Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "High activity and selectivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing furfuryl alcohol from furfural by vapor phase hydrogenation and preparation method thereof

InactiveCN102631930AHigh activity and selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemistryCoprecipitation

The invention belongs to the technical field of catalysts, and relates to a catalyst for preparing furfuryl alcohol from furfural by vapor phase hydrogenation and a preparation method thereof. The catalyst comprises the following components in percentage by weight: 26-50% of CuO, 22-40% of Cr2O3, 0.1-11% of Al2O3, 0.1-11% of SiO2 and 1-15% of an assistant. The catalyst is prepared by a coprecipitation method. The application temperature of the catalyst is 120-210 DEG C, the air speed of the furfural liquid is 0.4-0.6hr<-1>, and the reaction pressure is 0.001-0.5MPa. The catalyst provided by the invention has high activity and selectivity; the furfural conversion rate is 100%; the furfuryl alcohol selectivity is greater than or equal to 93%; and the catalyst can be used for industrial production of furfuryl alcohol by furfural vapor phase hydrogenation.

Owner:NANJING XIHUI NEW MATERIAL

Catalyst in use for hydrogenation reaction of benzene selection, preparartion method and application

InactiveCN1795983AHigh activity and selectivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneNanoreactor

The invention provides a ruthenium catalyst for benzene selective hydrogenation reaction and its preparation method. It is characterized by that: (1). the nucleation and growth processes of ruthenium nano particle can be controlled in the nano reactor composed of water nucleus enclosed with surfactant and implemented; and (2). the porous inorganic protective layer is formed by utilizing in-situ hydrolysis of ethyl metasilicate in nano reactor system containing ruthenium nano particles. The ruthenium content is said catalyst is 7-15 wt%, said catalyst can be used for benzene selective hydrogenation reaction, when the benzene conversion rate is 40%, cyclohexene selectivity is 72-75%, TOF(H2) can be up to above 3560h-1, and its yield can be up to above 40%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing transitional metal carbides catalytic material and use

InactiveCN101371988AThe method is simpleHigh activity and selectivityPhysical/chemical process catalystsOrganic compound preparationDecompositionMolecular sieve

The invention discloses a preparation method and the application of a catalytic material for transition metal carbides, belonging to the preparation technical field of the catalytic material. The invention is characterized in that in the method, carbon material, oxide or molecular sieve, and the like, are used as vectors and transition metal compounds are used as precursors. The vectors and the transition metal precursors are mixed by dipping or mechanical method and a microwave-assisted chemical sedimentation method is adopted to prepare the catalyst for loaded transition metal carbides. The weight percentage of loading of the transition metal compounds is 1-200 percent. Particles of the catalyst for the loaded transition metal carbides are highly uniformly distributed on the surface of the vectors. And the catalyst can be applied to a plurality of reactions of electrocatalysis oxidation of methanol, hydrazine decomposition, acetonitrile hydrogenation, etc. The preparation method and the application have the beneficial effects of simple preparation process and easy operation. And the obtained catalytic material shows high activity in the electrode reaction and a plurality of catalytic reactions of fuel cells.

Owner:DALIAN UNIV OF TECH

Supported catalysts having a high sintering stability and a process for producing them

InactiveUS6372687B1High activity and selectivityHigh operational lifeOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl groupOrganic compound

Supported catalysts having a high sintering stability and comprising one or more noble metal cluster carbonyl compounds of the formula (1)and their use for the dehydrogenation, hydrogenation and oxidation of organic compounds wherewherein the compounds of the formula (1) are located in the pores of a mesoporous support material.

