Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Axial temperature difference is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

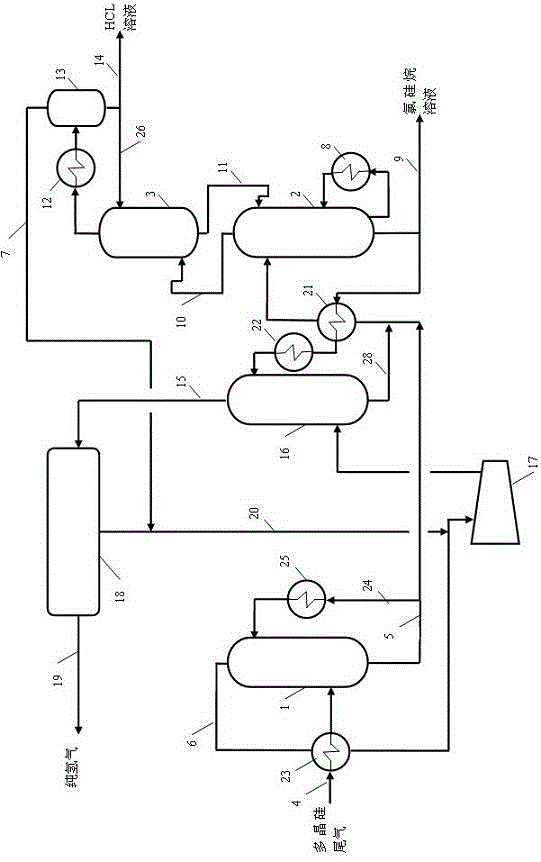

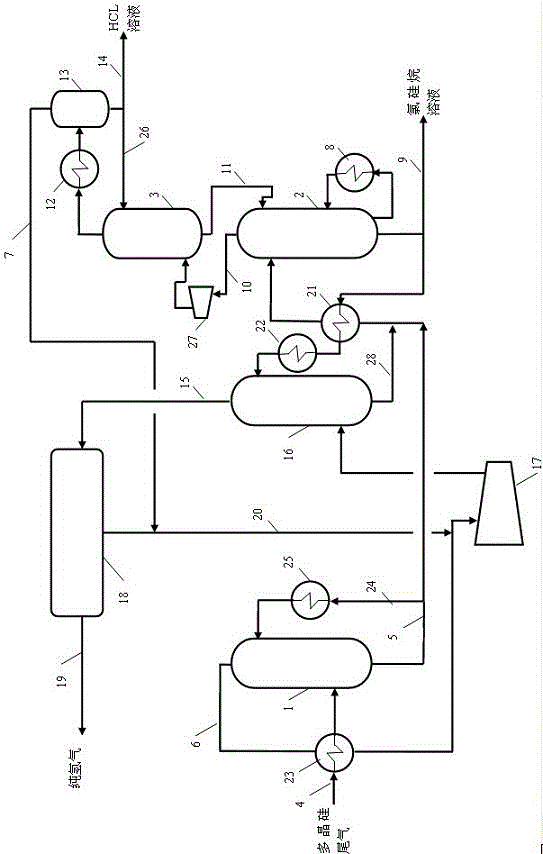

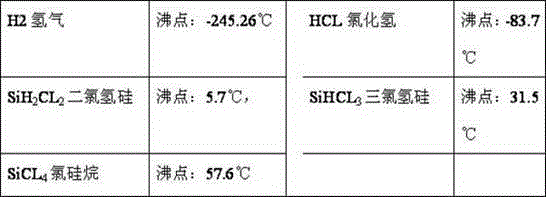

System and process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment

InactiveCN102249187ASolve environmental problemsEfficient recyclingChlorine/hydrogen-chloride purificationHydrogen separation using liquid contactHydrogenReboiler

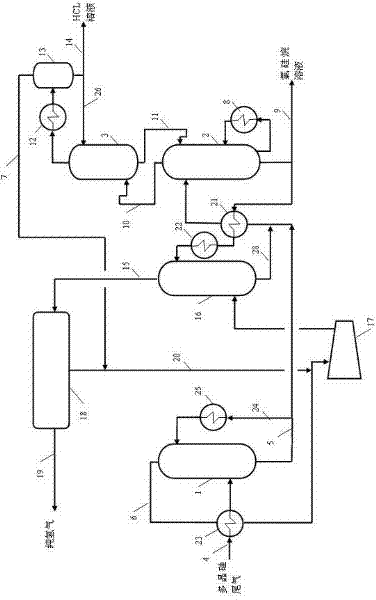

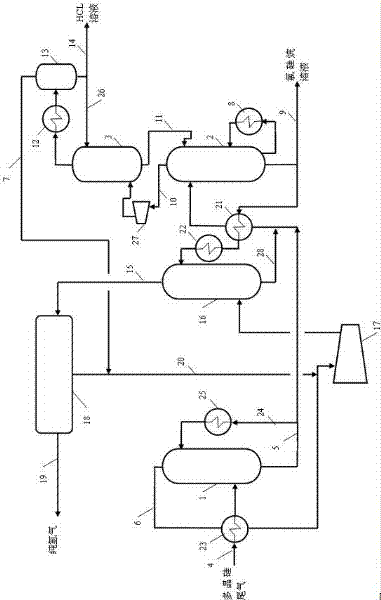

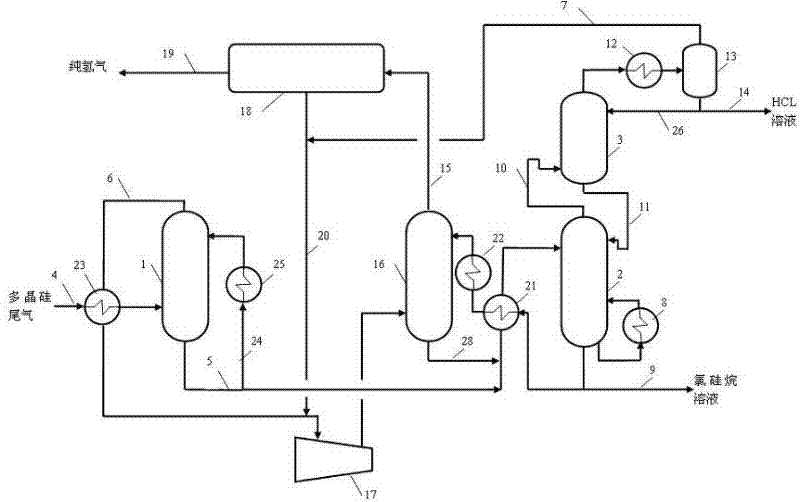

The invention discloses a system for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment, and the system mainly comprises a tail gas circulated condensing and washing tower, a chlorosilane stripper and a HCl rectifying tower, wherein the tail gas circulated condensing and washing tower is equipped with a polysilicon tail gas inflow pipe, a first chlorosilane solution outflow pipe and a first hydrogen outflow pipe, and the first chlorosilane solution outflow pipe is connected with the chlorosilane stripper; the chlorosilane stripper is equipped with a reboiler, a second chlorosilane solution outflow pipe, a first HCl outflow pipe and a stripping backflow pipe, and the first HCl outflow pipe and the stripping backflow pipe are connected with the HCl rectifying tower; and the HCl rectifying tower is equipped with a condenser, a separator and a second HCl outflow pipe which are connected in turn, and the separator is equipped with a non-condensable gas outflow pipe. The invention also discloses a process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment. Through the system and process disclosed by the invention, the polysilicon tail gas is turned into things of value, the resources are saved, and simultaneously the energy consumption during the treatment process is reduced.

