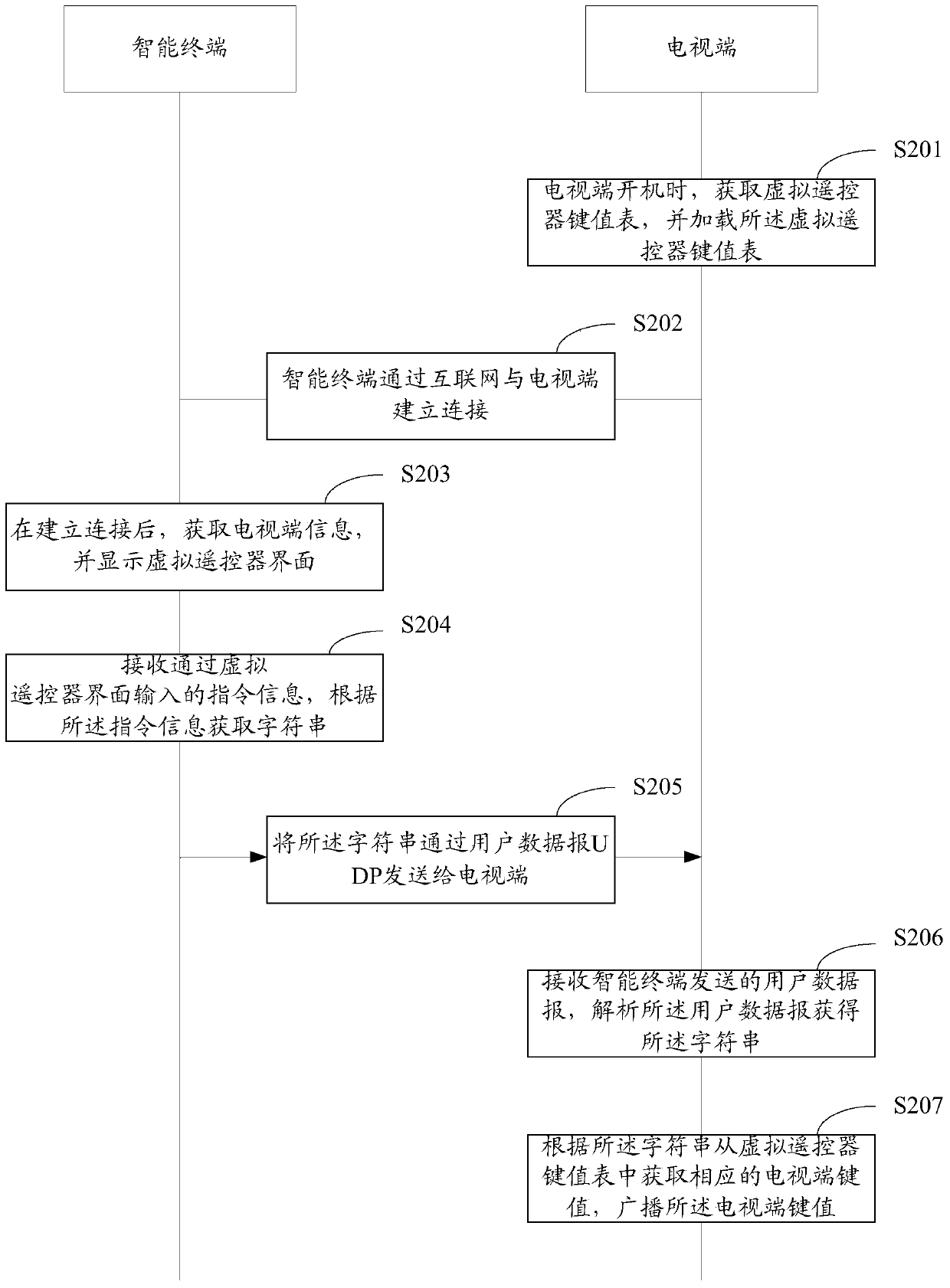

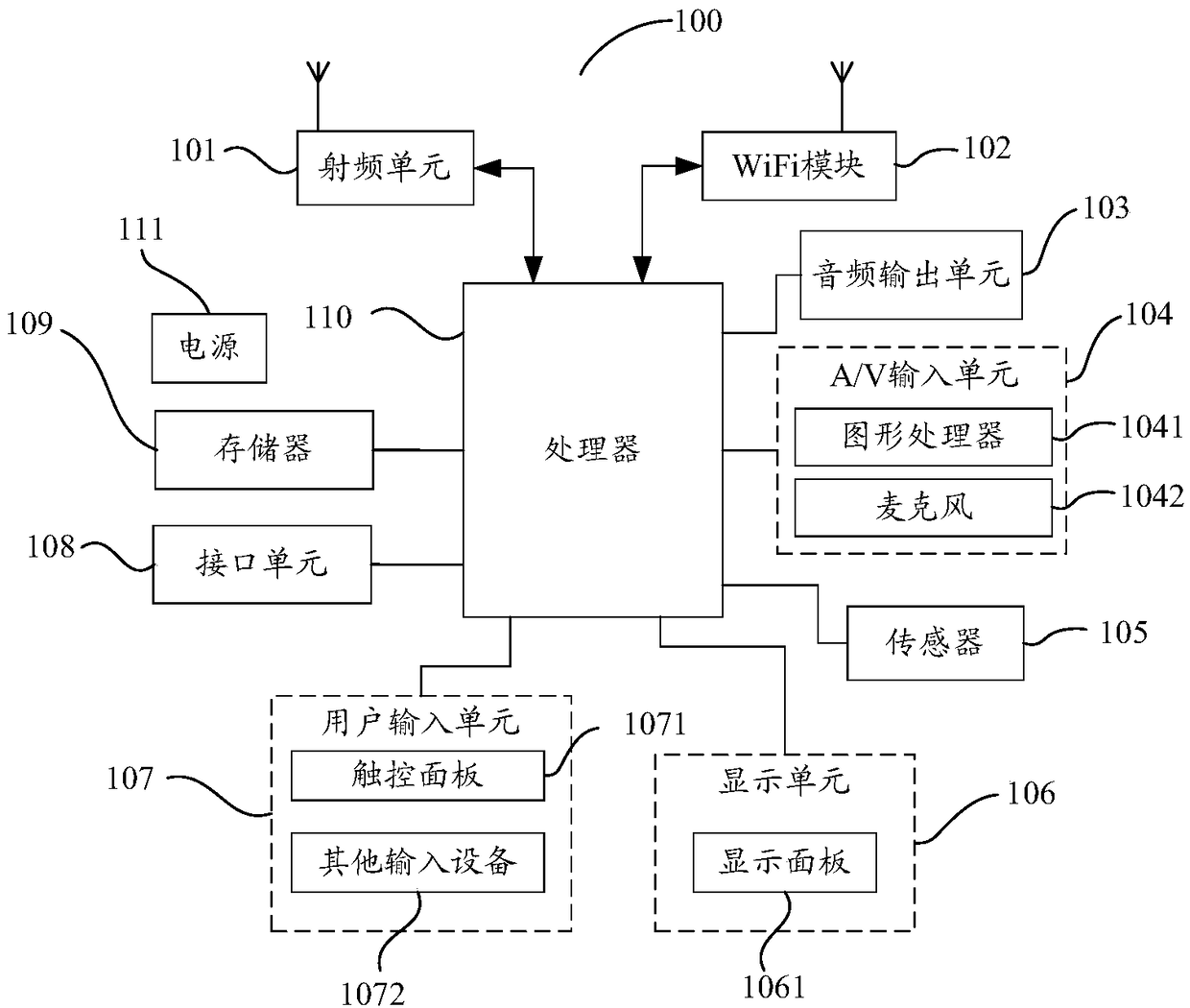

Remote control method and system as well as TV terminals

ActiveCN103702162AImprove experienceRealize voice remote controlSelective content distributionRemote controlTechnology of television

The invention is suitable for the technical field of TVs and provides a remote control method and system as well as TV terminals. The method comprises the steps that intelligent terminals establish connections with the TV terminals through the Internet; after establishing connections, the intelligent terminals acquire information of the TV terminals and display virtual remote control unit interfaces; the intelligent terminals receive command information input by users via the virtual remote control unit interfaces, acquire corresponding character strings according to the command information and send the character strings to the TV terminals via the user datagram protocol (UDP); the TV terminals receive the UDP sent by the intelligent terminals and analyze the UDP to acquire the character strings; the TV terminals acquire corresponding TV terminal key values from tables of key values of the virtual remote control units according to the character strings and broadcast the TV terminal key values. The method has the beneficial effects that remote control and voice remote control of the TV terminals can be achieved via the intelligent terminals; the method is convenient and simple to operate; the compatibility of the intelligent terminals as the remote control units and the controlled ranges of the TVs are enlarged.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

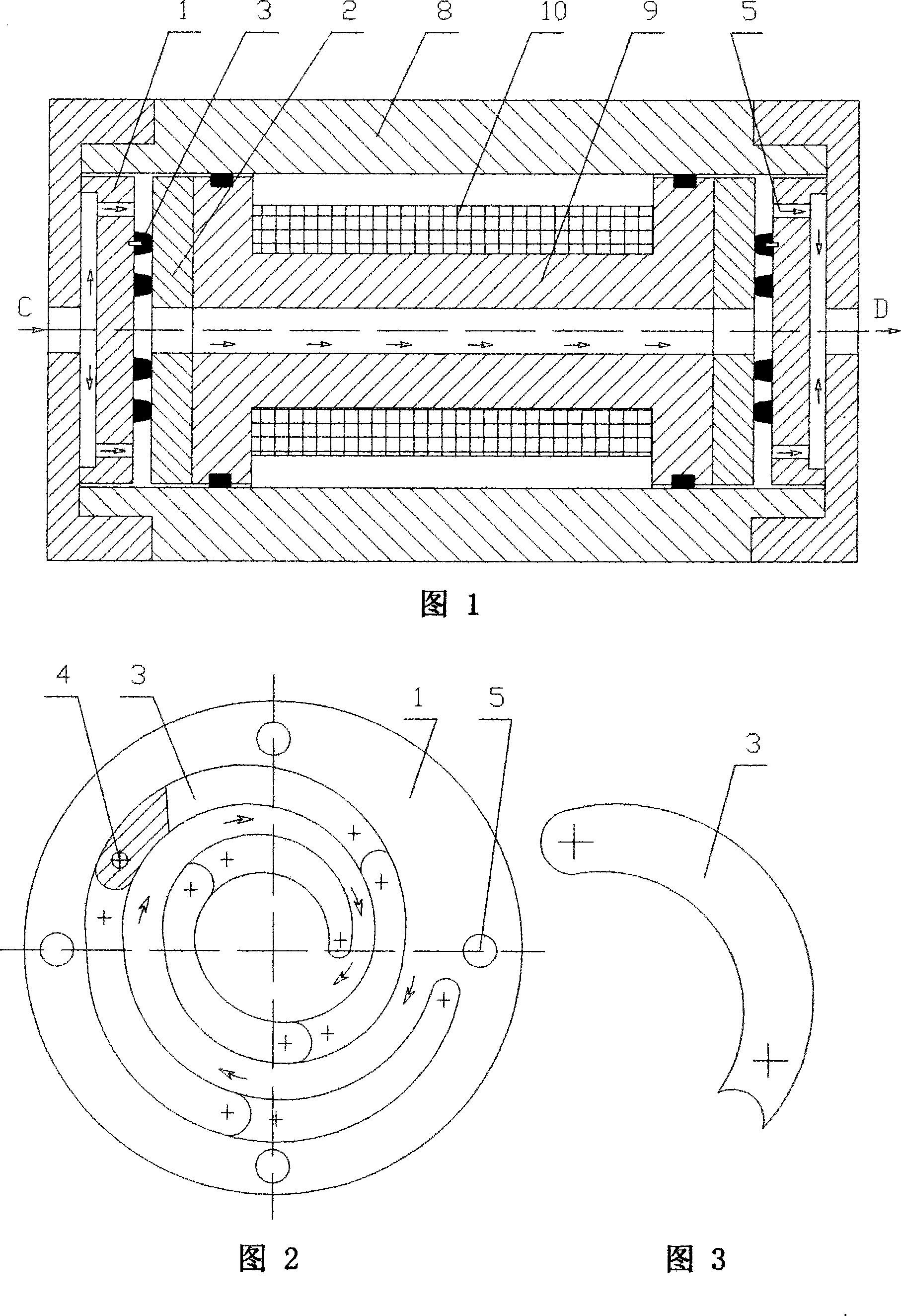

Magnetorheological valve of helical fluid channel

InactiveCN101245799ASimple structureEasy to manufacture and installNon-rotating vibration suppressionFluid dynamicsPath lengthMagnetorheological fluid

The invention provides a magneto-rheological fluid (MRF) valve of a spiral liquid passage, which mainly solves the problem of nonlinear flow of the MRF along the liquid passage in the MRF valve, enlarges the flowing path length of the electro-magneto-rheological fluid, improves the utilization ratio of the line of magnetic force, improves the pressure difference of the controllable fluid of the electro-magneto-rheological fluid under the equivalent current intensity and unchangeable magnetic gap, and achieves the objects of saving energy and reducing the dimension of the MRF valve. The proposal of the MRF valve is that the corresponding end surface of a positioning disc to a magnetic guide disc is provided with a nonlinear liquid passage. The MRF valve has the advantages of simple structure of MRF valve, convenient manufacture and installation, increasing no volumes of the MRF valve, and enlarging the control range of the MRF valve.

