Fischer-Tropsch synthesis tubular fixed bed reactor with segmented cooling in catalytic bed layer

A fixed-bed reactor, catalytic bed technology, applied in chemical instruments and methods, chemical/physical processes, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as difficult process control, increased catalyst loss, and large catalyst loss. , to ensure the yield and selectivity, increase the upper limit of the maximum pipe diameter, and improve the heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

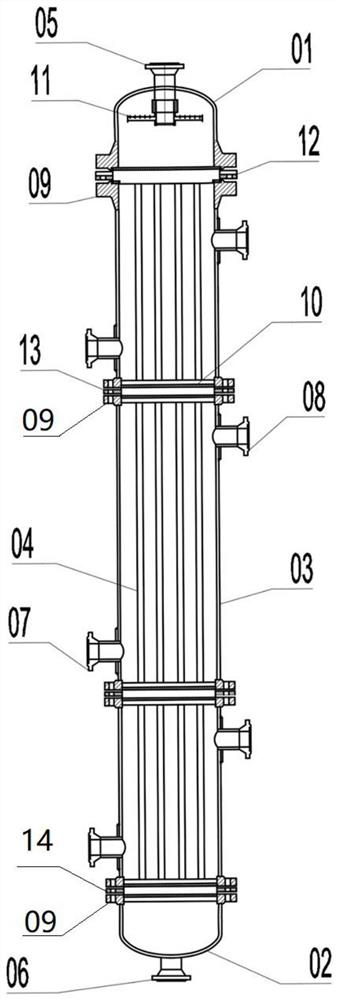

[0052] The invention provides a Fischer-Tropsch synthesis tubular fixed bed reactor with segmented cooling in the catalytic bed, such as figure 1 As shown, the fixed bed reactor includes an upper head 01, a cylinder 03 and a lower head 02 connected in sequence from top to bottom, wherein:

[0053] The upper sealing head 01 is provided with a raw material gas inlet 05, and the upper sealing head 01 is provided with a gas distributor 11 that communicates with the raw material gas inlet 05 to make the feed gas evenly distributed;

[0054] A reaction product outlet 06 is arranged at the bottom of the lower head 02, and a liquid collector (not shown in the figure) that communicates with the reaction product outlet 06 is arranged in the lower head 02;

[0055] In the cylinder 03, a continuous reaction tube 04 is arranged between the upper head 01 and the lower head 02. The reaction tube 04 is not segmented, which is convenient for the filling and replacement of the catalyst. The up...

Embodiment 2

[0061] like figure 1As shown, in this embodiment, on the basis of Embodiment 1, the cylindrical body 03 is divided into three cooling sections, and the catalytic bed is cooled and heat exchanged in stages. When the cooling medium in the second cooling section cools and heats the bed, as the reaction proceeds, the concentration of the reactants in the reaction tube gradually decreases, and the reaction exotherm decreases accordingly, and a lower cooling medium is also used to exchange heat for the bed. , resulting in a lower temperature in the reactor at this time and a decrease in the reaction rate. Therefore, on the basis of the two-stage heat exchange, a third cooling section is set for cooling and heat exchange, and the temperature of the cooling medium in the third cooling section is slightly higher than the temperature of the cooling medium in the second cooling section, so as to reduce the temperature difference between the inside and outside of the tube and maintain the...