Owner:SICHUAN TECHAIRS

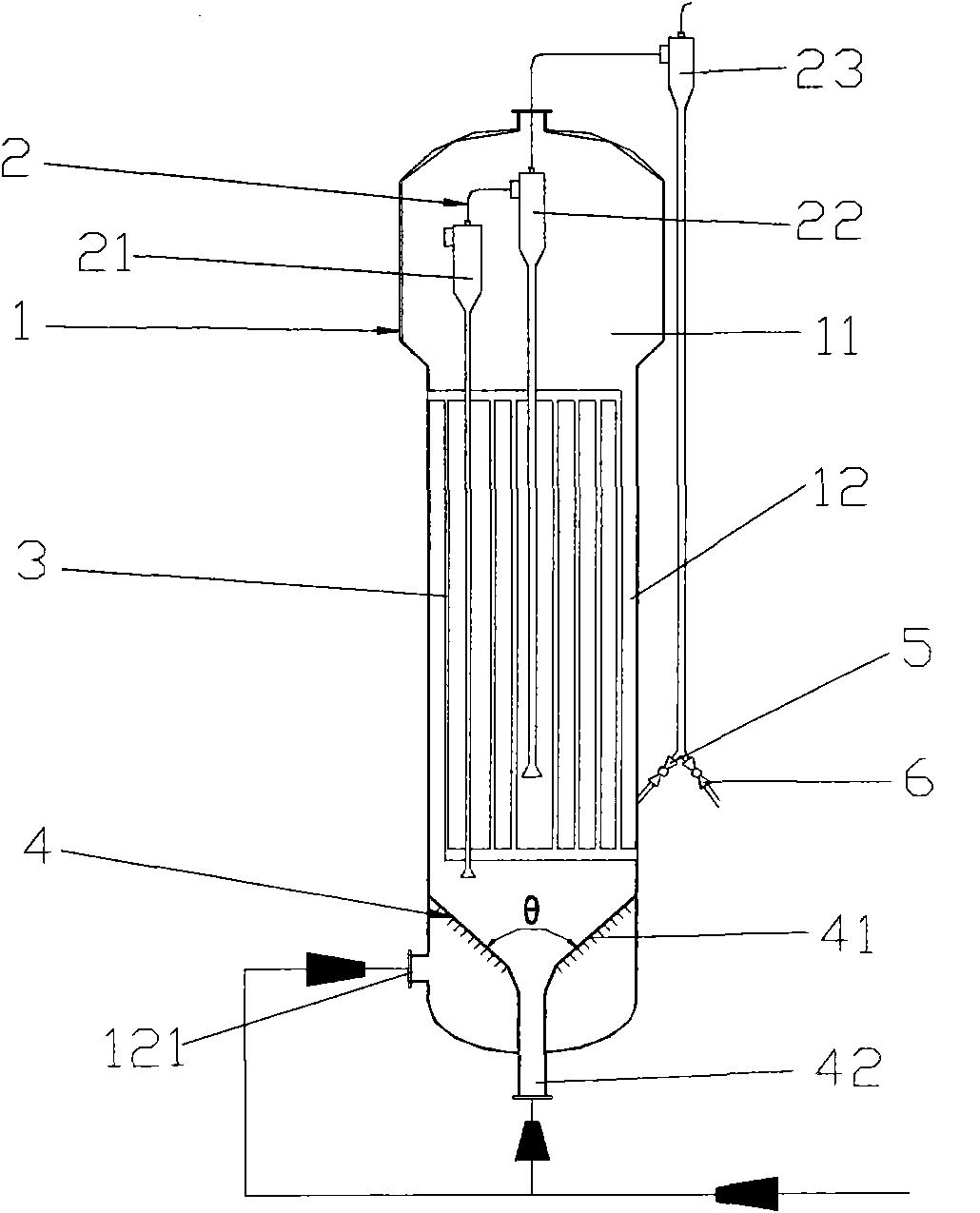

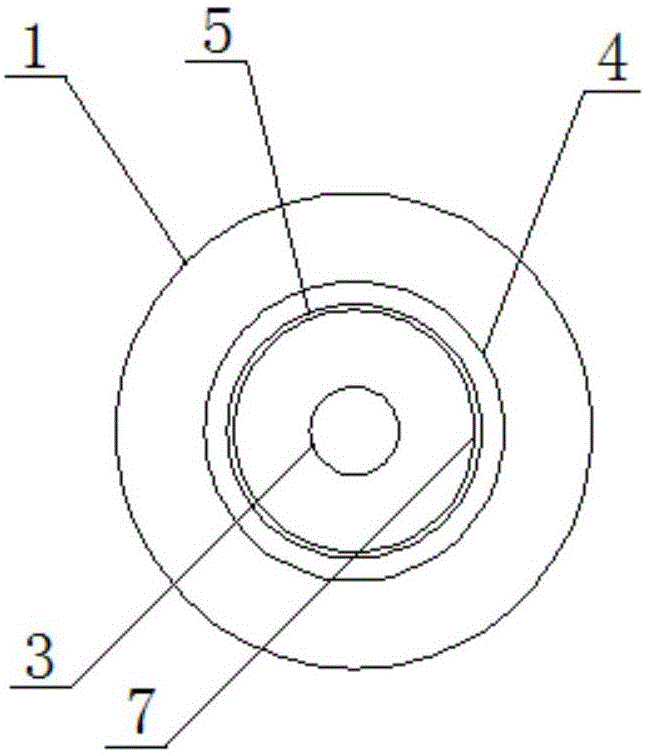

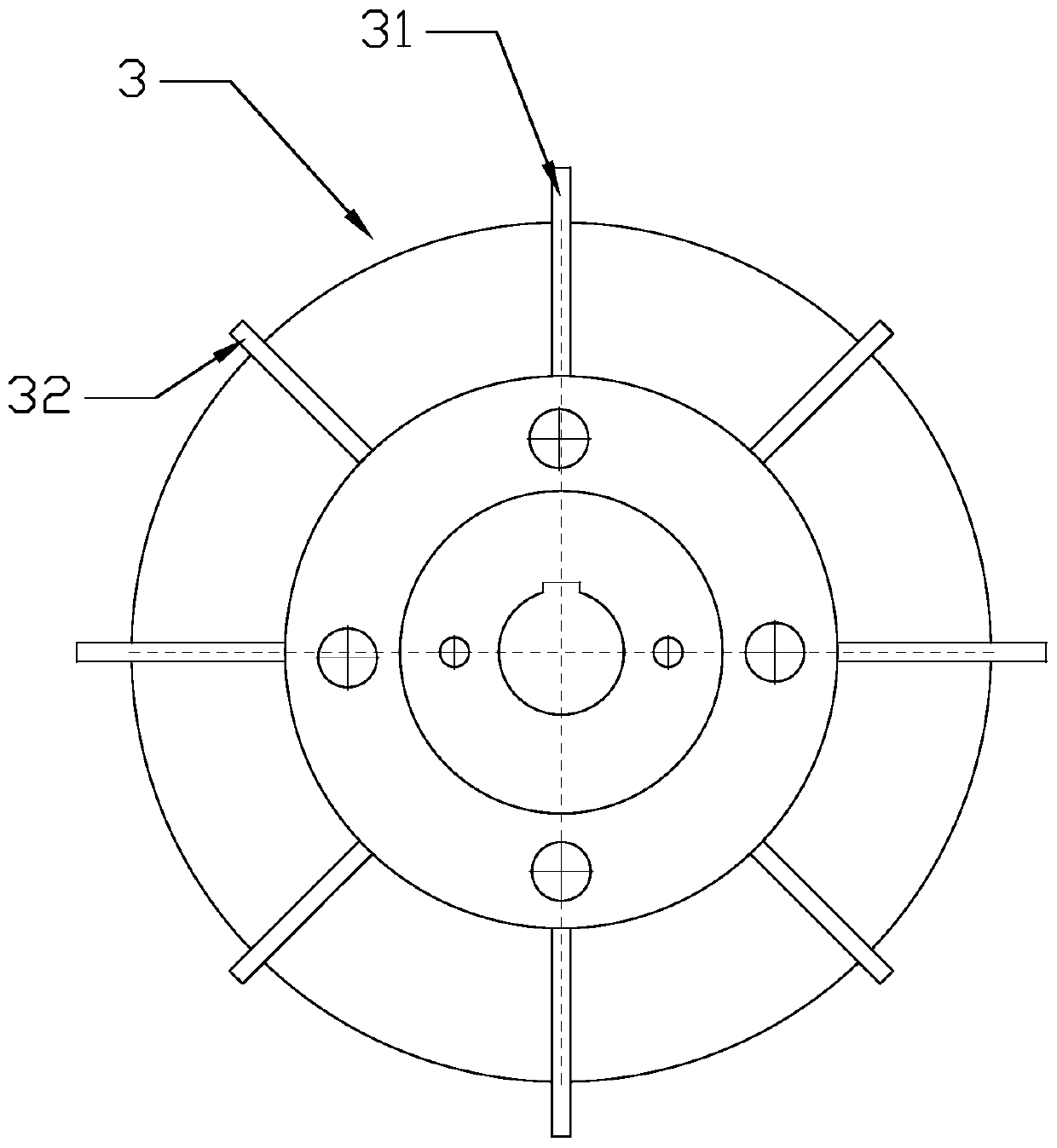

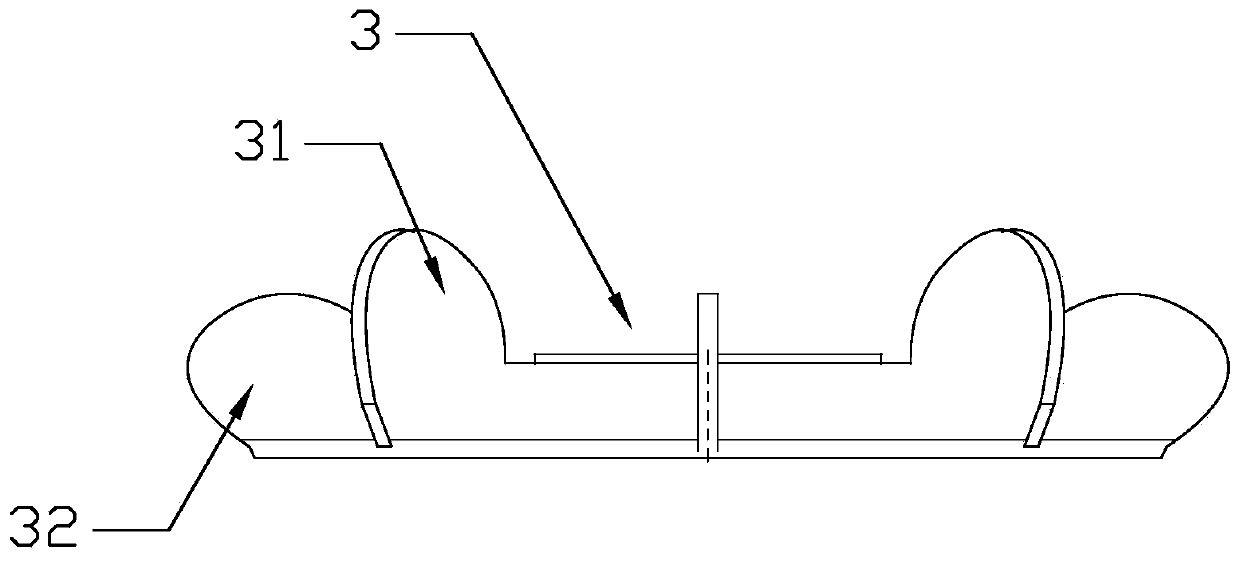

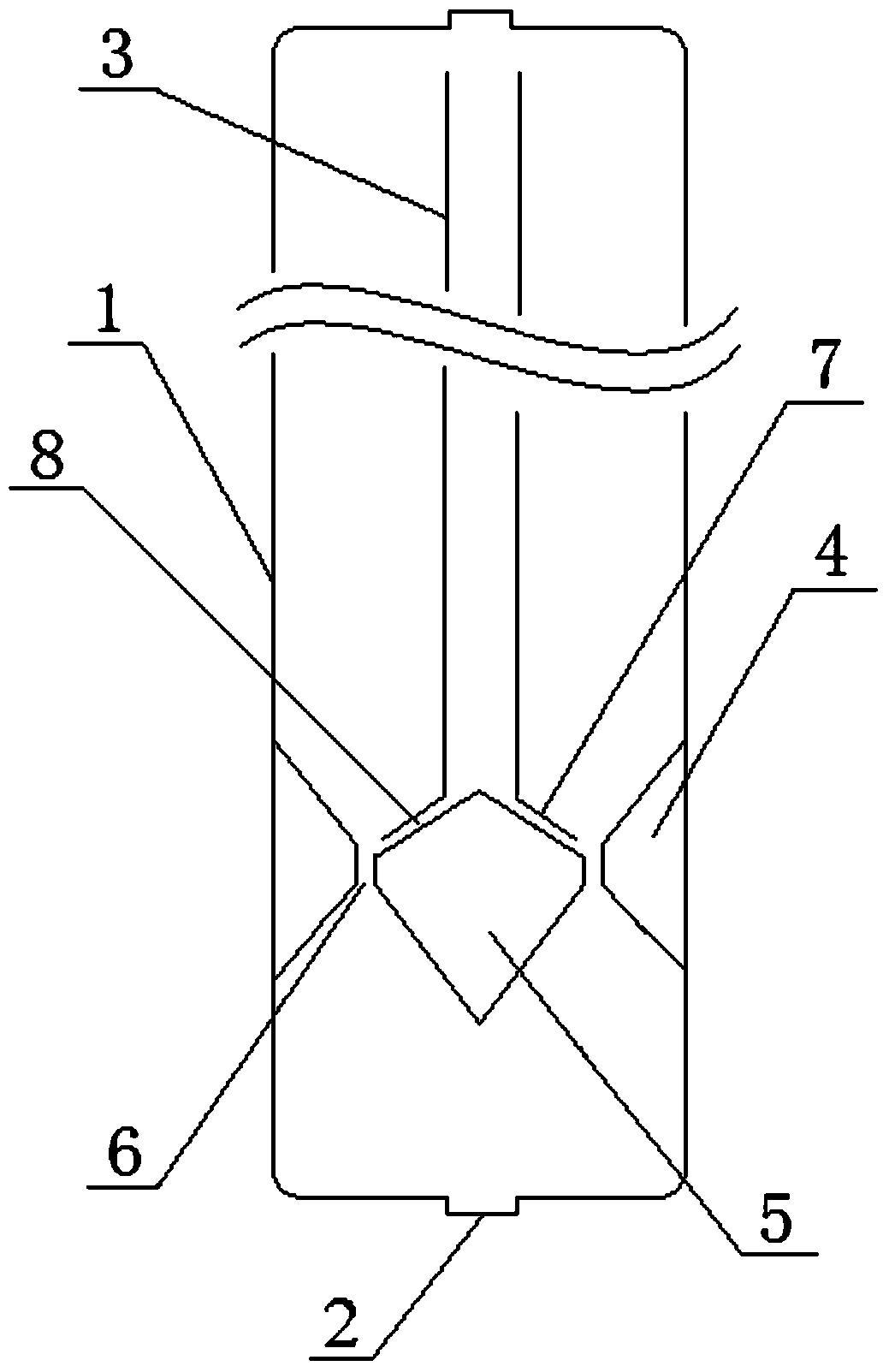

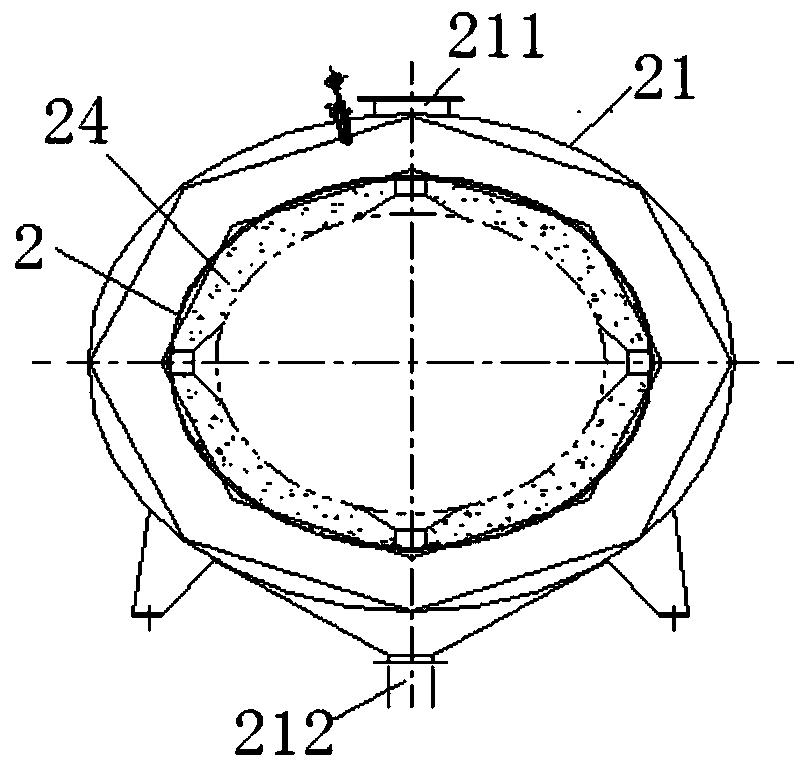

Spout type fluidized bed reactor for synthesis of organic silicon

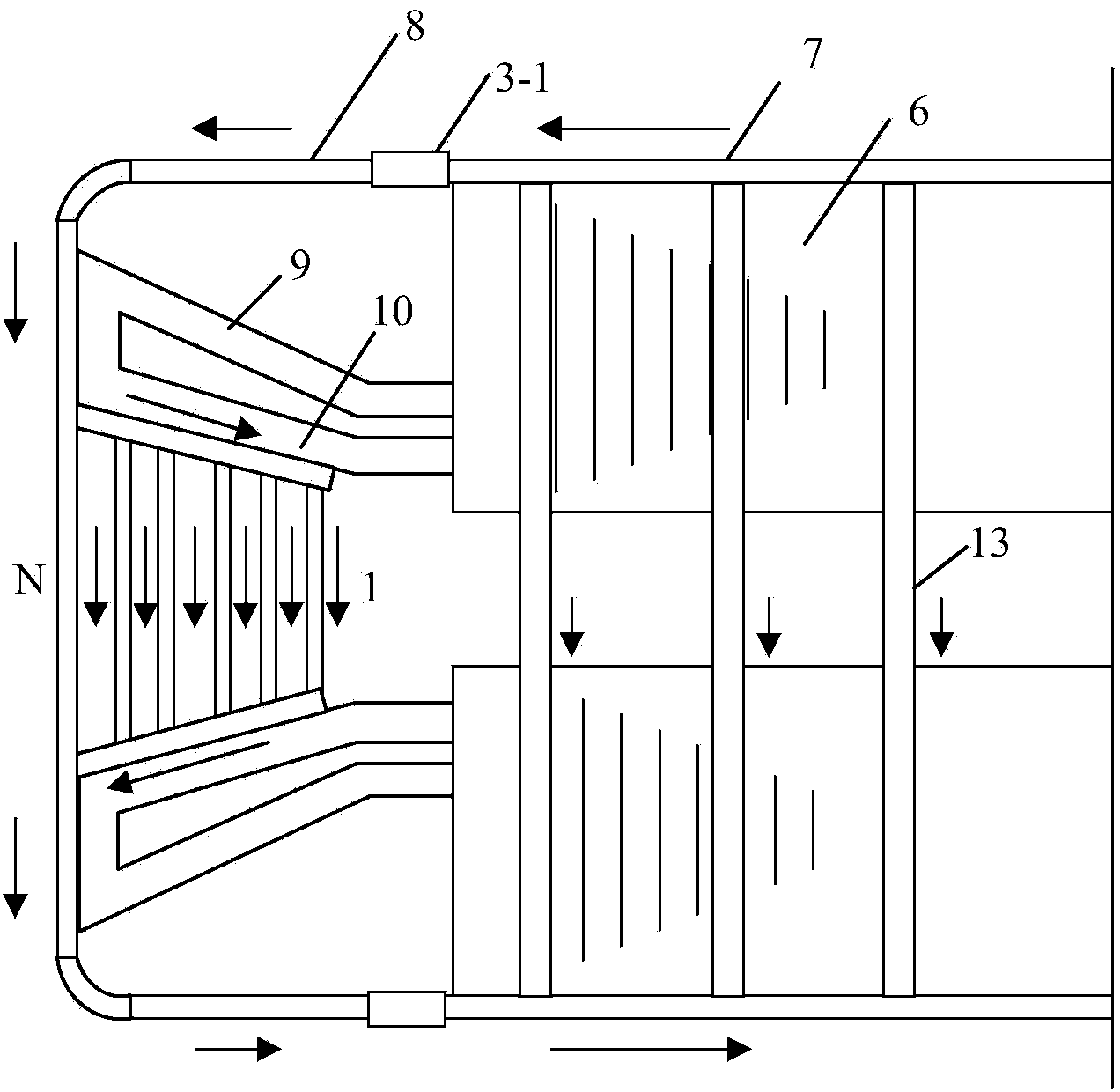

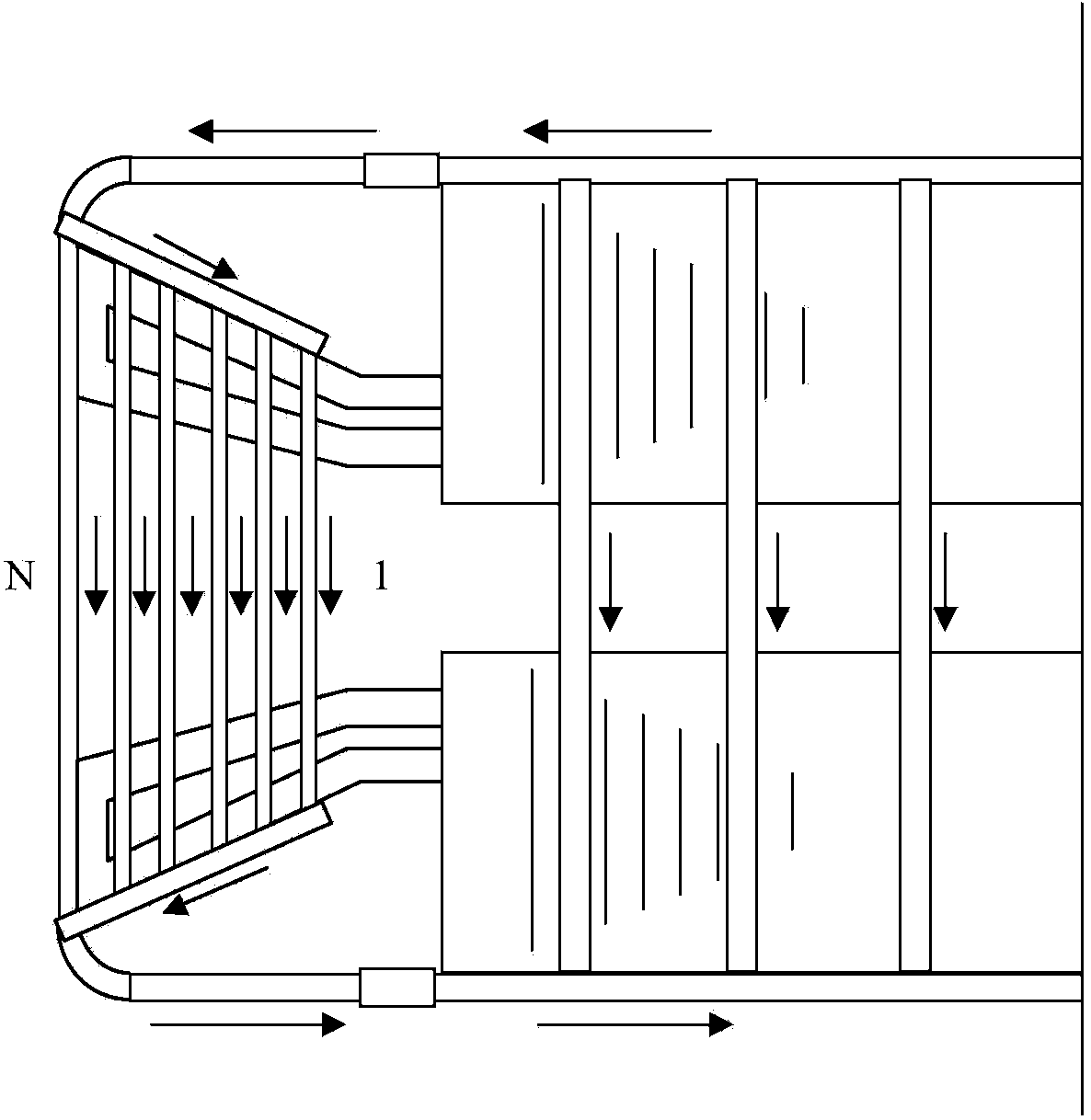

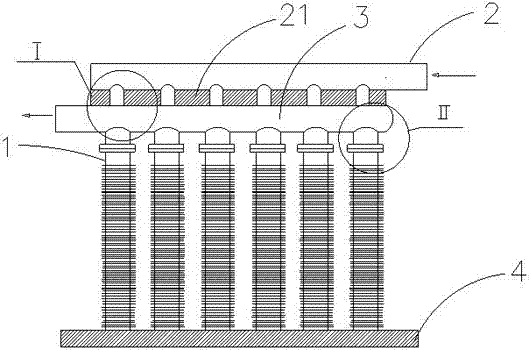

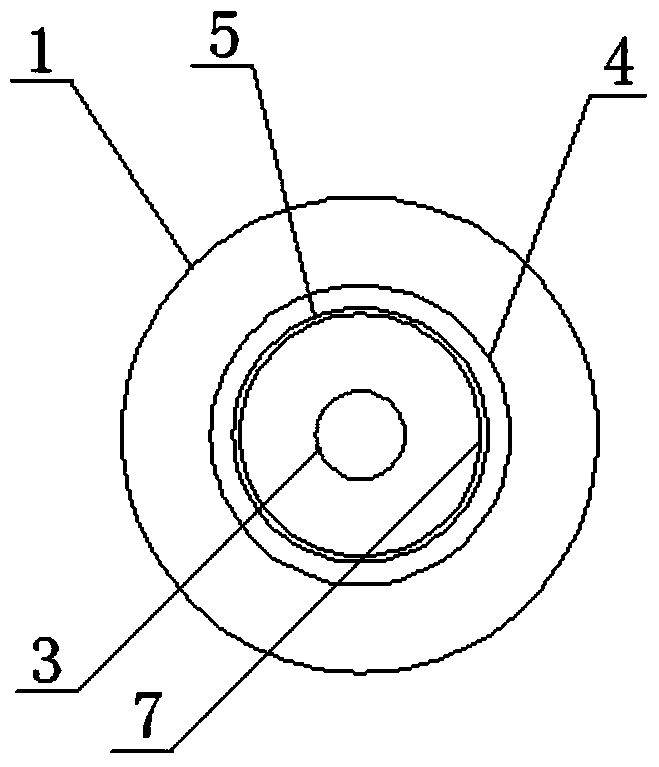

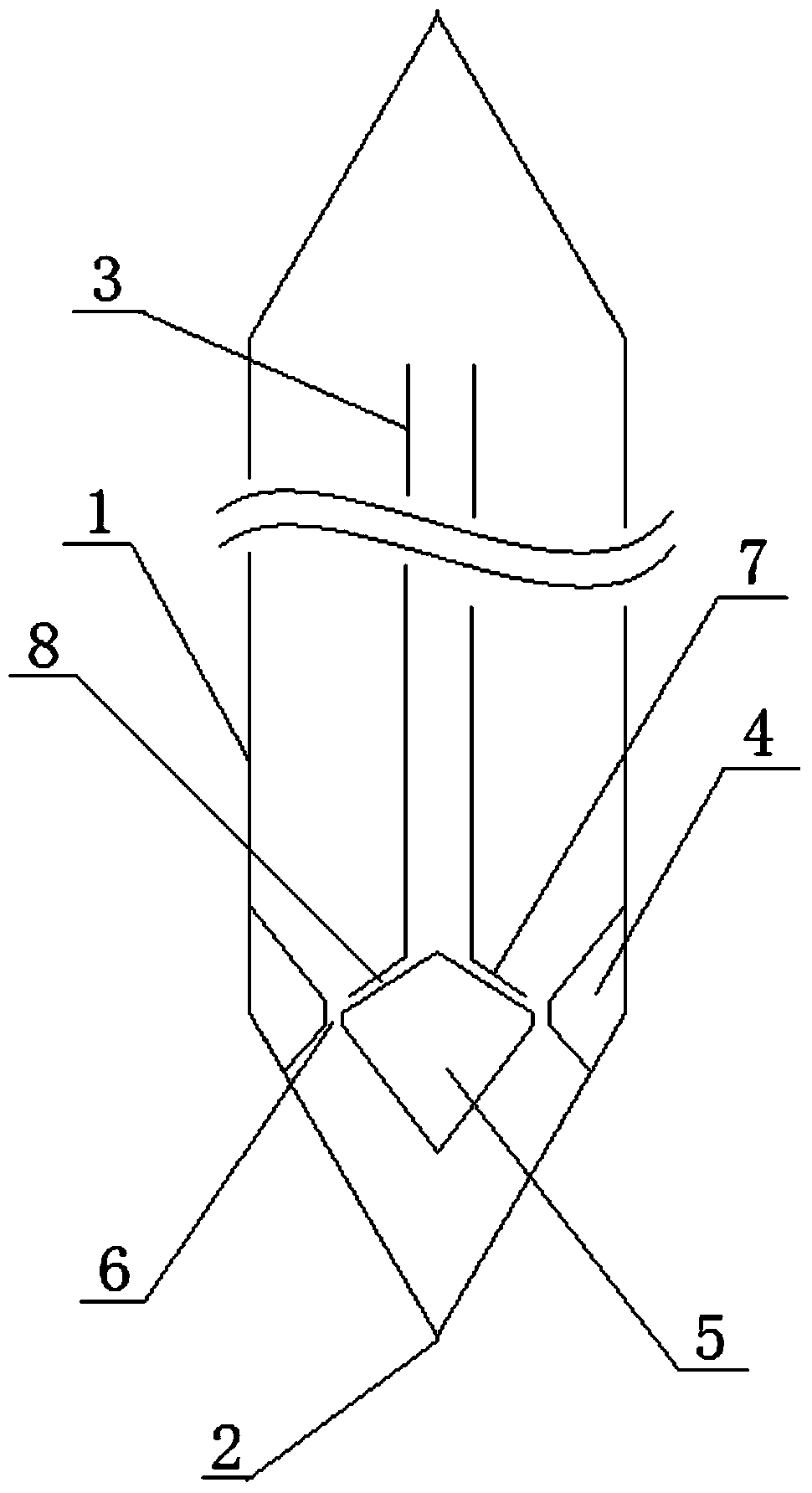

ActiveCN102078784AUniform heat exchangeAxial temperature difference is smallGroup 4/14 element organic compoundsChemical/physical processesCycloneFluidized bed

A spout type fluidized bed reactor for synthesis of organic silicon comprises a reactor body, an expanded section, tube bore-hole type combination distributors, cyclone separator components, a back-to-bed valve, a powder-ridding tank valve and tubular heat exchangers, wherein the tube bore-hole type combination distributor is arranged at the bottom of the reactor bed body and comprises a conical gas distributor, a straight tube pore-type distributor and a spouted gas tube; the tubular heat exchangers are arranged in the reactor bed body, heat exchange carriers flowing through the heat exchanging tubes from bottom to top, to achieve single-tube pass heat transfer, so that the heat transfer between the tube surfaces and reacting fluid is even, and radial and axial temperature difference aresmall; particles separated by the cyclone separating device are directly returned back to the bed by the inner and external cyclone separating devices in time and not be taken out of the bed or partial particles are taken out, thereby reducing the catalyst content in the bed and the temperature fluctuation and being beneficial to improving reaction efficiency.