Owner:黑龙江科大科技开发有限公司

Process for pumping and exploiting coal bed gas by together using ground well drilling and underground hole drilling

The invention relates to a coal bed gas exploiting technique, in particular to a process for pumping and exploiting coal bed gas by together using ground well drilling and underground hole drilling, solving the problem of low efficiency of the traditional method for pumping and exploiting the coal bed gas. The process comprises the following steps of: (1) carrying out well drilling on the ground; (2) carrying out long hole drilling in underground coal beds; (3) making drilled holes and ground drilled wells crosslink and communicate in the appointed points by utilizing an orientation technique of a long hole drilling machine; (4) effectively closing the underground long drilled holes; (5) fracturing the ground drilled wells and the underground long drilled holes by utilizing fracturing equipment on the ground; (6) after fracturing, closing the ground drilled wells; and (7) opening the closed ends of the underground long drilled holes and then installing relevant pumping and discharging pipelines connected with underground pumping and discharging systems. The process improves the pumping and exploiting speed and efficiency of the coal bed gas, shortens the construction period of coal bed gas pumping and exploiting engineering and saves the construction investment of the coal bed gas pumping and exploiting engineering.

Owner:山西蓝焰煤层气集团有限责任公司

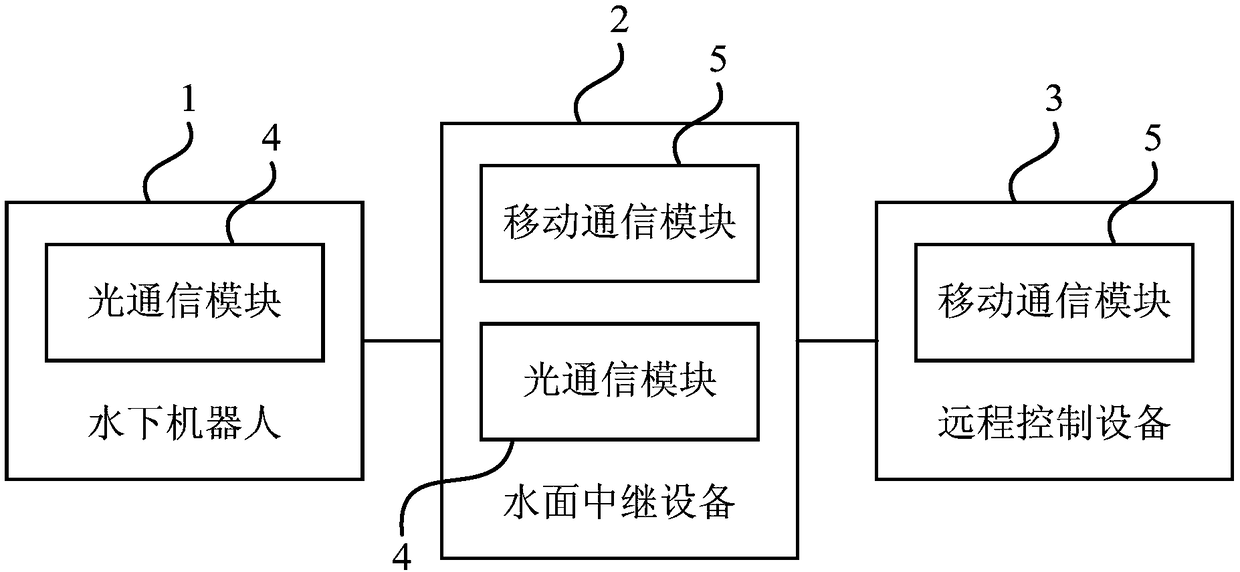

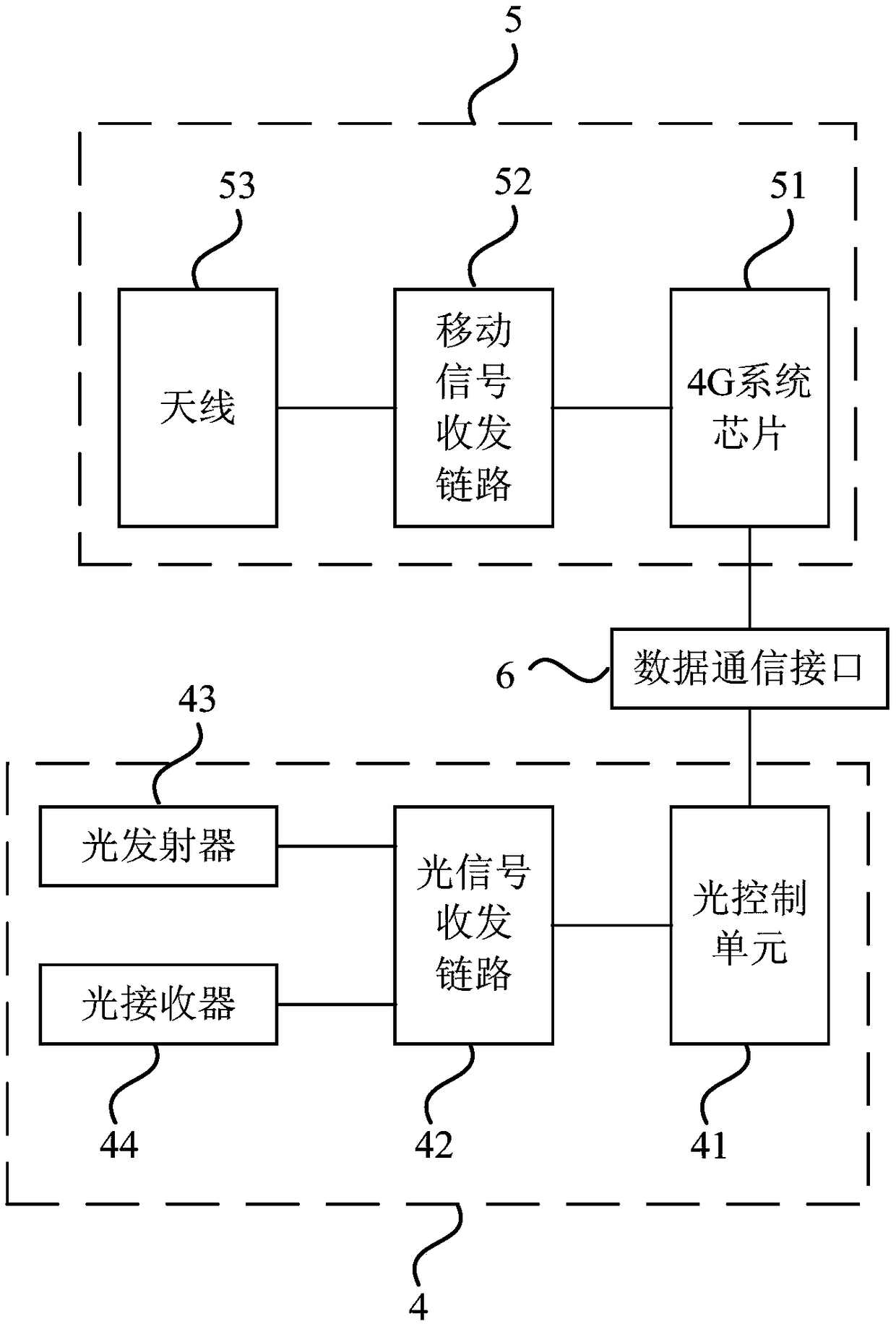

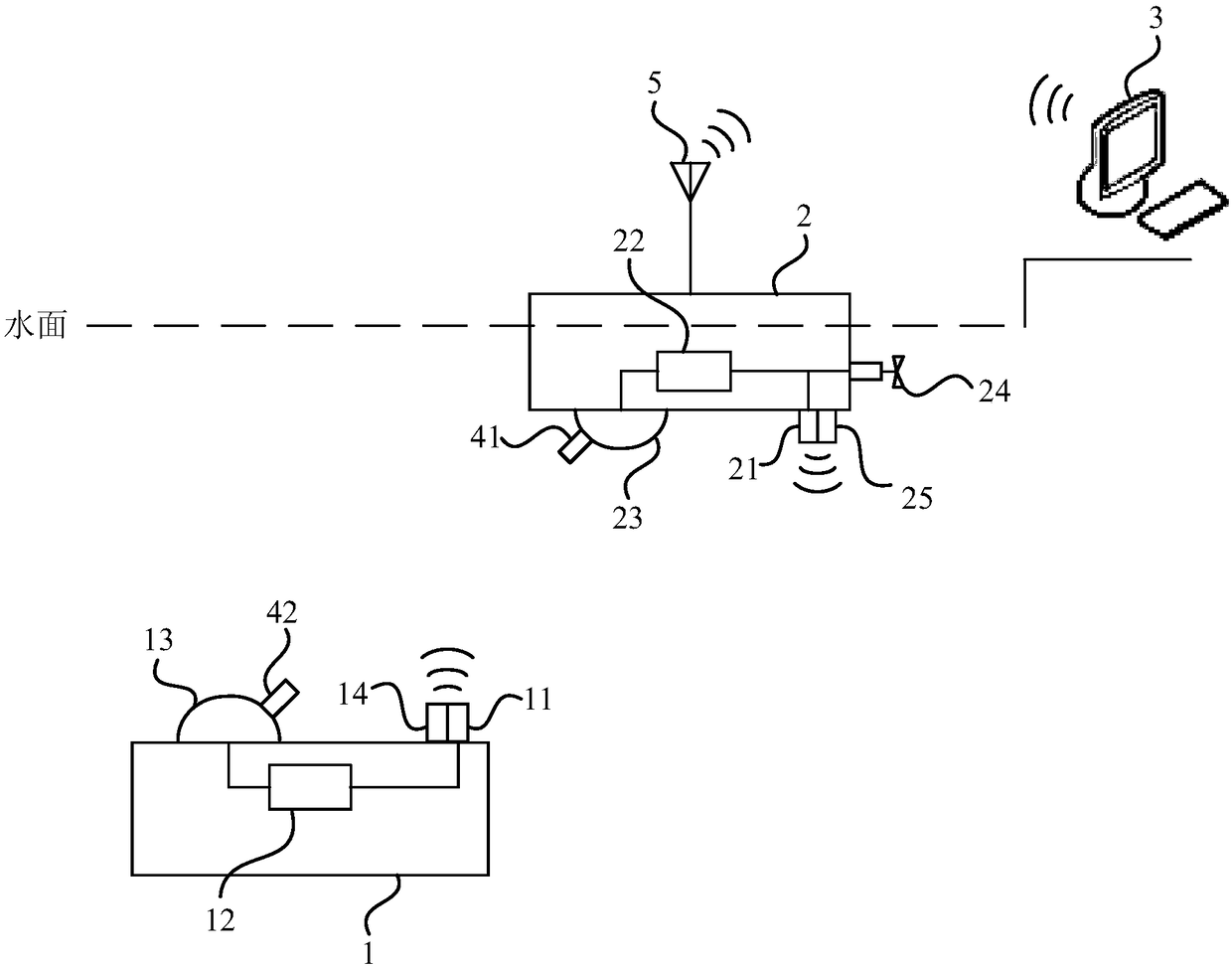

Underwater control system

PendingCN108809404ALarge range of controlSave manpower and material resourcesRadio transmissionPosition/course control in two dimensionsControl systemMarine engineering

The embodiment of the invention discloses an underwater control system. The system comprises an underwater robot, water surface relay equipment and remote control equipment; an optical communication module for performing optical communication is arranged in each of the underwater robot and the water surface relay equipment; a mobile communication module for performing mobile communication is arranged in each of the water surface relay equipment and the remote control equipment, the water surface relay equipment establishes the communication connection between the underwater robot and the remote control equipment through the optical communication module and the mobile communication module. Through the technical scheme disclosed by the embodiment of the invention, the control cost of the underwater robot can be reduced, the manpower and material resource are saved, and the control rage of the underwater robot is enlarged.

Owner:深圳鳍源科技有限公司

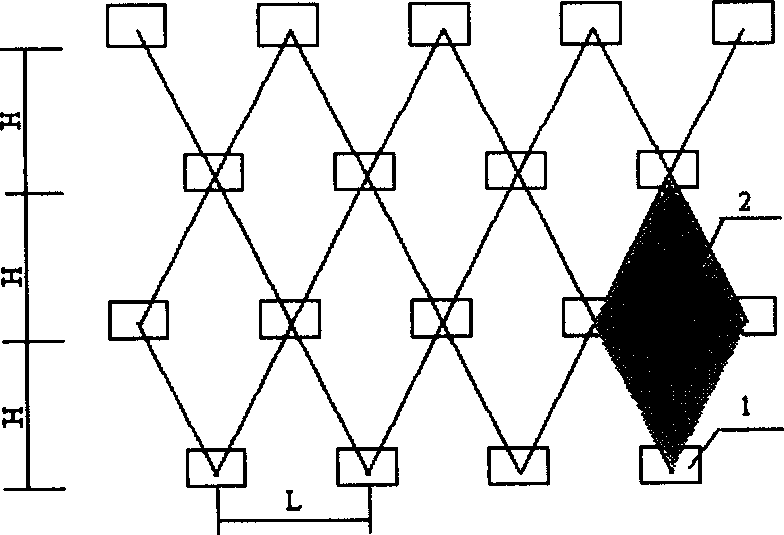

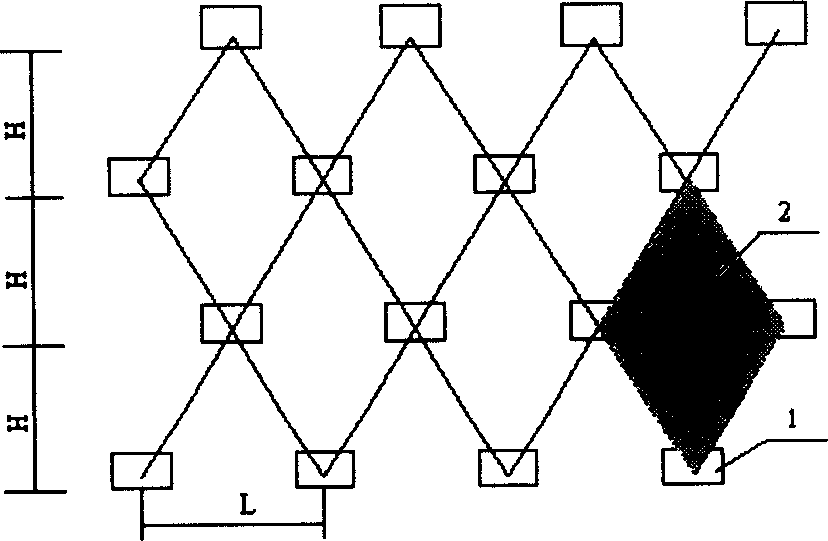

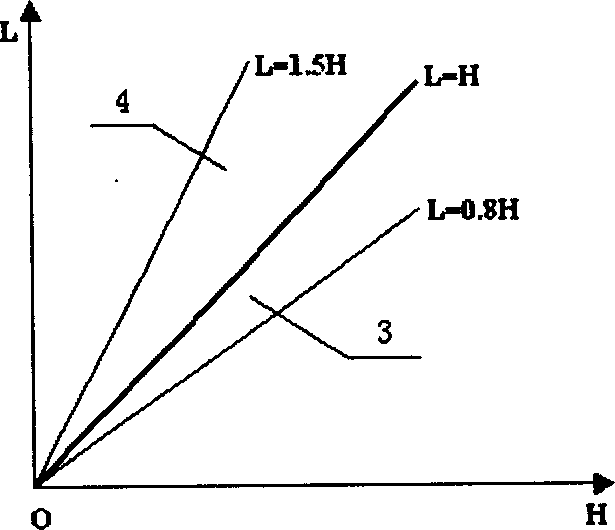

Sill-free sublevel caving method with drift space greater than sublevel height

InactiveCN1734055ALarge range of controlReduce digging ratioUnderground miningSurface miningSpelunkingUltimate tensile strength