Owner:AVENTIS RES & TECH GMBH & CO KG

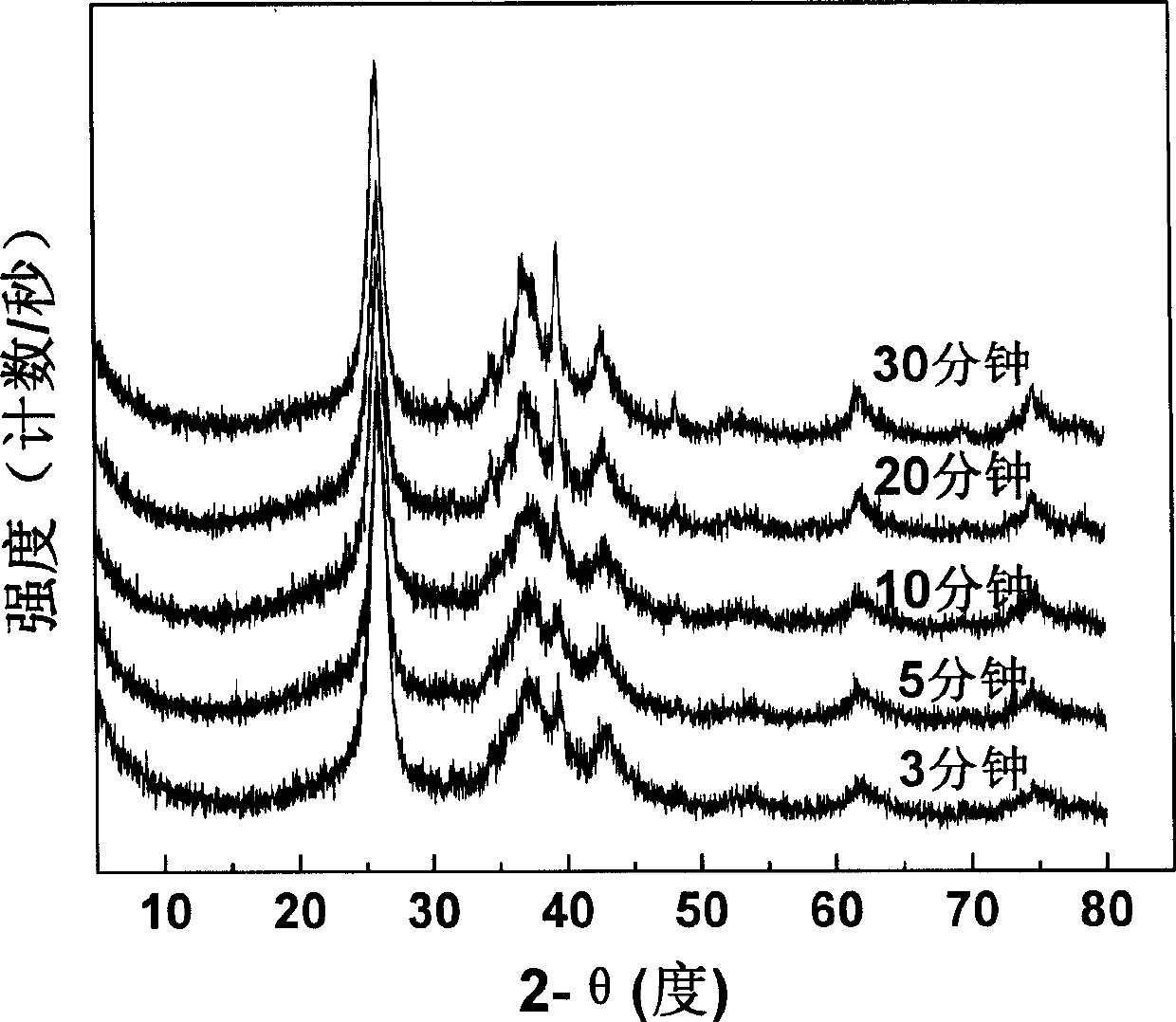

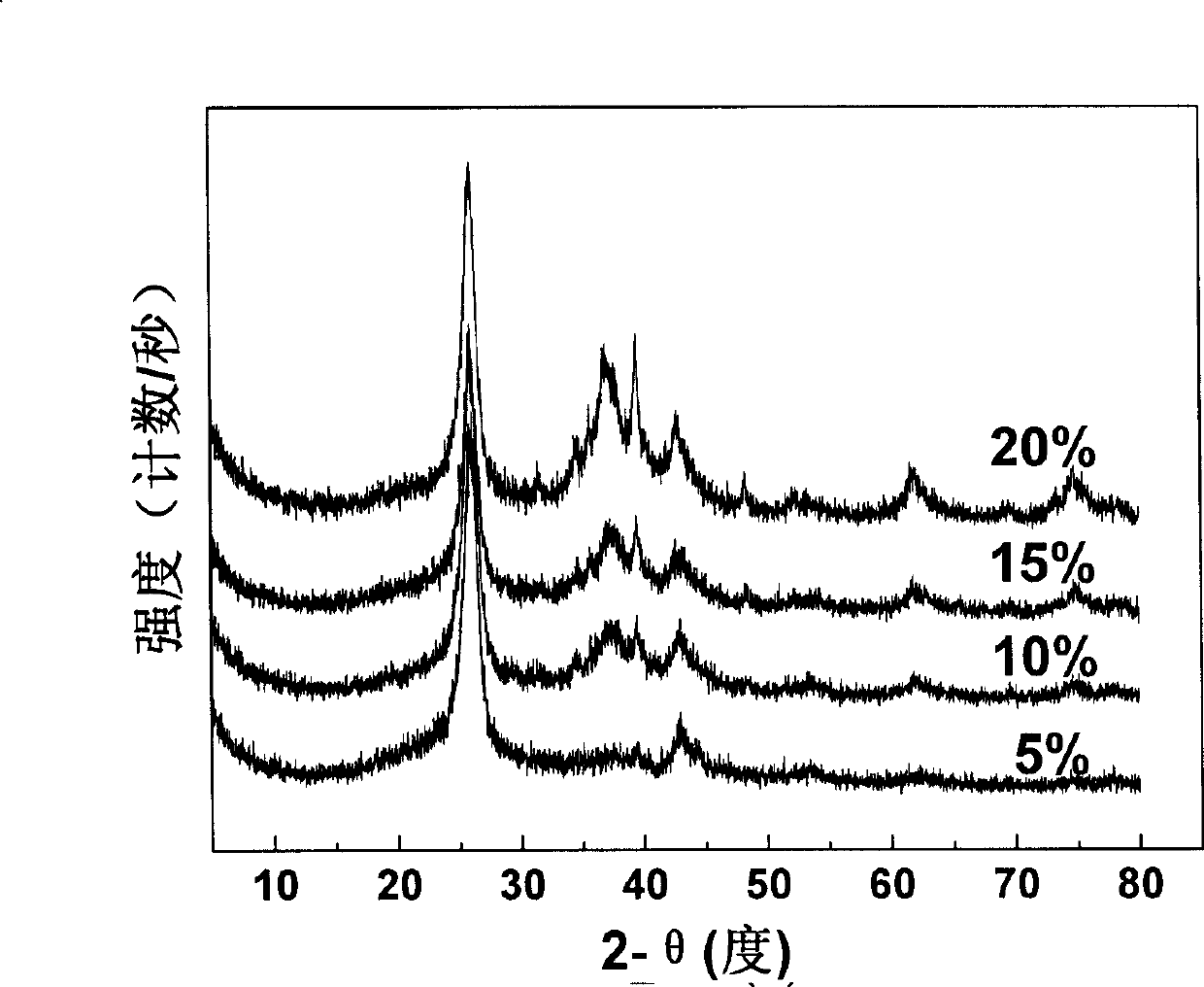

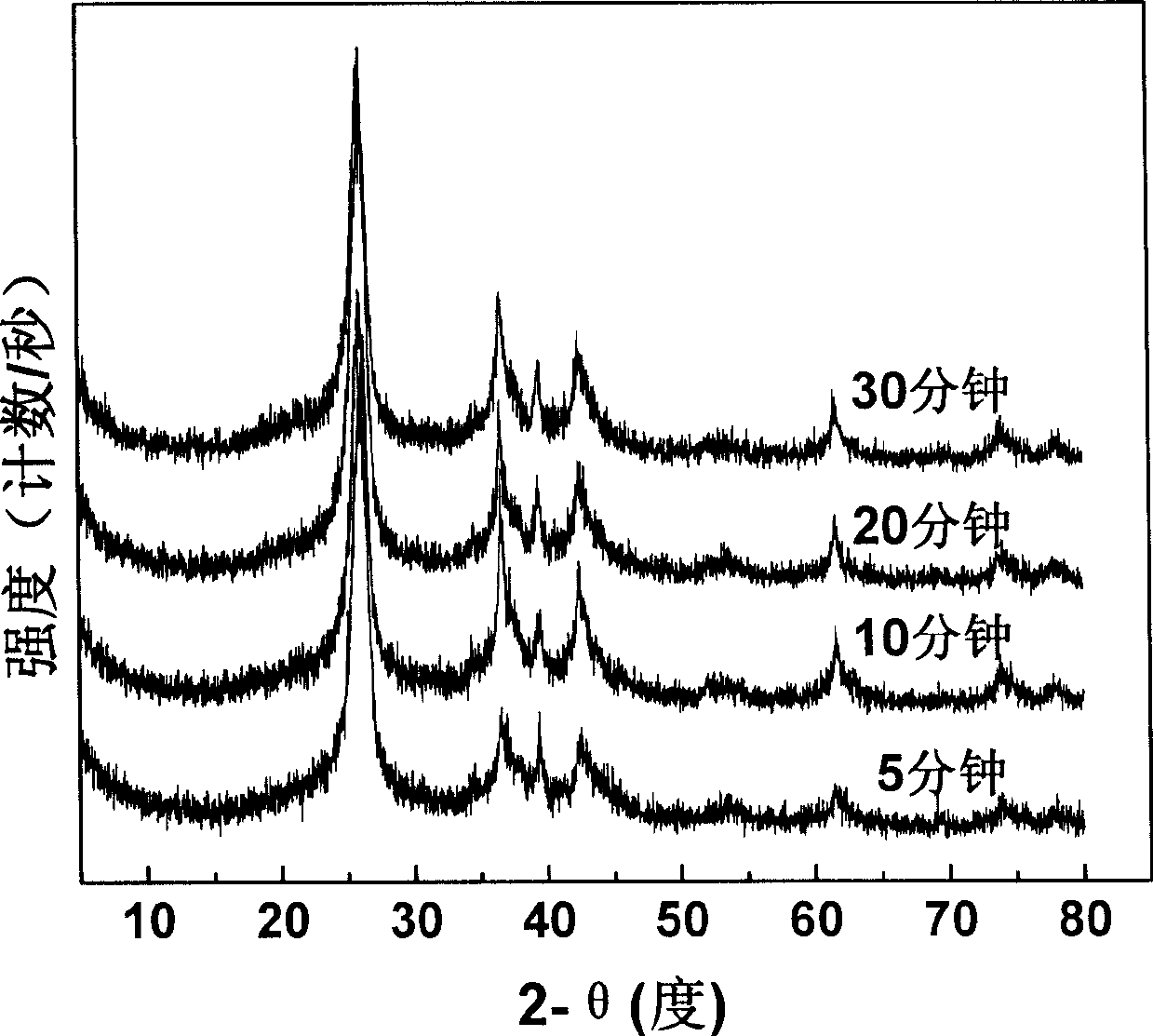

Preparation method of propenyl ethanoate catalyst and synthesis method of propenyl ethanoate

ActiveCN104437670AHigh activity and selectivityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylateEthylic acid

The invention relates to a preparation method of a propenyl ethanoate catalyst, a catalyst obtained by the method and a synthesis method of propenyl ethanoate, and mainly solves the problem that the catalysts are not high in activity and selectivity in the prior art. According to the preparation method of the propenyl ethanoate catalyst, the catalyst comprises a carrier, an active component and a co-catalyst, wherein the carrier is selected from at least one of SiO2 or Al2O3; the active component comprises a metal Pd and a metal Cu; the co-catalyst is potassium acetate. The preparation method comprises the following steps: (1) loading alkali metal carboxylate on the carrier to obtain an alkali metal carboxylate modified carrier, wherein the alkali metal carboxylate accounts for 1.0-15wt% of the modified carrier; and (2) loading the metal Pd and the metal Cu with required quantity by using a solvated metal atom impregnation method (SMAI). The problem can be better solved and the propenyl ethanoate catalyst can be used for industrial production of propenyl ethanoate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heteropoly acid catalyst and preparation method thereof

