Method for preparing ethanol through low carbon ester hydrogenation

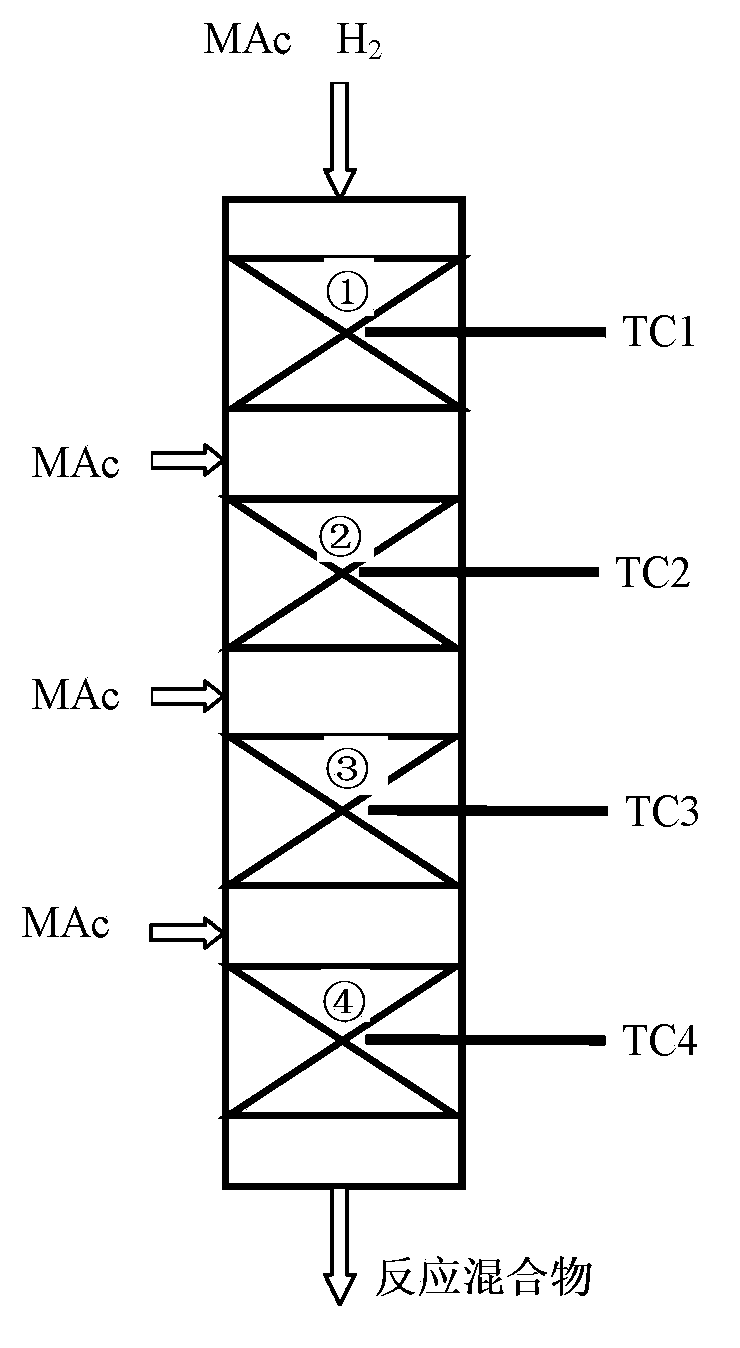

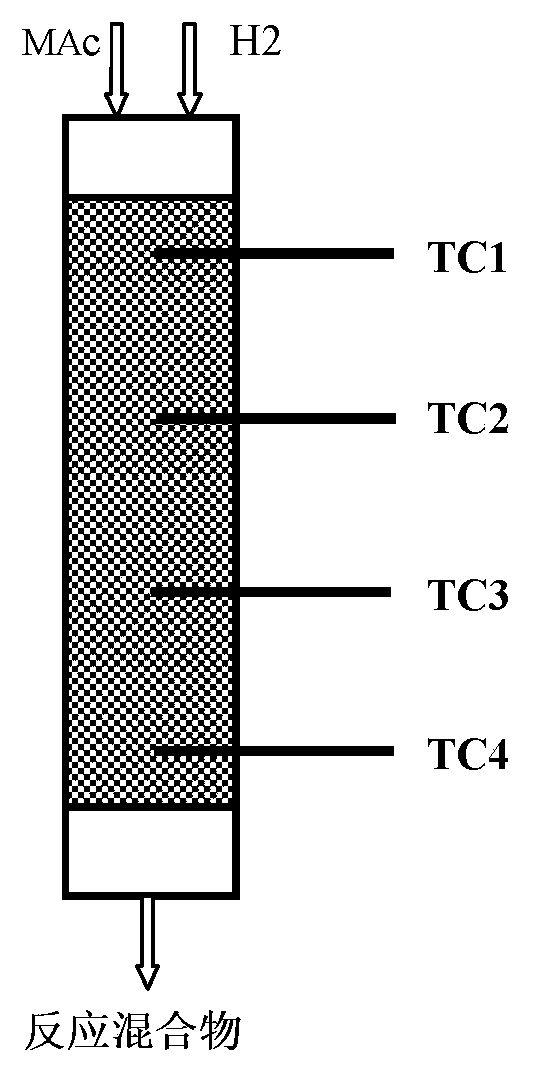

A low-carbon ester and hydrogen preparation technology, applied in the field of catalytic chemistry, can solve the problems of difficult control, difficult industrial production, uneven temperature distribution of catalyst beds, etc., to improve selectivity, prolong catalyst life, improve raw material conversion rate and catalyst effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation and molding of embodiment 1 catalyst

[0033] The preparation steps of the Cu-Zn-Al-O catalyst of the present invention are as follows: the nitrate mixed solution of copper nitrate hexahydrate, zinc nitrate hexahydrate, and aluminum nitrate nonahydrate is vigorously stirred at room temperature, and the precipitating agent Na 2 CO 3 The solution was slowly dropped into it, and the co-precipitation reaction was carried out at a constant pH value to 9.0 and a constant stirring speed. After continuing to stir for 150 min, the precipitate was aged overnight. The precipitate was washed with deionized water until neutral, and centrifuged. The obtained precipitate was dried in an oven at 120°C for 24 hours. After drying, the sample was placed in a muffle furnace, and the temperature was raised to 350°C at a heating rate of 2°C / min, and roasted for 2 hours to obtain a roasted sample, which was granulated, crushed, and screened for 10~ 20 mesh spare. The copper-ba...