This invention relates to an underground mining technology, especially to a sectionalized avalanche mining method without bottom pole whose route space is more than the sectionalized height. The bodily technique method as follows: after choosing the sectionalized height, confirming the route space L according the following methods: the route space L is more the sectionalized height H, the route space L =(1.0-1.5).sectionalized height H. This invention is mainly applied in the underground mining, and this technique method can improve the control range of each route greatly, and save the mining quantity, and reduce the ratio of grubbing and plucking, and improve the mining efficiency.

Owner:宝钢集团上海梅山有限公司

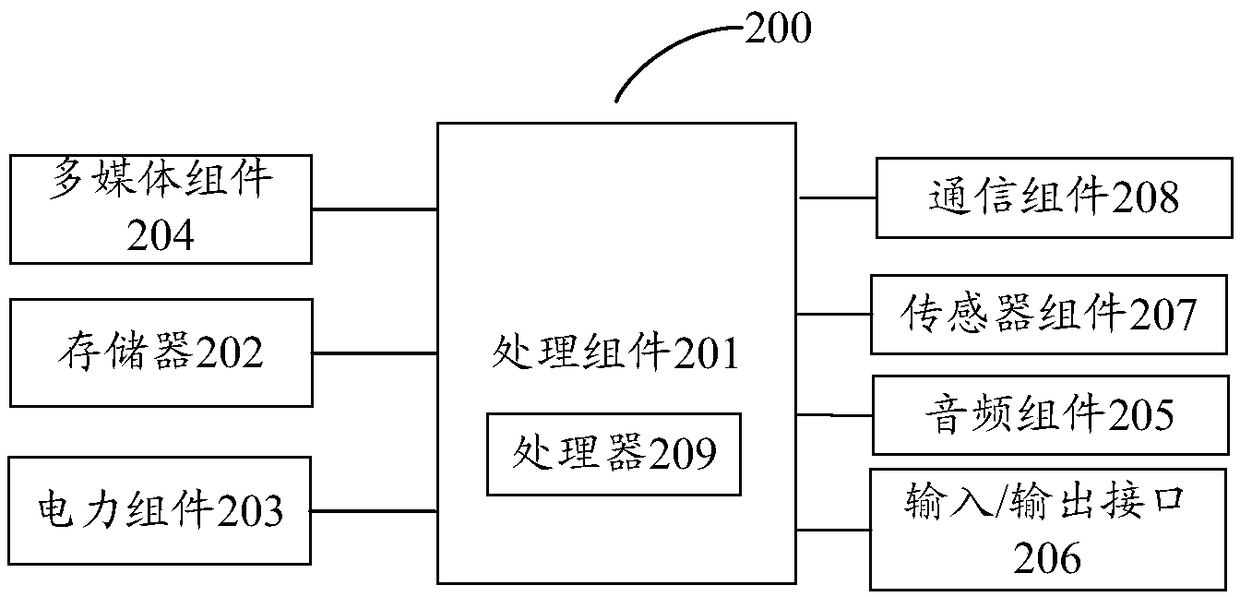

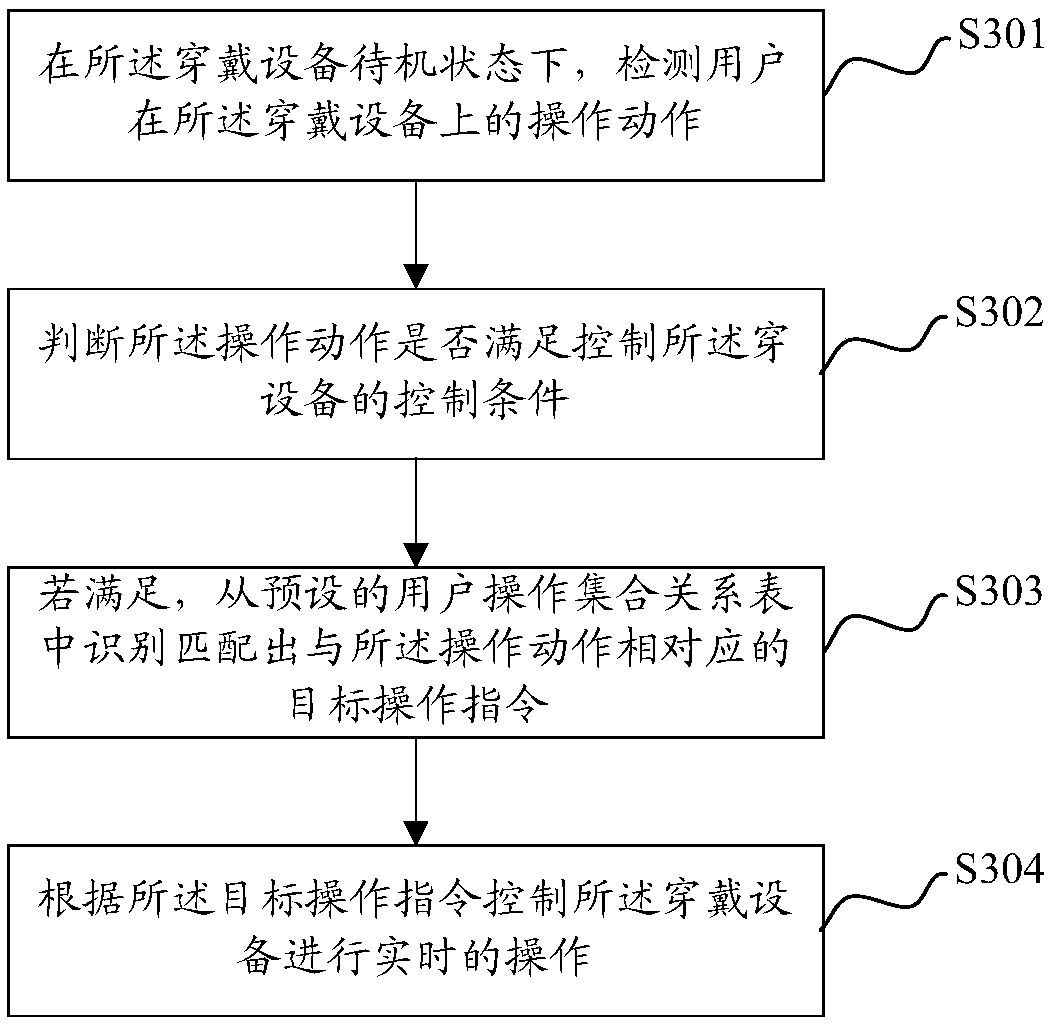

Control method of wearable device, wearable device and computer readable storage medium

InactiveCN108874121AEasy to controlLarge range of controlInput/output for user-computer interactionGraph readingUsage experienceEmbedded system

The invention discloses a control method of a wearable device, a wearable device and a computer readable storage medium. An operation action of a user on the wearable device is detected in a standby state of the wearable device; when the operation action is judged to meet a control condition of controlling the wearable device, a target operation instruction corresponding to the operation action isrecognized and matched from a preset user operation set relation table; the wearable device is controlled to carry out real-time operation according to the target operation instruction; and the operation on the wearable device is determined by detecting a corresponding relation between the operation action on the wearable device and the target operation instruction, so that the wearable device can be controlled in a position except a display screen, the problem that the operation on the display screen of the wearable device of the user is inconvenient and inaccurate is solved, the operation is relatively simple, the control range of the wearable device by the user is greatly expanded, and the usage experience of the user for the device is improved.

Owner:NUBIA TECHNOLOGY CO LTD

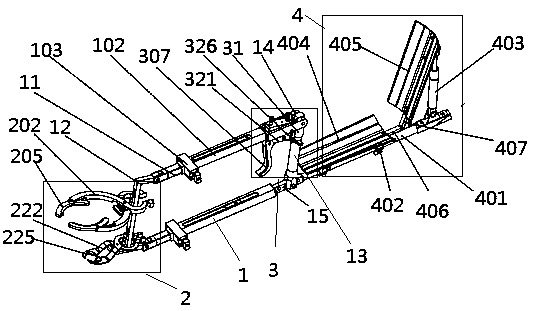

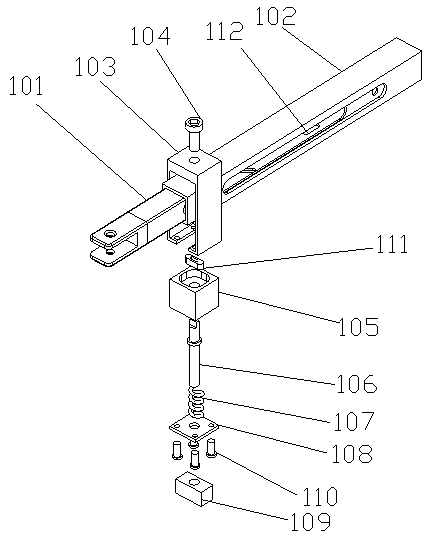

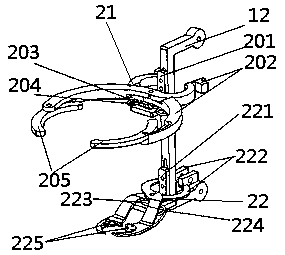

Notch stem remaining type pineapple picking auxiliary tool

The invention discloses a notch stem remaining type pineapple picking auxiliary tool. The notch stem remaining type pineapple picking auxiliary tool comprises a telescopic bracket; a self-adaptive clamping shearing integrated device is arranged at the front end of the telescopic bracket; a transmission mechanism which is connected with the self-adaptive clamping shearing integrated device is arranged in the middle of the telescopic bracket; a weight bearing auxiliary mechanism is arranged at the tail end of the telescopic bracket; the telescopic bracket comprises two telescopic pieces; one endof one of the telescopic pieces is hinged to one end of the other of the telescopic pieces through a supporting frame, and the other end of one of the telescopic pieces is hinged to one end of the other of the telescopic pieces through a handle; the two telescopic pieces, the supporting frame and the handle are connected to form a planar four-rod mechanism. The notch stem remaining type pineapplepicking auxiliary tool has the characteristics of high picking efficiency, high adaptability, and convenience in use.