Owner:HOSHINE SILICON IND CO LTD

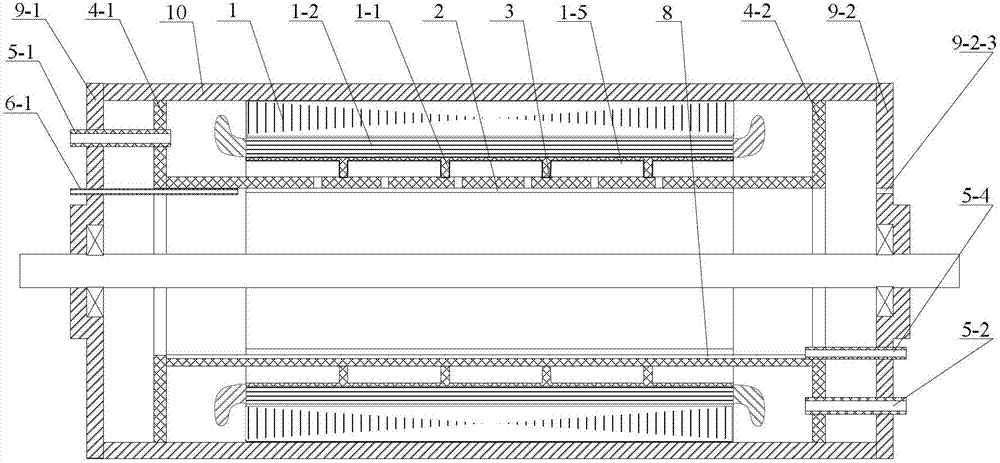

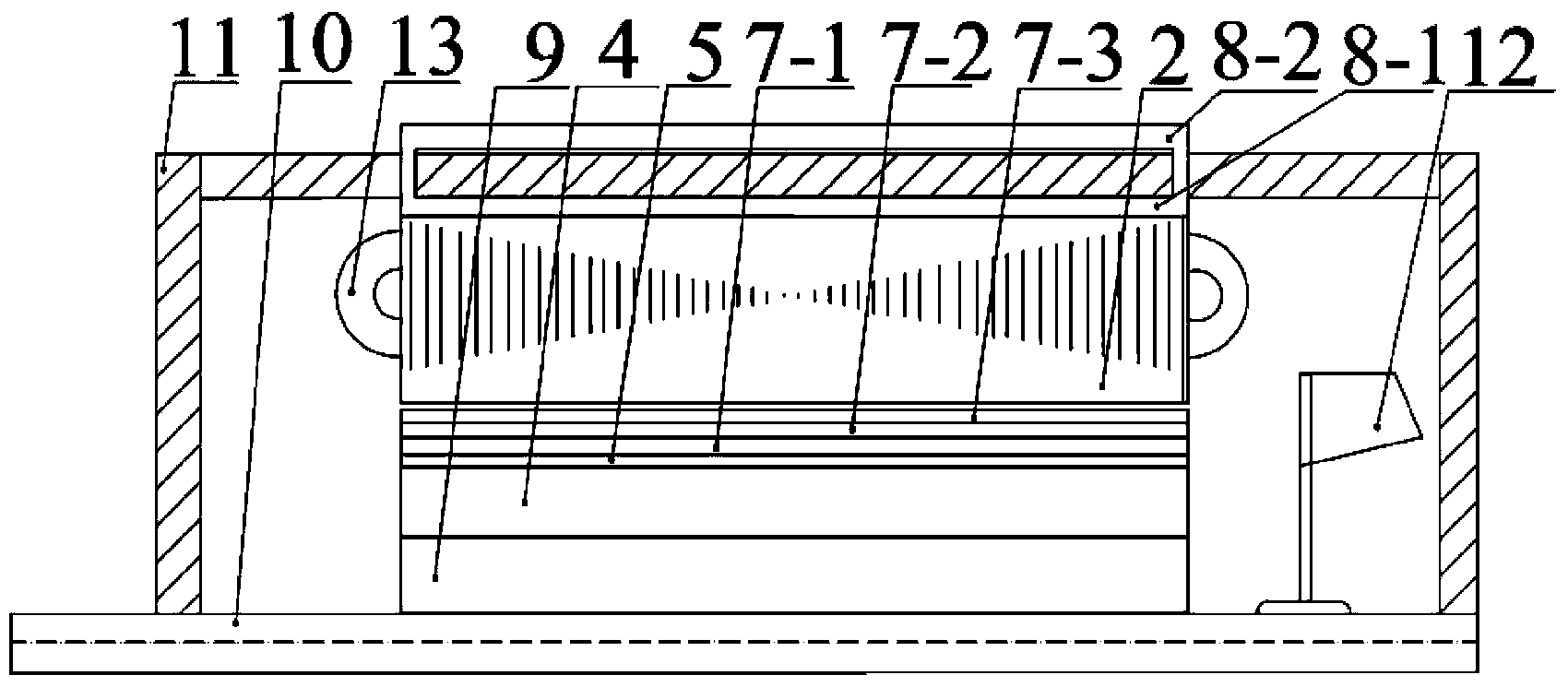

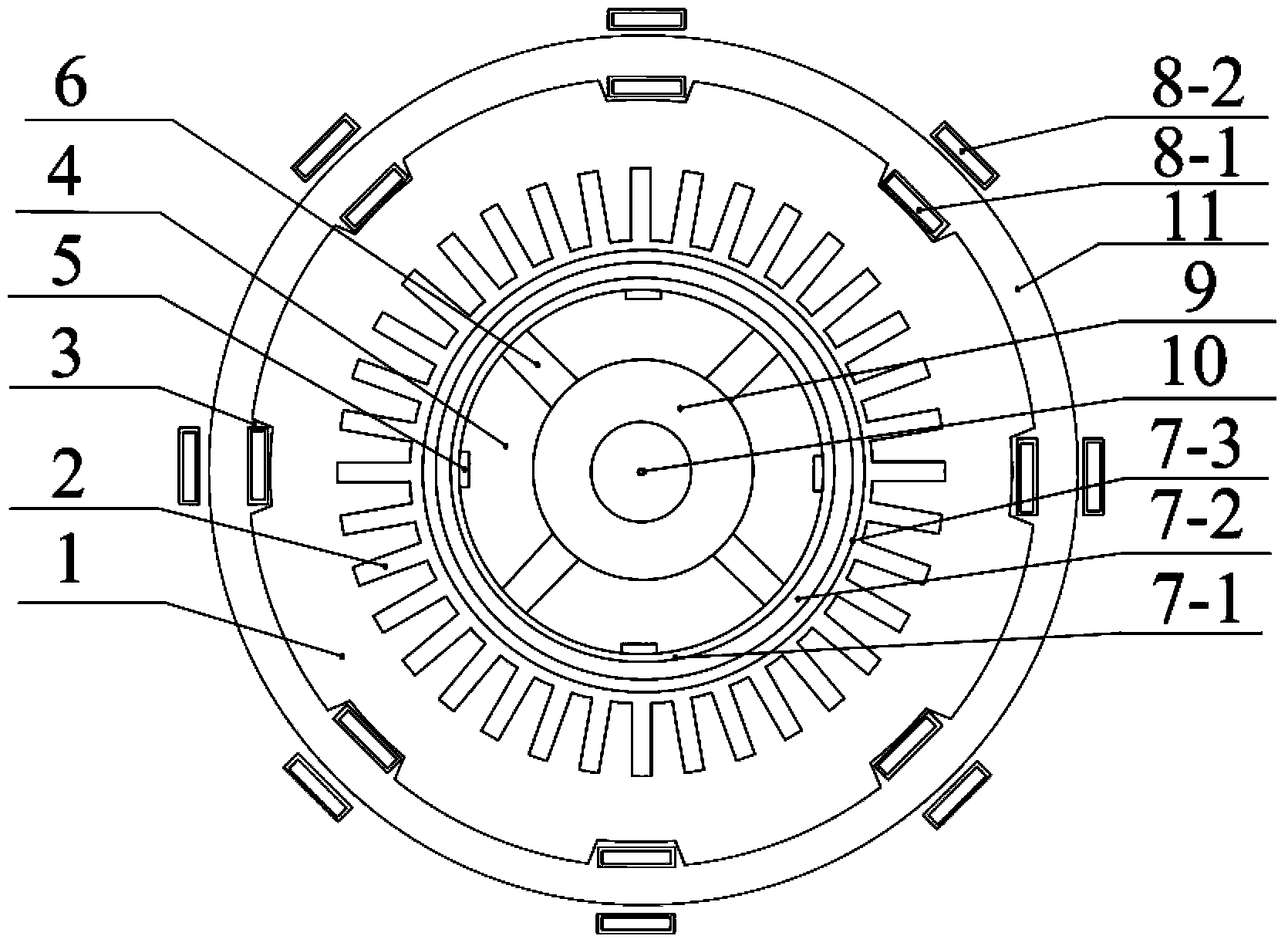

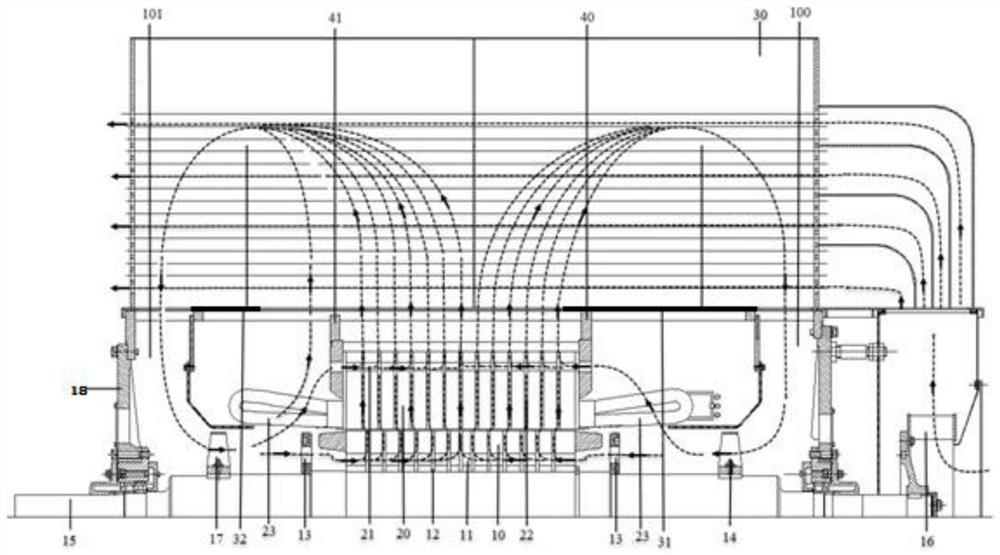

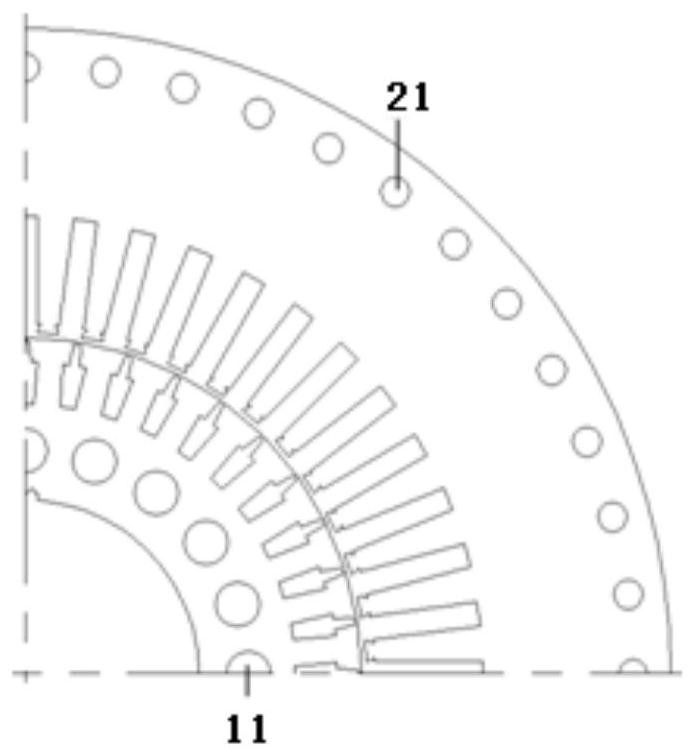

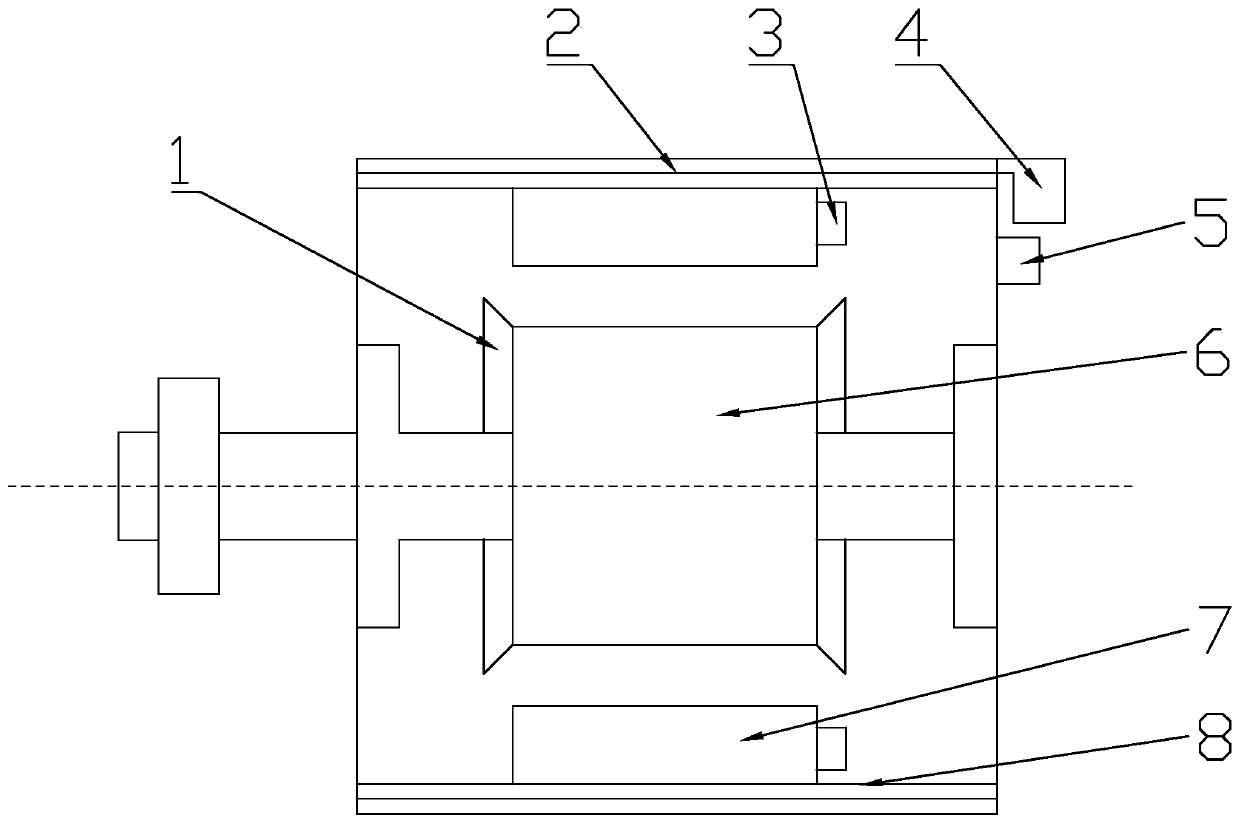

Gas-liquid interlaced cooling high power density motor

ActiveCN103199652AReduce working temperature riseImproved cooling systemCooling/ventillation arrangementWorking temperatureEngineering

The invention discloses a gas-liquid interlaced cooling high power density motor, and belongs to the field of high power density motors. An armature winding of the motor is wrapped by an insulating bushing, supported by a non-metal T-type support, and fixed through a slot wedge, and an axial cooling medium channel inside a stator core is formed. A space defined by a non-metal airtight cylinder, a housing case inner wall, the stator core, a first annular sealing plate and a second annular sealing plate in an enclosed mode constitutes a stator side airtight cooling cavity. Liquid-state cooling media flow from a liquid inflow guiding tube into the axial cooling medium channel inside the stator core, trickle down onto a rotor through first to Nth trickling holes, flow out from a liquid outflow guiding tube and a second liquid outflow guiding tube, and are cooled through a liquid cooling device. Gas-state cooling media enter from a gas inflow guiding tube and flow out from a gas medium outlet hole. Different cooling channels are combined into an interlaced multi-dimensional space cooling system, working temperature rise of the motor is effectively reduced, stability is improved, and unbalanced thermal stress influences caused by axial temperature difference are reduced.

