Equivalent circuit parameter identification method of induction heating model

A technology of induction heating and parameter identification, applied in the field of effective circuit parameter identification, induction heating model resistance, inductance calculation, can solve the problem of no secondary side circuit parameter calculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In the following, the present invention will be further clarified by taking cold crucible smelting of molten sodium borate glass as an example in conjunction with specific embodiments, and the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

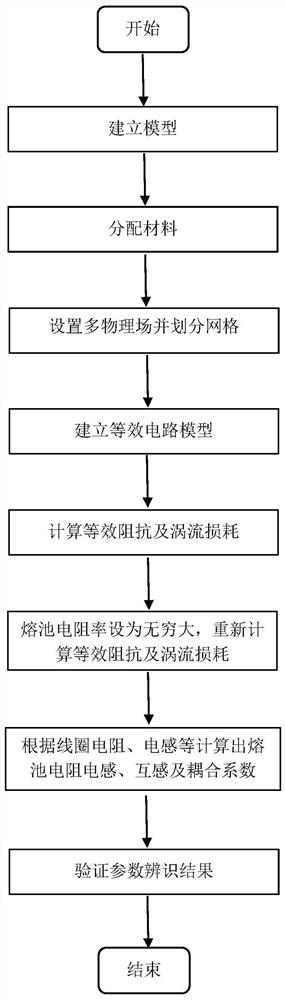

[0052] A method for calculating the resistance and inductance of an induction heating model, the process parameters figure 1 , including the following steps:

[0053] (1) Build a model.

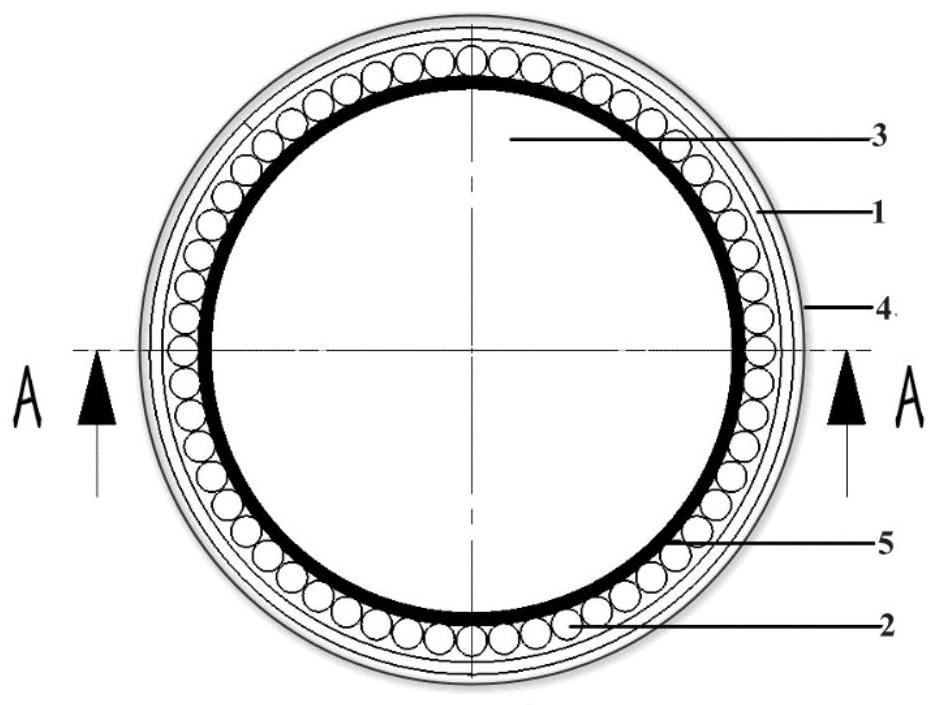

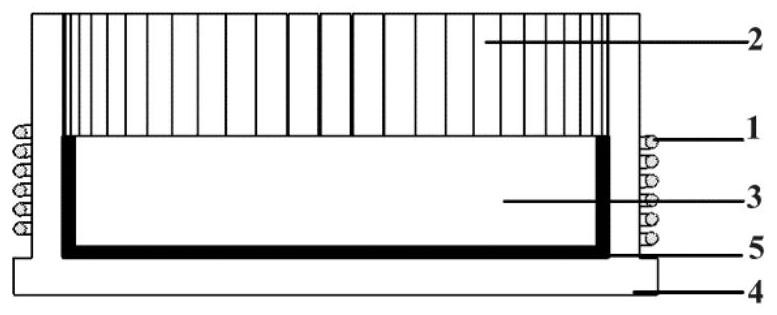

[0054] In this embodiment, the two-dimensional symmetrical finite element simulation model of the induction heating model is established as shown in Figure 2 (a) and Figure 2 (b), which mainly consists of an induction coil 1, a water cooling tube 2, a crucible melting pool 3, and a crucible base 4 , The crucible wall 5 constitutes.

[0055] The induction coil 1 is located outside the crucible, and its coil height is consistent with the height of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com