Owner:WENZHOU UNIVERSITY

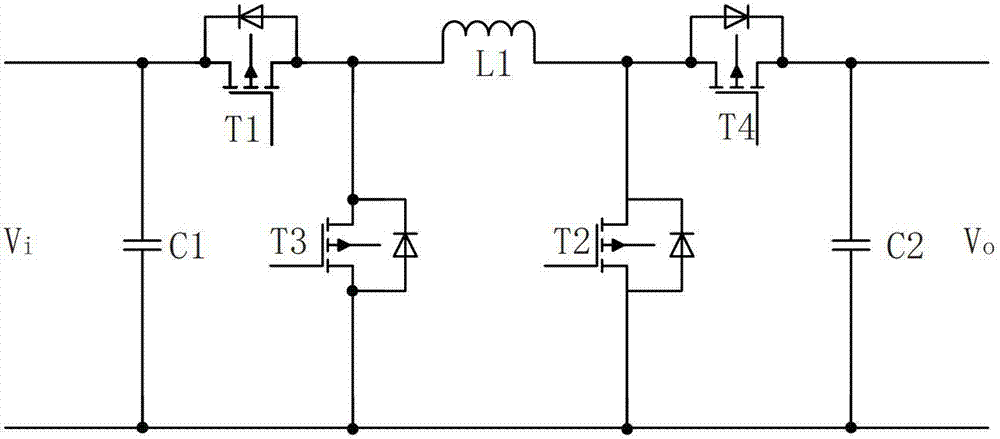

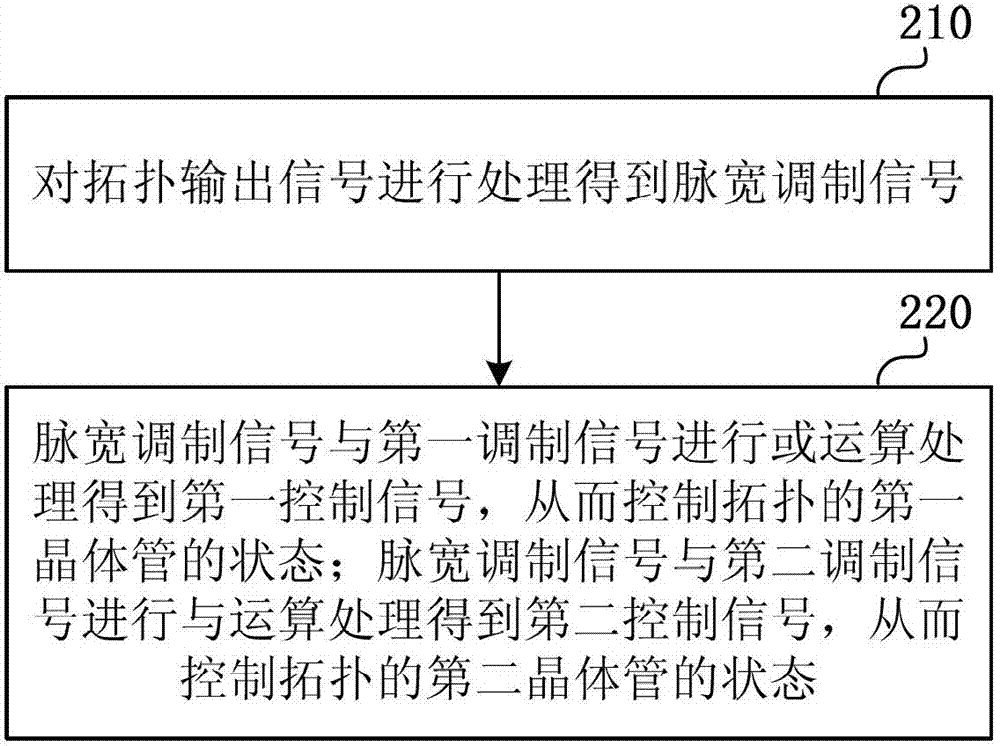

Control method and device

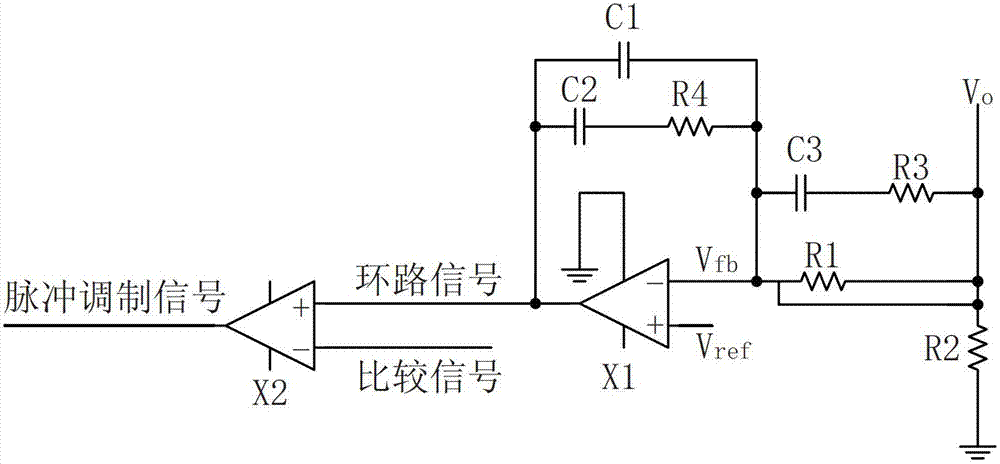

ActiveCN102739052AAchieve smooth switchingLarge range of controlDc-dc conversionElectric variable regulationControl signalControl circuit

The embodiment of the invention relates to a control method and device which are applied to BUCK-BOOST topology. The method concretely comprises the following steps: processing topological output signal to obtain a pulse width modulation signal; performing OR operation on the pulse width modulation signal and a first modulation signal to obtain a first control signal so as to control the state of a first transistor of the topology; performing AND operation on the pulse width modulation signal and a second modulation signal to obtain a second control signal so as to control the state of a second transistor of the topology. Therefore, the method realizes three topological states and smooth handover, and simultaneously the control circuit is relatively simple; and the control range is enlarged and the control precision is improved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

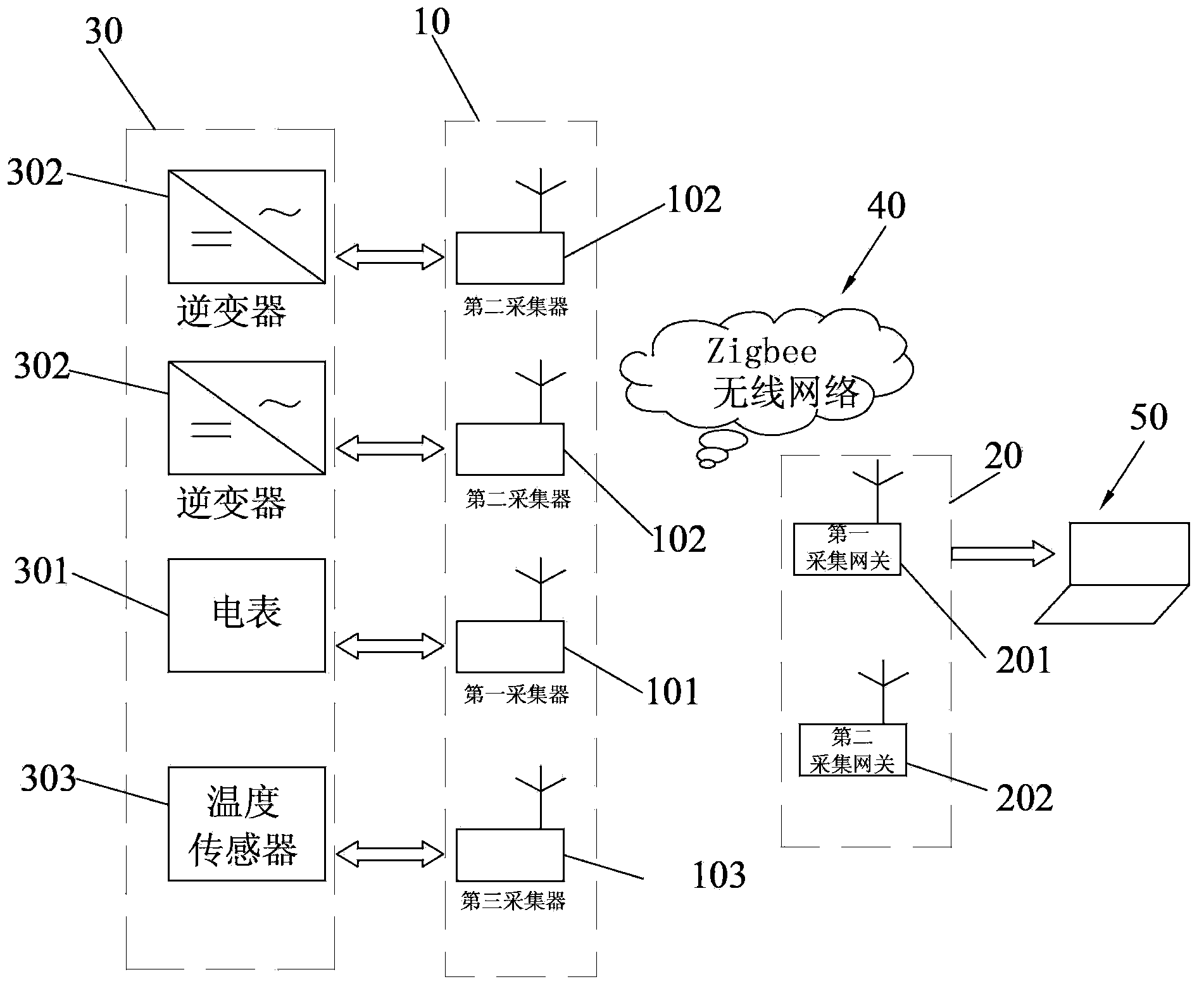

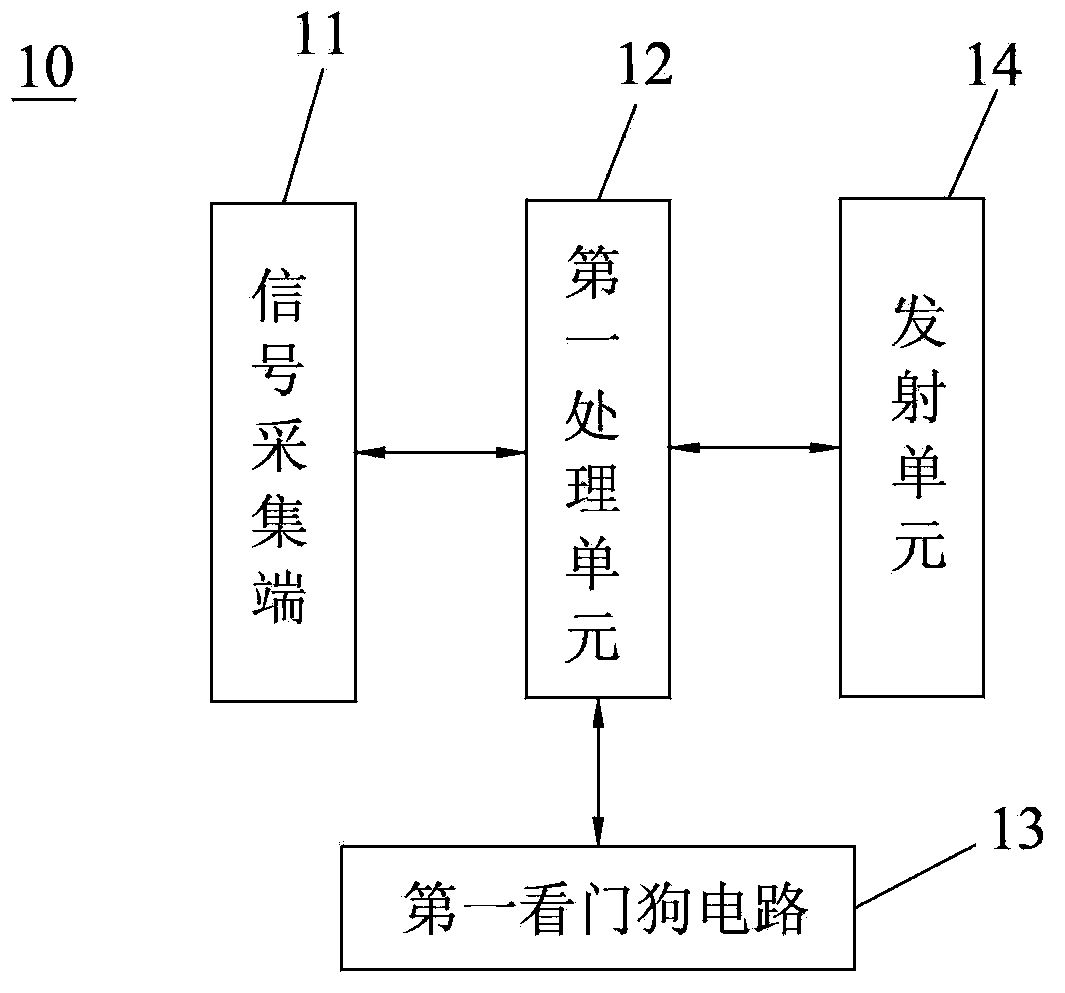

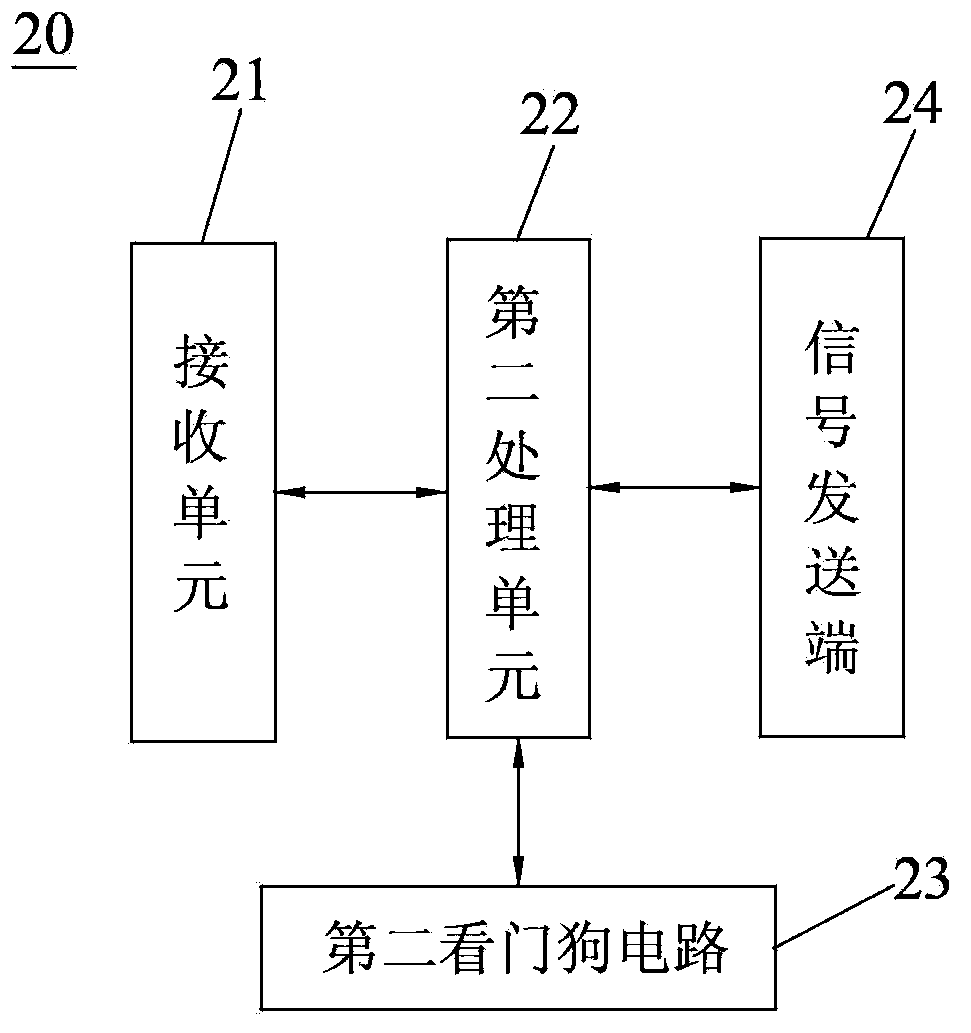

Photovoltaic power generation system data collecting device and collecting method based on Zigbee