ActiveCN105709829AIncrease total acidityHigh activity and selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsBoron oxideActive component

The invention discloses a heteropoly acid catalyst and a preparation method thereof. The catalyst adopts alumina as the carrier, uses heteropoly acid as the active component, and takes boron oxide as the assistant, wherein the surface of the alumina carrier is coated with silica. The preparation method consists of: coating the surface of the alumina carrier with an appropriate amount of silica, and then loading heteropoly acid and the assistant component. The catalyst has high activity and selectivity when used for preparation of ethylene by ethanol dehydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

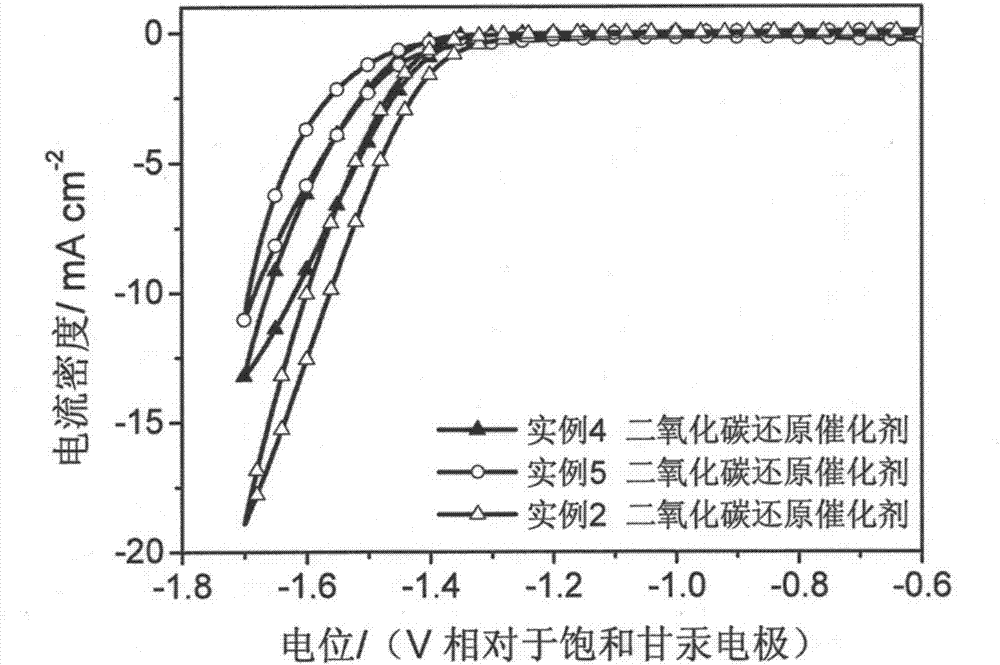

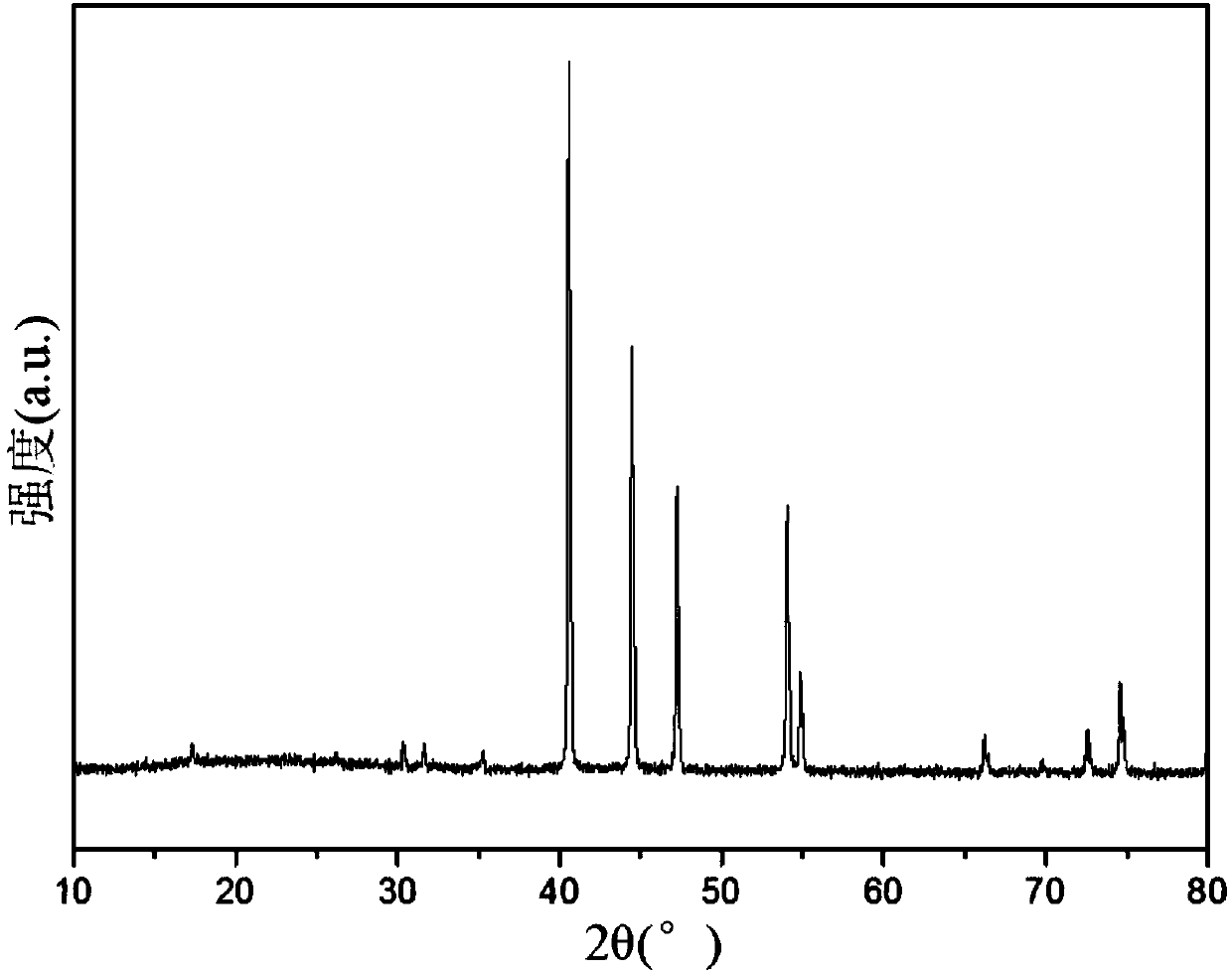

Elemental bismuth catalyst for electrochemical reduction of carbon dioxide as well as preparation and application of elemental bismuth catalyst

ActiveCN107020075AHigh activity and selectivityInhibition of competing side effectsChemical industryElectrolytic organic productionMicro nanoCarbon dioxide

The invention provides preparation and application of a catalyst for electrochemical reduction of carbon dioxide. The catalyst for the electrochemical reduction of the carbon dioxide is characterized by comprising a micro-nano-grade elemental bismuth catalyst; the micro-nano-grade elemental bismuth catalyst is synthesized by a water solution chemical reduction method; a preparation method comprises the following steps: heating a mixed solution of bismuth nitrate and hydrazine hydrate and refluxing; carrying out chemical reduction reaction; after washing a solid product and centrifuging and separating, drying in vacuum to prepare micro-nano-grade elemental bismuth, wherein the micro-nano-grade elemental bismuth has a clear (012) crystal surface. The micro-nano-grade elemental bismuth catalyst provided by the invention has high catalytic activity and selectivity on carbon dioxide reduction and needs low over-potential; the energy efficiency is improved. Furthermore, the preparation method of the catalyst has simple operation, moderate conditions and high yield and easy industrialized production .

Owner:DONGHUA UNIV +1

Catalyst and method for the alkylation of hydroxyaromatic compounds

InactiveUS20030073572A1Good product formation rateGood choiceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOxideAlkyl transfer

