Casting method of large-scale high pressure resisting multi-cylinder-block cast

An oil cylinder body and high-pressure-resistant technology, which is applied in the casting field of castings, can solve the problems of easy deposition of slag in castings, large wall thickness difference, complex structure, etc., and achieve good chemical composition of molten iron, uniform cooling speed and high temperature. evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

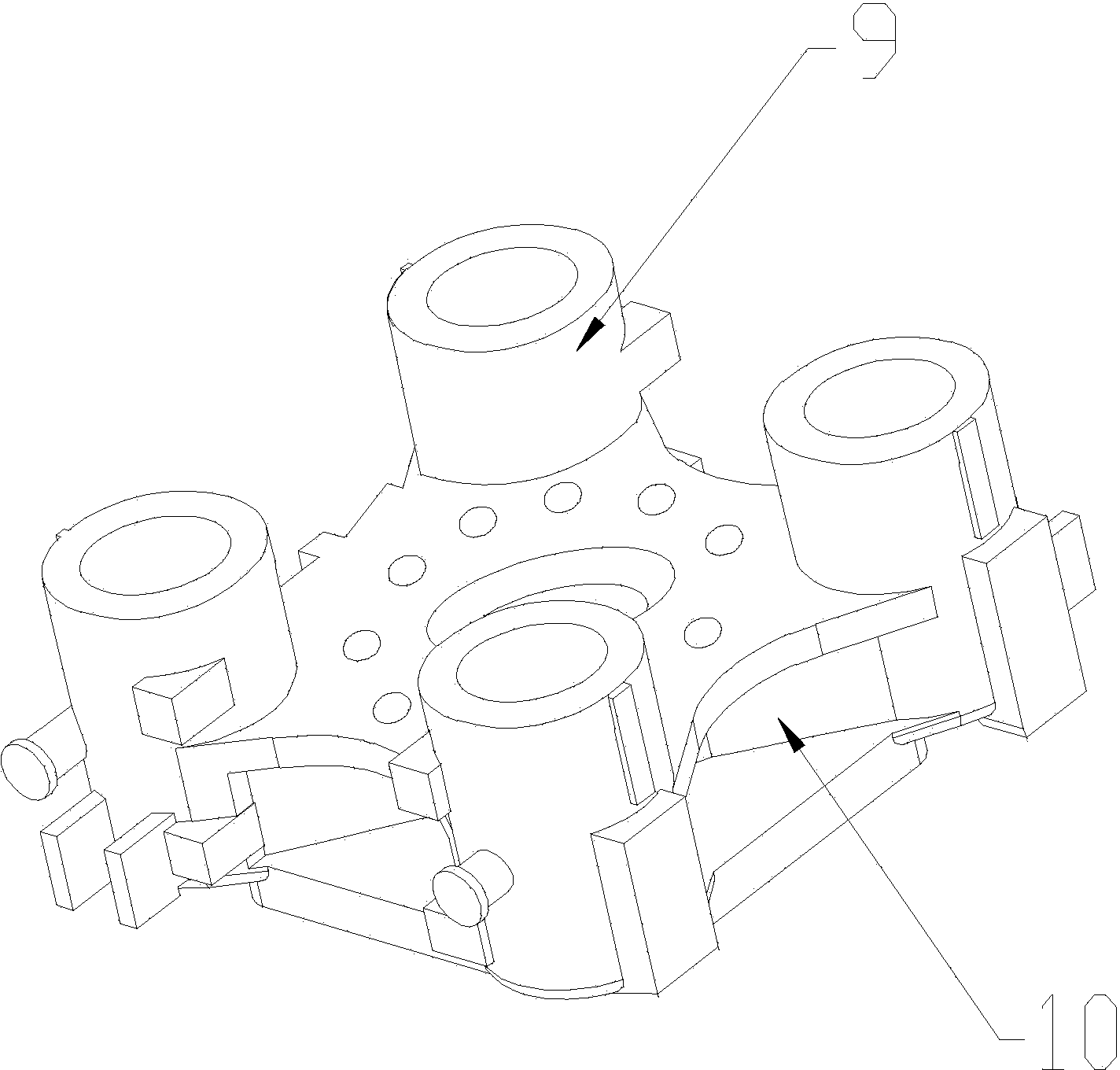