Embodiment 3

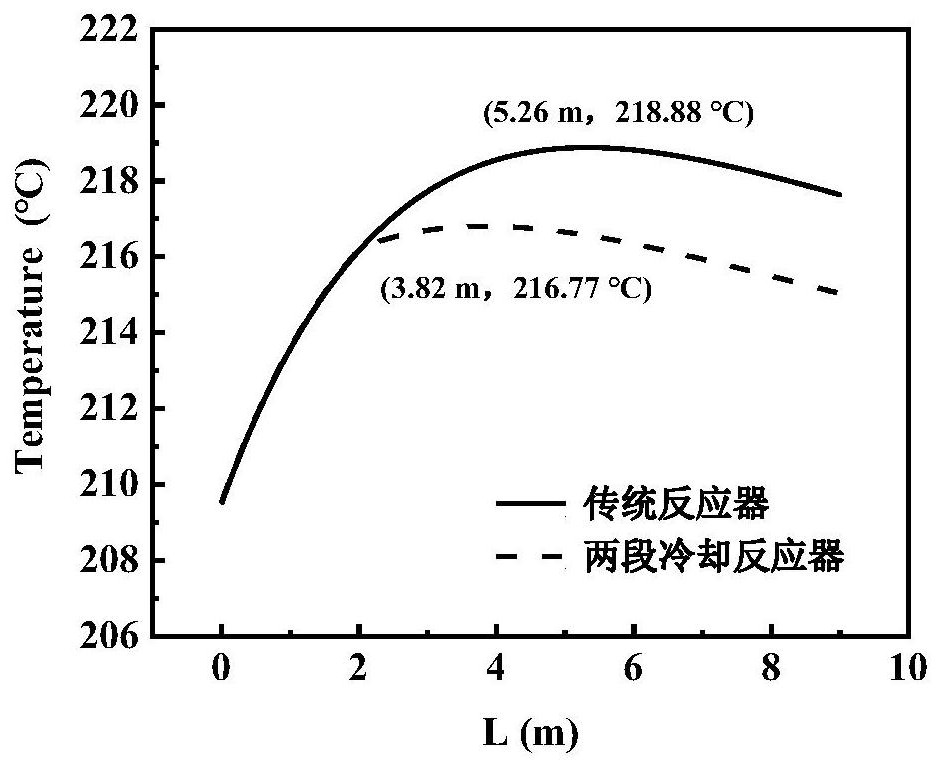

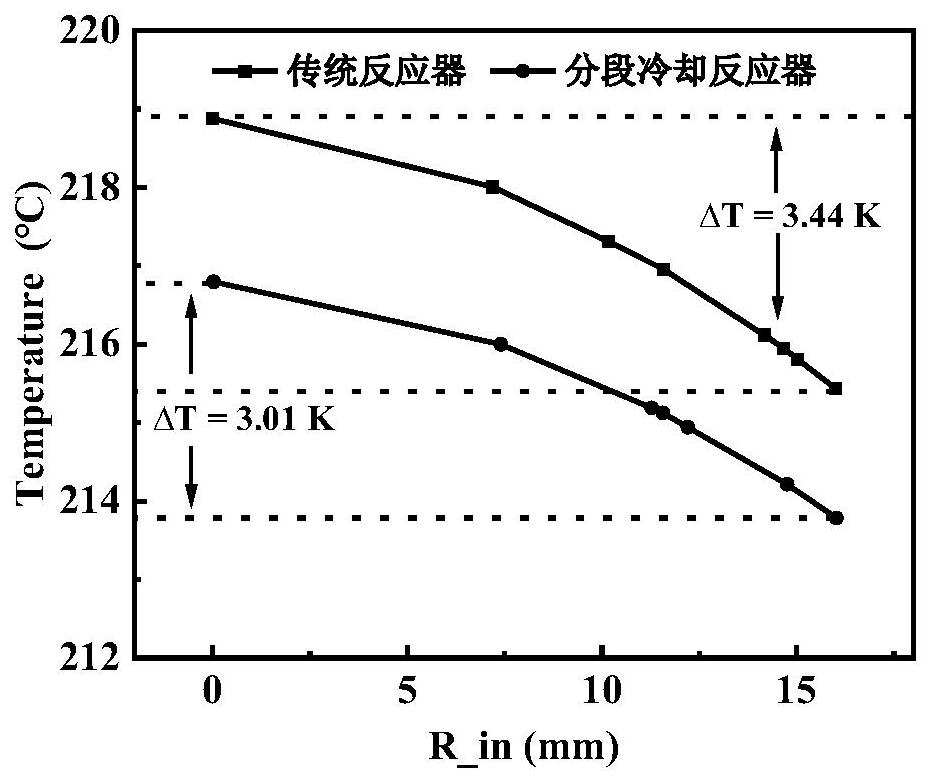

[0064] In this example, the multi-physics simulation software COMSOL is used to design and simulate a tubular fixed-bed reactor for Fischer-Tropsch synthesis, and simulate and analyze the temperature distribution and reaction conversion rate in the inner axis and radial direction of the reactor. The parameters of the reactor model to be designed are as follows: the length of the reaction tube is 9m, the diameter of the tube is 0.038m, the reaction temperature is 209.50℃, the reaction pressure is 3.79MPa, and the space velocity is 3000h. -1 , the reaction raw material molar ratio H 2 / CO is 2:1; the catalyst used is a cobalt-based Fischer-Tropsch synthesis catalyst, the optimal reaction temperature range of this catalyst is 216-220℃, the bed porosity is 0.3, and the thermal conductivity of the catalyst is 1.09J / (kg·K) , the catalyst density is 640kg / m 3 , the catalyst heat capacity is 650W / (m·K), the cooling boiling water temperature is 209.50℃, and the convection heat transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com