Owner:SABIC INNOVATIVE PLASTICS IP BV

Hydrogenation catalyst, its preparation and use

ActiveUS20060154810A1Improve performanceHigh activityCatalyst carriersOther chemical processesActivated carbonSurface layer

The present invention discloses a hydrogenation catalyst comprising metallic palladium supported on activated carbon support, wherein the penetration depth of metallic palladium in the support is at least about 10 μm and up to about 100 μm, the crystallite size of palladium is between about 40 Å and about 120 Å, and the palladium in the surface layer from the surface of support to a depth of 1 μm is from about 5% to about 40% based on the total atom number of palladium and other elements. The present invention further discloses a process for preparing the hydrogenation catalyst, and a use of said hydrogenation catalyst in the purification of crude terephthalic acid.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of method of 2-butene isomerization to produce 1-butene

InactiveCN102267853AHigh activity and selectivityLow priceHydrocarbon by isomerisationMetal/metal-oxides/metal-hydroxide catalystsDouble bondOxide

The invention discloses a method for isomerizing 2-butene to produce 1-butene, which is characterized in that the method comprises the following steps: calcining catalyst carrier alumina at a temperature of 400-600°C for 1-12 hours to increase the surface area of the alumina At 150-210m2 / g, dissolve 0.146-23.82 parts by weight of metal salt in 82-100 parts by weight of deionized water to prepare an aqueous solution, and then put 57 parts by weight of the catalyst carrier that has been roasted into the above-mentioned metal salt solution. Stand and soak for 16-24 hours, filter off the residual liquid, bake at a temperature of 120-160°C for 4-10 hours until the water is completely removed, and then bake at a temperature of 500-600°C for 1-12 hours to obtain a metal composite oxide catalyst; The catalyst prepared by the above method is loaded in a fixed-bed catalytic reactor, and the 2-butene gas with a content of 85.0-99.0% is passed through the catalyst bed, at a temperature of 300-480°C and a pressure of 0.1-0.5MPa, the 2-butene Under the condition that the gas hourly space velocity of the feed is 60-900h-1, the double bond isomerization reaction is carried out, the gas after the reaction is regularly sampled and analyzed, and the 1-butene content is 19.0-27.0%.

