Device and method for producing polylactic acid material

A technology of polylactic acid and prepolymerization tank, which is applied in the field of equipment for producing polylactic acid materials, and can solve the problems of high residual amount of lactide monomer and unfavorable post-processing of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

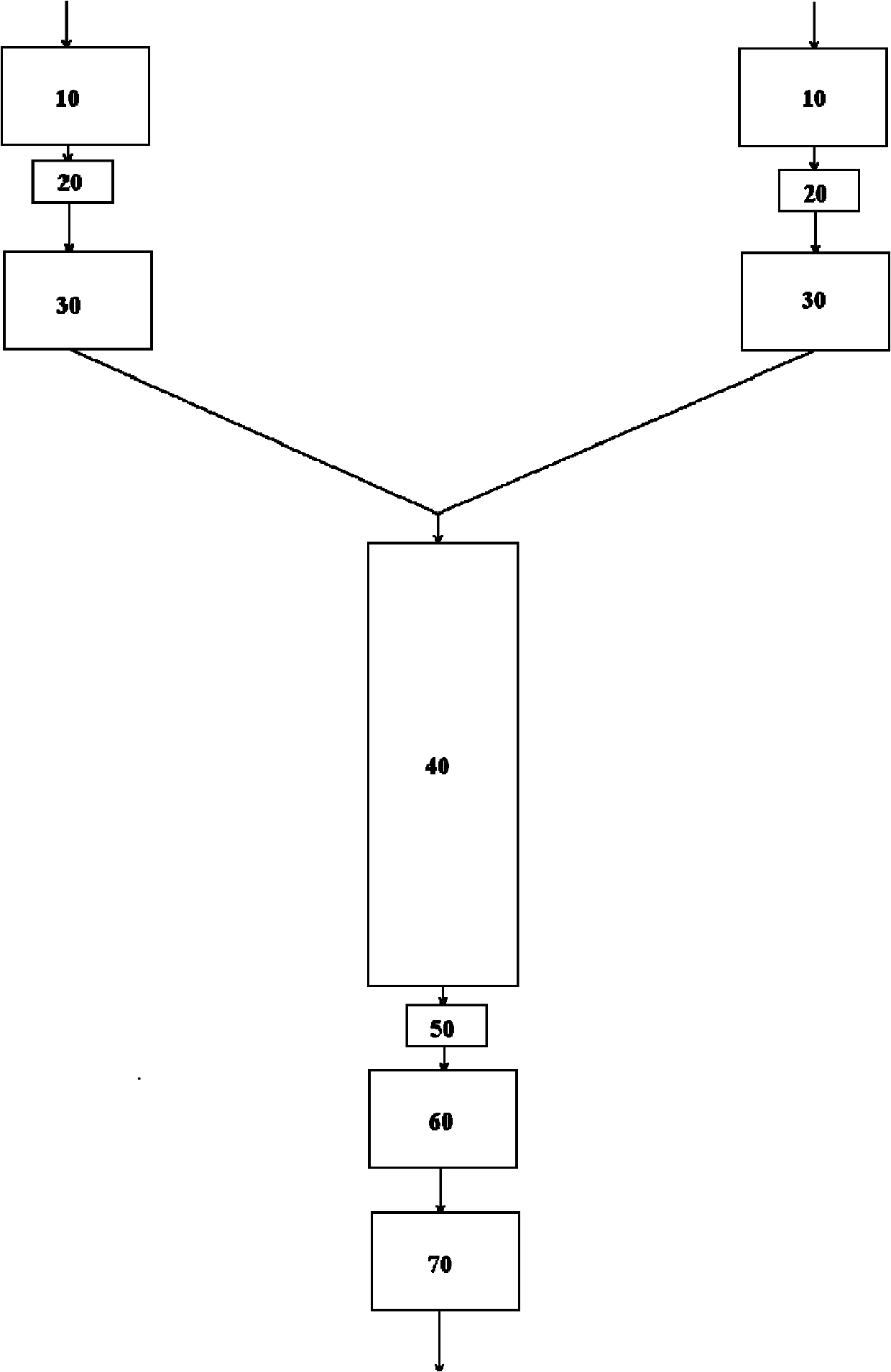

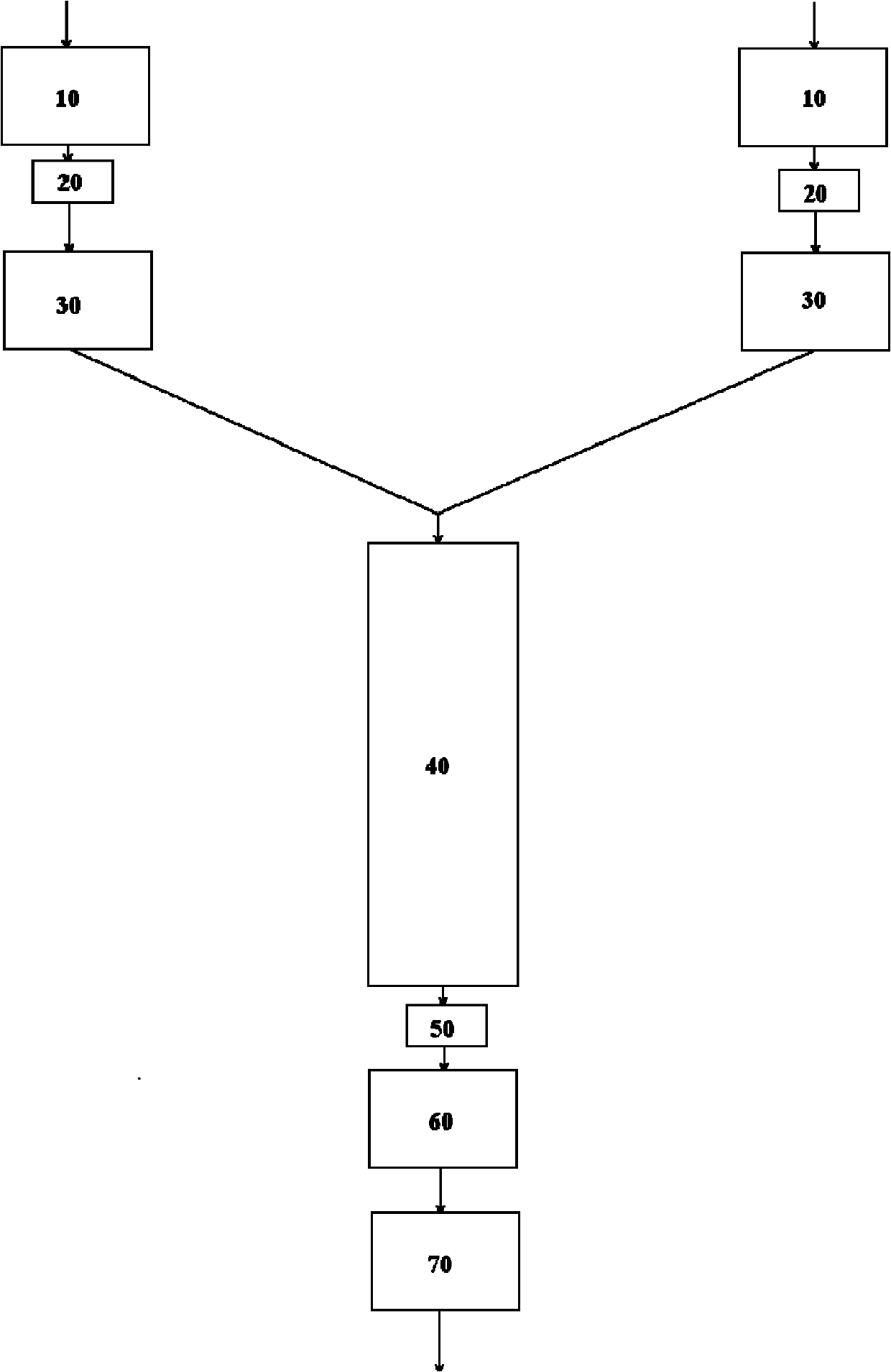

Method used

Image

Examples

Embodiment 1

[0062] Add 15kg of L-lactide into a 500L pre-melting kettle, pump out the air in the kettle and fill it with nitrogen, then raise the temperature to 120°C after vacuuming and nitrogen filling several times. After the L-lactide is completely melted, it is supplied to a 15L prepolymerization tank by a melt metering pump. Add 15g of stannous octoate therein so that its weight based on L-lactide is 0.1% by weight, heat up to 130°C, then start prepolymerization at 0.1Mpa, open when the L-lactide conversion rate reaches 10% Outlet valve, which feeds the contents of the prepolymerization tank into the tubular reactor. The tubular reactor used consisted of 4 sections, each 1.1 m long, with a total length of 4.4 m. The polymerization temperature is controlled at 160-210°C by means of multi-stage temperature control, and then the polymerization is started at 0.4Mpa. The total residence time of materials in the tubular reactor was 3 hours, and the conversion rate of L-lactide was 99%. ...

Embodiment 2

[0064] Add 15kg of DL-lactide into a 500L pre-melting kettle, pump out the air in the kettle and fill it with nitrogen. After several times of vacuuming and nitrogen filling, the temperature is raised to 140°C. After the DL-lactide is completely melted, it is supplied to a 