Efficient condenser

A condenser and high-efficiency technology, which is applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of insignificant increase in subcooling degree and insufficient heat exchange of cooling water, and achieve obvious effect of energy saving and consumption reduction. , The effect of preventing direct impact on the heat exchange tube and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

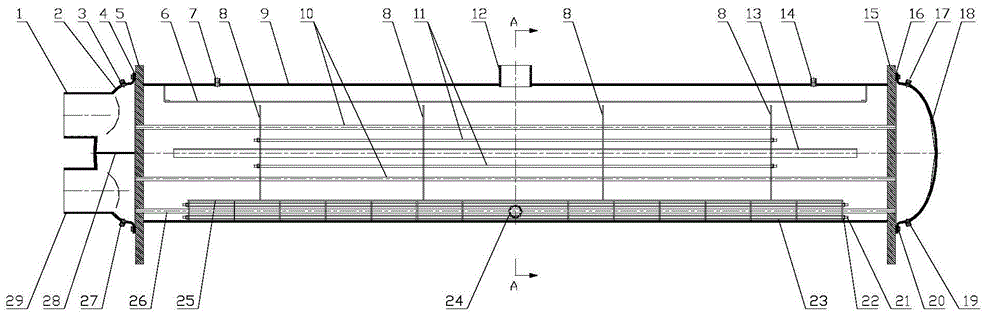

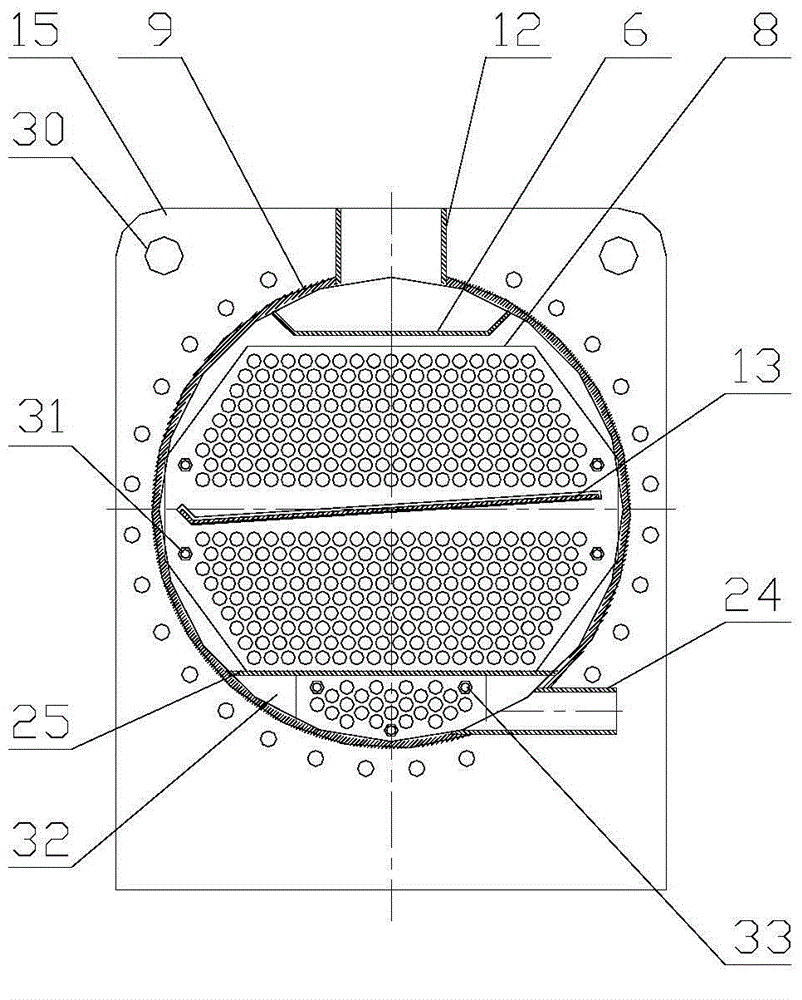

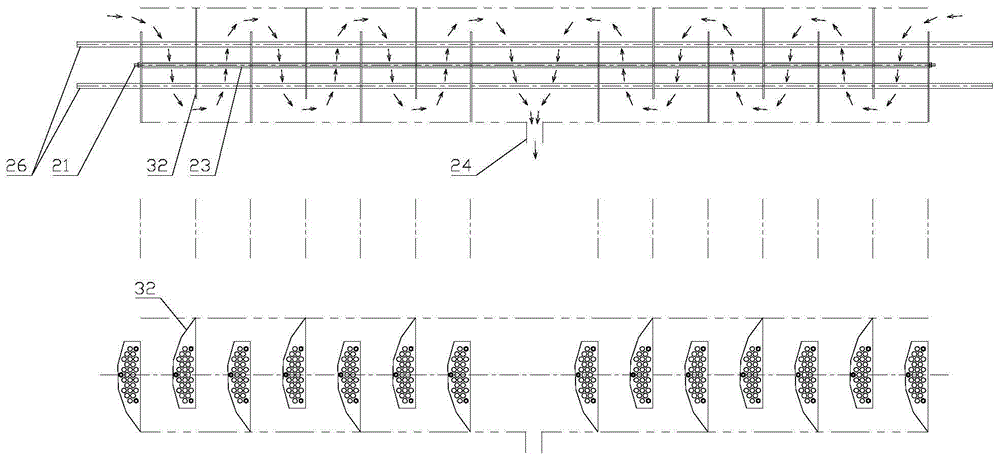

[0029] Example 1:A high-efficiency condenser, including a shell 9, fixed on the first end cover 2 and the second end cover 18 at both ends of the shell 9 by bolts 20, and respectively arranged on the first end cover 2, the second end cover 18 and the shell Between the bodies 9, the first tube sheet 5 and the second tube sheet 15 of the shell 9 are closed, and the top and bottom ends of the middle part of the shell 9 are respectively provided with a refrigerant gas inlet 12 and a refrigerant liquid outlet 24, inside the shell 9 From top to bottom, a plurality of heat exchange tubes 10 and supercooling tubes 26 form a condensation heat exchange zone and a supercooling zone, and the two ends of each heat exchange tube 10 and supercooling tube 26 pass through the first tube The plate 5 and the second tube sheet 15 communicate with the inner cavity of the first end cover 2 and the second end cover 18; the first end cover 2 is provided with a split rib 28, which divides the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com