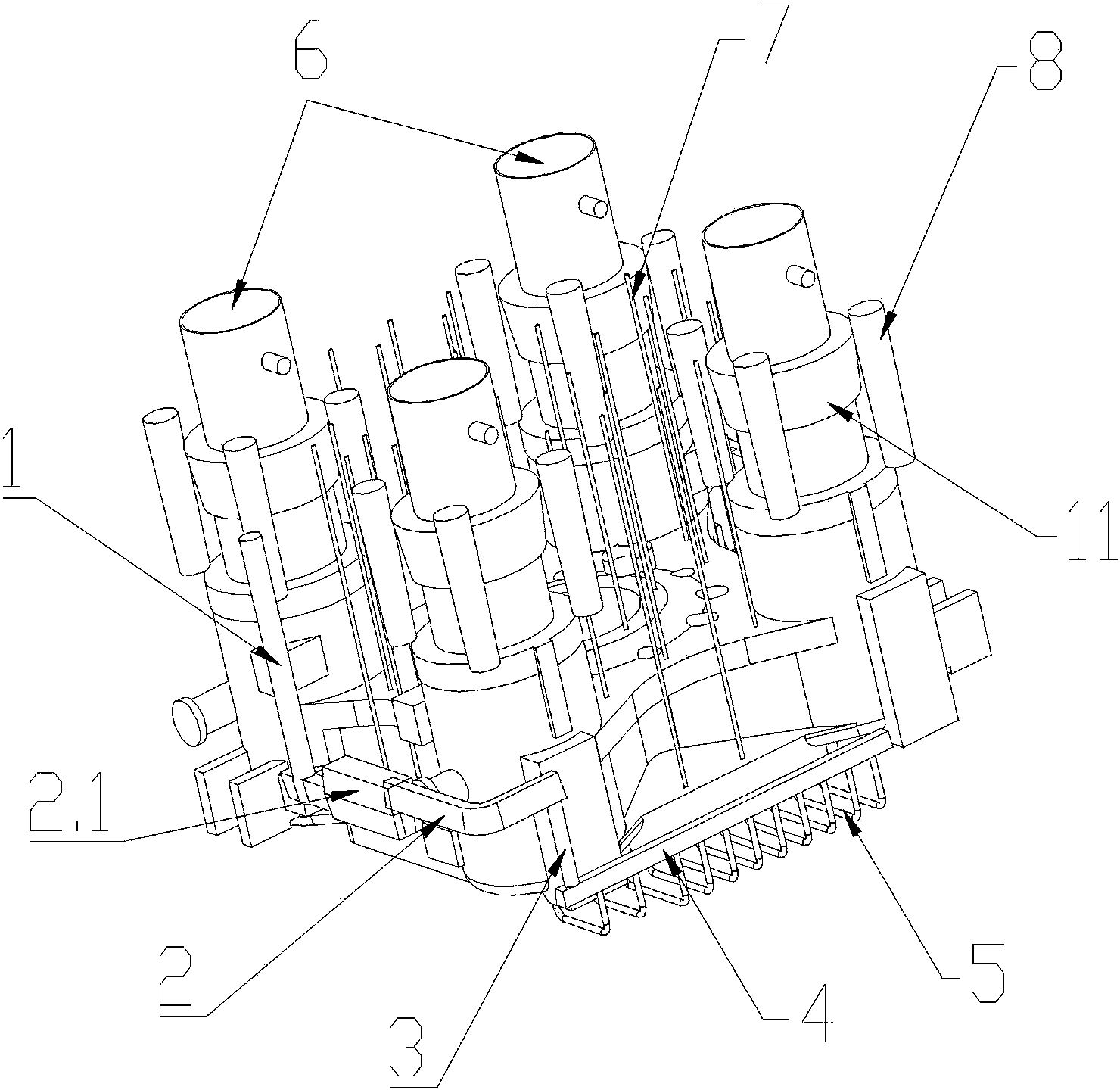

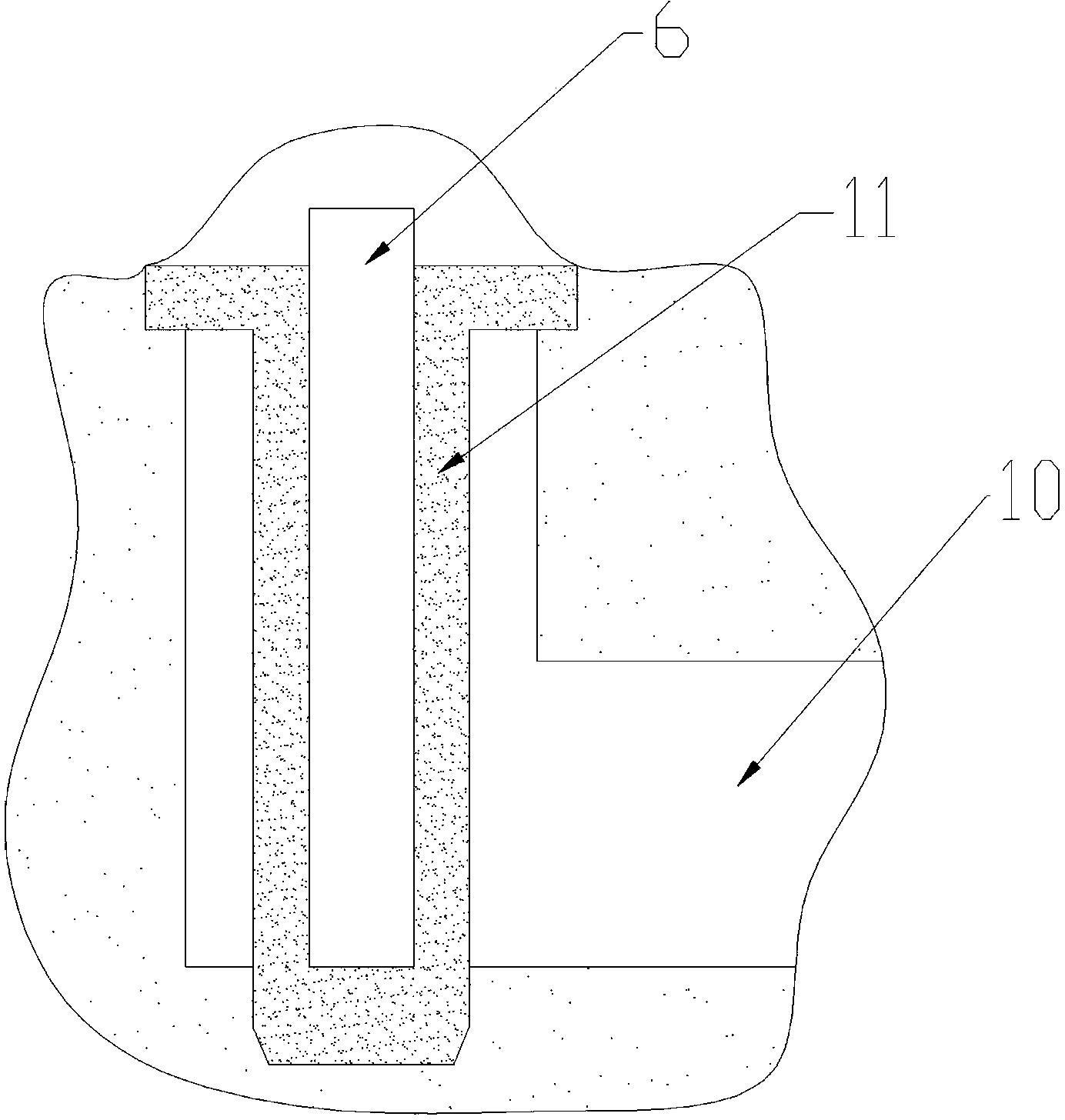

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of casting method of large-scale high-pressure resistant multi-oil cylinder body casting comprises the following steps:

[0025] 1) Mold manufacturing;

[0026] 2) Sand mold manufacturing;

[0027] 3) Pouring molding;

[0028] In step 2) sand mold manufacturing, the sprue is designed as the first sprue 1 and the second sprue 3, the runner is designed as the first runner 2 and the second runner 4, and the inner runner 5. It is designed as multiple runners parallel to each other. The first straight runner 1 is used as the entrance of molten iron. The cavity is also conducive to the floating of slag and gas to reduce pouring defects. The first sprue 1, the first runner 2, the second sprue 3, the second runner 4 and the ingate 5 are connected in sequence, and the inflow Chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com