Owner:成都欣华源科技有限责任公司

Method for reoving mercaptan from gasoline

InactiveCN1511925AHigh activity and selectivityEnhanced mass transferGasoline stabilisationCatalytic distillationBoiling point

The present invention provides a kind of method for removing mercaptan from gasoline. FCC gasoline containing C4-C12 fractions and proper amount of hydrogen are fed to fixed bed reactor, so that mercaptan in gasoline is reacted with diene to produce sulfide with relatively high boiling point. The reaction product is made to enter the catalytic distillation tower filled with double-functional mercaptan-removing catalyst to eliminate mercaptan from light gasoline, and the reaction produced sulfide and heavy fraction are drained from the bottom of the tower.

Owner:SINOPEC QILU CO

Regeneration method for deactivated hydrodesulfurization catalyst

ActiveCN105642312AFacilitate interaction and redispersionHigh activity and selectivityCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsChemistryAmmonium

The invention discloses a regeneration method for a deactivated hydrodesulfurization catalyst. The method includes: (1) using an acid solution to clean a sieved deactivated hydrodesulfurization catalyst, and then performing drying treatment; (2) preparing a mixed solution containing ammonium gluconate and a metal additive, conducting saturated impregnation on the material obtain in step (1), and then performing drying, with the metal additive being one or more of Na, K, Mg, Ca, Cu and Zn elements; (3) firstly roasting the material dried in step (2) at a constant temperature of 260-320DEG C for 3-5h, with the O2 content of the roasting atmosphere being less than wt%; and then carrying out constant temperature roasting at 380-450DEG C for 4-7h, with the O2 content of the roasting atmosphere being higher than 20wt%. The method can improve the activity and selectivity of a regenerated FCC gasoline selective hydrodesulfurization catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high regularity mesoporous molecular sieve Fe-MCM-41

InactiveCN102198949AHigh acidityHigh activity and selectivityMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveFerric salts

The invention provides a preparation method of a high regularity mesoporous molecular sieve Fe-MCM-41. The preparation method is characterized in that an aftertreatment for a Si-MCM-41 matrix is carryed out to make the Si-MCM-41 matrix have an interaction with at least one soluble ferric salt to introduce a hetero atom Fe into the Si-MCM-41 matrix without any influence for a structure of the Si-MCM-41 matrix and thus a high regularity mesoporous molecular sieve Fe-MCM-41 is synthesized. The high regularity mesoporous molecular sieve Fe-MCM-41 has the advantages of uniform aperture sizes, big specific surface area and aperture volume, and favorable thermostability.

Owner:BEIJING UNIV OF CHEM TECH

Nanocrystalline metal-loaded titanium carbide catalyst and method for preparing chloro aniline with nanocrystalline metal-loaded titanium carbide catalyst in reduction mode

InactiveCN104028289AAvoid decreased activityHigh activity and selectivityCatalyst carriersOrganic compound preparationChloronitrobenzeneOrganic synthesis

Owner:CHINA WEST NORMAL UNIVERSITY

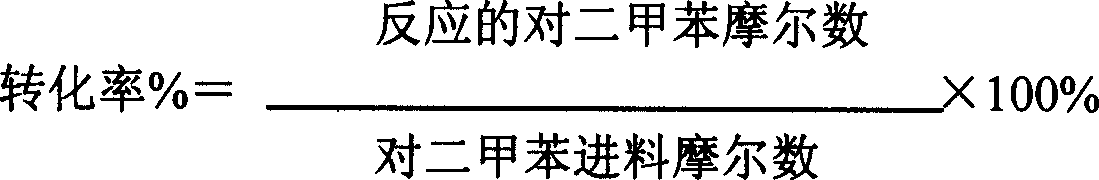

Preparation of tephthalyl intrile

InactiveCN1490309AHigh activity and selectivityHigh selectivityPreparation by hydrocarbon ammoxidationRare-earth elementChemistry

A process for preparing P-phenyldimethyl nitrile from P-xylene, ammonia gas and o2 features that its catalyst has the formula: V1.0CraTibAcBdCeOx, where A is chosen from P, B, Bi, Sb and As, B is chosen from alkal metal and alkali-earth metal, and C is chosen from Mn, Ni, Co, Pb, Fe, Mo, W and RE. Its advantage is high output rate of target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparation of furfuryl alcohol by furfural liquid phase hydrogenation and preparation method

ActiveCN105498788AHigh activity and selectivityEasy to prepareOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFurfuryl alcoholHigh activity

The invention discloses a catalyst for preparation of furfuryl alcohol by furfural liquid phase hydrogenation and a preparation method. The catalyst comprises: Cuo, Cr2O3, La2O3 and SiO2. The mole ratio of CuO / Cr2O3 is 1.8-2.4, the mole ratio of CuO / La2O3 is 60-160, and the mole ratio of CuO / SiO2 is 2-6. The method includes: taking the components according to the dosage to prepare the catalyst for preparation of furfuryl alcohol by furfural liquid phase hydrogenation by co-precipitation. The catalyst provided by the invention overcomes the disadvantages of the prior art, and has the advantages of high activity and selectivity of furfuryl alcohol, low price and continuous applicability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel catalyst for synthesizing tertiary-butyl substituted benzene phenols and its preparation process

InactiveCN1546235AHigh activity and selectivityEasy to prepareOrganic chemistryMolecular sieve catalystsSide productChemistry

The invention is a new catalyst for synthesizing tert-butyl to replace phenol and the process, belongs to the synthesizing method for tert-butyl to replace phenol and relative solid acid catalyst, which refers to crystal silicon aluminum acid salt catalyst and the process. the catalyst is made up mainly by micropore aluminosilicate, and loads one to three kinds of elements of boracium, magnesium, aluminum, phosphorus, calcium, titanium, zinc, molybdenum as active components, the process is convenient, the activity and the selectivity are high, can be sued repeatedly; the reaction uses moderate operation condition and continuous flow method, the tert-butyl replaced phenol can be produced by putting phenols and alkylation agent through the catalyst bed; the environment of the process is friendly, the side product is little, the process is simple.