InactiveCN103384089ALow costIntelligent managementTransmission systemsCircuit arrangementsTraffic capacityData acquisition

The invention discloses a photovoltaic power generation system data collecting device based on a Zigbee. The photovoltaic power generation system data collecting device comprises a plurality of collectors and at least one collecting gateway. The collects are respectively connected with at least one detected device of a photovoltaic power generation system and collect and send the electric power data of the detected device. One end of the collecting gateway is connected with at least one collector through a Zigbee wireless network and receives the electric power data, and the other end of the collecting gateway is connected with a power station monitoring server and uploads the electric power data to the power station monitoring server. Compared with the prior art, distribution type photovoltaic power station monitoring is achieved through the mode of the Zigbee wireless network, the monitoring problem of large-scale photovoltaic power stations and photovoltaic power stations similar to village distributed type roofs can be solved, pulling and burying road-crossing cables are of no need in using process, data traffic cost is avoided, and low cost and intelligent management of the power station is achieved. In addition, the invention further discloses a photovoltaic power generation system data collecting method based on the Zigbee.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

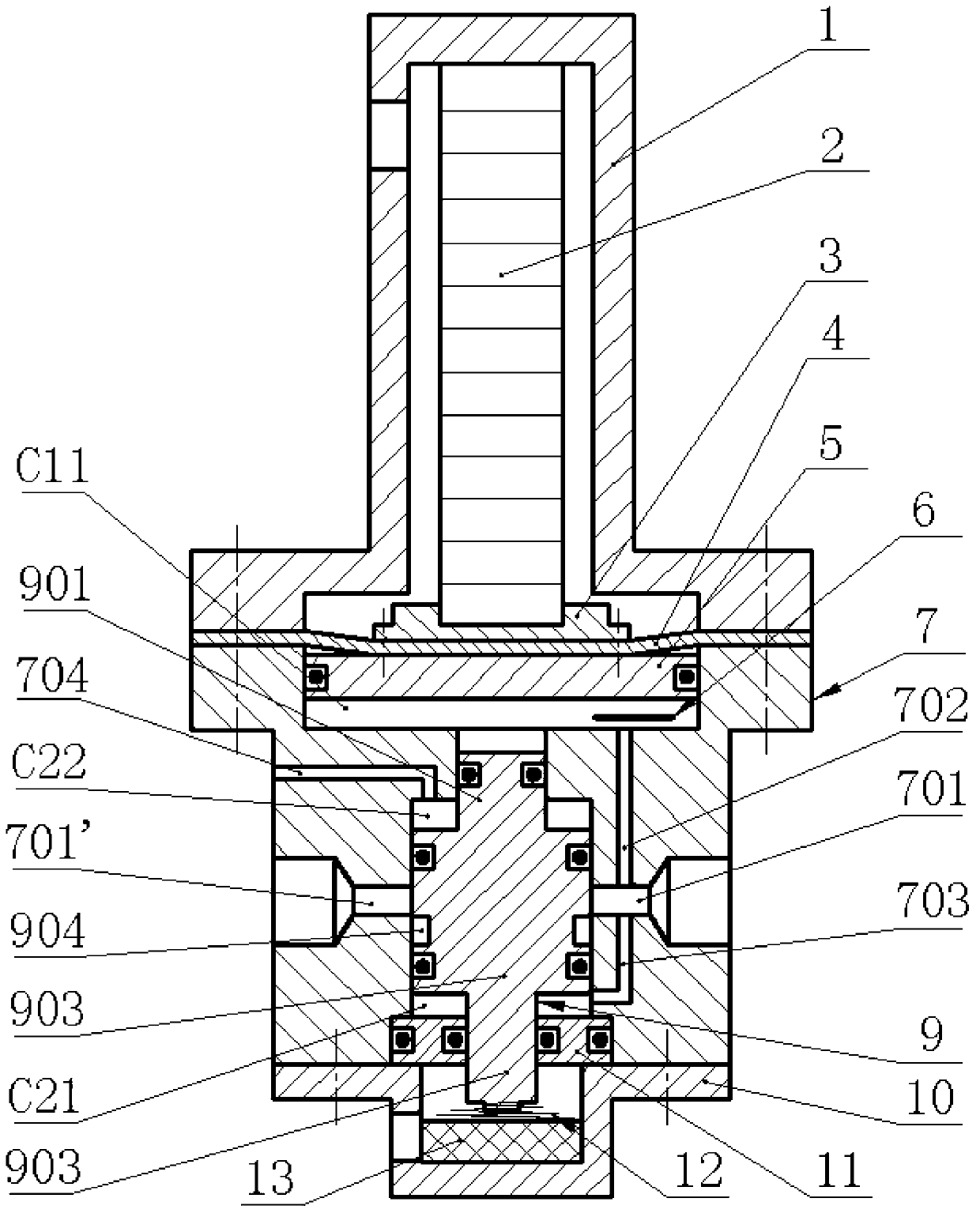

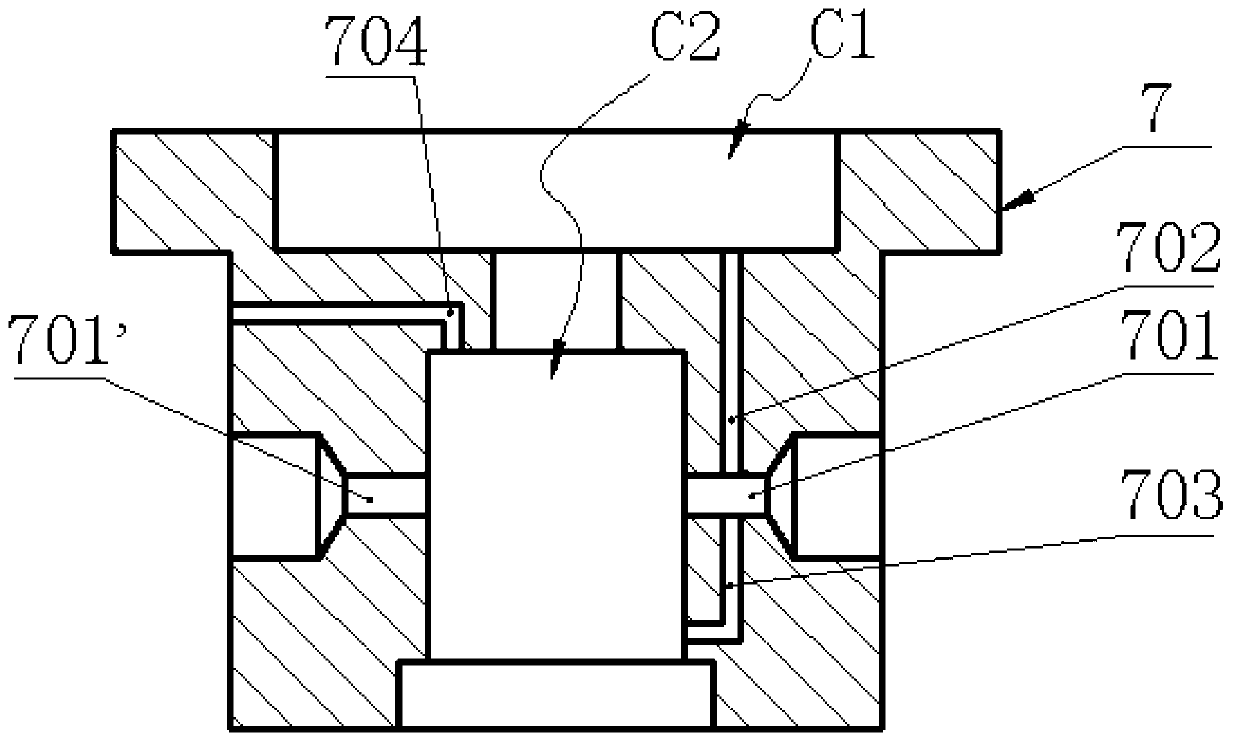

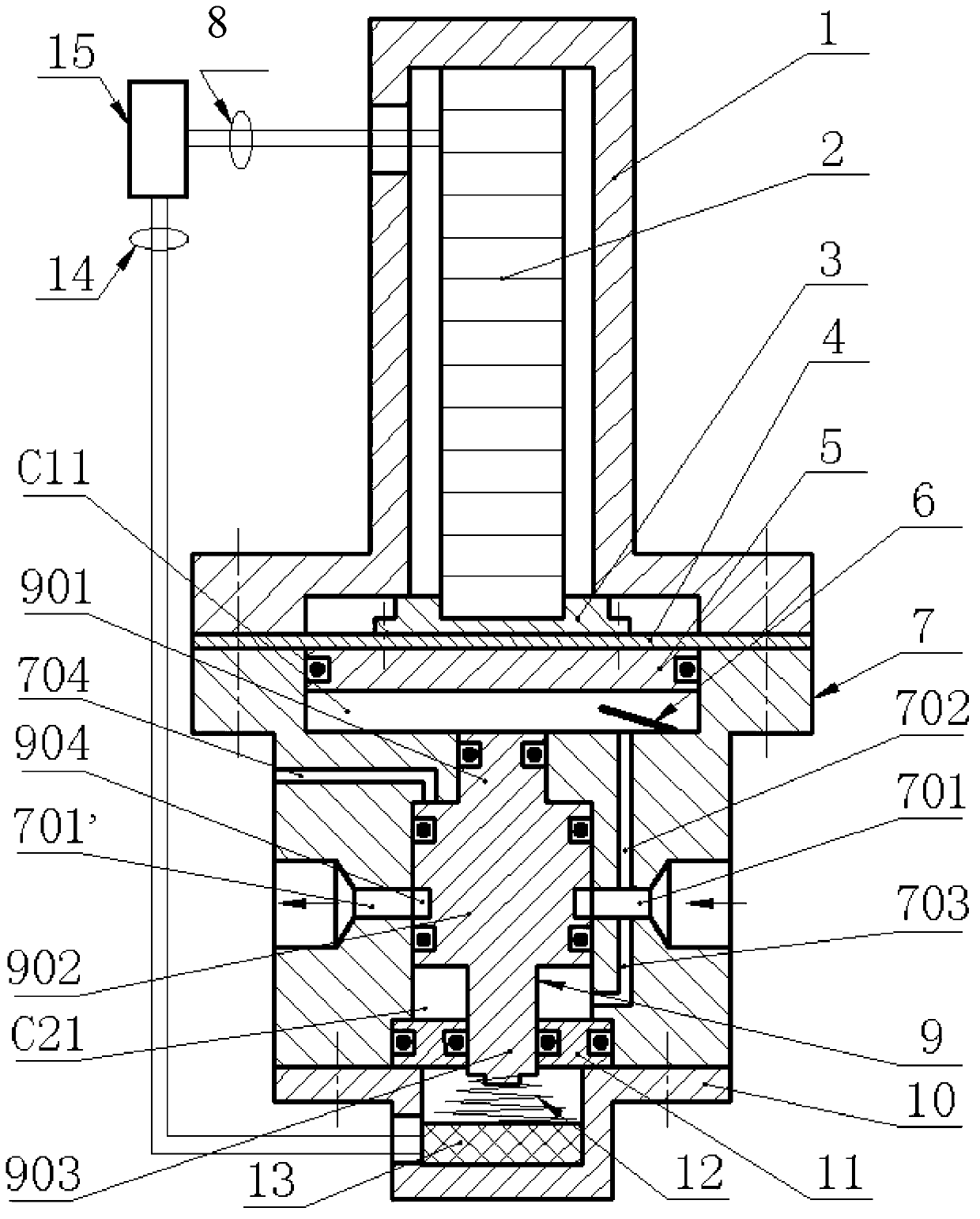

Intelligent large-flow electro-hydraulic valve

InactiveCN102996838ALarge displacementLarge adjustment rangeOperating means/releasing devices for valvesSlide valveElectricityElectro hydraulic

The invention relates to an intelligent large-flow electro-hydraulic valve, and belongs to a hydraulic valve. An upper housing and a lower housing are fixed on a valve seat; an elastic diaphragm is pressed between the valve seat and the upper housing; a partition board is pressed between the valve seat and the lower housing; a valve body is sleeved inside a valve cavity; the valve body is composed of a valve core, and an upper post rod and a lower post rod; a top block and a piston are fixed at two sides of the elastic diaphragm; the top block presses a piezoelectric stack inside the upper housing; the piston, the valve seat, the upper post rod and a one-way valve form an upper compression chamber; the valve core, the lower post rod, the valve seat and the partition board form a lower compression chamber; an inlet and an outlet are communicated through a valve core ring slot and form a valve hole; the inlet is communicated with the upper compression chamber and the lower compression chamber; the lower post rod presses a disk spring and a sensor inside the lower housing; and the sensor and the piezoelectric stack are respectively connected with an electric control unit through lead groups. The intelligent large-flow electro-hydraulic valve has the advantages that the displacement of the valve core is increased by the compression chambers; the movement state of the valve core can be measured by the sensor; and the intelligent large-flow electro-hydraulic valve is large in valve flow and damping regulating range, high in flow control accuracy and high in reliability, and especially suitable for large-scale precise flow and damping regulation.