Owner:BEIJING JIAOTONG UNIV

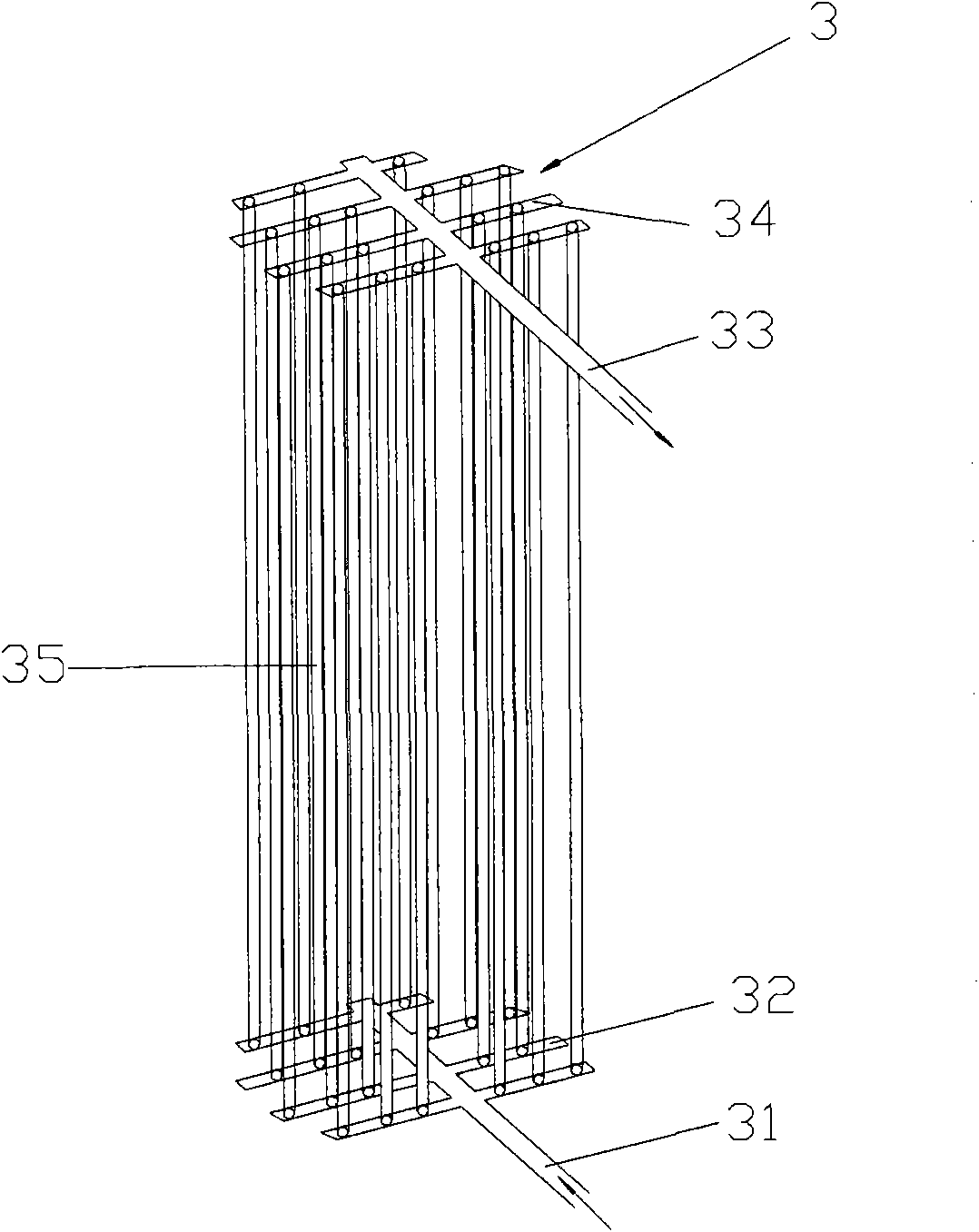

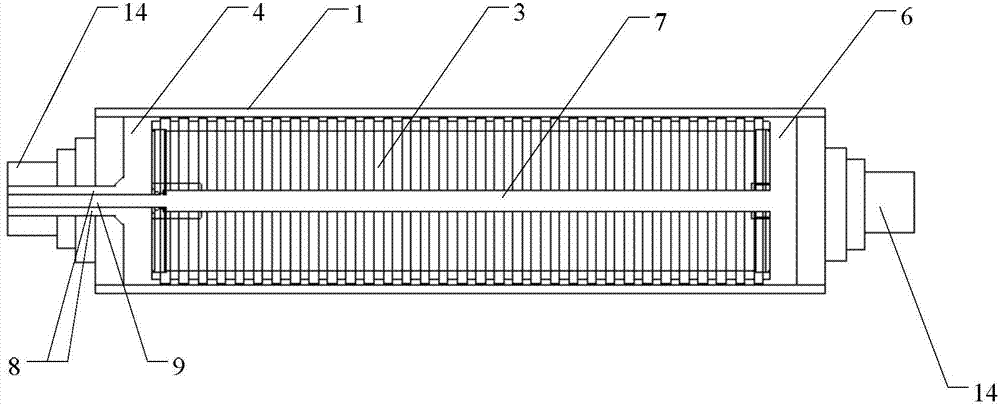

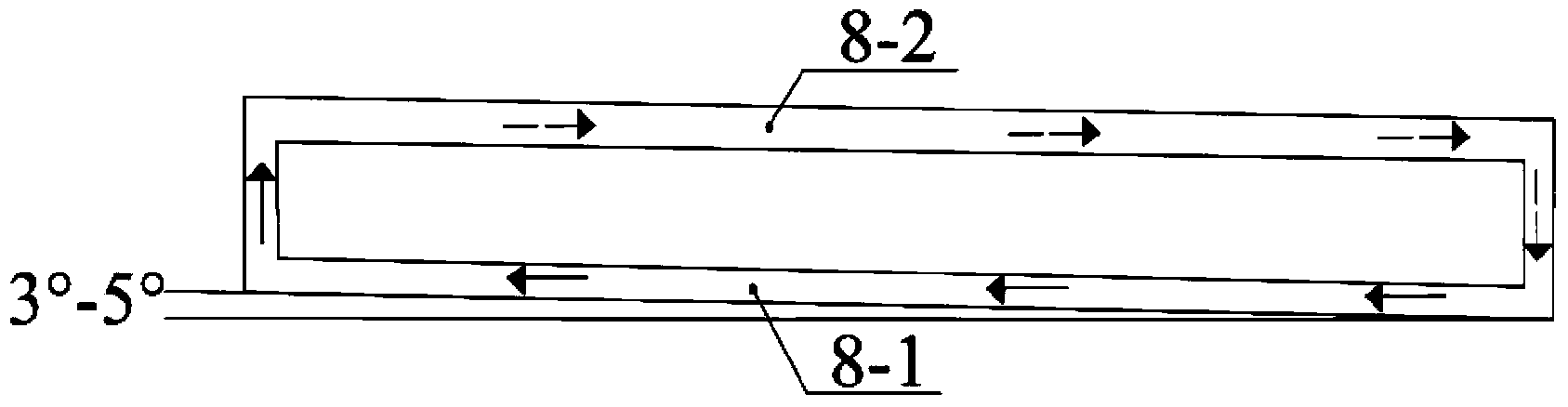

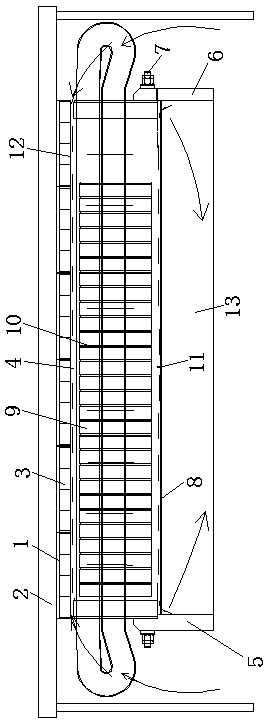

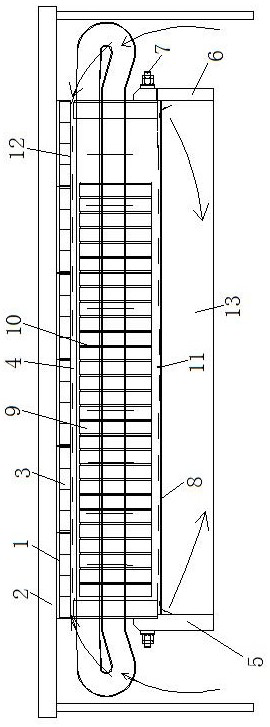

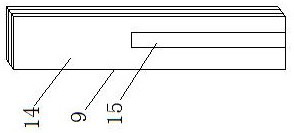

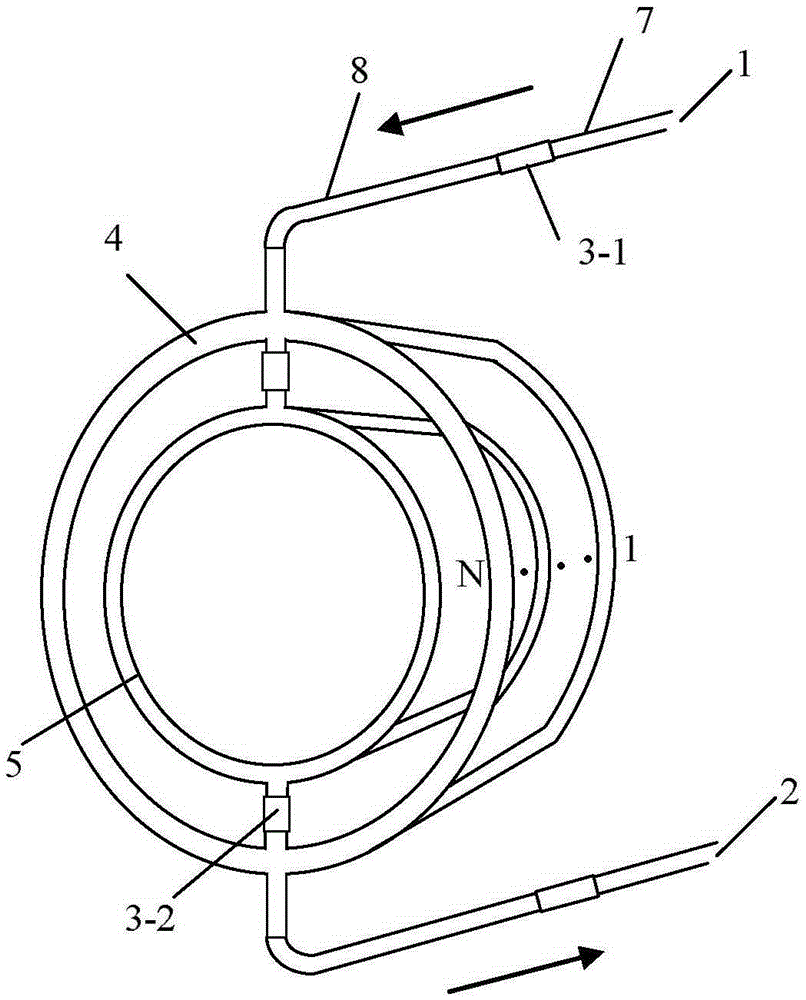

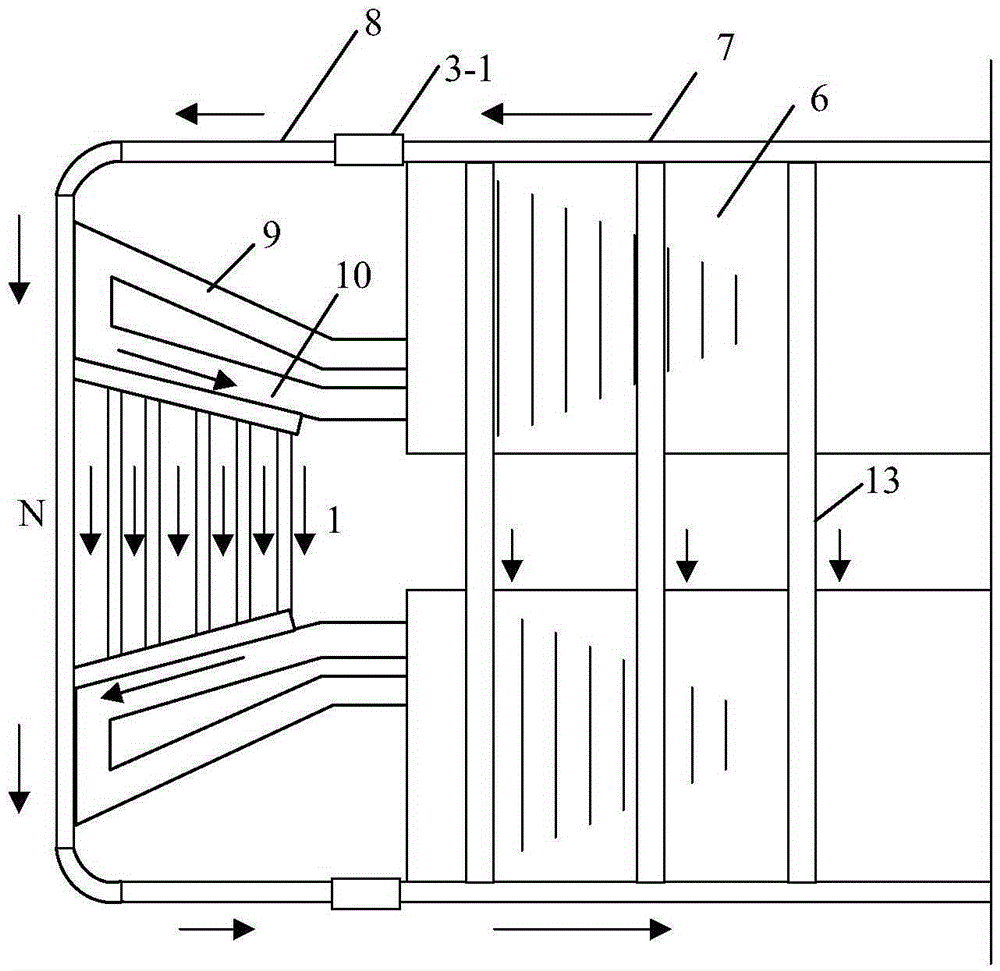

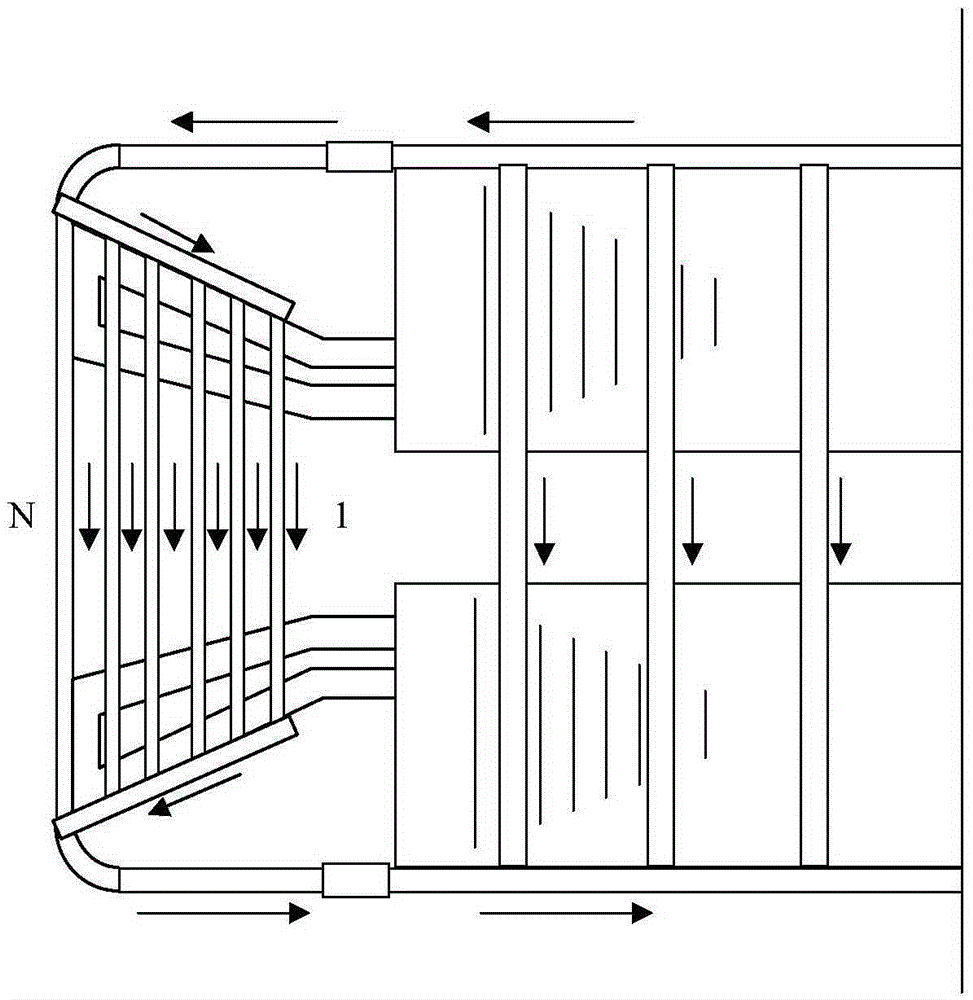

Motor multipath series-parallel water cooling system

ActiveCN103715830AAxial temperature difference is smallGuaranteed uptimeCooling/ventillation arrangementWater coolingConductor Coil

The invention discloses a motor multipath series-parallel water cooling system. The motor multipath series-parallel water cooling system comprises a water pipe at the tail end of the stator core yoke portion of the linear portion of an electric generator and a motor end winding external cooling waterway, and a water loop is composed of the water pipe at the tail end of the stator core yoke portion of the linear portion of the electric generator and the motor end winding external cooling waterway; the motor end winding external cooling waterway is composed of a cooling water pipe cooling system loop of a lower winding layer and a cooling water pipe cooling system loop of an upper winding layer; the cooling water pipe cooling system loop of the lower winding layer is composed of at least one set of circumferential water pipes which are communicated in the direction from the linear portion to the nose end, and the cooling water pipe cooling system loop of the upper winding layer is composed of at least one set of circumferential water pipes which are communicated in the direction from the linear portion to the nose end; the inner-diameter pipe wall of the cooling water pipe cooling system loop of the end lower winding layer is laid on the outer-layer surface of the lower winding layer; the outer-diameter pipe wall of the cooling water pipe cooling system loop of the end upper winding layer is laid on the inner-layer surface of the upper winding layer.

Owner:BEIJING JIAOTONG UNIV

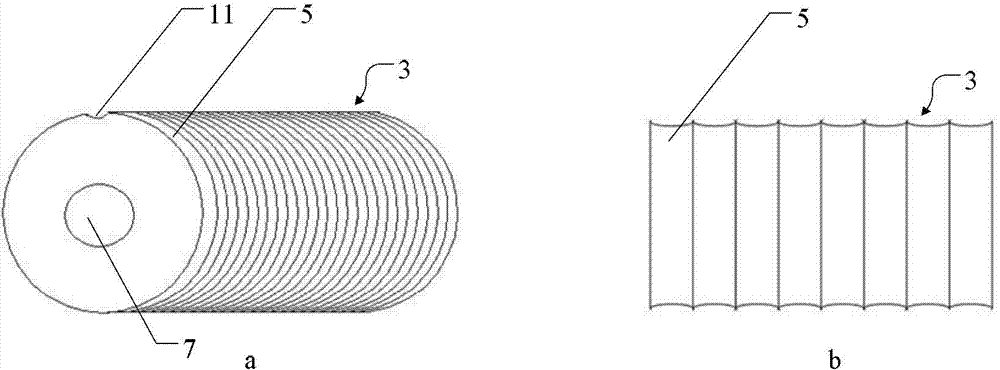

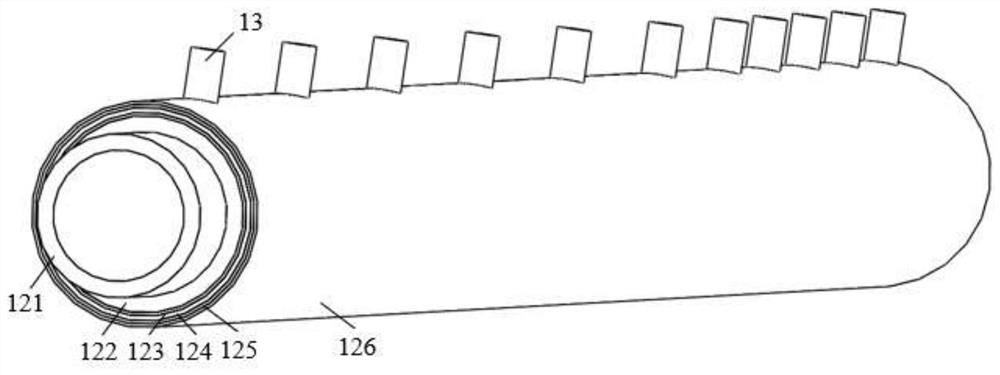

Heating device of film laminating machine

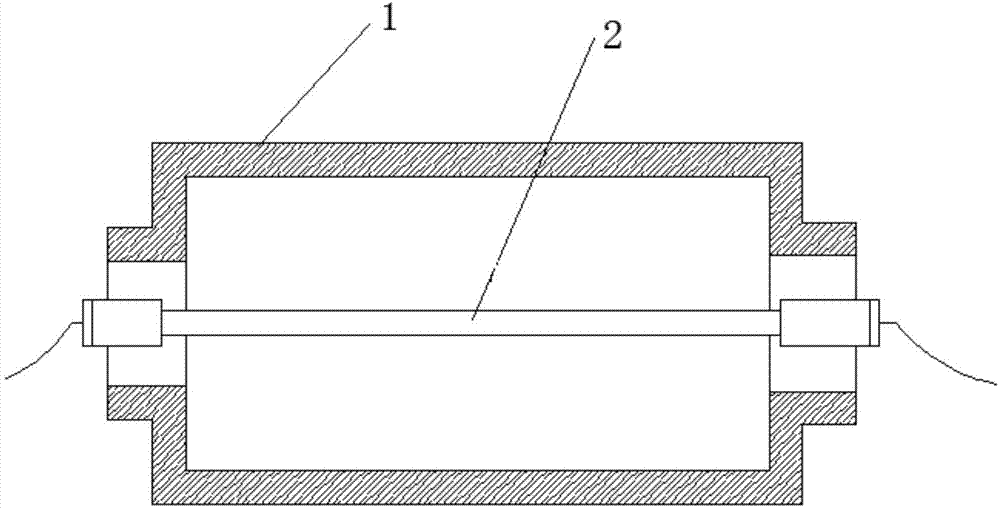

InactiveCN103770456ARealize the utilization of reciprocating cycleAxial temperature difference is smallPrinting press partsHeat conductingEngineering

The invention discloses a heating device of a film laminating machine and belongs to the field of film laminating machines. According to the technical scheme, heat-conducting media enter a water inlet, pass through a first cavity, flow into a second cavity along the space between an inner roller and an outer roller, flow back to the heating device after returning to a water outlet through a water outlet pipe, and then flow into the water inlet after being heated again by the heating device. In this way, uniform heating is conducted on the outer roller, and circulating utilization of the heat-conducting media is achieved. The heating device of the film laminating machine can greatly increase the operating speed of the film laminating machine.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Permanent magnet synchronous motor device with closed self-circulation cooling system for stator

ActiveCN103973061AReduce working temperature riseAxial temperature difference is smallMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention particularly relates to a permanent magnet synchronous motor device with a closed self-circulation cooling system for a stator, and belongs to the field of electrical technologies. The permanent magnet synchronous motor device comprises a motor shaft and a rotor core. The rotor core sleeves the motor shaft, a non-magnetic ring is arranged between the motor shaft and the rotor core, a stator core sleeves the rotor core, a vacuum jacket is arranged between the rotor core and the stator core, a housing case sleeves the stator core, and cooling pipes are respectively arranged on the inner side and the outer side of the housing case. The permanent magnet synchronous motor device has the advantages that the permanent magnet synchronous motor device is provided with the vacuum jacket of a rotor, so that heat generated due to eddy-current loss on the surface of the rotor can be effectively stopped against being transmitted to permanent magnets; heat inside a motor can be quickly carried away by the closed self-circulation cooling system for the stator, so that temperature rise of the motor can be reduced, influence of high temperature rise on demagnetization of the permanent magnets can be decreased, the service lives of the permanent magnets and the service life of the motor can be prolonged, and the overload capacity of the motor can be improved.

Owner:江苏利得尔电机有限公司

Finned tube heat exchanger and application thereof and afterheat boiler

ActiveCN106895727AImprove heat transfer efficiencyLow costIndirect heat exchangersCombustion technology mitigationEvaporationEngineering

The invention relates to the technical field of heat exchangers, and discloses a finned tube heat exchanger and application thereof and an afterheat boiler. The finned tube heat exchanger belongs to a radial heat transfer heat tube, and has the advantages of high heat transfer efficiency, short axial length, small size and light unit heat exchange weight; a sucking core has no need to be arranged in the tube; and inner tube fins of a first layer of inner tubes can be used for guiding condensed water to flow onto the inner walls of outer tubes to absorb heat for evaporation, so that the whole inner walls of the outer tubes become the heat absorption evaporation surface area of phase change liquid. The finned tube heat exchanger is applied to industrial afterheat, can reduce industrial pollution, and also can fully use the industrial afterheat; and the industrial afterheat is secondarily converted to energy for recycling by human. The afterheat boiler adopts the finned tube heat exchanger consisting of heat tubes to recover heat; the finned tube heat exchanger is small in size, and can be flexibly arranged on a flue; and the heat tubes belong to radial heat transfer, so that the heat exchange area with waste smoke in the flue is largely increased, and the heat exchange efficiency is improved.

