Process for producing lower alcohol by direct hydration of low carbon olefin

A technology for low-carbon olefins and lower alcohols, which is used in the preparation of hydroxyl addition and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

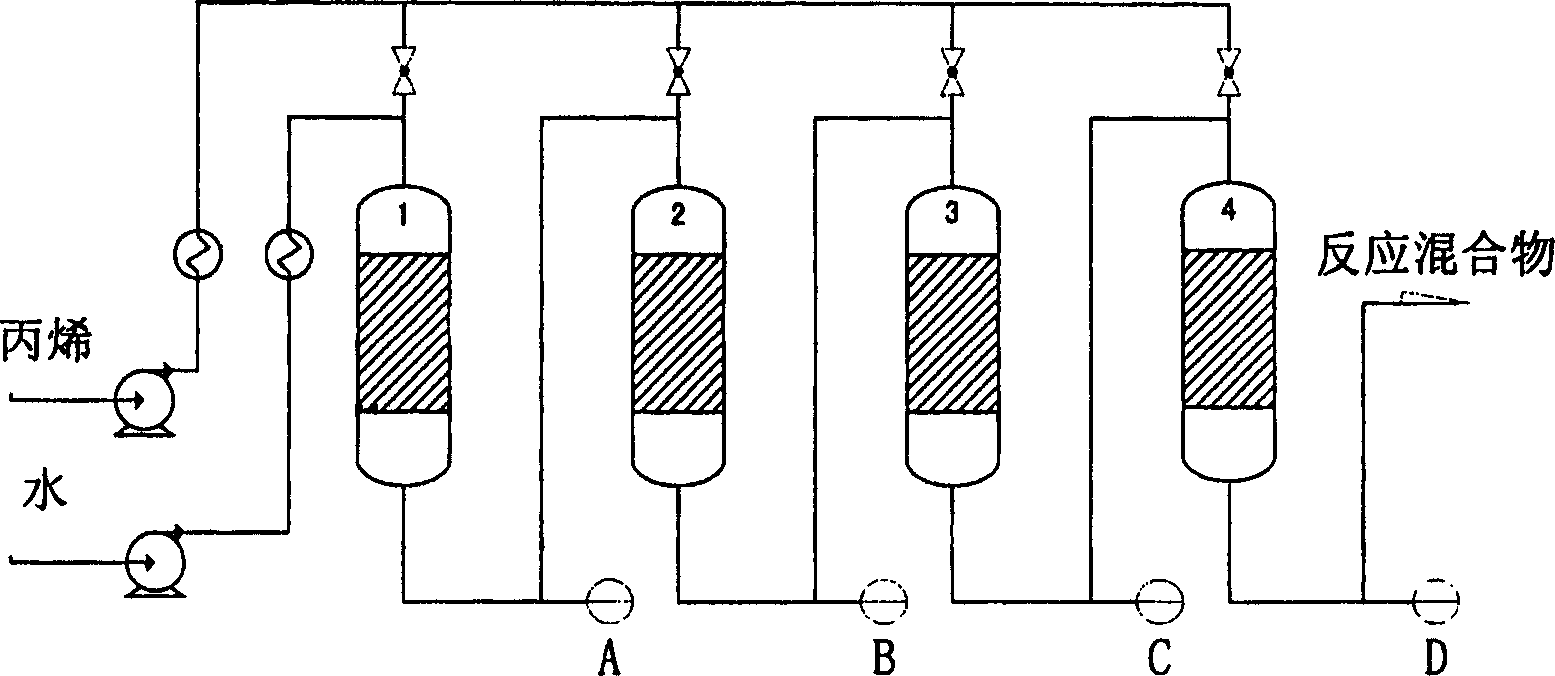

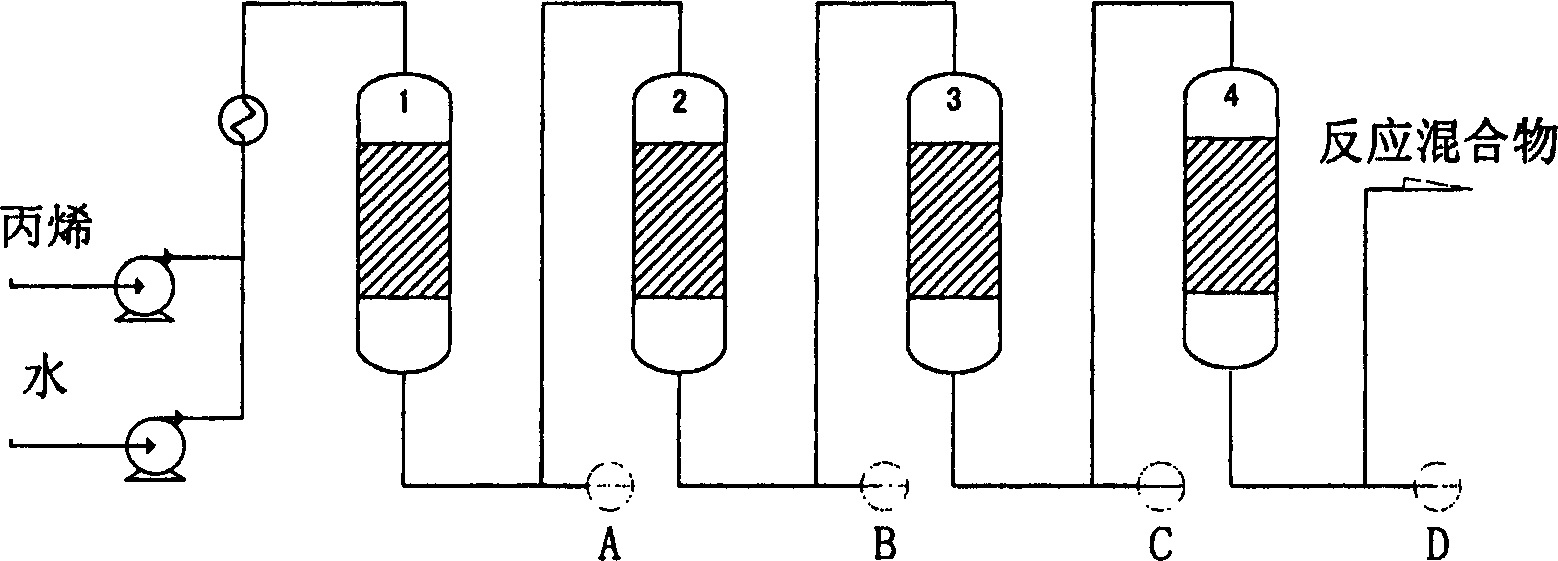

[0020] For a schematic diagram of the reaction process, see figure 1 , four Φ inner 25 × 800mm single-tube trickle-bed adiabatic reactors (1, 2, 3, 4). 100 milliliters of cation exchange resin catalysts (the trade mark is D008 commercial catalysts) are filled respectively in the four reactors. The feed propylene concentration is greater than 95.0m%, and the amount of feed propylene per hour is 66 grams; equally divided into four parts and enters four reactors; the reaction water is deionized water, and the feed deionized water per hour is 420 grams, from the first into the first reactor, and the reacted mixture directly enters the next reactor, and the molar ratio of the total feed water to feed propylene in the reaction process is 14.85. An online gas chromatograph (A, B, C, D) is installed at the outlet of each reactor, and the reaction mixture flowing out of each reactor is analyzed to obtain the yield of the product. The reaction conditions of each reactor are: pressure ...

Embodiment 2

[0028] The test is carried out under the same apparatus and reaction conditions as in Example 1. The feed amounts of fresh propylene per hour for the four reactors were 15, 18, 16.5, and 16.5 grams respectively. The test results are shown in Table 3.

[0029] the bed

Embodiment 3

[0031] The test is carried out under the same apparatus and reaction conditions as in Example 1. The feed amounts of fresh propylene per hour for the four reactors were 12, 15, 20, and 19 grams respectively. The test results are shown in Table 4.

[0032] the bed

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com