Production method of high alpha phase silicon nitride powder

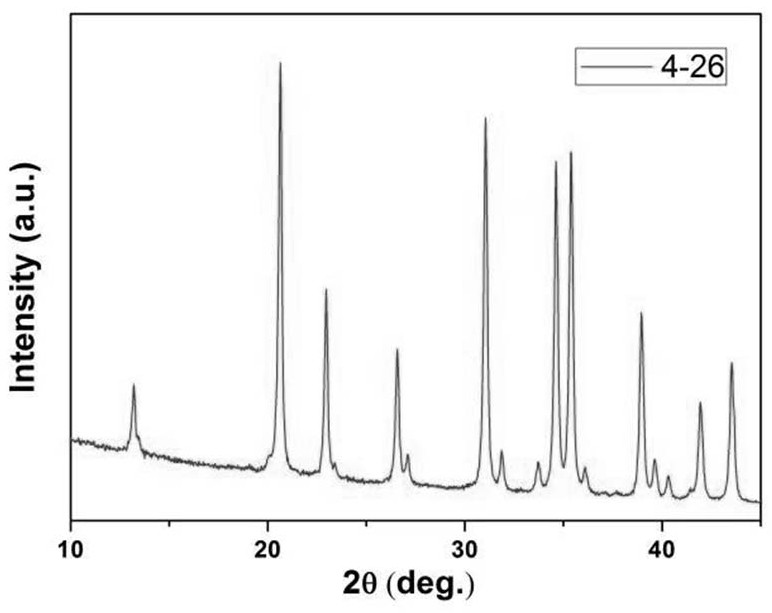

A technology of phase silicon nitride powder and production method, which is applied in the industrial production of high α-phase silicon nitride powder and the field of silicon nitride production, and can solve the problems of high residual free silicon content, influence on development, unstable process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The production method of high alpha phase silicon nitride powder adopts the following steps:

[0034] A: Grind and pulverize silicon powder until D90 is 6 μm;

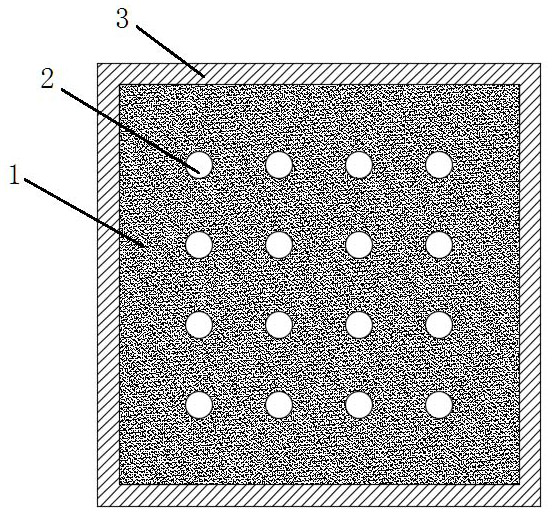

[0035] B: Put the ground silicon powder into the saggar with a thickness of 15-30mm; after the silicon powder is put into the saggar, divide the powder in the saggar into a plurality of square grids. The length of the side is 3-4cm, and the material hole is made on the material at the intersection of the grid. The diameter of the material hole is 0.8cm, and the material hole reaches the bottom of the saggar; image 3 It is a schematic diagram after the saggar is filled with silicon powder.

[0036] C: A plurality of saggers filled with silicon powder are stacked up and down into a stack, and the sum of the thicknesses of the silicon powder in each sagger in the stacked stack is less than or equal to 300mm;

[0037] D: Put multiple stacks of saggars filled with silicon powder into the vacuum heating furnace, th...

Embodiment 2

[0049] The production method of high alpha phase silicon nitride powder adopts the following steps:

[0050] A: Grind and pulverize silicon powder until D90 is 6 μm;

[0051] B: Put the ground silicon powder into the saggar with a thickness of 15-30mm; after the silicon powder is put into the saggar, divide the powder in the saggar into a plurality of square grids. The length of the side is 3-4cm, and the material hole is punched on the material at the intersection of the grid. The diameter of the material hole is 0.6cm, and the material hole reaches the bottom of the sagger;

[0052] C: A plurality of saggers filled with silicon powder are stacked up and down into a stack, and the sum of the thicknesses of the silicon powder in each sagger in the stacked stack is less than or equal to 300mm;

[0053] D: Put multiple stacks of saggars filled with silicon powder into the vacuum heating furnace, the total weight of the silicon powder in the multiple stacks of saggars filled wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com