Owner:NANKAI UNIV

Method for preparing heterogeneous catalyst used for epoxy cyclohexane and application thereof

InactiveCN102343278AHigh activity and selectivityHigh selectivityOrganic chemistryMolecular sieve catalystsIonMolecular sieve

The invention relates to a preparation method of a heterogeneous catalyst, and particularly relates to a preparation method of a heterogeneous catalyst used for epoxy cyclohexane and an application thereof. The catalyst takes SiO2-based mesopore molecular sieve as a carrier, the method comprises the following steps: forming a metal organic complex by organic metal salt and a complex in advance, then combing with an ionic liquid phase, highly dispersed and loaded on a tunnel surface of a porous SiO2 material by a grafting method. So that the catalyst has good catalysis performance in the application of cyclohexene on catalytic oxidation preparation of epoxy cyclohexane, in addition, the catalyst has the characteristics of controllable structure, good stability, easy separation, easy recovery and the like.

Owner:BEIJING UNIV OF TECH

MnOx-FeOx-CuSO4/TiO2 medium-low temperature SCR catalyst and preparation method thereof

InactiveCN107930652ALarge specific surface areaGood for adsorption capacityGas treatmentPhysical/chemical process catalystsNitrogen gasNitrogen

The invention discloses an MnOx-FeOx-CuSO4 / TiO2 medium-low temperature SCR catalyst and a preparation method thereof. The preparation method comprises the following steps of: (1) mixing hexadecyl trimethyl ammonium bromide, tetrabutyl titanate and anhydrous ethanol, and adjusting the pH value of the mixed solution with glacial acetic acid to prepare a Ti precursor sol; (2) adding the prepared Ti precursor sol into CuSO4.5H2O, continuing to adjust the pH value of the obtained solution with glacial acetic acid, and performing stirring under the protection of nitrogen to obtain a main active substance load; and (3) adding Mn(Ac)2.4H2O, Fe(NO3)3.9H2O and deionized water into the main active substance load sequentially, continuing to stir the obtained mixed liquid, then aging the mixed liquid in a water bath, and performing drying and calcining to obtain the finished catalyst product. The SCR catalyst prepared by using the preparation method has high activity of denitration at medium-low temperatures of 200-350 DEG C, can adapt to requirements of practical industrial application, and has a very broad prospect of industrial application.

Owner:SHENZHEN JINGTE INTELLIGENT MFG TECH CO LTD

Composite solid acid catalyst, preparing process and application in the alkylation

ActiveUS20110100876A1High activity and selectivityHigh acid densityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlkyl transferInorganic acids

The present invention provides a composite solid acid catalyst consisting of from 50%-80% by weight of a porous inorganic support, from 15% to 48% by weight of a heteropoly compound loaded thereon, and from 2% to 6% by weight of an inorganic acid. The present invention further provides a process for preparing said composite solid acid catalyst and a process for conducting an alkylation reaction by using such catalyst. The composite solid acid catalyst of the present invention has the acid sites type of Brönsted acid and has an acid sites density of not less than 1.4×10−3 mol H+ / g. Moreover, said composite solid acid catalyst has the homogeneous acid strength distribution, and is a solid acid catalyst having excellent performances.

Owner:CHINA PETROCHEMICAL CORP +1

Hydrodewaxing catalyst and its preparing method

ActiveCN1952072AReduce side reactions such as hydrogenolysis and crackingHigh activity and selectivityPetroleum wax recoveryChemistryMolecular sieve

The invention disclosed a deparaffinage as well as its preparing method. The ingredients of the catalyst include TON and MFI molecular sieve, inorganic smelting proof oxide and hydrogenated active precious metal, of which the dispersity of the precious metal on the catalyst is 20wt%-60wt% and the average diameter of the metal is 1nm-4nm. The catalyst has proper metal dispersity and mocrocrystal size; so that it matches the catalyst's acidifying function with its hydrogenating function. It decreased the side reaction of hydrogenolysis and crack as well as increased the activity and selectivity of the catalyst. When the catalyst is used in the hydrogenating deparaffinage process, it can not only decrease the product's pour point, it can also improve the viscosity index and the liquid yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