Owner:ZHEJIANG NORMAL UNIVERSITY

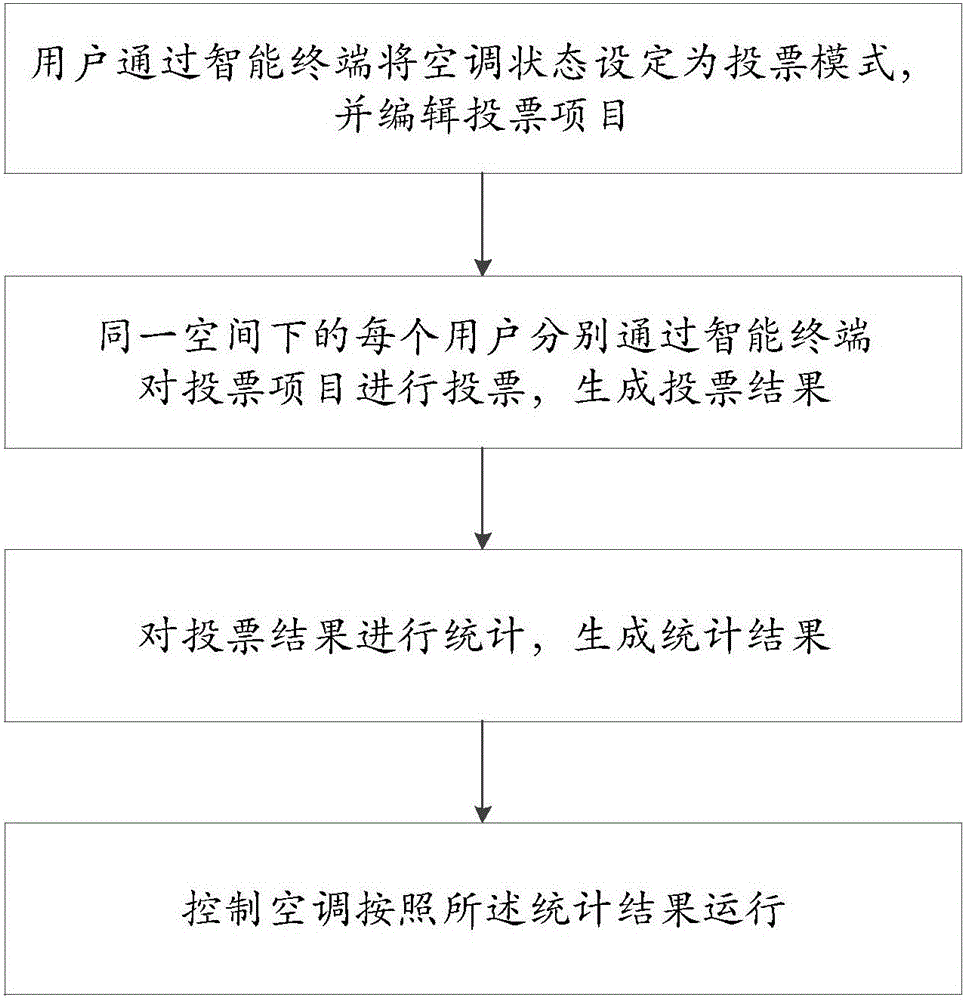

Method and system for cooperative control of air-conditioner by means of multi-user voting and air-conditioner

ActiveCN105783204AMeet comfort requirementsMeet the needs of useMechanical apparatusSpace heating and ventilation safety systemsPublic placeLiving room

The invention relates to the control field of air-conditioners, in particular to a method and system for cooperative control of an air-conditioner by means of multi-user voting and the air-conditioner. The method includes the following steps that users set the state of the air-conditioner in a voting mode through an intelligent terminal, and further edit voting items; each user in the same space votes for the voting items through the intelligent terminal, and accordingly voting results are generated; the voting results are counted for generating a statistical result; and the air-conditioner is controlled to operate according to the statistical result. According to the method, system and air-conditioner, the air-conditioner function is voted by the users, and the voting results are counted, and hence the obtained statistical result can meet the requirement of multiple users for comfort; a novel control mode with wide application range is added for the air-conditioner, the using comfort of the air-conditioner by the users is greatly improved in public places such as living rooms, offices, libraries, lecture halls and restaurants, and therefore the using requirement for the air-conditioner by the majority of users is satisfied.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Method for electrolyzing high-content low-grade lead bullion

InactiveCN103290429ARich in metal gradesLarge range of controlPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention relates to a method for electrolyzing high-content low-grade lead bullion. The method comprises the following steps of melting the high-content low-grade lead bullion containing copper, antimony and bismuth into a pot to be stirred for removing the copper, thoroughly removing the copper-containing floating slag, adding alkali to remove arsenic and tin, pumping the lead liquid into an anode plate casting machine to be cast into an anode plate, reasonably matching the use amount of the combined additives to electrolyze the anode plate and the electrolyte according to the chemical components of the anode plate and the chemical components of the electrolyte, extracting cathode lead, washing the cathode lead with water to remove the electrolyte on the surface of the lead and thus obtaining the precipitated lead, casting the refined precipitated lead to obtain lead pig with the quality reaching the No.1 national standard, gathering the antimony, bismuth, copper, gold and silver onto the anode plate to form anode paste, and further comprehensively recovering the antimony, bismuth, copper, gold and silver in balance. By adopting the method, the lead bullion with high contents of copper, antimony and bismuth can be electrolyzed into the qualified precipitated lead in one step, so that the secondary electrolysis cost can be reduced, and the enriched metal grade in the anode paste can be improved.

Owner:湖南省桂阳银星有色冶炼有限公司

Novel aircraft carrier flying-off deck

InactiveCN102862684AIncrease takeoff weightImprove combat effectivenessLaunching/towing gearFuel tankEngineering

The invention discloses a novel aircraft carrier flying-off deck, which comprises an ascending flying-off desk section, wherein a carrier plane flying-off acceleration equipment cabin is arranged below a starting section, a brake is arranged outside two tank wheels which are installed on a support through a wheel shaft inside the cabin, the two tank wheels are connected, a rubber plate is hung on the inner surface of a reinforced crawler belt, and the crawler belt is provided with a special crawler belt plate with a towing hook. Two tank engines with an independent oil box and an independent water box respectively are arranged on an engine support at the side of each tank wheel, the tank engines are connected with the tank wheels through a clutch and a transmission case, and a crawler belt tension wheel installation support is provided with a crawler belt tension wheel with a crawler belt traction motor. The starting section of the ascending flying-off deck is provided with a deck narrow seam, and a telescopic automatic switch, a brake releasing switch and a brake anchoring rod are respectively arranged on the middle-rear section and nearby the end of the deck narrow seam and on flying-off station deck on the rear part. The novel aircraft carrier flying-off deck integrates the advantages of a flat ejection flying-off deck and an ascending flying-off deck, and is also free from the defects of the two flying-off decks.