25L prepolymerization tank through a melt metering pump. Add 15g stannous benzoate therein so that its weight based on DL-lactide is 0.1% by weight, be warming up to 180°C, then start prepolymerization at 0.4Mpa, when the DL-lactide conversion rate reaches 30% Open the discharge valve and feed the contents of the prepolymerization tank into the tubular reactor. The tubular reactor used consisted of 4 sections, each 1.1 m long, with a total length of 4.4 m. The polymerization temperature is controlled at 180-200°C by means of multi-stage temperature control, and then the polymerization is started at 1.0Mpa. The total residence time of materials in the tubular reactor was 0.5 hour, and the conversion rate of...

Embodiment 3

[0066]A mixture of 15 kg of L-lactide and glycolide (the weight ratio of L-lactide and glycolide is 80:20) was added into a premelting kettle with a volume of 500 L, and the air in the kettle was removed and filled with nitrogen. After evacuating and filling with nitrogen several times, the temperature was raised to 130°C. After L-lactide and glycolide are completely melted, they are supplied to a 15L prepolymerization tank by a melt metering pump. 7.5g stannous chloride is added thereto so that it is 0.05% by weight based on the total weight of L-lactide and glycolide, the temperature is raised to 140°C, and then prepolymerization is started at 0.4Mpa, when L-lactide After the overall conversion rate of glycolide and glycolide reaches 21%, the discharge valve is opened, and the contents of the prepolymerization tank are fed into the tubular reactor. The tubular reactor used consisted of 4 sections, each 1.1 m long, with a total length of 4.4 m. The polymerization temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com