Embodiment 2

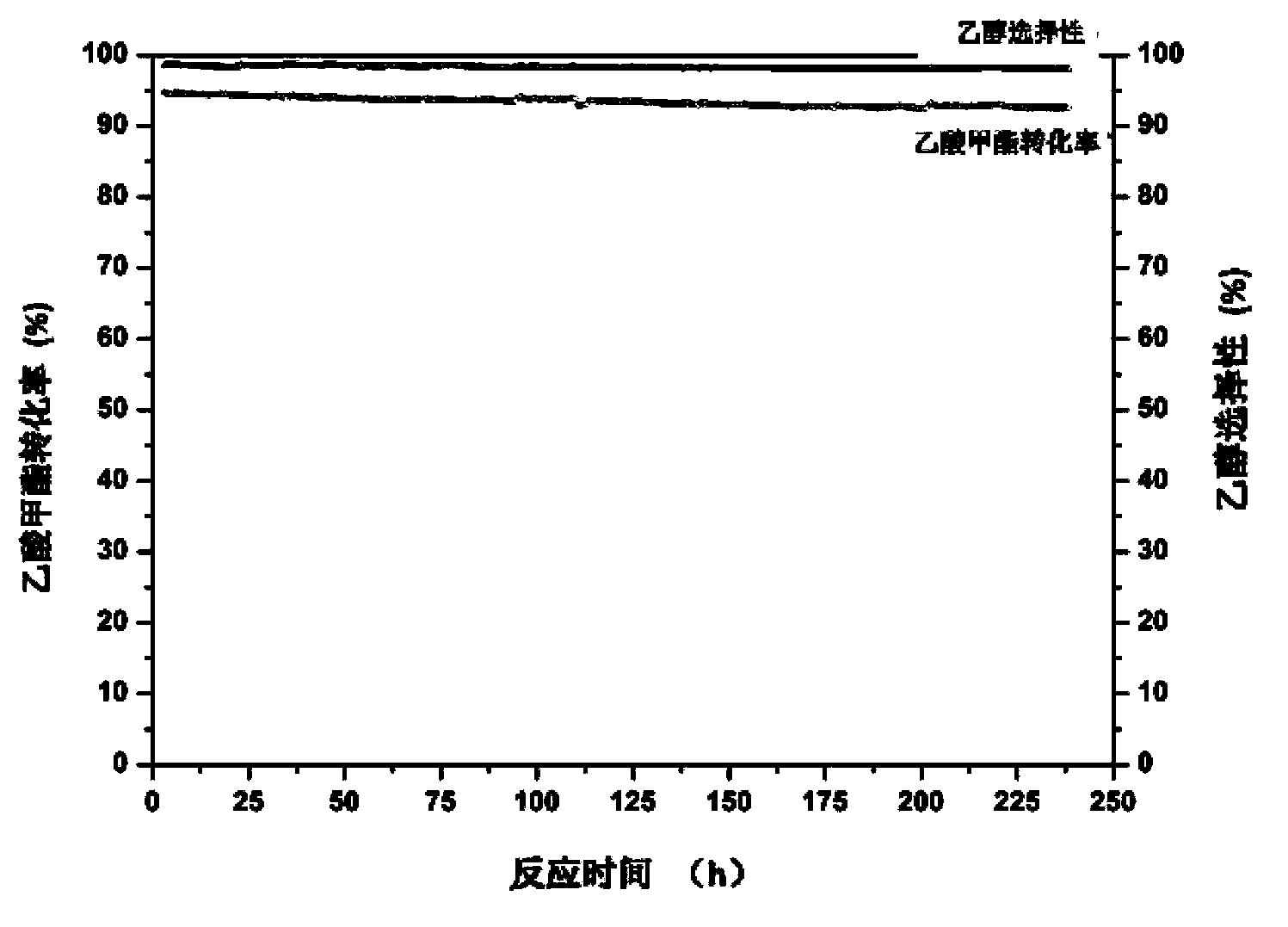

[0036] Embodiment 2. Catalyst pretreatment and reaction

[0037] When starting to investigate, at first the catalyst prepared in Example 1 was reduced for 5 hours at 350°C under the condition of pure hydrogen, or adding diluent gas, or synthesis gas, then the temperature of the bed was dropped to the specified reaction temperature, and the The feed gas reacts. The reactor is heated by an electric furnace, and the reaction temperature is determined by a thermocouple inserted into the catalyst bed. The composition of raw gas and product gas was detected by Angilent7890 gas chromatography.

Embodiment 3

[0038] Embodiment 3. the analytical method of product

[0039] The starting materials and the resulting products were analyzed using an Agilent 7890A gas chromatograph. The chromatograph is equipped with dual detectors FID and TCD, and has a ten-way valve, which allows the products to enter the packed column and capillary column respectively at the same time. The hydrogen flame detector detects hydrocarbons, alcohols and ethers in the product, and the thermal conductivity detector detects hydrogen and hydrogen in the raw materials and products. Data were processed with Agilent's Chemstation software.

[0040] The specific chromatographic conditions of Agilent are as follows:

[0041] Chromatography: Agilent 7890A

[0042] FID column: HP-PLOT-Q 19091S-001, 50m x 0.2mm (inner diameter), 0.5μm film thickness

[0043] Carrier gas: helium, 2.5ml / min

[0044] Oven temperature: 35°C for 5 minutes

[0045] 35-150°C, 5°C / min

[0046] 150℃ for 10min

[0047] Inlet: Split (50:1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com