Owner:王长存

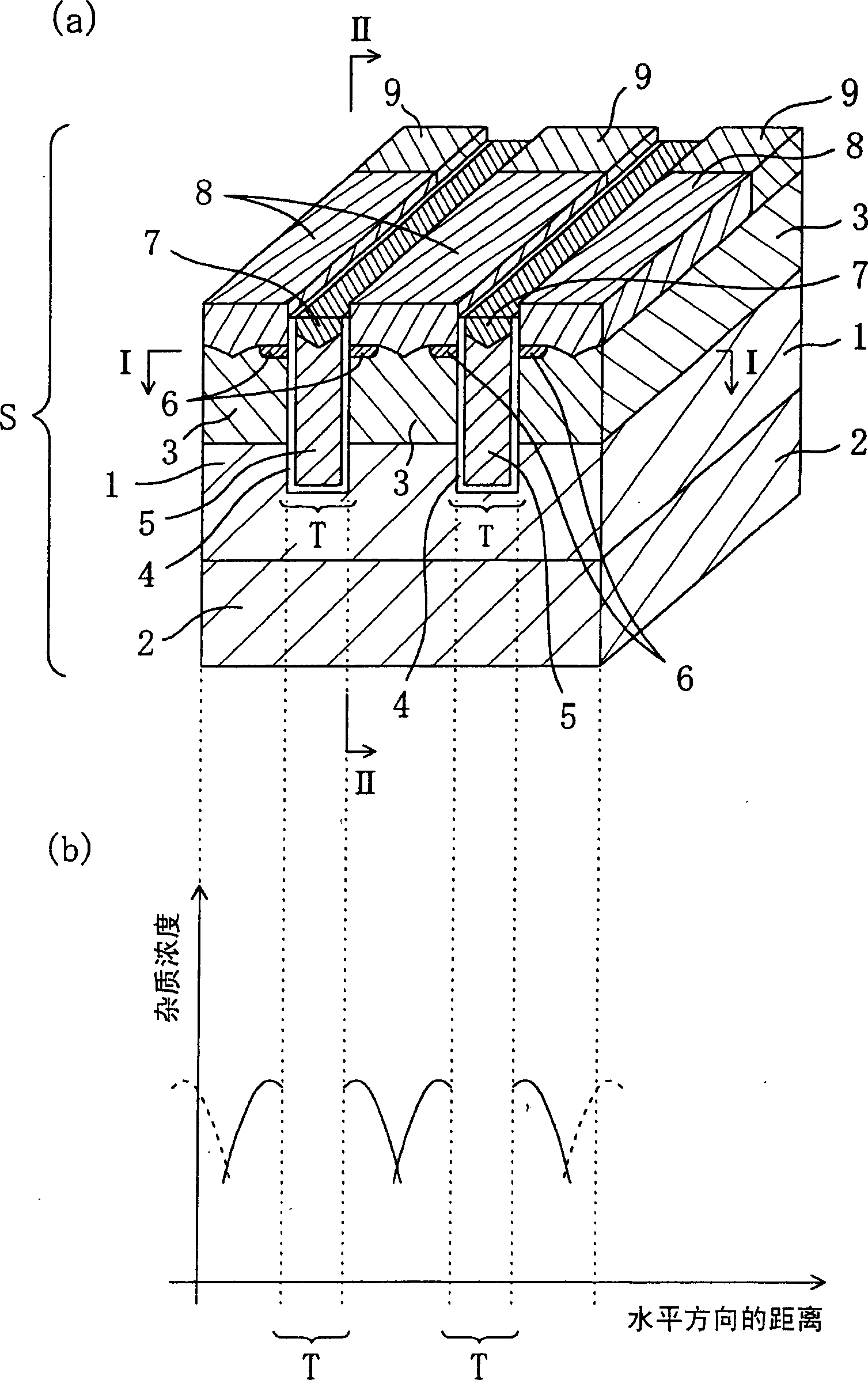

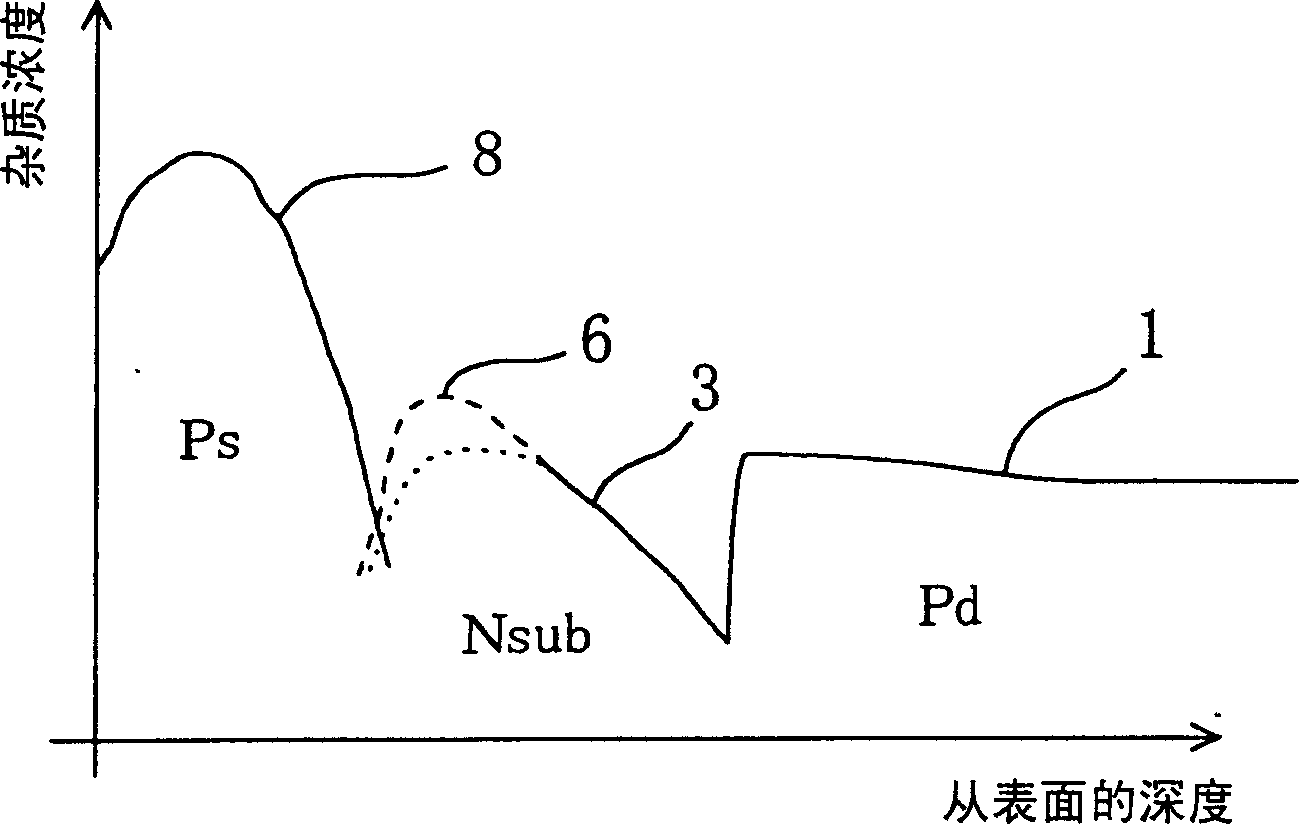

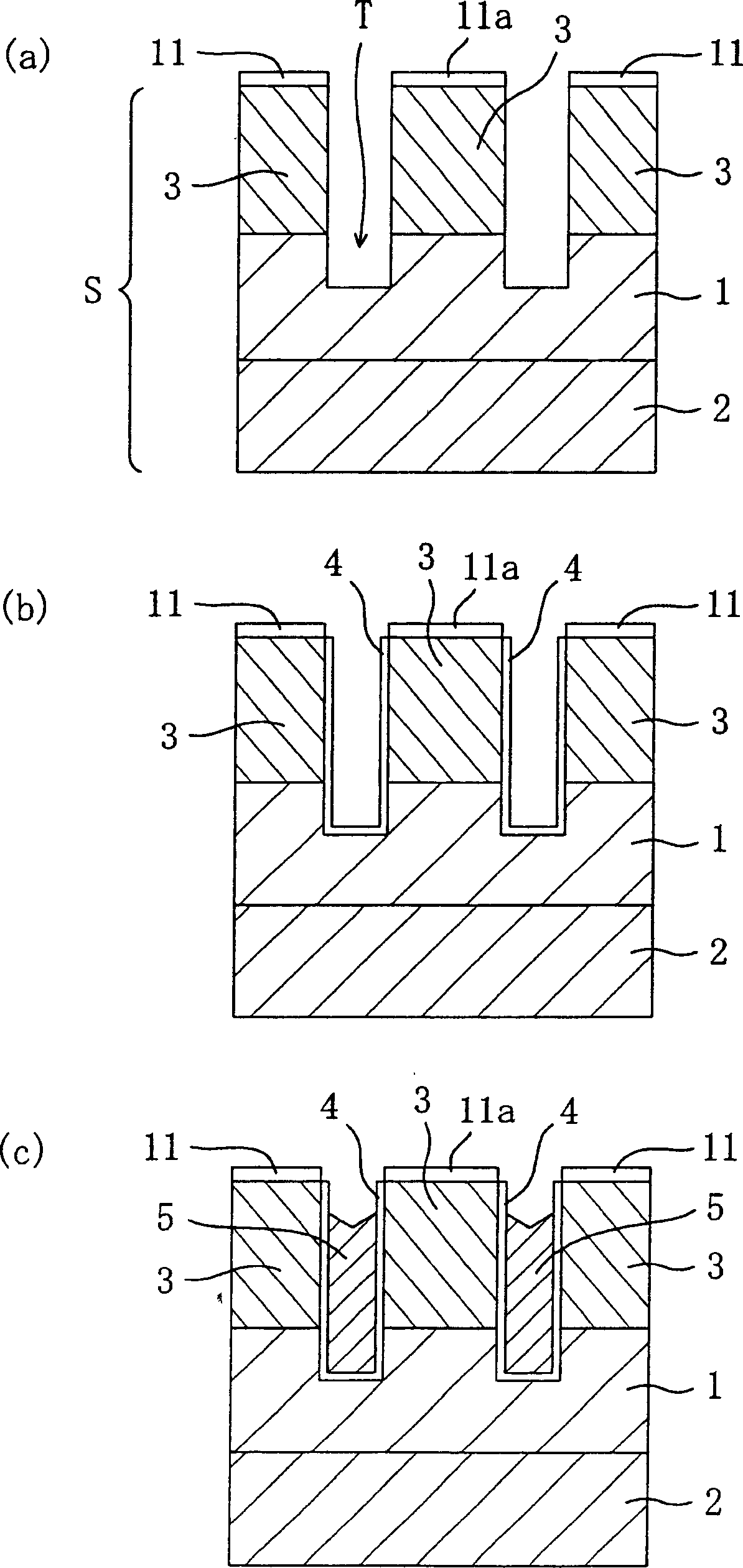

Semiconductor device and method for fabricating the same

InactiveCN1658400AImprove punch-through withstand voltageLarge range of controlSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationEngineering

Provided is a semiconductor device with a trench gate structure having a high punch-through withstand voltage and a wide control range for the threshold voltage Vt, and to provide its manufacturing method. A semiconductor device is provided with a p-type drain region that is formed into a silicon substrate S; a low-concentration p-type drain region (EPI)1; a high-concentration p-type source region 8 that is formed at the upper part of the low-concentration drain region 1; an n-type substrate region 3 that is formed between the high-concentration p-type source region 8 and the low-concentration p-type drain region (EPI)1, a trench T; a gate insulating film 4 and a gate electrode 5 that are formed inside the trench T, an insulating film 7 closing the trench T; and an n-type pocket region 6 that is formed between the n-type substrate region 3 and the high-concentration p-type source region 8. By the n-type pocket region 6, there is formed a barrier blocking the spread of a depletion layer from the low-concentration p-type drain region 1, without reinforcing the electric field strength applied to the low-concentration p-type drain region 1 side.

Owner:コラボイノベーションズインコーポレイテッド

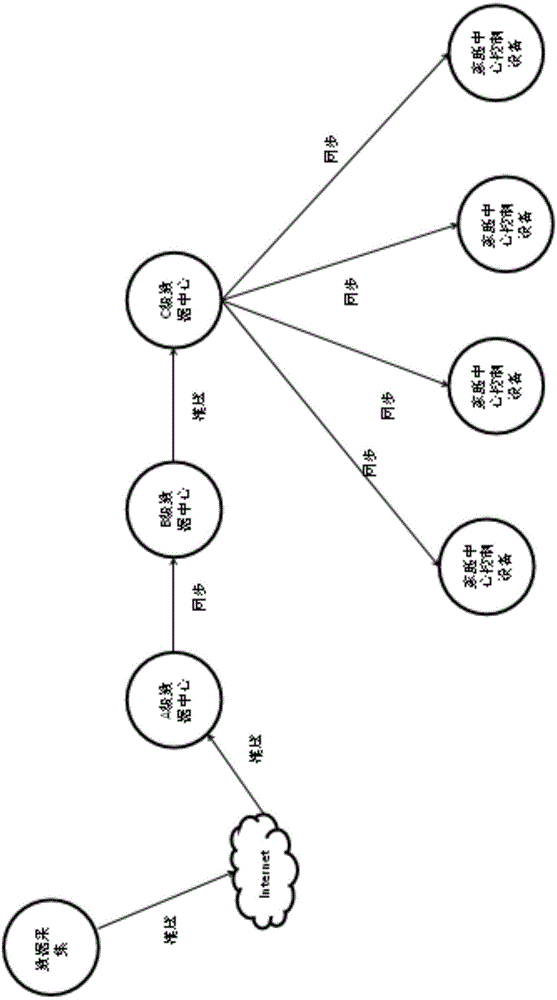

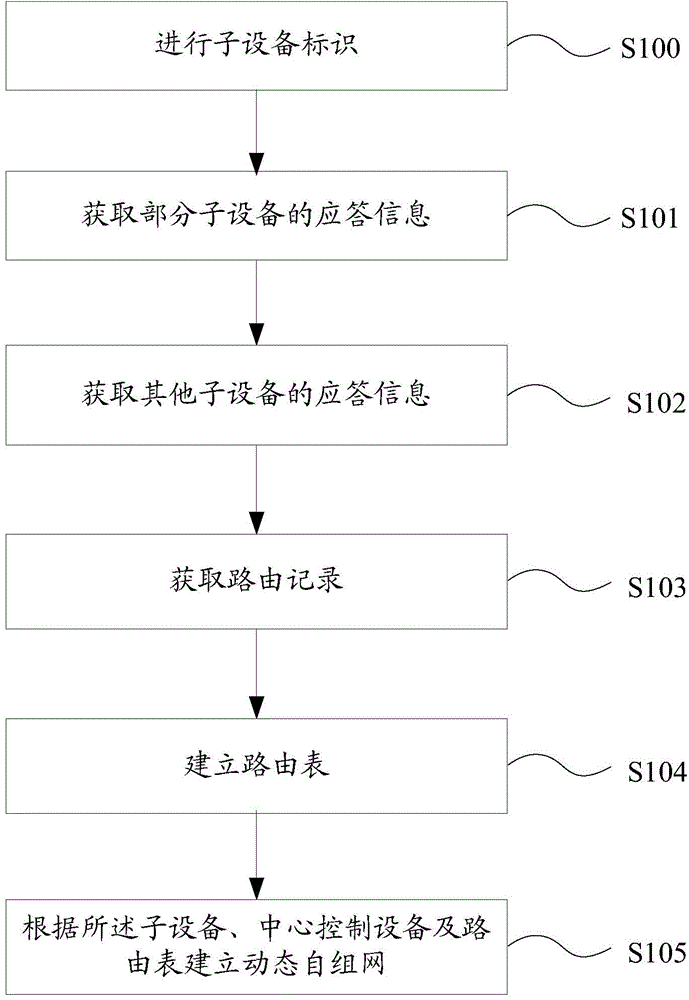

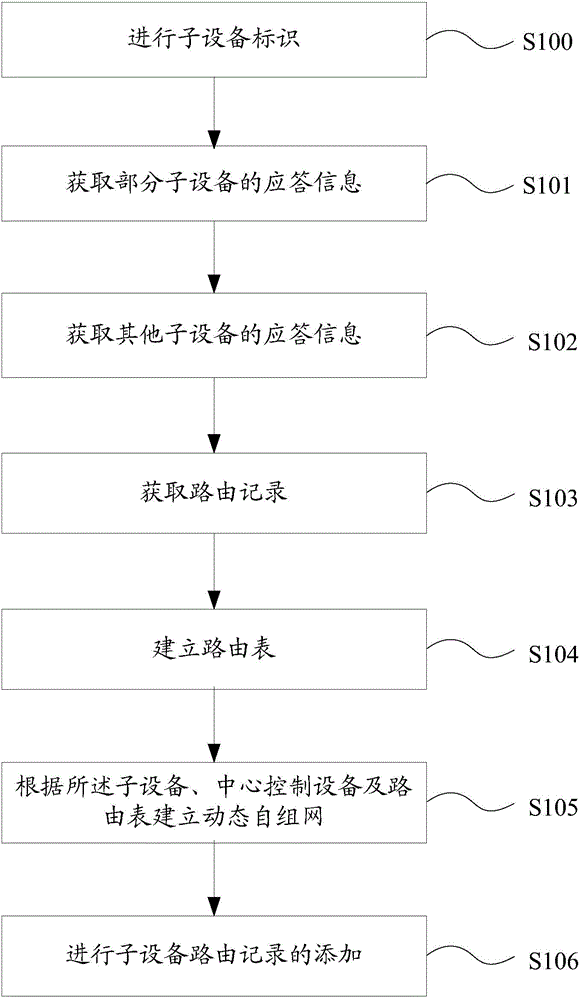

Multi-smart home equipment dynamic ad hoc network construction method

InactiveCN104917656AShorten the transmission distanceRealize communication controlData switching by path configurationRouting tableSelf routing

The invention provides a multi-smart home equipment dynamic ad hoc network construction method. The method comprises the steps that central control equipment establishes route records of a source node and a relay node according to a response record of sub equipment; according to a primary route record and multilevel route records, a route table is established; and according to the sub equipment, central control equipment and route table, a dynamic ad hoc network is established. Through adoption of the method, the problems of poor systematicness and reliability in control process of multi-smart home equipment are solved. Communication control of multi-smart home equipment and the central control equipment in a house can be realized, so that the characteristic of short transmission distance between smart home equipment under a condition of a programmable logic controller (PLC) is realized. The method adopts a manner of self routing and independent networking of the smart home equipment, and uses all the smart home equipment as route relays through setting of hop upper limit (5 hops) of the route in the house, thereby enlarging the control range of the central control equipment over the sub equipment, and realizing the maximum coverage of the central control equipment over the smart home equipment in the house.