Owner:HUNAN UNIV OF TECH

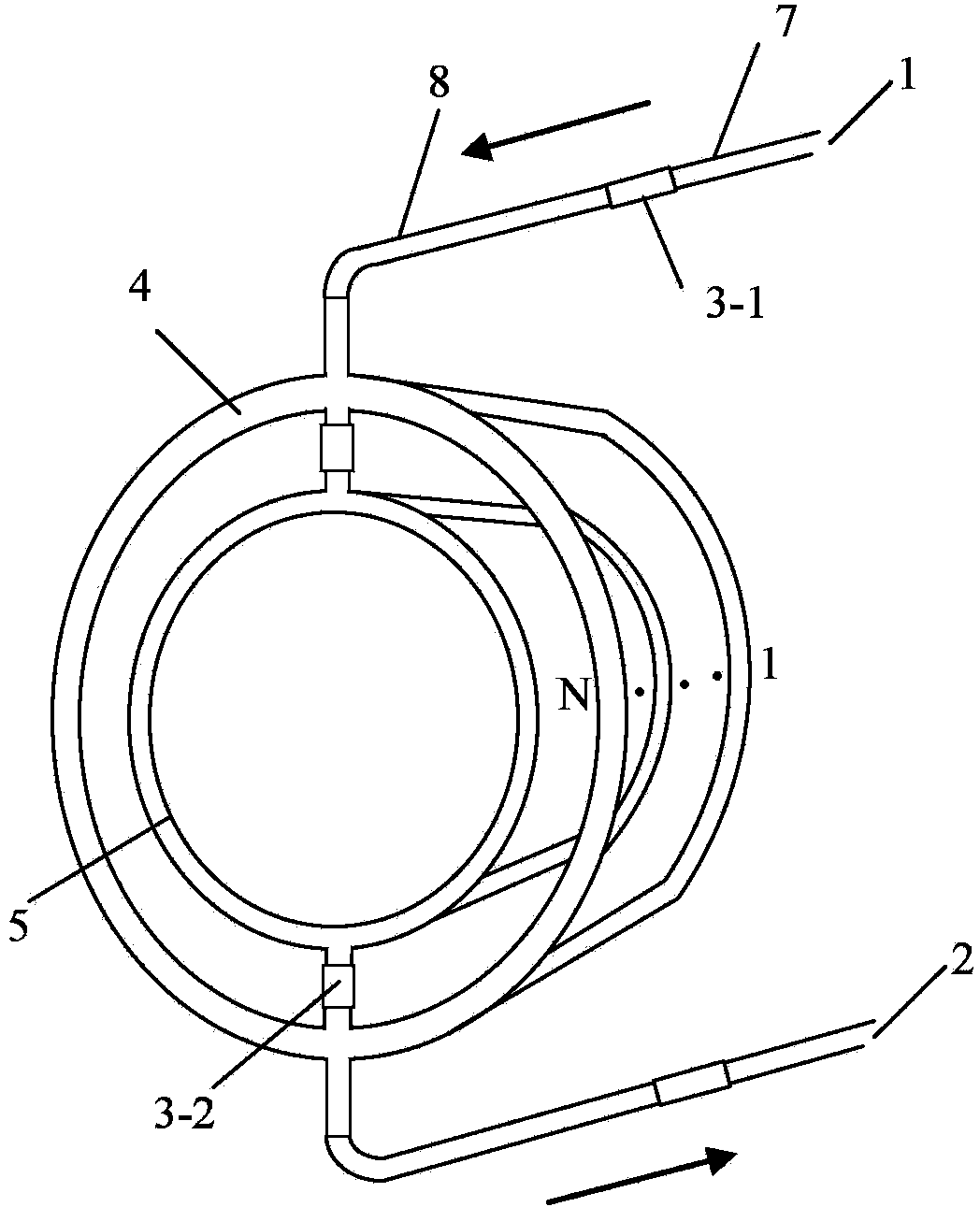

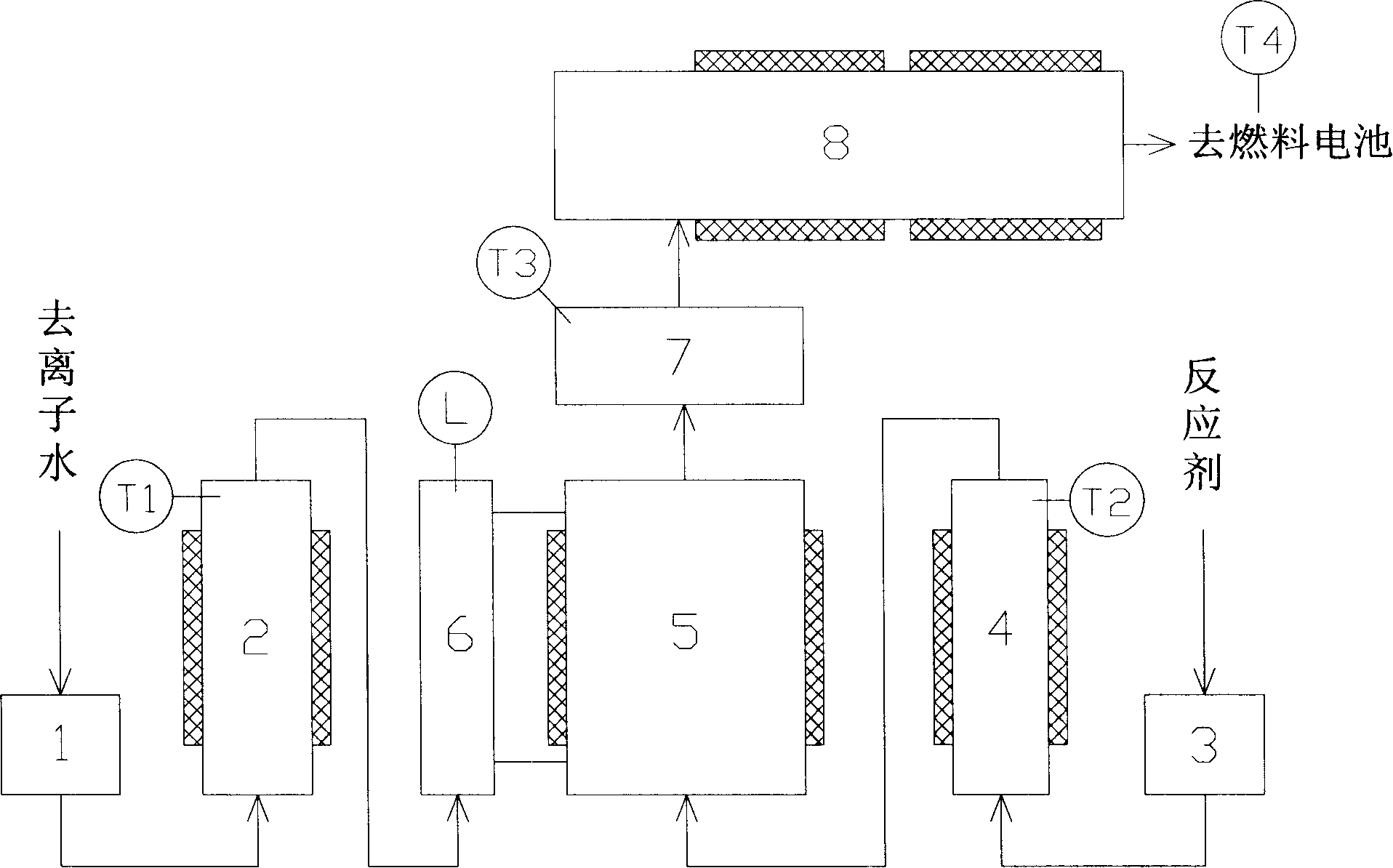

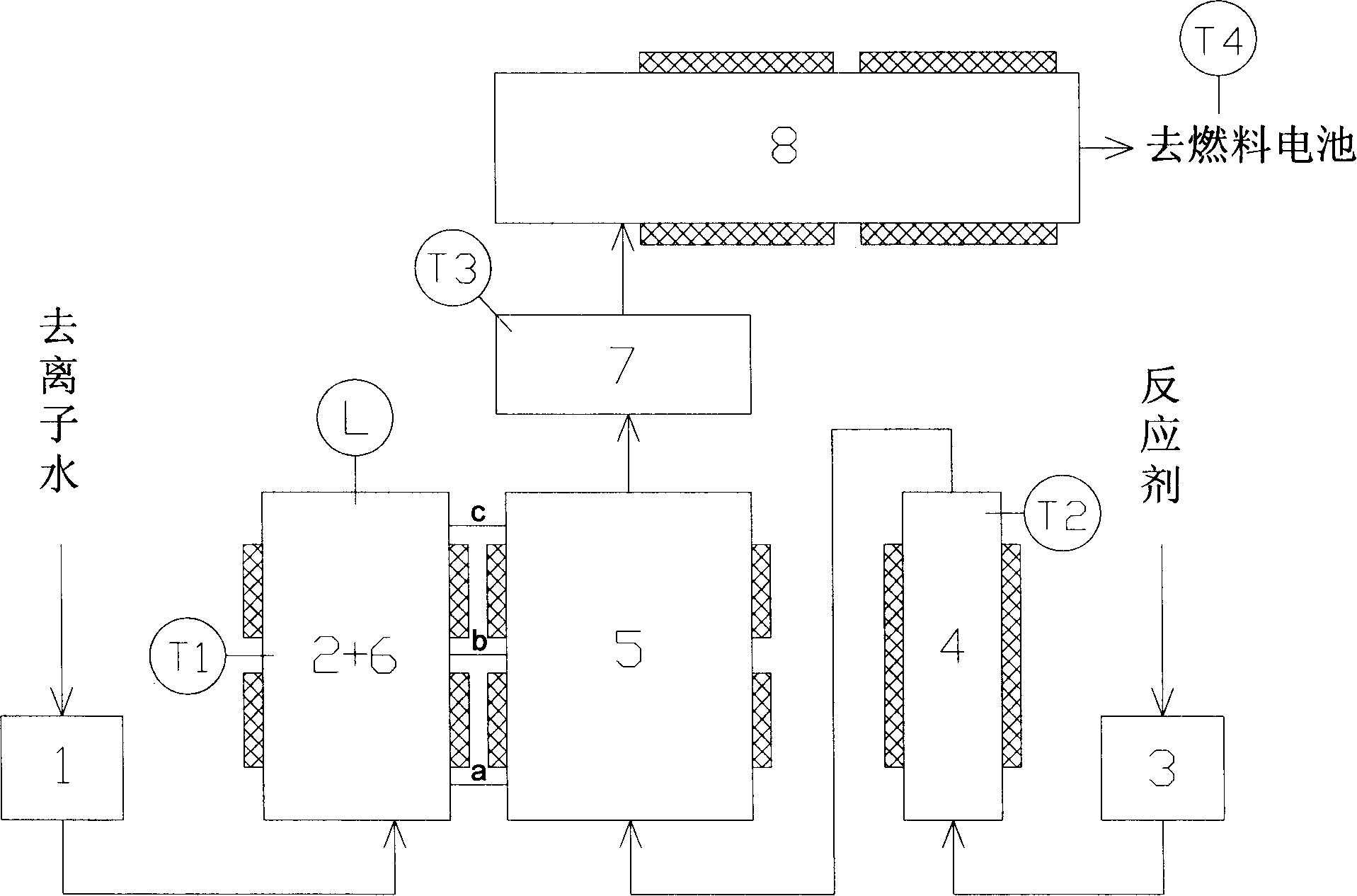

Humidification system for small-sized PEM fuel battery test platform

InactiveCN101165953AReduce heating loadAxial temperature difference is smallFuel cell auxillariesElectrical testingGas phaseControl system

This invention provides a gas heating and wetting system used in test platforms of small PEM fuel batteries, which applies a method of preheating gas-phase and liquid-phase to a preset temperature for increasing the control accuracy of a small wetting system so as to reduce load of heating of a wetter, in which, deionized water entering into an wetting system and the reactant gas can be pre-designed to a bit higher than saturated temperature by a control system in terms of the flow of the wetted reactant gas, thus, the gas reactant entering into the wetter imbibes by transmitting medium under the temperature closing to saturation so as to reduce axial temperature difference of the wetter.

Owner:SHANGHAI PALTON FUEL CELL SYST

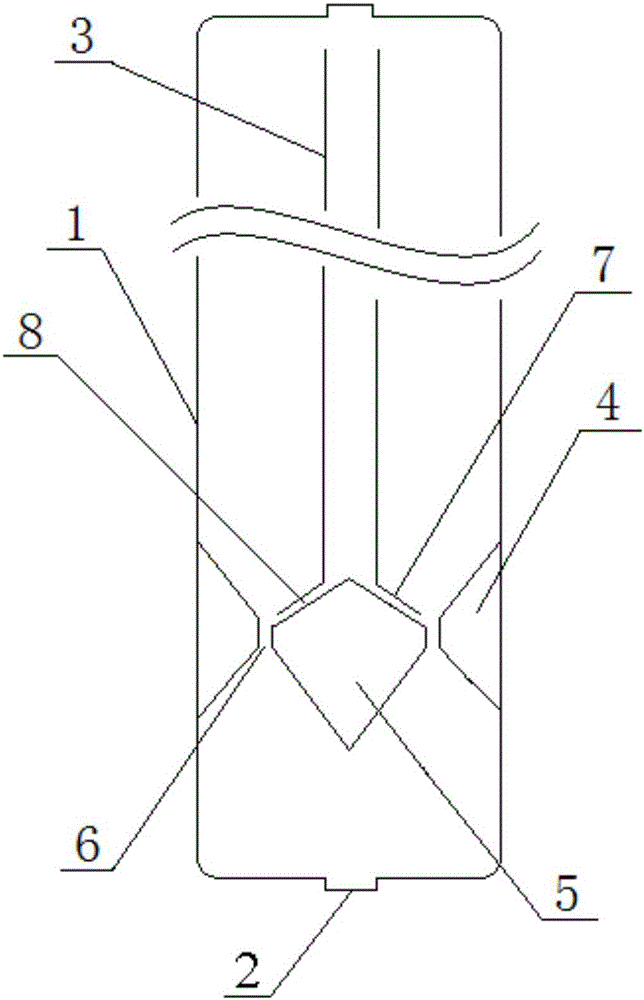

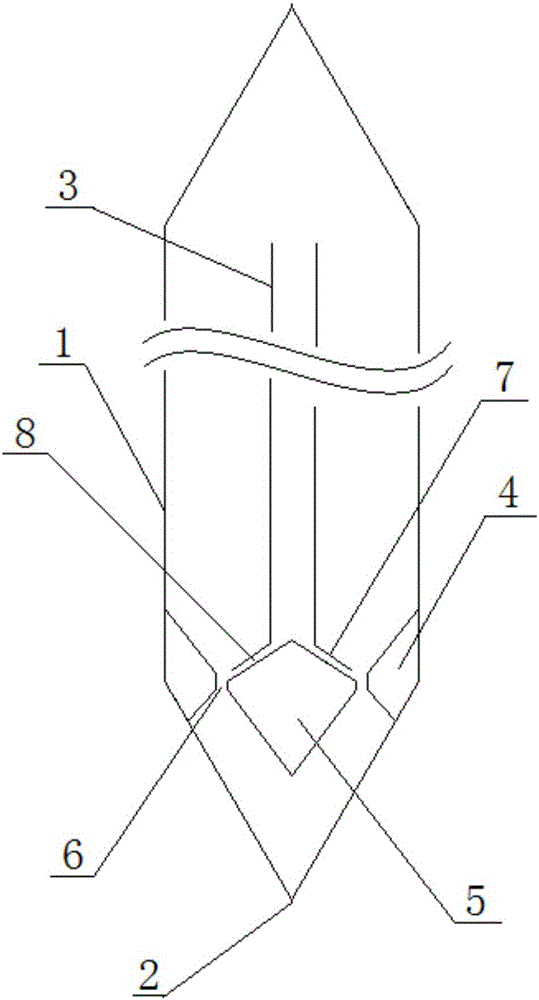

Suspended bed reactor and method for realizing liquid phase self circulation by using same

ActiveCN107519826AReduce line speedIncrease the line speed after smallHydrocarbon oils refiningChemical/physical processesInlet channelEngineering

The invention provides a suspended bed reactor and a method for realizing liquid phase self circulation by using the same. The reactor comprises a reactor shell and a liquid-phase circulation pipe and an inlet jet distributor which are arranged in the shell; the inlet jet distributor includes an annular boss and a guiding object, the annular boss is arranged on the inner side wall of the shell near a liquid flow inlet, the guiding object is arranged above the liquid flow inlet, the largest outer diameter of the guiding object and the smallest inner diameter of the annular boss are arranged in a relative manner to make the aperture diameter of a liquid inlet channel formed between the guiding object and the annular boss smallest. According to the suspended bed reactor, with use of self pressure energy of inlet materials and pressure energy generated by the difference of the densities of the interior and the exterior of the liquid-phase circulation pipe, liquid phase self circulation in the reactor is formed, not only can the linear speed of a liquid phase be improved to facilitate coke discharging, but also the axial temperature difference of the reactor can be reduced, and the reaction released heat can be used for heating an inlet feed material. At the same time, the interior of the reactor has no flow dead zone, and coking can be effectively reduced or even avoided.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

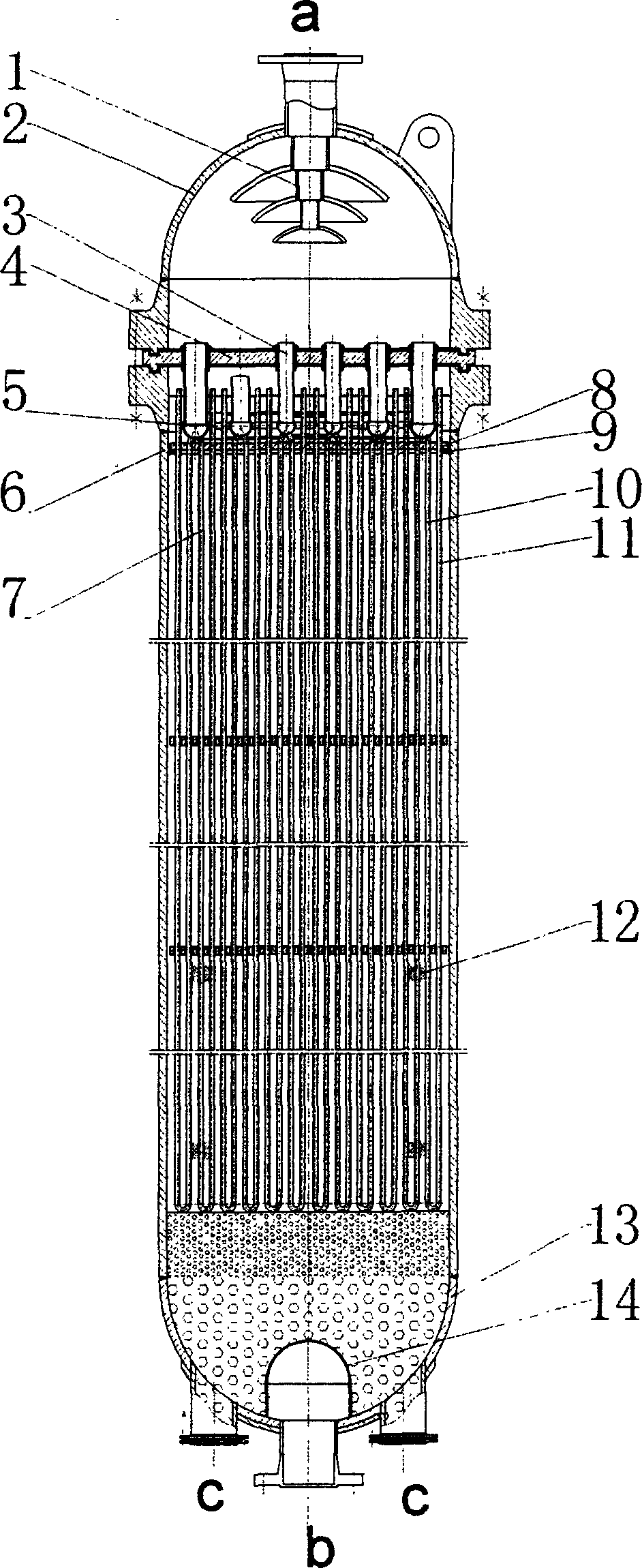

U shape tubular isothermal low-temperature methanol synthesis tower

InactiveCN1799684AReduce backmixingMake full use of spaceOrganic compound preparationHydroxy compound preparationEngineeringTower

The invention relates to a new U-shaped isothermal low-pressure methanol converter, comprising a outer cylinder, and inner elements, wherein, said outer cylinder comprises a upper closure head, a cylinder body, a positioning ring, and a lower closure head; and said inner elements comprises a separation plate, a cold gallbladder, and a support ring, while said upper closure head has a charging pipe; said lower closure head has a discharging pipe; the air guiding pipe of cold gallbladder is sealed on the separation plate with stuffing and catalyst is arranged outside said cold gallbladder; the cold gallbladder pipe is in multiple rings U-shaped and via support ring supported on the positioning ring welded on the inner wall of outer cylinder to hang and support cold gallbladder; said outer cylinder also comprises a new air distributor inside the upper closure head to connect the charging pipe. The invention provides a new U-shaped isothermal low-pressure methanol converter with uniformly distributed charged air, high synthesizing efficiency, simple structure and lower producing cost, which can apply large methanol synthesizing device.

Owner:ZHEJIANG UNIV OF TECH

Motor

ActiveCN112072855AAxial temperature difference is smallLarge air volumeMagnetic circuit rotating partsElectric machinesAir volumeElectric machinery

The invention discloses a motor. A sealing part is arranged on a cooling bottom plate at the cooling medium inlet end of an outer air path, so that airflow driven by an inner fan enters through an airinlet duct and can only enter a cooling cover through a rotor and a stator to force a cooling medium to enter the stator to cool the stator, the air volume of a straight-section winding is increased,the temperature difference between the cooling straight section winding and the cooling end winding is reduced, the axial temperature difference of the stator is reduced, the temperature distributionuniformity is improved, the hot spot temperature difference of the windings is reduced, and the motor operation reliability is improved; the air volume is reasonably distributed, the temperature difference between the temperature entering a motor body through the shaft extension side of a cooling assembly and the non-shaft side is reduced, the temperature uniformity of the two sides of the motoris improved, and meanwhile the cooling effect of a stator is improved.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

