Efficient and uniform heating device for motor hot jacket

A technology of uniform heating and motor heating, applied in induction heating devices, coil devices, induction heating, etc., can solve the problems of poor axial temperature distribution uniformity of motor heat sleeves, inability to meet temperature uniformity, and T-shaped process slot ablation. , to avoid the local temperature rise too fast, solve the poor uniformity of heating temperature, and improve the uniformity and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

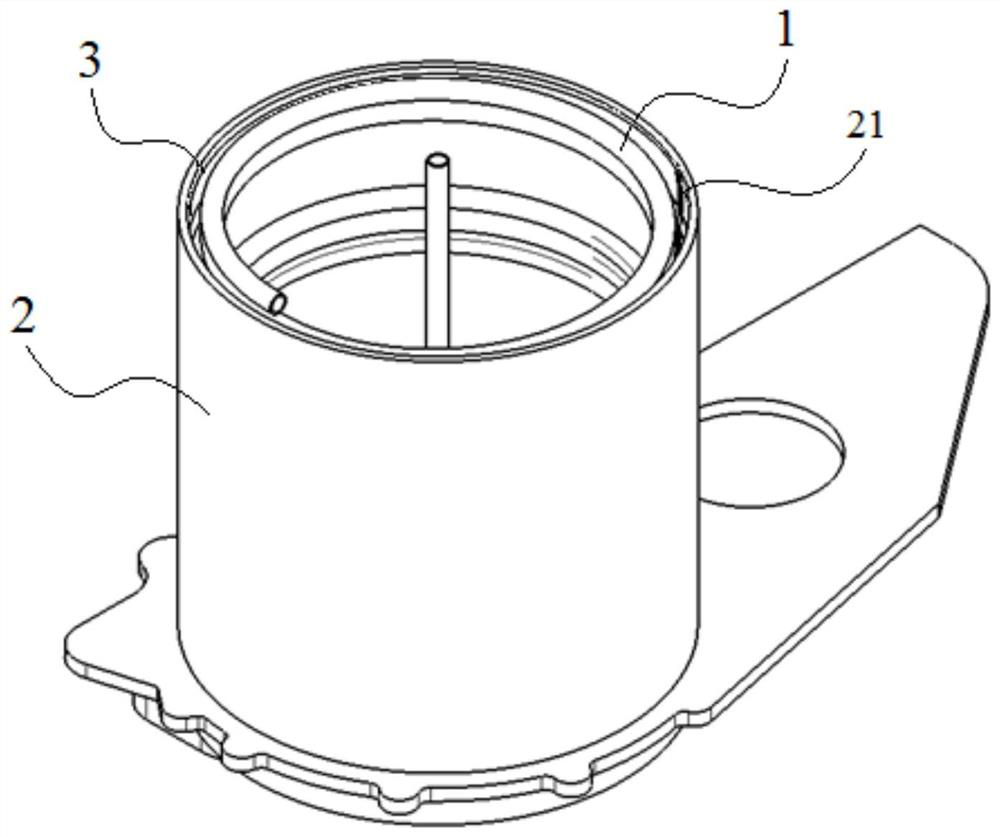

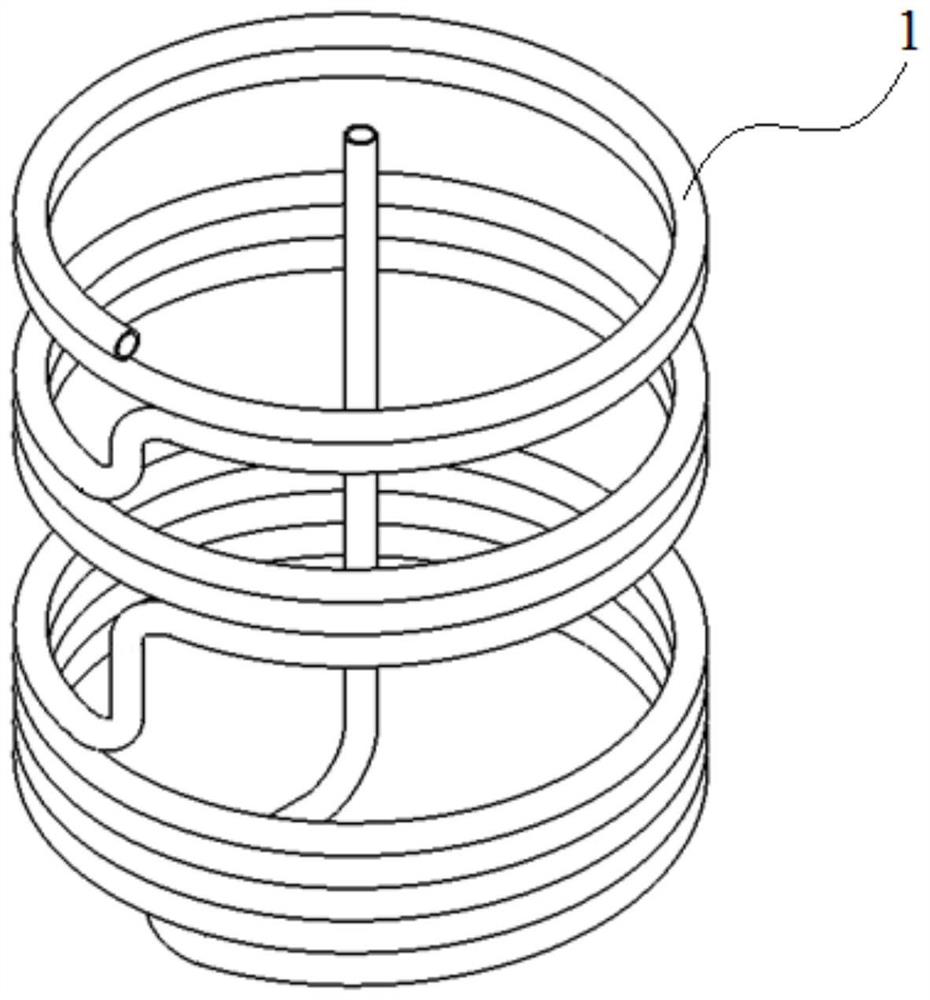

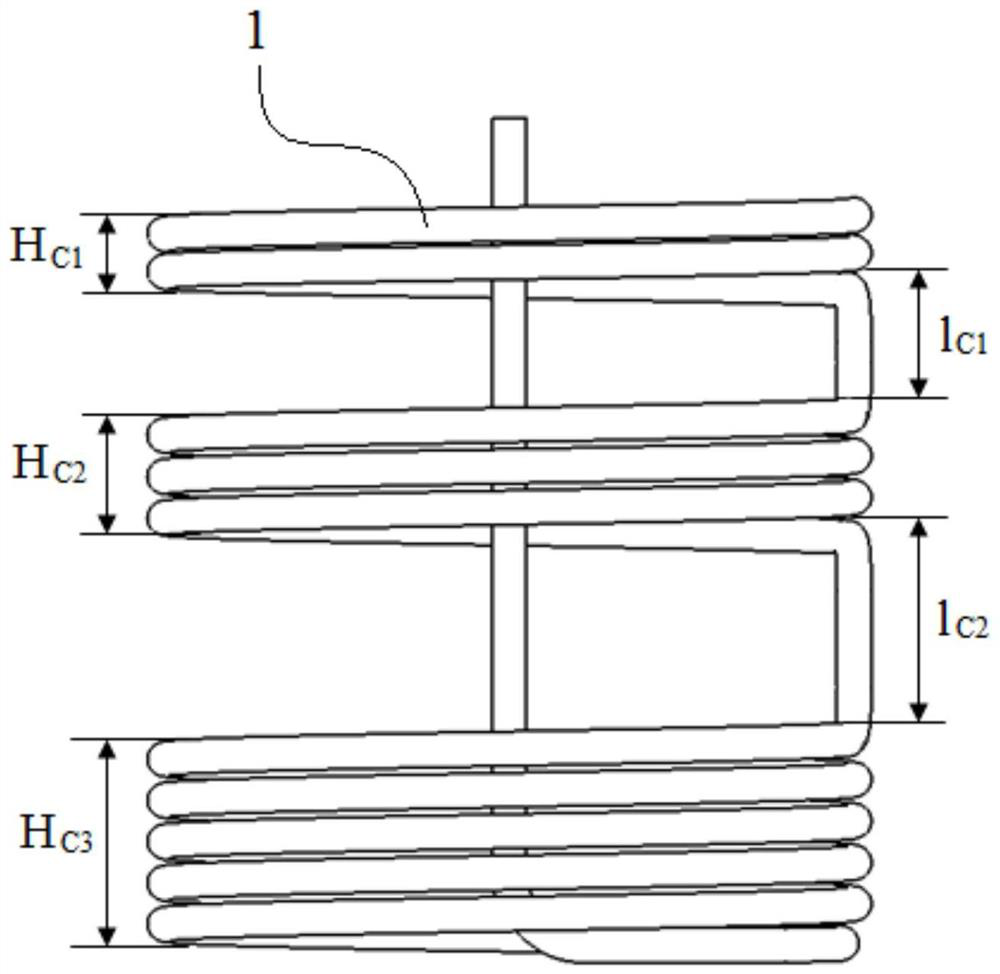

[0027] Such as Figure 1 to Figure 4 As shown, the high-efficiency and uniform heating device of the motor heat sleeve in this embodiment includes an induction coil 1 that can be adapted to the inner cavity of the motor heat sleeve 2, and is arranged on the periphery of the induction coil 1 to connect the induction coil 1 and the motor heat sleeve. 2 separated insulating layer 3 and an AC power module (not shown in the figure) connected to the induction coil 1, the induction coil 1 is a multi-turn hollow spiral copper coil, and the hollow pipe of the hollow spiral copper coil is a water channel, which is used for heating Cool the induction coil. The induction coil 1 is wound in a group crosstalk manner to form n coil groups in series, the hollow spiral copper coils in each coil group are evenly wound, and the winding radii of the hollow spiral copper coils in the n coil groups are the same, The longitudinal distance between two adjacent coil groups is greater than the outer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com