Owner:重庆本原致创科技发展有限公司

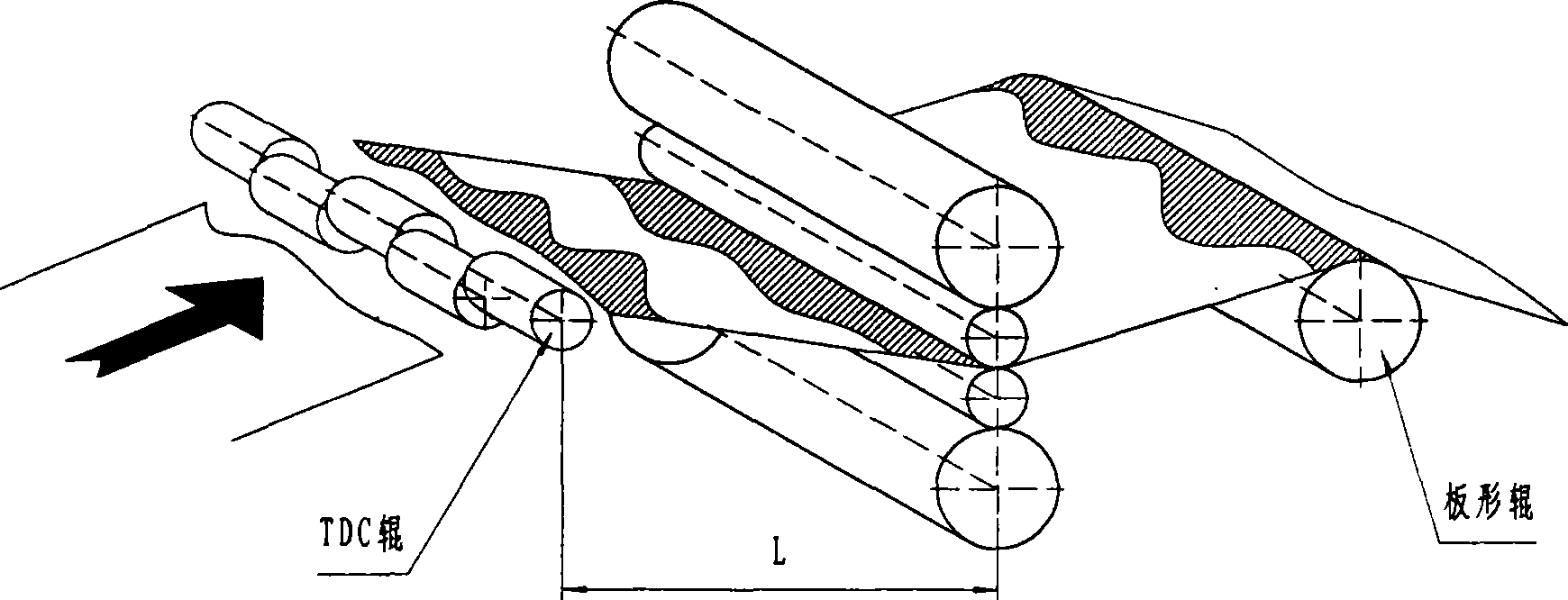

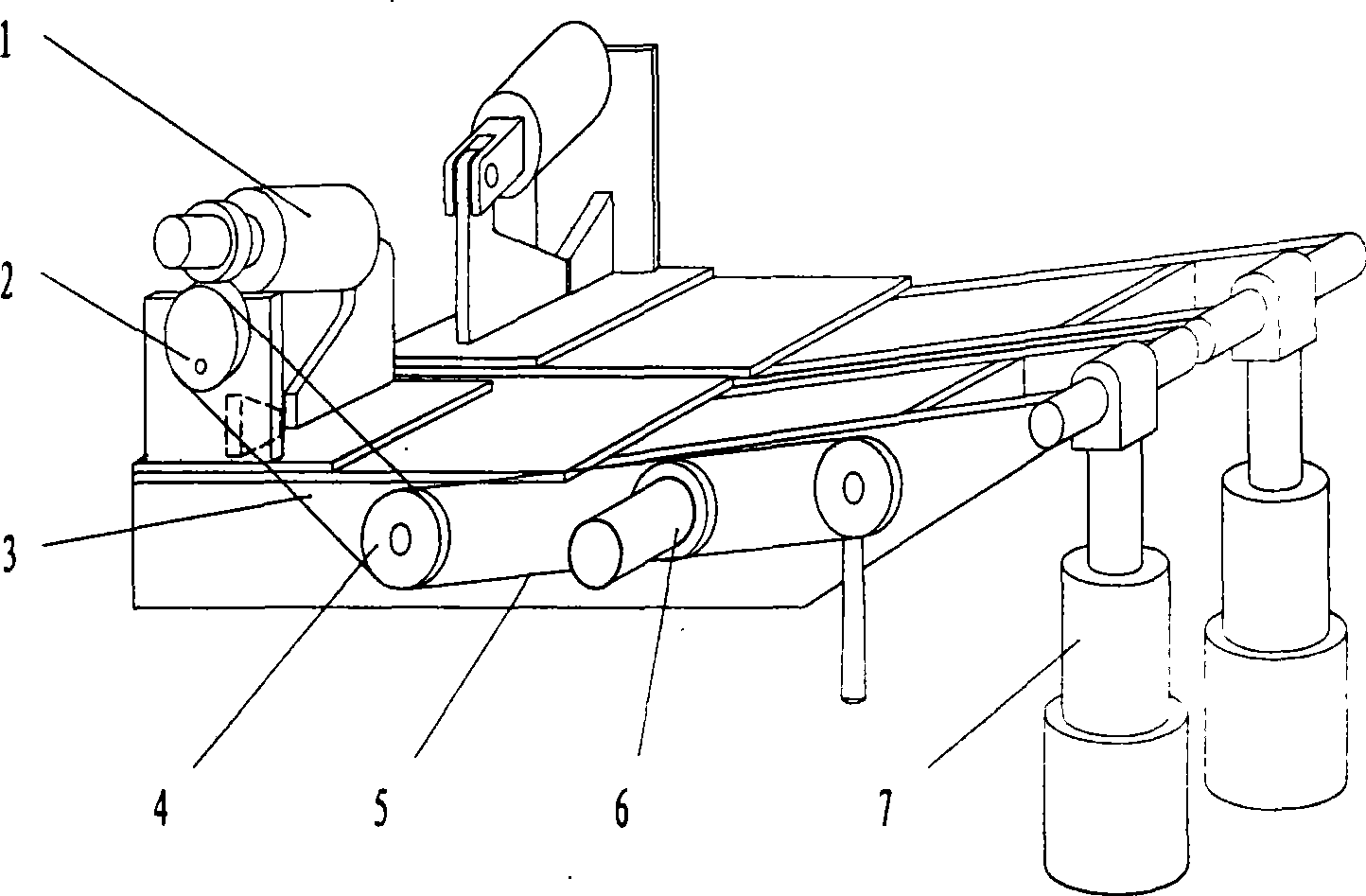

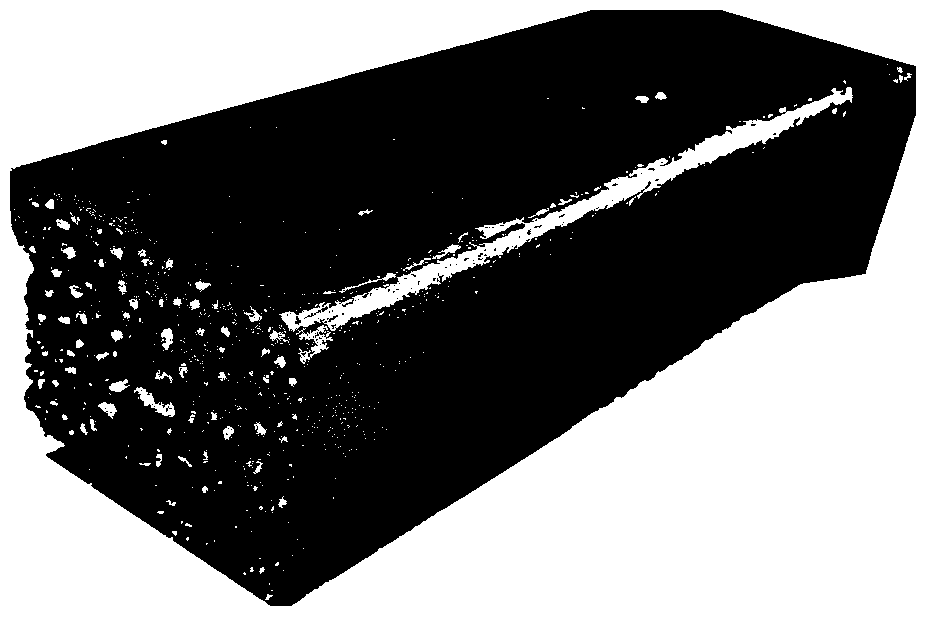

Tension-plate shape measurement-adjusting instrument

ActiveCN101480665ALarge range of controlImprove detection-control accuracyTension/compression control deviceMetal rolling arrangementsProduction lineStress distribution

The invention is used for on-line detection and regulation for the tension and the tensile stress distribution of band materials on a rolling production line of metal band materials, which mainly comprise a subsection roller and a subsection roller position regulating mechanism, wherein the subsection roller is a tensile stress distribution control roller (TDCR) published with the patent publication number of CN101288880A, each cylinder of the (TDCR) is newly provided with a set of position and pressure sensors which provide straightness signals of the band materials, and the straightness of the band materials is regulated by the cylinders according to the strength of the signals; the subsection roller is arranged on the subsection roller position regulating mechanism and is driven by each cylinder provided with a set of position and pressure sensors which provide tension signals of the band materials, and the tension of the band materials is regulated by the cylinders according to the strength of the tension signals. The invention separates the detection-control of the tension from the detection-control of the tensile stress distribution, thereby enhancing the precision of the detection-control of the tension and the tensile stress distribution and enlarging the control range. Furthermore, the invention can be combined with various plate shape control modes to form a plate shape comprehensive control system which can regulate the defects of various plate shapes.

Owner:张明

Method for preparing aluminum base foam material by utilizing negative pressure foaming

All performances especially the function characteristics of an aluminum base foam material are closely related with its density and pore structure. The invention provides a method for preparing the aluminum base foam material by utilizing negative pressure foaming. The method comprises the following steps: heating industrially pure aluminum or aluminum alloy for melting to form molten aluminum, adding a tackifier to the molten aluminum, and adding a foaming agent to the molten aluminum to form molten aluminum containing small pores; putting the molten aluminum containing small pores in a closed foaming cavity, and carrying out air exhaust to reduce the pressure in the foaming cavity and expand the molten aluminum with the reduction of the pressure in the cavity in order to form foams; and cooling the foams with the cavity while maintaining the pressure in the foaming cavity constant to obtain the aluminum base foam material. Foam materials with designed profile, weight and density can be prepared through one-time molding by using the method. The active controllability of the foam aluminum foaming process is realized to obtain the foam aluminum material having a specific amount of porosity, so the uniformity of the pore structure is improved; and direct foaming molding is realized, so the consumption of the foaming agent is saved.

Owner:北京宏钧新材料技术有限公司

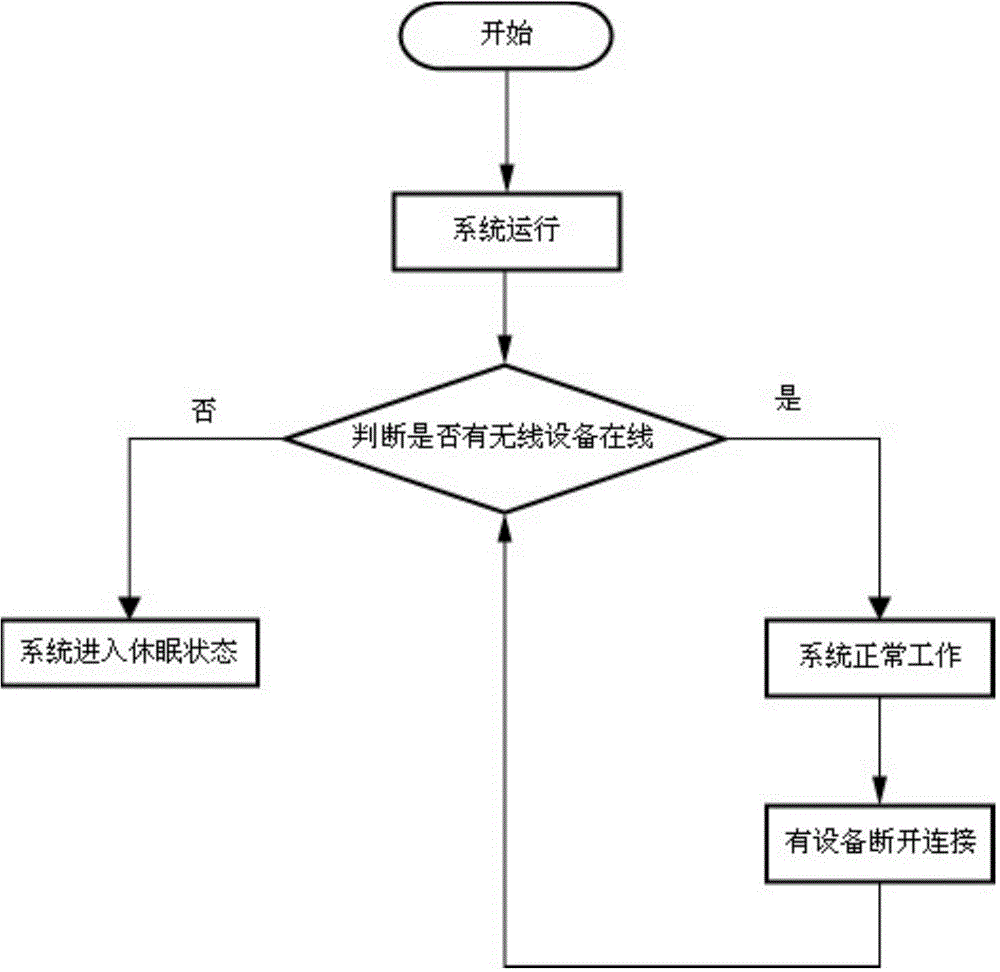

Connection dormancy method based on household router

InactiveCN103561456AWith connection dormancy functionLarge range of controlPower managementEnergy efficient ICTComputer networkSleep state

The invention provides a connection dormancy method based on a household router. The situation that the router is heated due to the fact that the router is kept in a work running state for a long time, network drop or network offline is caused, and power consumption is generated occurs and currently hinders the development of the household router. The dormancy method includes the steps that (1) the router is turned on, started and run; (2) equipment is connected with the router and connects to the internet; (3) the working state of wireless chips is detected by the router; (4) the equipment is away from an effective connection distance or is directly disconnected; (5) the working state of the wireless chips is detected again by the router; (6) when the router detects that the wireless chips are in a connectionless state, a switch of a wireless network transceiver is turned off, and an interface of the wireless network transceiver is in a sleep state; (7) the router is in a dormancy state; (8) the equipment is connected to the router again; (9) when the router detects that the wireless chips are in a connection state, the switch of the wireless network transceiver is turned on, and then the router normally works. The connection dormancy method is used for the household router.

Owner:TAICANG T&W ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com