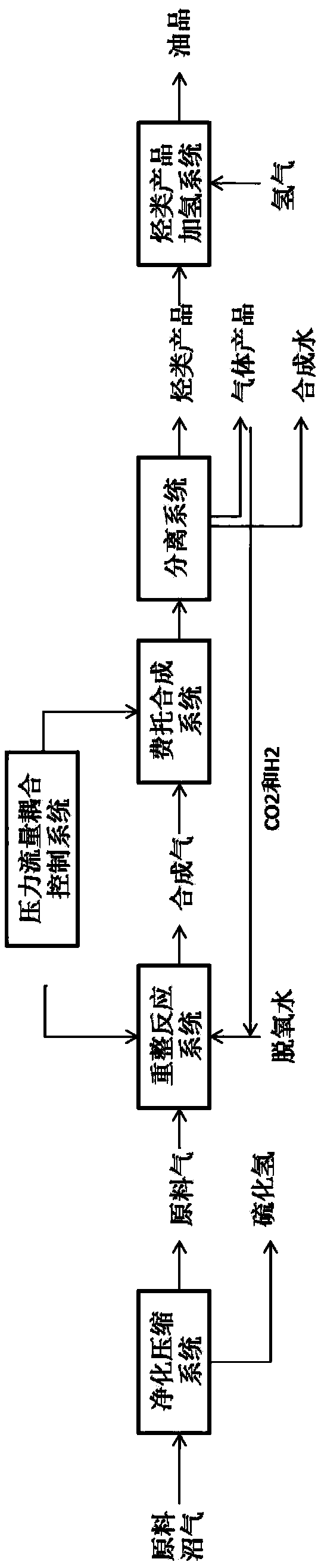

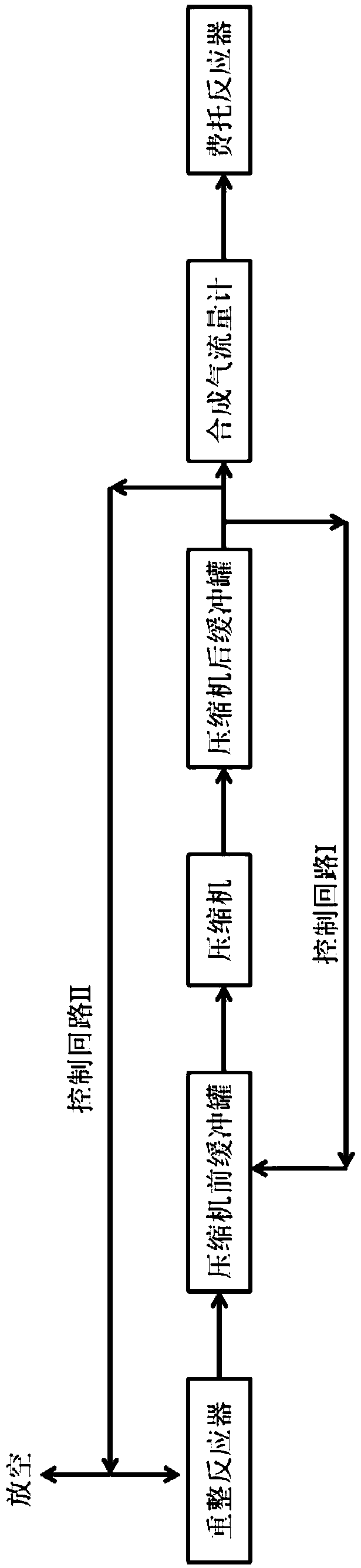

Method for making oil product taking methane as raw material

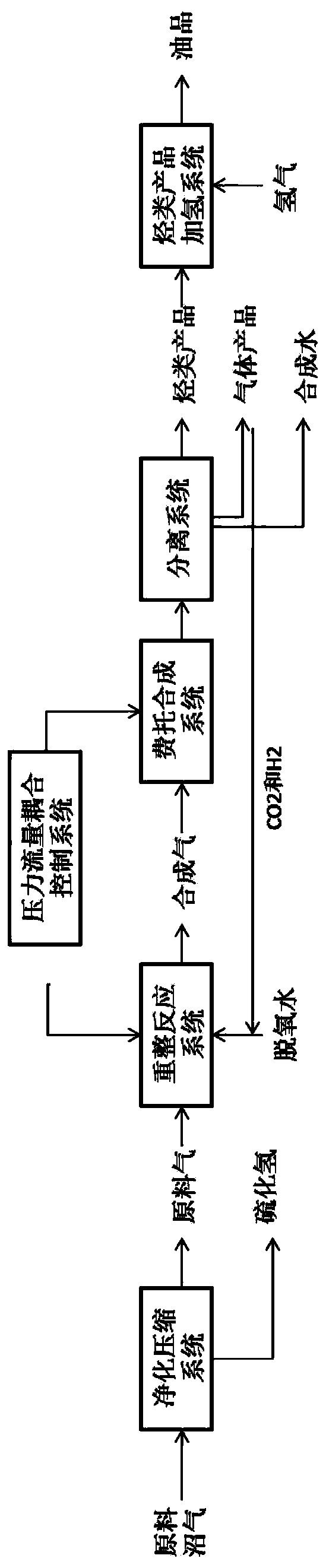

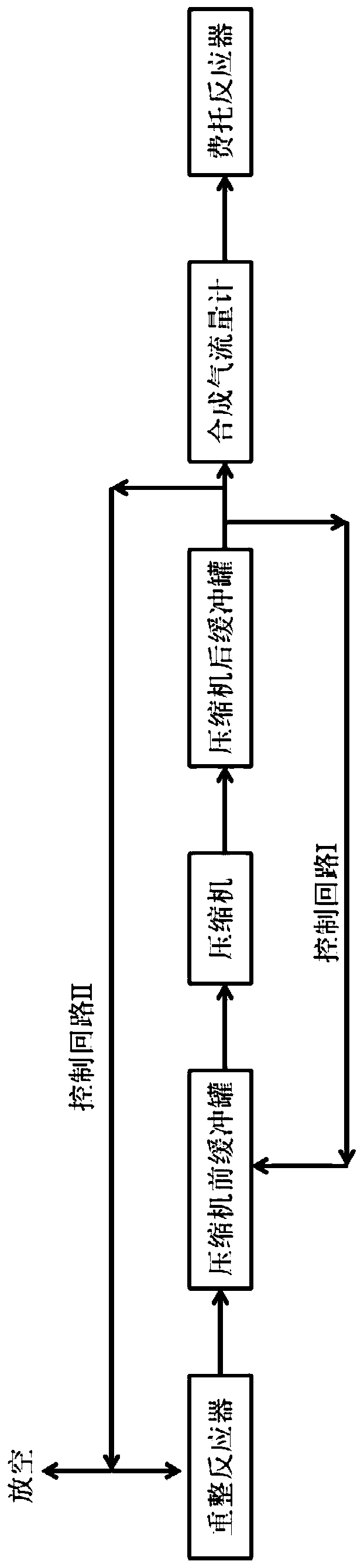

ActiveCN109135796AReduce in quantityReduce difficultyHydrogenRefining to change hydrocarbon structural skeletonFully developedMethane

The invention belongs to the technical field of energy utilization, and provides a method for making an oil product taking methane as a raw material. The method comprises the following steps that (1)the raw material methane serves as virgin gas of reforming reaction after being decontaminated, purified and compressed through a purification compression system; (2) the virgin gas enters into a reforming reaction system and is translated into synthesis gas; (3) the synthesis gas enters a Fischer-Tropsch synthesis system for reaction to generate a Fischer-Tropsch synthesis product; (4) the obtained Fischer-Tropsch synthesis product is subjected to gas-liquid separation in a separation system to obtain a hydrocarbon product, a gas product and synthetic water respectively; (5) the hydrocarbon product enters a hydrocarbon product hydroisomerization system for hydrogenation and quality improvement to obtain the oil product not containing sulfur, nitrogen and arene; and the balance of pressureand material flow between a reforming reactor and a Fischer-Tropsch synthesis reactor is controlled through a pressure flow coupling control system. The method fully develops and utilizes potential value of the methane to achieve that the methane is translated into the oil product.

Owner:北京嘉岳能源科技开发有限公司

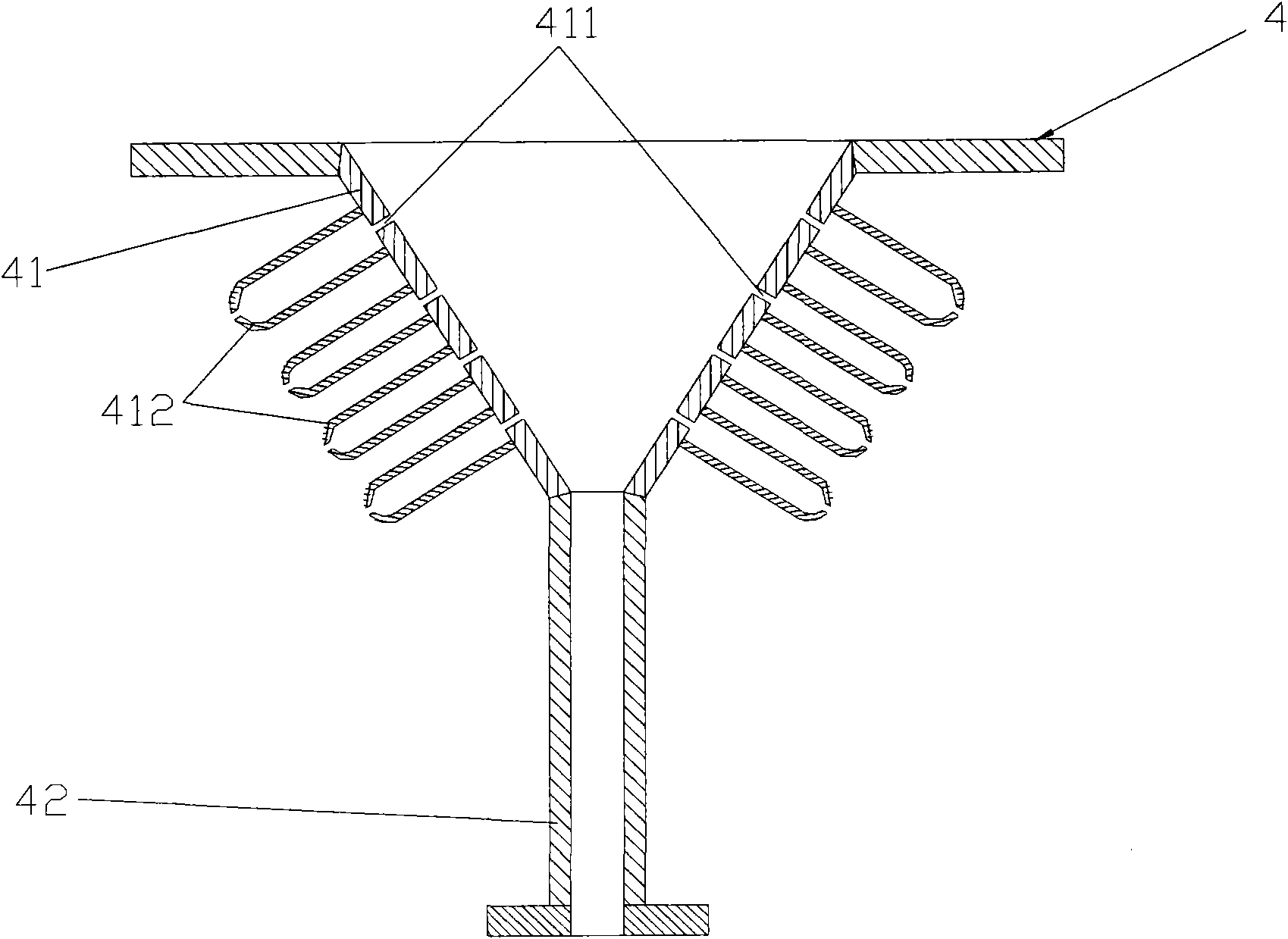

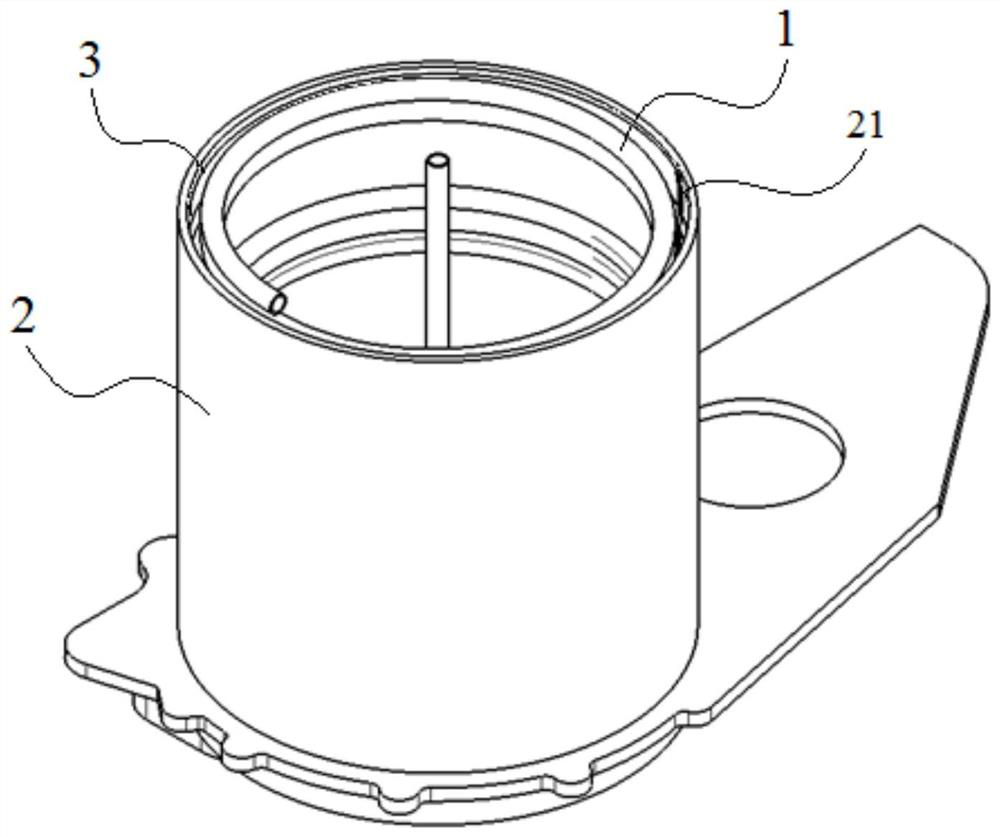

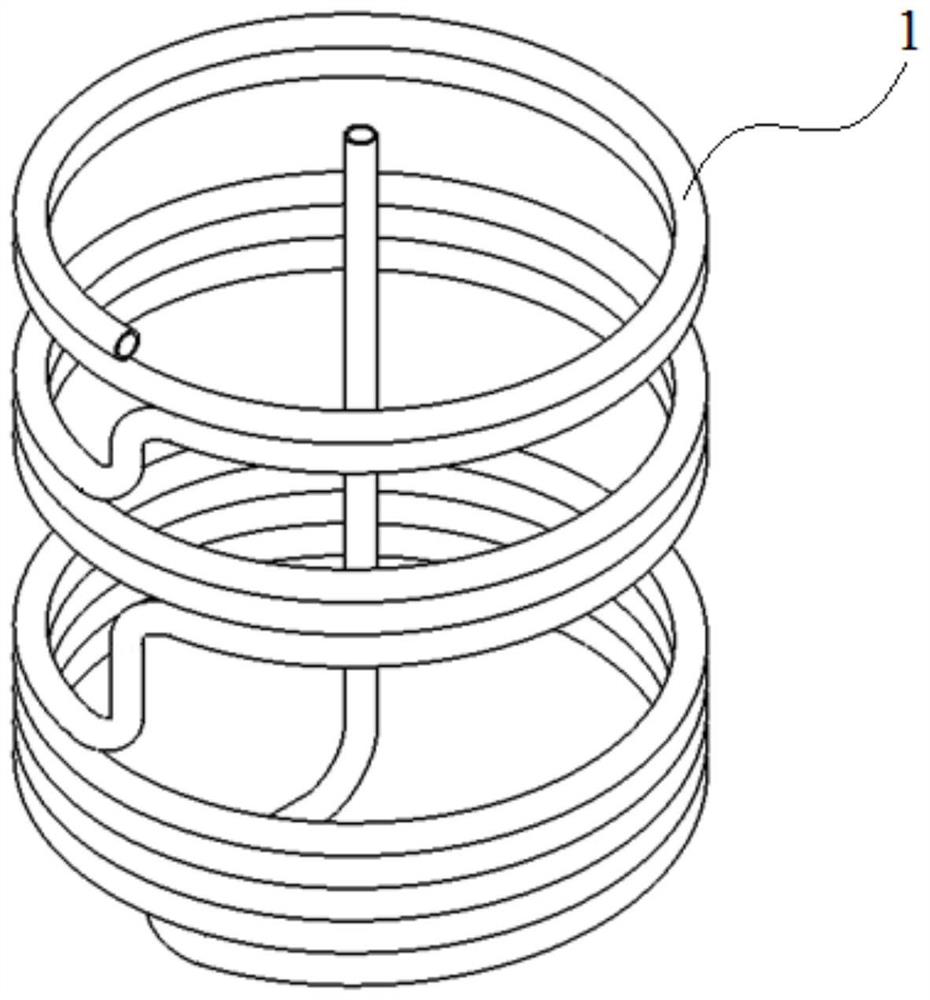

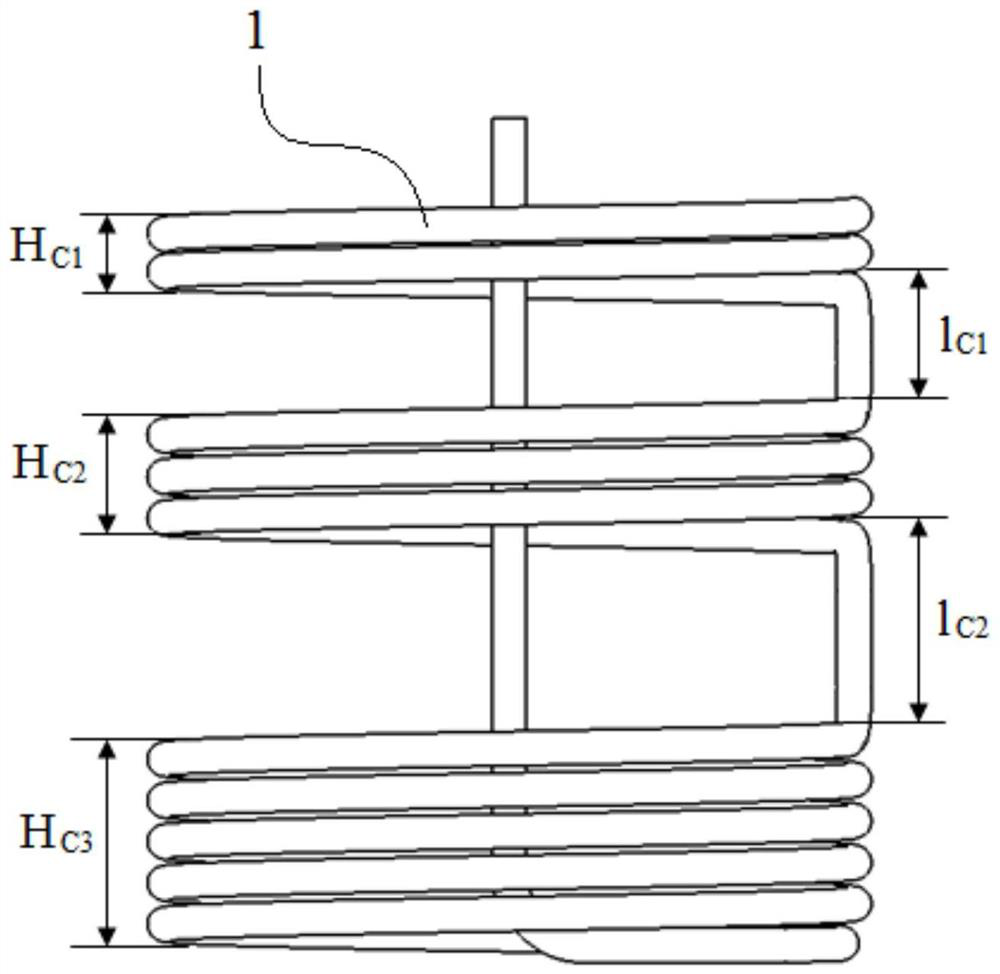

Efficient and uniform heating device for motor hot jacket

ActiveCN113597035AAxial temperature difference is smallAvoid excessive local temperature riseCoil arrangementsIncreasing energy efficiencyElectric machineEngineering

The invention discloses an efficient and uniform heating device for a motor hot jacket. The device comprises an induction coil capable of matching an inner cavity of the motor hot jacket and an alternating current power supply module connected with the induction coil, and the induction coil is a multi-turn hollow spiral copper coil; the induction coil is wound in a grouping crosstalk mode to form n coil groups which are connected in series, the hollow spiral copper coils in each coil group are uniformly wound, the winding radiuses of the hollow spiral copper coils in the n coil groups are the same, and the longitudinal distance between every two adjacent coil groups is larger than the outer diameter of each hollow spiral copper coil; n is an integer, and n is greater than or equal to 2. According to the invention, the heating efficiency and the heating uniformity can be improved.

Owner:深蓝汽车科技有限公司

Device for improving uniformity of axial temperature distribution of stator

ActiveCN110504771AStructural design does not affectAxial temperature difference is smallMagnetic circuit stationary partsSupports/enclosures/casingsElectric generatorWind speed

The invention discloses a device for improving uniformity of axial temperature distribution of a stator, and belongs to the technical field of electric generators. The device comprises a rotor core and a rotor engine base; the device is characterized by further comprising a stator core, a stator pressing plate I, a stator pressing plate II, a core penetrating screw and an axial annular plate; thestator core comprises a plurality of core sections, and a stator air duct is arranged between any two adjacent core sections; the plurality of core sections are connected with each other through the core penetrating screw; the axial annular plate is fixed between the stator pressing plate I and the stator pressing plate II; circumferential annular plates are fixed on the core sections; a stator-rotor gap is arranged between the stator core and the rotor core; and the stator pressing plate I, the stator pressing plate II, the axial annular plate and the stator core enclose the stator core backspace. According to the device for improving the uniformity of the axial temperature distribution of the stator provided by the invention, the static pressure difference can be kept constant, and theaxial wind speed of the stator air duct is relatively uniform, so that favorable conditions are provided for the axial uniform distribution of a stator coil and the iron core temperature, the axial temperature difference between the stator coil and the core is reduced, the structure is simple, and the adjustment is easy.

Owner:DONGFANG ELECTRIC MACHINERY

Composite heat dissipation structure of vehicle generator

PendingCN110212699AImprove cooling effectGood cooling effectCooling/ventillation arrangementSupports/enclosures/casingsStatorElectricity

The invention discloses a composite heat dissipation structure of a vehicle generator. The composite heat dissipation structure comprises a machine shell, and a generator rotor and a generator statorarranged in the machine shell, and further comprises a fan, a cooling water channel, an electric control water pump, a temperature sensor and a controller; the fan is arranged at the end of the generator rotor and synchronously rotates along with the generator rotor; the cooling water channel is arranged in the outer surface of the machine shell, and the electric control water pump is arranged onthe machine shell and is connected with the cooling water channel; the temperature sensor is installed on the surface of the generator stator; the controller is installed on the machine shell and electrically connected with the electric control water pump and the temperature sensor; the temperature sensor is used for collecting temperature signals in the machine shell in real time and sending thetemperature signals to the controller; and the controller receives the temperature signals sent by the temperature sensor to control the electric control water pump to be opened and closed. The composite heat dissipation structure has the advantages of being high in efficiency, controllable, remarkable in cooling effect and strong in universality.

Owner:WENZHOU UNIVERSITY

System and process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment

InactiveCN102249187BSolve environmental problemsEfficient recyclingChlorine/hydrogen-chloride purificationHydrogen separation using liquid contactHydrogenReboiler

The invention discloses a system for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment, and the system mainly comprises a tail gas circulated condensing and washing tower, a chlorosilane stripper and a HCl rectifying tower, wherein the tail gas circulated condensing and washing tower is equipped with a polysilicon tail gas inflow pipe, a first chlorosilane solution outflow pipe and a first hydrogen outflow pipe, and the first chlorosilane solution outflow pipe is connected with the chlorosilane stripper; the chlorosilane stripper is equipped with a reboiler, a second chlorosilane solution outflow pipe, a first HCl outflow pipe and a stripping backflow pipe, and the first HCl outflow pipe and the stripping backflow pipe are connected with the HCl rectifying tower; and the HCl rectifying tower is equipped with a condenser, a separator and a second HCl outflow pipe which are connected in turn, and the separator is equipped with a non-condensable gas outflow pipe. The invention also discloses a process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment. Through the system and process disclosed by the invention, the polysilicon tail gas is turned into things of value, the resources are saved, and simultaneously the energy consumption during the treatment process is reduced.

