A coke oven gas fine desulfurization process

A desulfurization process, coke oven gas technology, which is applied in the petroleum industry, combustible gas purification, removal of gas pollutants, etc. Improved desulfurization efficiency and uniform reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

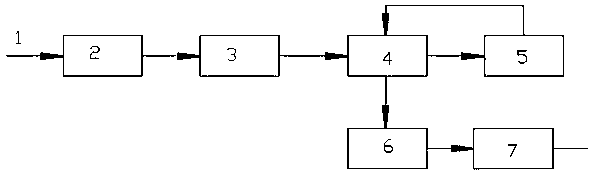

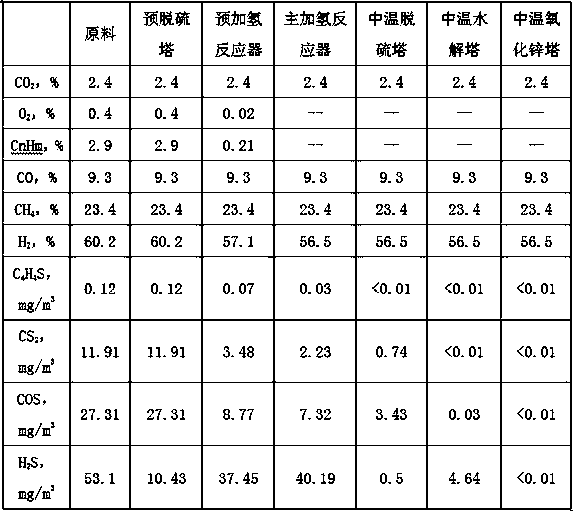

[0025] The desulfurization process of coke oven gas in a unit in Shanxi is attached figure 1 As shown, under the condition of 60-80°C, coke oven gas 1 is treated by deoiling tower and pre-desulphurization tower 2 equipped with activated carbon desulfurizer, and the treated gas is pressurized to 2.5MPa by compressor, and then passed through heat exchanger 4 Exchange heat with the gas from the hydrogenation reactor 5, the temperature after the heat exchange is 260°C, enter the pre-hydrogenation reactor 3, and use activated carbon as the carrier, and use Cu, Ti, Ce as the active component of the catalyst Under the action of catalysis, the desulfurization and deoxidation reaction is carried out, and then enters the tubular hydrogenation reactor 5 after being heated by the heater. After heat exchange by heat exchanger 4, the temperature drops to 280°C, and enters the medium temperature desulfurization tower to remove H 2 S and most of the organic sulfur, the desulfurizer loaded in...

Embodiment 2

[0031] The desulfurization process of coke oven gas in a unit in Shanxi is attached figure 1 As shown, under the condition of 60-80°C, coke oven gas 1 is treated by deoiling tower and pre-desulphurization tower 2 equipped with activated carbon desulfurizer, and the treated gas is pressurized to 2.5MPa by compressor, and then passed through heat exchanger 4 Exchange heat with the gas coming out of the hydrogenation reactor, the temperature after the heat exchange is 280°C, enter the pre-hydrogenation reactor 3, and use alumina as the carrier and Cu, Ti, Ce as the active component of the catalyst Under the action of catalysis, the desulfurization and deoxidation reaction is carried out, and then the heater enters the tube hydrogenation reactor 5. The reactor is filled with nickel-molybdenum hydrodesulfurization catalyst, and the reaction temperature is 280-370 ° C. After heat exchange by heat exchanger 4, the temperature drops to 360°C, and enters the medium temperature desulfur...

Embodiment 3

[0033] The desulfurization process of coke oven gas in a unit in Shanxi is attached figure 1 As shown, under the condition of 60-80°C, the coke oven gas 1 is treated by the deoiling tower and the pre-desulphurization tower 2 equipped with activated carbon desulfurizer. The desulfurization tower 3 is evenly divided into three layers, and activated carbon, calcium oxide and Three desulfurizers of room temperature composite oxide, the treated gas is pressurized to 2.5MPa by the compressor, and then the heat exchange is carried out with the gas from the hydrogenation reactor through the heat exchanger 4. The temperature after the heat exchange is 300°C, and enters The pre-hydrogenation reactor 3, under the catalysis of catalysts with active carbon as the carrier and Cu, Ti and Ce as the active components, performs desulfurization, deoxidation and olefin saturation reactions, and then enters the tube heating process after heating up by the heater. Hydrogen reactor 5, the reactor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com