Temperature control device and control method of substrate for additive manufacturing

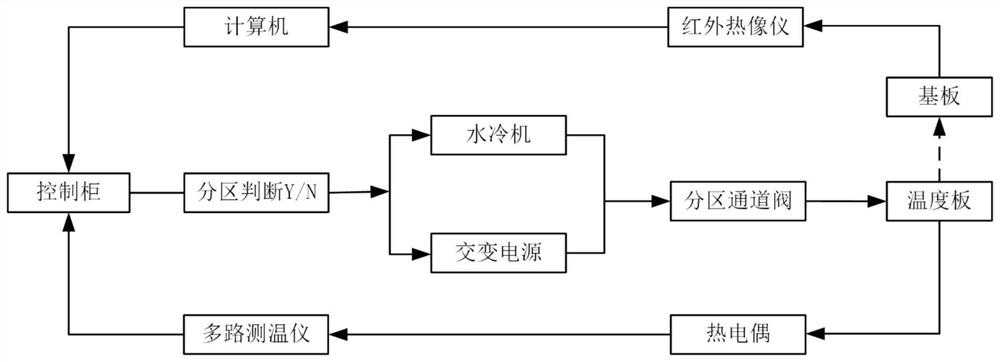

A temperature control device and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of harsh ambient temperature, large heat loss, short service life, etc., to achieve zoned temperature control, timely and accurate temperature control, prevention of cracking and large deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

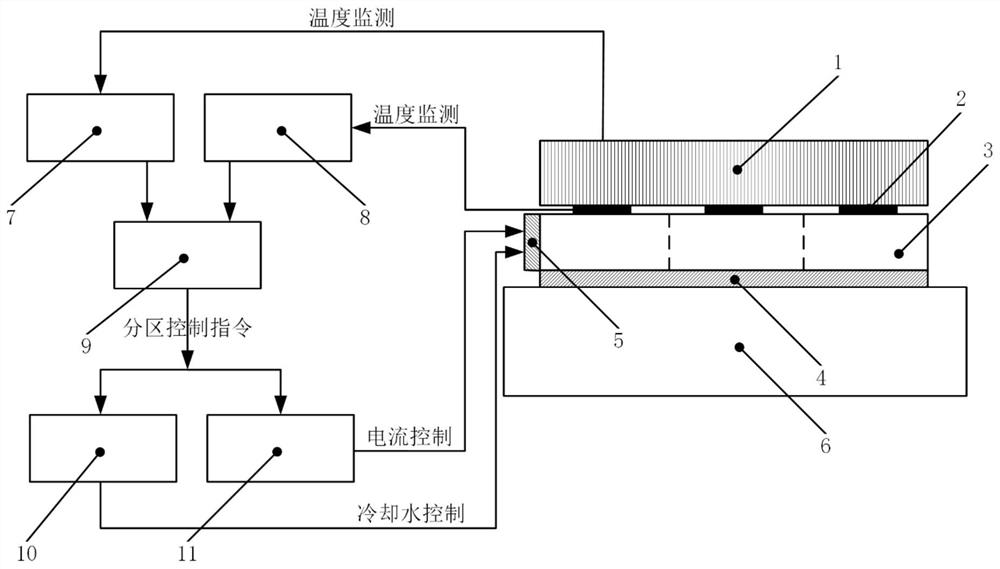

Method used

Image

Examples

Embodiment

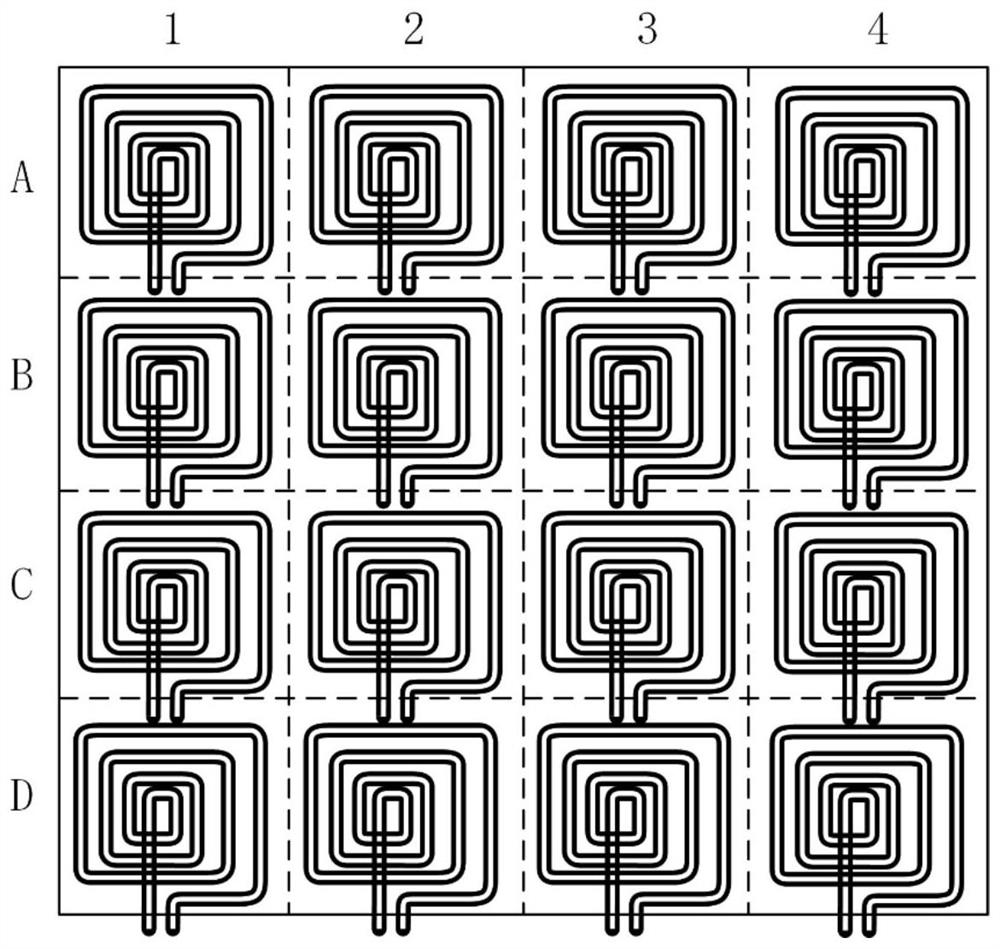

[0040] Such as image 3 As shown, the temperature control board 3 is filled with insulating and heat-conducting polymer material methyl vinyl silicone rubber. According to the size of the substrate and formed parts and the path planning, it is divided into 4 rows and 4 columns, a total of 16 rectangular temperature control partitions, numbered A(1-4)-D(1-4), and a spiral excitation copper tube coil is placed in each partition.

[0041] In order to achieve better temperature control effect. The shape of the spiral tube is planned to be a rectangle following the shape of the temperature control zone. The partition shape of the temperature control board is not limited to rectangle, and can also be adjusted to triangle, circle, etc. according to actual needs.

[0042] The multi-channel thermometer 8 relies on the thermocouple 2 to be pasted between the temperature control board 3 and the substrate 1 to monitor the temperature of the lower surface of the substrate 1 and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com