Owner:SICHUAN TECHAIRS

A suspended bed reactor and a method for realizing liquid phase self-circulation using the reactor

ActiveCN107519826BReduce line speedIncrease the line speed after smallHydrocarbon oils refiningChemical/physical processesFluid phaseEngineering

The invention provides a suspended bed reactor and a method for realizing liquid phase self circulation by using the same. The reactor comprises a reactor shell and a liquid-phase circulation pipe and an inlet jet distributor which are arranged in the shell; the inlet jet distributor includes an annular boss and a guiding object, the annular boss is arranged on the inner side wall of the shell near a liquid flow inlet, the guiding object is arranged above the liquid flow inlet, the largest outer diameter of the guiding object and the smallest inner diameter of the annular boss are arranged in a relative manner to make the aperture diameter of a liquid inlet channel formed between the guiding object and the annular boss smallest. According to the suspended bed reactor, with use of self pressure energy of inlet materials and pressure energy generated by the difference of the densities of the interior and the exterior of the liquid-phase circulation pipe, liquid phase self circulation in the reactor is formed, not only can the linear speed of a liquid phase be improved to facilitate coke discharging, but also the axial temperature difference of the reactor can be reduced, and the reaction released heat can be used for heating an inlet feed material. At the same time, the interior of the reactor has no flow dead zone, and coking can be effectively reduced or even avoided.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Measuring system for critical heat flux density in horizontal pipe and regulation and control method

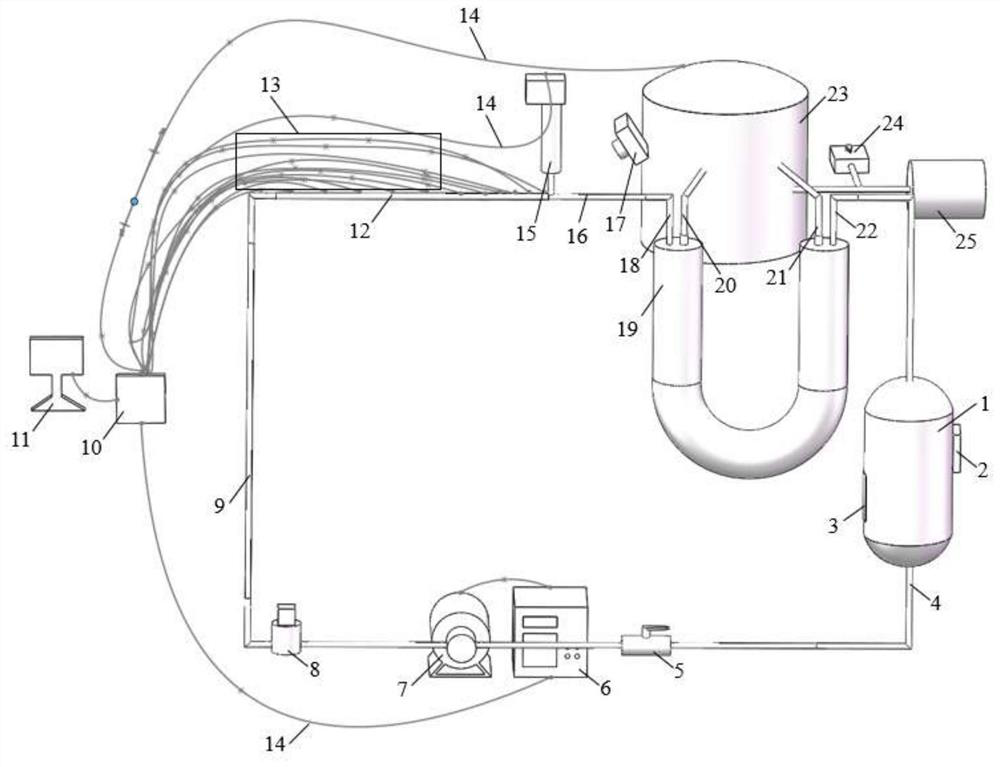

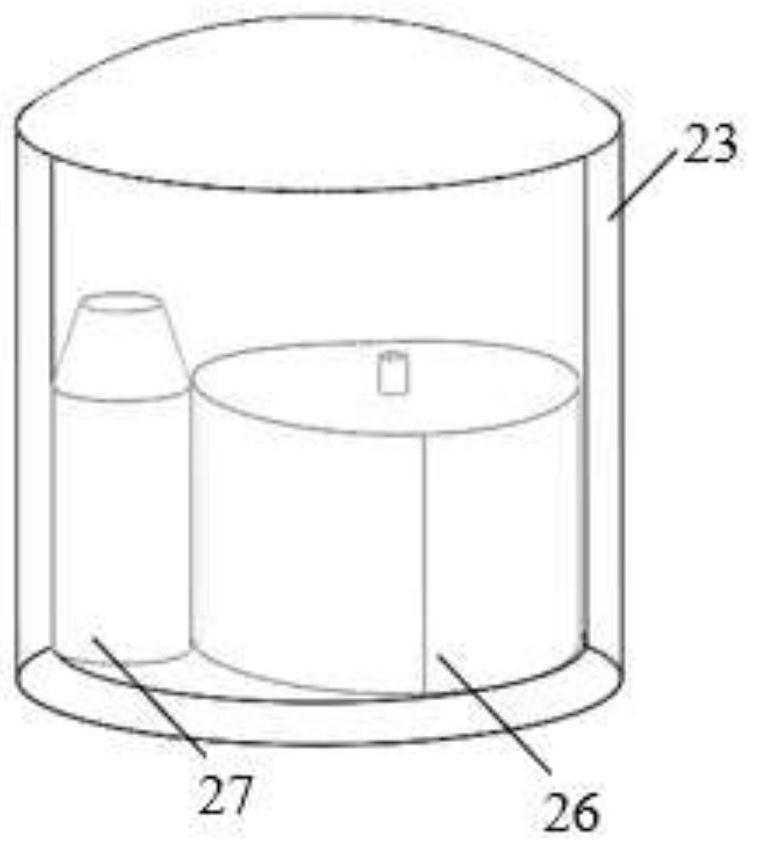

InactiveCN113670971AHigh precisionAxial temperature difference is smallMaterial heat developmentInvestigating phase/state changeFrequency changerGear pump

The invention discloses a measuring system for critical heat flux density in a horizontal pipe and a regulation and control method. The measuring system comprises a refrigerant liquid storage tank, an electric fan, a heating sheet, a circulation pipeline, a ball valve switch, a frequency converter, a gear pump, a mass flow meter, a preheating section, a data acquisition module, an industrial computer, an experiment section, a T-shaped thermocouple, a communication line, a pressure sensor, a visual transparent pipe, a high-speed camera, a refrigerant inlet pipeline, a U-shaped condenser, a cooling water inlet pipeline, a cooling water outlet pipeline, a refrigerant outlet pipeline, a water tank, an electromagnetic expansion valve, a liquid nitrogen tank, a water pump and a plastic water bottle. The measuring system has the advantages of being simple in system, reliable in judgment condition and high in measuring precision when used for monitoring and measuring the critical heat flux density phenomenon in the low-heat-flux and low-mass-flow-rate horizontal pipe. The regulation and control method has the advantages of being easy and convenient to operate and good in system stability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A Method for Improving the Uniformity of Stator Axial Temperature Distribution

ActiveCN110460180BUniform axial wind speedGuarantee the reliability of useMagnetic circuit stationary partsWind energy generationAir velocityEngineering

The invention discloses a method for improving the axial temperature distribution uniformity of a stator, and belongs to the technical field of generators. The method is characterized by comprising the steps of a, installing a stator axial temperature distribution uniformity device on a wind driven generator; b, installing and arranging a stator pressing plate I, a stator pressing plate II, an axial annular plate, a circumferential annular plate and a stator core of the stator axial temperature distribution uniformity device, setting an included angle between the circumferential annular plateand the axial annular plate to be 85-95 degrees, and forming a back space of the stator core; and c, setting an air flow circulating in the back space of the stator core to be the same in flow rate and opposite in flow direction with an air flow circuiting in the clearance between the stator and the rotor at the same axial position. According to the invention, the static pressure difference can bemaintained at a fixed value, the axial wind speed of a stator wind channel is relatively uniform, the operation is simple, the adjustment is easy, the axial temperature difference between the statorcoil and the iron core can be effectively reduced, and the reliability and the stability of the generator are guaranteed.

Owner:DONGFANG ELECTRIC MACHINERY

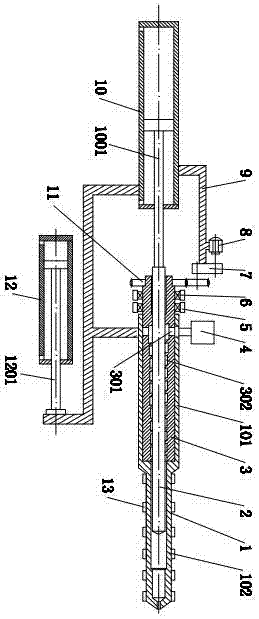

Inner groove screw and plunger coaxial injection molding machine

ActiveCN105751457BDisrupt and change the way of processingChange the processing methodThrust bearingEngineering

The invention relates to an injection molding machine with an inner threaded groove threaded rod and a plunger coaxial.The injection molding machine comprises a machine barrel, the plunger, the plastifying threaded rod, a hopper, a base, a radial thrust bearing set, a transmission mechanism, a motor, an injection base frame, an injection oil cylinder, a gear, a moving oil cylinder and an electric heating ring.The injection molding machine is characterized in that a radial channel is formed in the plastified threaded rod, and a continuous inner threaded groove through the total length is formed in the inner wall of a center hole of the plastifying threaded rod; a plastifying region and an injection region are arranged in the machine barrel, the plastifying region is located on the left part of the machine barrel, the injection region is located on the right part of the machine barrel, the plastifying threaded rod is located in the plastifying region and can rotate, when the plastifying threaded rod does rotational motion, material plastifying is completed through relative rotation between the inner threaded groove and the plunger, and the plunger moves linearly in the center hole of the injection region of the machine barrel to complete injection of the molten material.The injection molding machine has the advantages of being better in plastifying performance, simple and compact in structure and low in manufacturing, using and maintaining cost, and products are high in quality.

Owner:ANHUI HUATENG AGRI TECH CO LTD

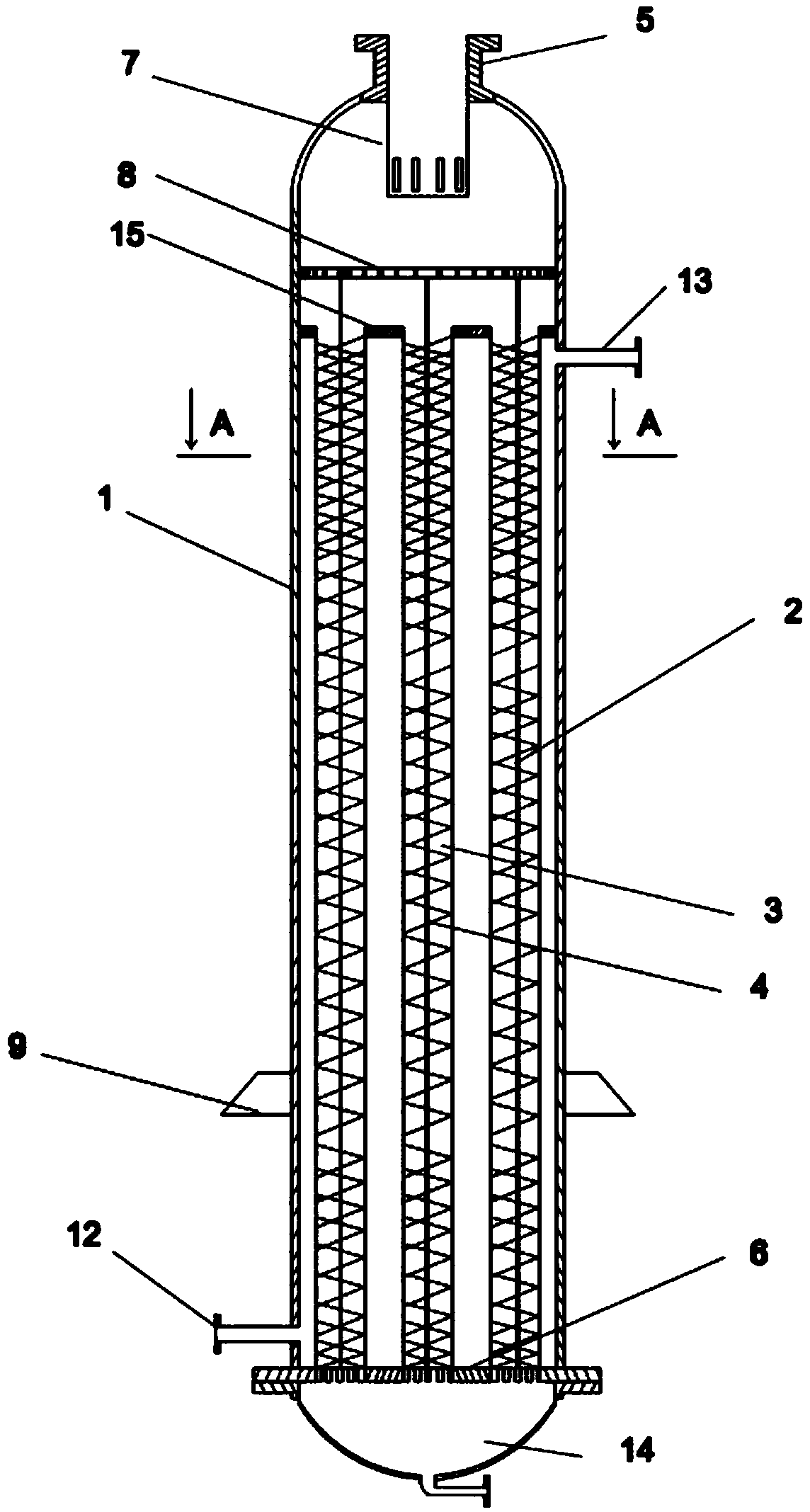

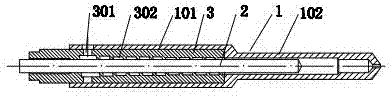

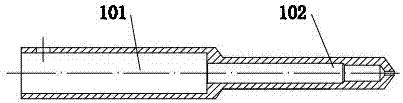

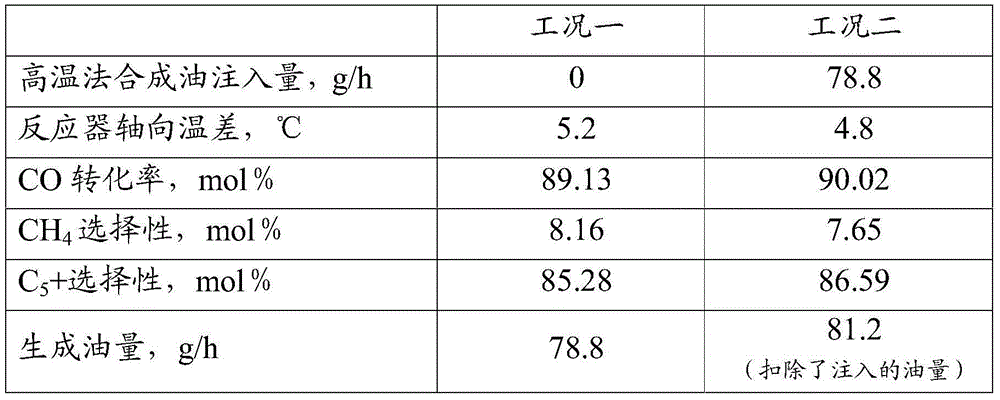

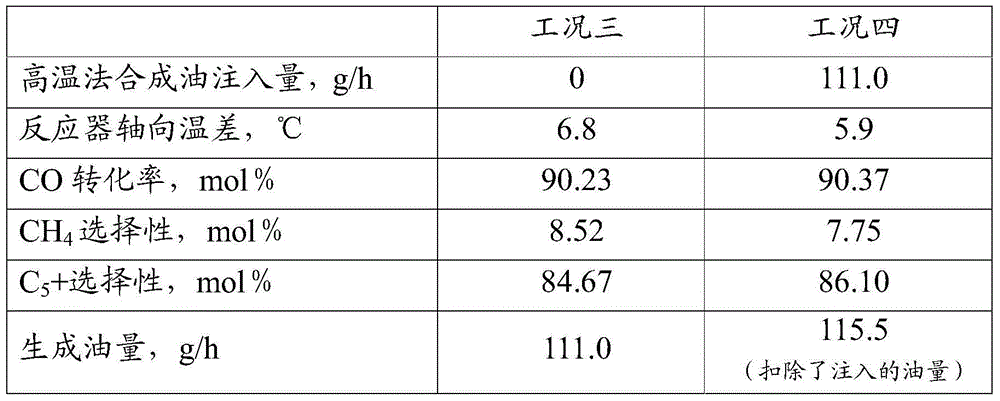

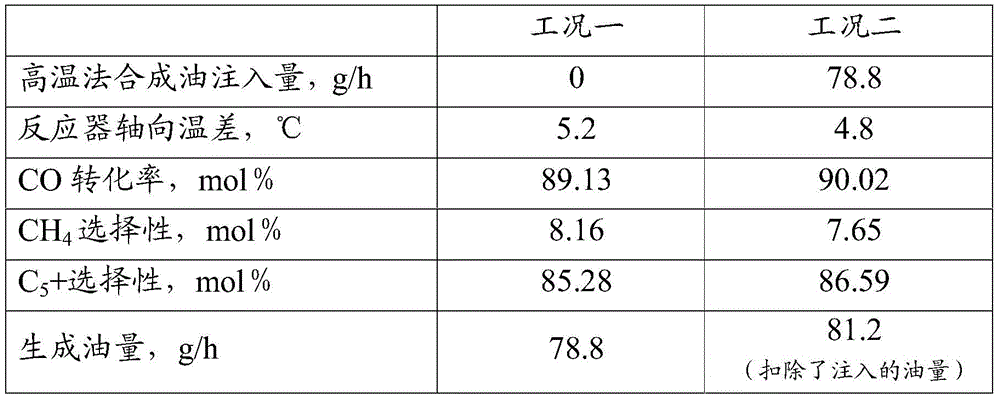

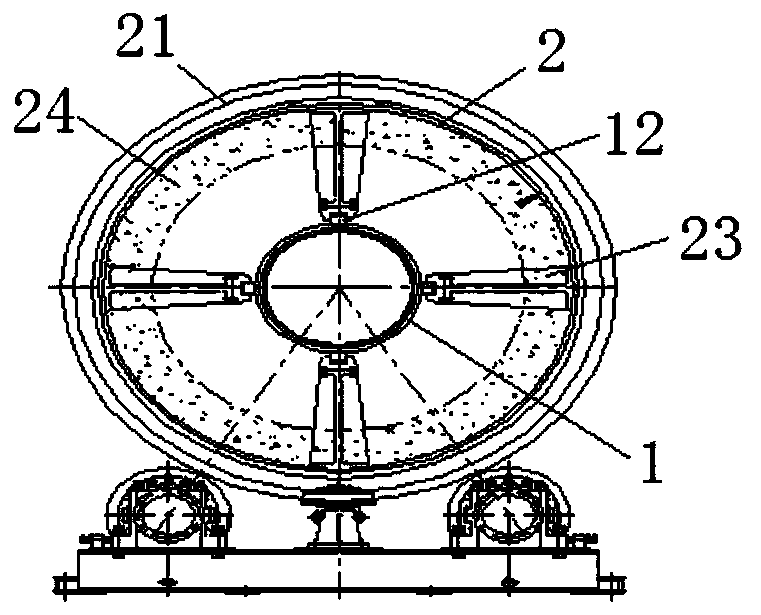

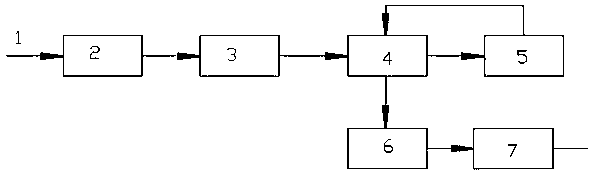

Fixed bed fischer-tropsch synthesis method

ActiveCN104560103AAxial temperature difference is smallHigh selectivityLiquid hydrocarbon mixture productionSynthesis methodsLiquid hydrocarbons

The invention discloses a fixed bed fischer-tropsch synthesis method. A synthesis gas and high-temperature method fischer-tropsch synthesis oil enter a fixed bed fischer-tropsch synthesis reactor, and are subjected to fischer-tropsch synthesis reaction under the action of a catalyst; and effluent of the reactor is separated to obtain the gas, liquid hydrocarbon and water. According to the fixed bed fischer-tropsch synthesis method, the axial temperature difference of the fixed bed fischer-tropsch synthesis reactor is effectively reduced; the temperature distribution of a catalyst bed is more uniform; the selectivity of liquid hydrocarbon products is improved; and the diesel distillate efficiency of the synthesis oil is increased through further chain increase of the high-temperature method fischer-tropsch synthesis oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of fixed bed Fischer-Tropsch synthesis method

ActiveCN104560103BAxial temperature difference is smallHigh selectivityLiquid hydrocarbon mixture productionSynthesis methodsLiquid hydrocarbons

Owner:CHINA PETROLEUM & CHEM CORP +1

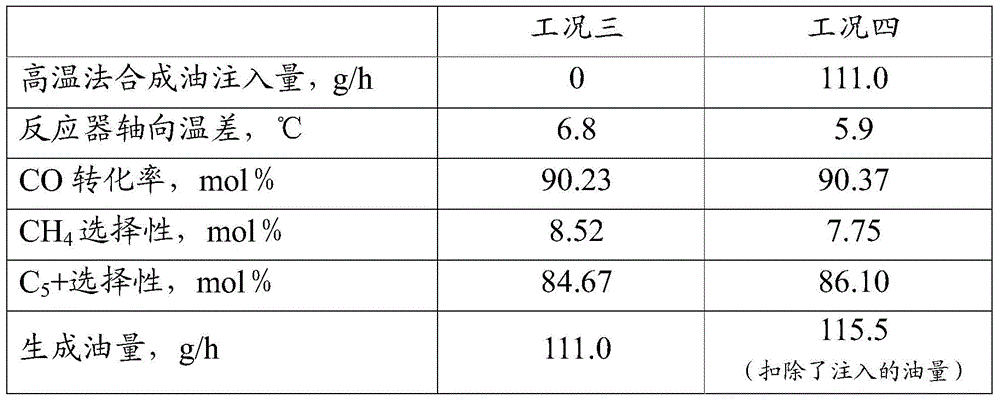

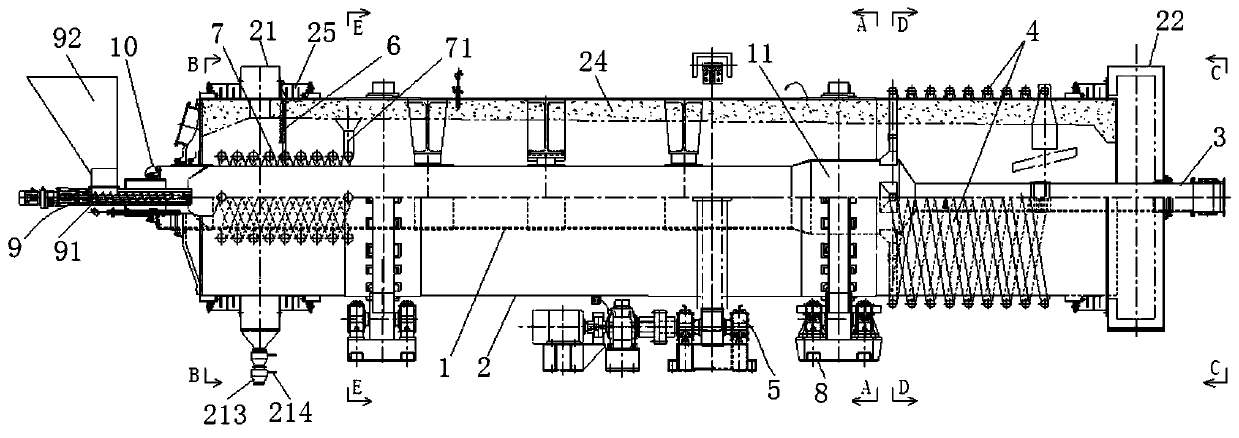

A thermal cracking device for Fischer-Tropsch synthesis reaction wax slag and its application method

ActiveCN106675590BAvoid breakingReduce lysis residence timeSpecial form destructive distillationWaxHelical blade

The invention relates to a thermal cracking device for a Fischer-Tropsch synthesis reaction wax residue and an application method of the thermal cracking device. The thermal cracking device is characterized by comprising a rotary kiln with an inner barrel and an outer barrel, wherein the outer barrel sleeves the outside of the inner barrel; a feed end is arranged at the initial end of the inner barrel; an outlet end is arranged at the tail end of the inner barrel and is connected with the initial end of an oil-gas outlet pipe; the tail end of the oil-gas outlet pipe extends out of the tail end of the outer barrel; a helical blade is arranged on the inner wall of the inner barrel; a discharge device is arranged at the outlet end of the inner barrel; the outer wall of the outer barrel is connected with a drive motor through a transmission mechanism; the outer barrel drives the inner barrel to rotate in common through operation of the drive motor; a smoke outlet cover is arranged at the initial end of the outer barrel; a smoke outlet and a residue discharge hole communicated with the inside of the outer barrel are arranged in the smoke outlet cover at interval; a smoke inlet cover is arranged at the tail end of the outer barrel; and a smoke inlet communicated with the inside of the outer barrel is formed in the smoke inlet cover; an overflow plate is arranged at the initial end of the outer barrel and is close to the smoke outlet cover; and a material return device is arranged at the feed end of the inner barrel.

Owner:SYNEFUELS CHINA +1

A heating device for a laminating machine

InactiveCN103770456BRealize the utilization of reciprocating cycleAxial temperature difference is smallPrinting press partsHeat conductingEngineering

The invention discloses a heating device of a film laminating machine and belongs to the field of film laminating machines. According to the technical scheme, heat-conducting media enter a water inlet, pass through a first cavity, flow into a second cavity along the space between an inner roller and an outer roller, flow back to the heating device after returning to a water outlet through a water outlet pipe, and then flow into the water inlet after being heated again by the heating device. In this way, uniform heating is conducted on the outer roller, and circulating utilization of the heat-conducting media is achieved. The heating device of the film laminating machine can greatly increase the operating speed of the film laminating machine.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Gas-liquid interlaced cooling high power density motor

ActiveCN103199652BReduce working temperature riseImproved cooling systemCooling/ventillation arrangementWorking temperatureEngineering

The invention discloses a gas-liquid interlaced cooling high power density motor, and belongs to the field of high power density motors. An armature winding of the motor is wrapped by an insulating bushing, supported by a non-metal T-type support, and fixed through a slot wedge, and an axial cooling medium channel inside a stator core is formed. A space defined by a non-metal airtight cylinder, a housing case inner wall, the stator core, a first annular sealing plate and a second annular sealing plate in an enclosed mode constitutes a stator side airtight cooling cavity. Liquid-state cooling media flow from a liquid inflow guiding tube into the axial cooling medium channel inside the stator core, trickle down onto a rotor through first to Nth trickling holes, flow out from a liquid outflow guiding tube and a second liquid outflow guiding tube, and are cooled through a liquid cooling device. Gas-state cooling media enter from a gas inflow guiding tube and flow out from a gas medium outlet hole. Different cooling channels are combined into an interlaced multi-dimensional space cooling system, working temperature rise of the motor is effectively reduced, stability is improved, and unbalanced thermal stress influences caused by axial temperature difference are reduced.

Owner:BEIJING JIAOTONG UNIV

A method for producing oil from biogas

ActiveCN109135796BAxial temperature difference is smallSolve the problem of large radial temperature gradientHydrogenRefining to change hydrocarbon structural skeletonProcess engineeringSeparation system

Owner:北京嘉岳能源科技开发有限公司

Motor cooling device and motor

ActiveCN109787381BAxial temperature difference is smallUniform axial temperature distributionMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineMechanical engineering

The invention provides a motor cooling device and a motor. The motor cooling device comprises the following parts of a plurality of stator vent holes formed in a stator core along an axial direction of the stator core; a first mounting member and a second mounting member respectively coupled to the both axial sides of the stator core and respectively formed with a plurality of first vent holes anda plurality of second vent holes along the axial direction; and a bracket comprising a main body and first and second support portions protruding radially outward from both sides of the main body, wherein the main body is formed with a plurality of bracket vent holes, the first mounting member and the second mounting member are respectively supported on the first support portion and the second support portion, the first vent hole and the second vent hole respectively form a first vent passage and a second vent passage that are independent of each other with the corresponding stator vent holes, and the flows of the air flowing through the first vent passage and the second vent passage are reciprocal and flow out to the outside through the bracket vent holes. According to the motor coolingdevice provided by the invention, the axial temperature difference of the motor can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

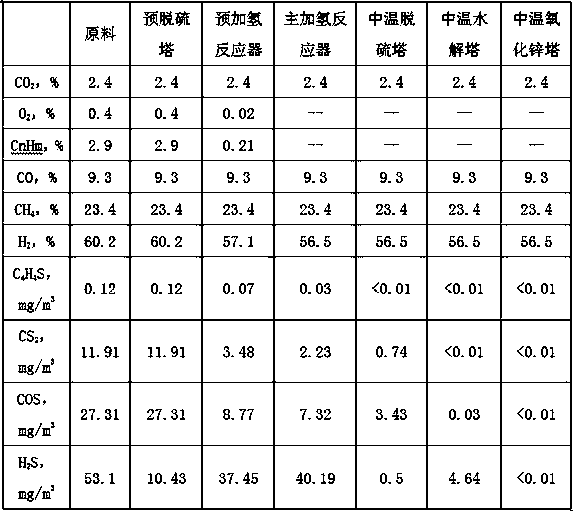

A coke oven gas fine desulfurization process

ActiveCN106350122BEasy to operateAxial temperature difference is smallGas purification by catalytic conversionGas purification with selectively adsorptive solidsHydrogenSulfur

The invention provides a fine desulfurization process for coke-oven gases. The fine desulfurization process comprises the following steps: treating the coke-oven gas in a deoiling tower and a pre-desulfurizing tower, performing heat exchange with main gas generated after main hydrogen desulfurization, feeding the gas into a pre-hydrogen desulfurization reactor, increasing the temperature through a heater, feeding the gas into a main hydrogen desulfurization reactor, performing heat exchange on a gas obtained after reaction so as to reduce the temperature to 280-360 DEG C, feeding the gas into a medium temperature desulphurization tower to remove H2S and most organic sulfur, further feeding the gas into a medium temperature hydrolysis tower to further convert the organic sulfur such as COS and CS2 into H2S, and finally feeding the gas into a medium temperature fine desulphurization tower in the presence of a medium temperature fine desulfurizing agent. After the coke-oven gases are treated by using the fine desulfurization process, the total sulfur can be reduced to be less than 0.05 mg / Nm<3>, a later synthesis catalyst can be effectively protected, and the service life of the synthesis catalyst can be prolonged.

Owner:WUHAN KELIN FINE CHEM

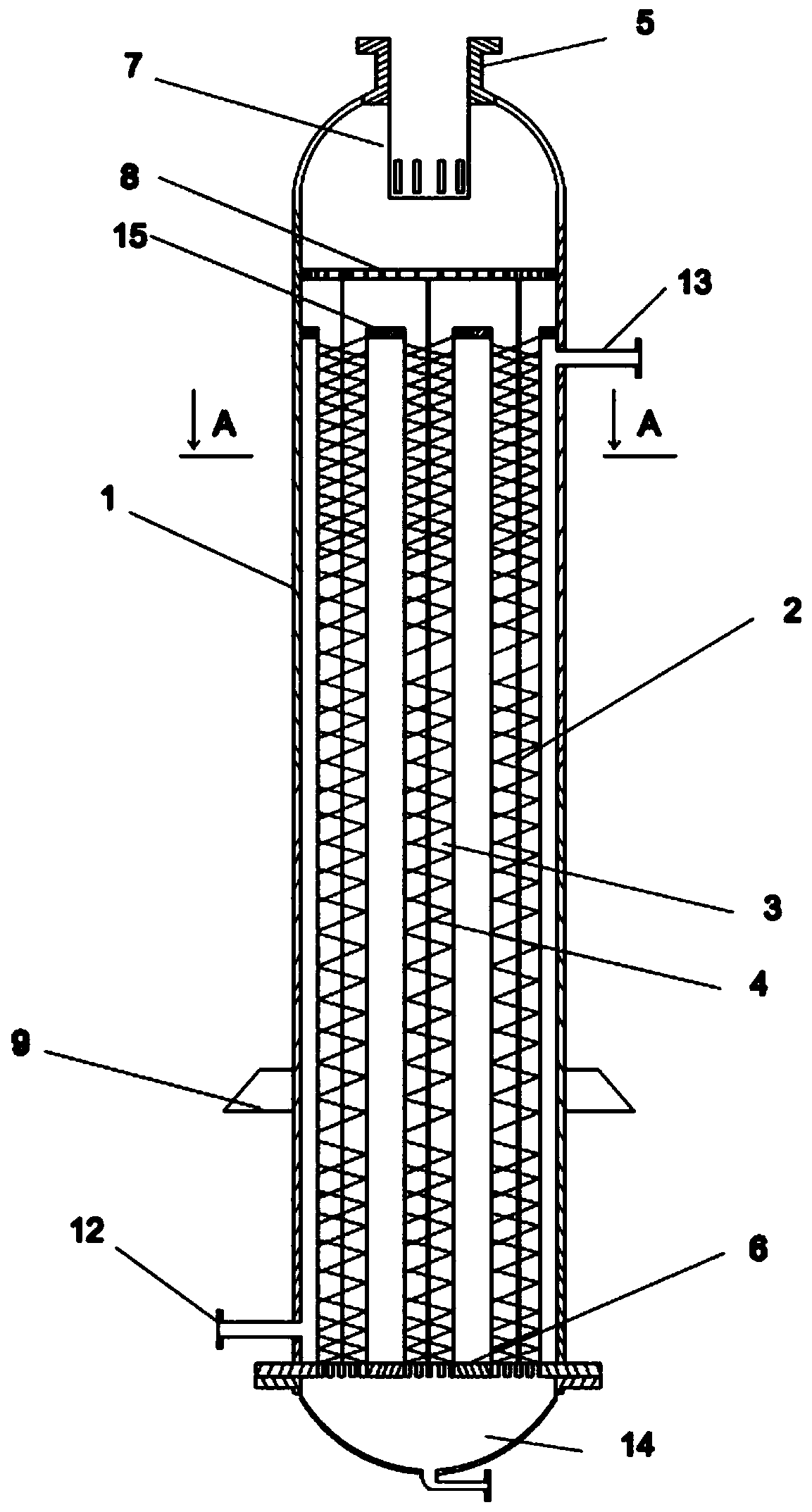

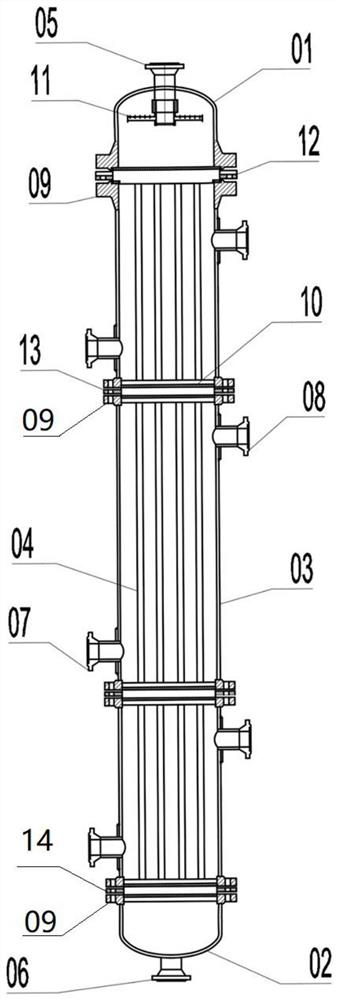

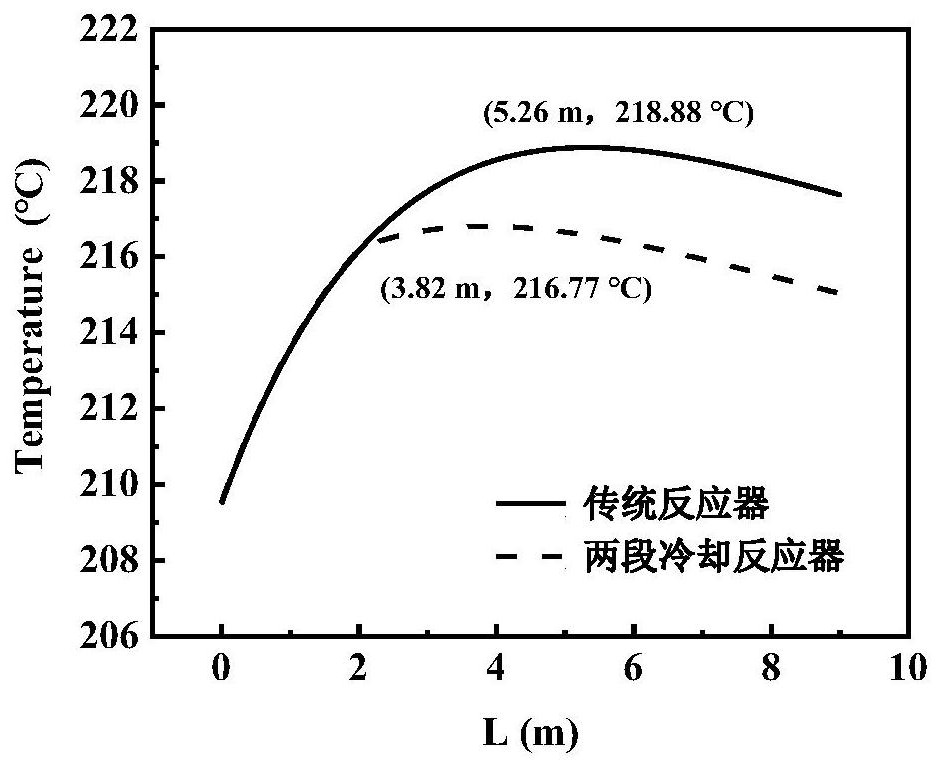

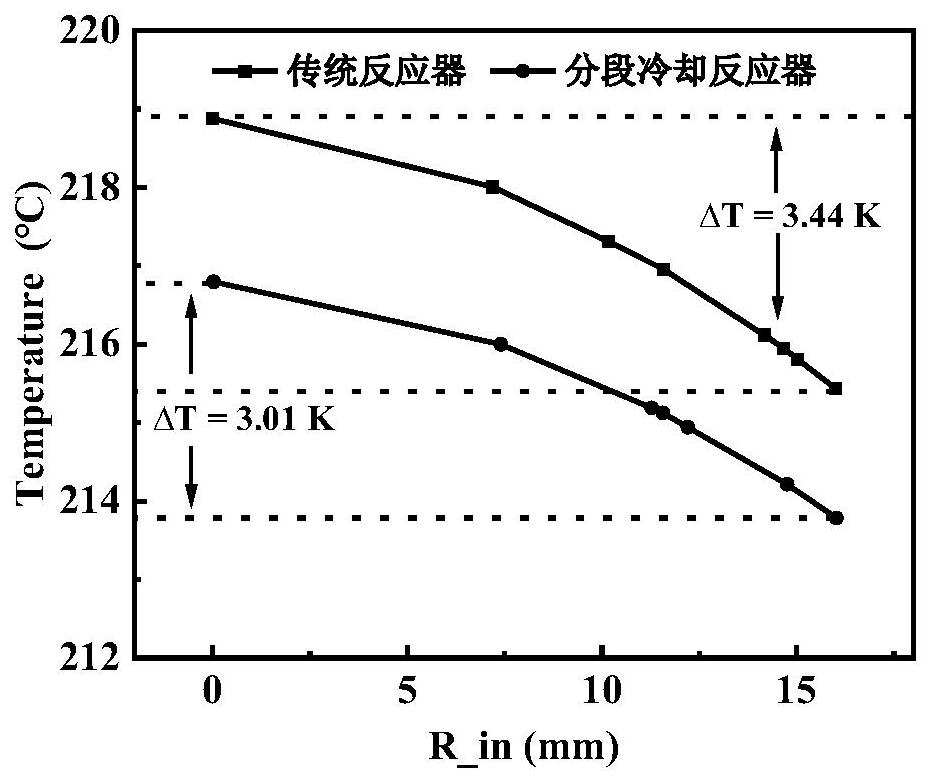

Fischer-Tropsch synthesis tubular fixed bed reactor with segmented cooling in catalytic bed layer

PendingCN114832734AAvoid flying temperatureAvoid axial temperature differenceLiquid hydrocarbon mixture productionChemical/physical processesThermodynamicsPtru catalyst

The invention provides a Fischer-Tropsch synthesis tubular fixed bed reactor for segmented cooling in a catalytic bed layer, the reactor comprises an upper seal head, a cylinder and a lower seal head, the upper seal head is provided with a feed gas inlet; a reaction product outlet is formed in the bottom of the lower sealing head; continuous reaction tube nests are arranged in the barrel to be filled with a catalyst, the upper ends of the reaction tube nests are fixedly connected to the upper tube plate, and the lower ends of the reaction tube nests are connected with the lower tube plate; the barrel is divided into two or more cooling sections, each cooling section is provided with a cooling medium inlet and a cooling medium outlet, a partition tube plate is arranged between every two adjacent cooling sections, and the cooling medium temperature of the second cooling section is lower than that of the first cooling section. By optimizing the temperature of the cooling medium and the segmentation position, the heat exchange effect is improved, the Fischer-Tropsch synthesis reaction hot-spot temperature is reduced, uniform distribution of axial and radial temperatures of the bed layer is facilitated, temperature runaway of the bed layer is avoided, meanwhile, the pipe diameter of the reaction tube nest can be increased, the number of the reaction tubes can be reduced, and the reaction pressure drop can be reduced.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A multi-channel series-parallel water-cooling system for motors

ActiveCN103715830BAxial temperature difference is smallGuaranteed uptimeCooling/ventillation arrangementEngineeringWater cooling

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com