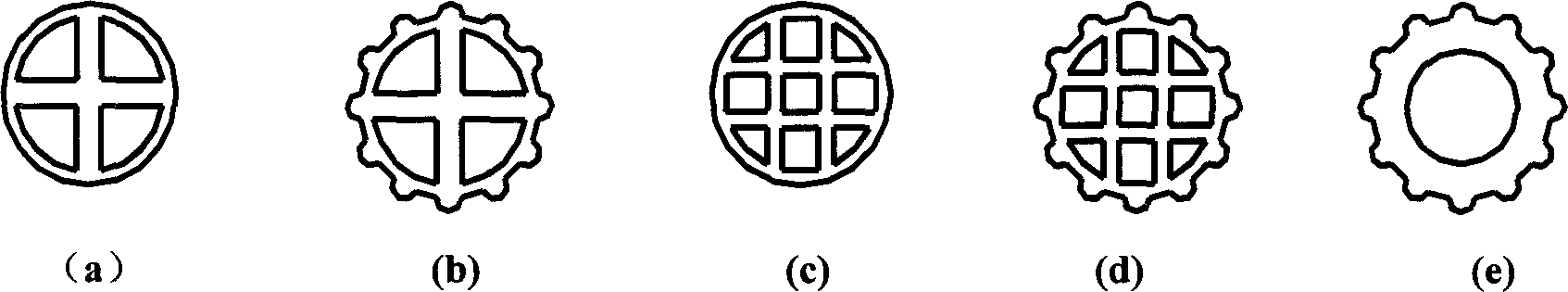

Method for preparing cyclohexene by benzene selective hydrogenation

ActiveCN103288574AHigh activity and selectivityHigh selectivityHydrocarbon by hydrogenationBenzeneCyclohexenes

The invention discloses a method for preparing cyclohexene by benzene selective hydrogenation, which is implemented by contacting benzene with hydrogen under selective hydrogenation conditions in the presence of a hydrogenation catalyst, wherein the hydrogenation catalyst comprises a supporter and a hydrogenation active component supported on the supporter, the supporter is donut-like SBA-15, and the hydrogenation active component contains one or more of Ru, Rh and Pd. When being used for catalyzing reaction of preparing cyclohexene by benzene selective hydrogenation, the hydrogenation catalyst disclosed by the invention can obviously enhance the selectivity of cyclohexene and the conversion rate of benzene.

Owner:BEIJING ENERGY ENG TECH +1

Cumene catalyst and preparation method thereof

ActiveCN109092295AHigh activity and selectivityGood effectHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention relates to a cumene catalyst and a preparation method thereof. The main technical problem is solved that the AMS conversion rate and cumene selectivity of a catalyst in the prior art arelow. The cumene catalyst comprises a carrier and the following active components including 0.05-10 g / L of metal palladium or an oxide of metal palladium and 0-5.00 g / L of Mo or an oxide of Mo. According to the technical scheme, the technical problem is solved well, and the cumene catalyst can be used for a reaction where hydrogen is added into alpha methyl styrene (AMS) to prepare cumene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for production of C6-C8 arene from light cycle oil

InactiveCN106588537AHigh activity and selectivityShort production lineHydrocarbon by isomerisationHydrocarbon by hydrogenationCycle oilTransalkylation

The invention relates to a method for production of C6-C8 arene from light cycle oil, and mainly solves the problems of long route, low C6-C8 arene yield and low purity in previous technologies. According to the invention, by means of hydrotreatment, and hydrogenation ring opening and transalkylation two-step reaction, light cycle oil can be converted to C6-C8 arene. The technical scheme well solves the problems, and can be used for the field of production of monocyclic light aromatic hydrocarbons from distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing 2-ethylhexyl alcohol through gas-phase hydrogenation of octenal and preparation method

InactiveCN106268827AHigh activity and selectivityHigh selectivityOrganic compound preparationHydroxy compound preparationRADIUSChemistry

The invention belongs to the technical field of catalysts, particularly relates to a catalyst for preparing 2-ethylhexyl alcohol through gas-phase hydrogenation of octenal, and solves the problem that the catalyst is easy to pulverize in a using process. The catalyst mainly consists of 25%-35% of copper oxide, 45%-60% of zinc oxide, 2%-10% of aluminum oxide, 2-10% of silicon dioxide and 0.01-1% of an aid. The BET specific surface area of the catalyst is 30m<2> / g-60m<2> / g, the pore volume of the catalyst is 0.17ml / g-0.30ml / g, and the average hole radius of the catalyst is 5nm-10nm. The catalyst prepared by a method disclosed by the invention has high activity and high 2-ethylhexyl alcohol selectivity, and besides, has better using strength and low color number.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 2-methylfuran

InactiveCN106699700AEasy to prepareHigh activity and selectivityOrganic chemistryNickel2-Methylfuran

The invention relates to a method for preparing 2-methylfuran. The objective of the invention is to solve problems that environmental pollution occurs in existing preparation of 2-methylfuran by using a Cu-based catalyst containing Cr and the selectivity is low and the reusability is poor as Cu-Co / gamma-Al2O3 is used. The method comprises the steps of taking a nickel phosphide catalyst as a catalyst to catalyze furfural to perform hydrodeoxygenation, and obtaining 2-methylfuran. The method has the advantages that a shortcoming of Cr pollution of the industrial catalyst is overcome; activity and selectivity of the catalyst are high, the conversion rate of furfural can reach 100%, and the selectivity of 2-methylfuran is over 83%. The method is used for preparing 2-methylfuran.

Owner:HEILONGJIANG UNIV

Process of catalytic ammoxidation for hydrogen cyanide production

ActiveUS7763225B2Improve performanceGood choiceHeterogenous catalyst chemical elementsCatalyst activation/preparationOxidation stateOxygen

A process for the ammoxidation of an alcohol feed, such as methanol, or a nitrile feed, such as propionitrile, or a mixture thereof, to form hydrogen cyanide uses a modified Mn—P catalyst having the following empirical formula:MnaP1AbOx where A=one or more of K, Ca, Mo, Zn, Fe or mixtures thereof; a=1 to 1.5; b=0.01 to 1.0 and x is a total number of oxygen atoms determined by the oxidation states of the other elements present.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

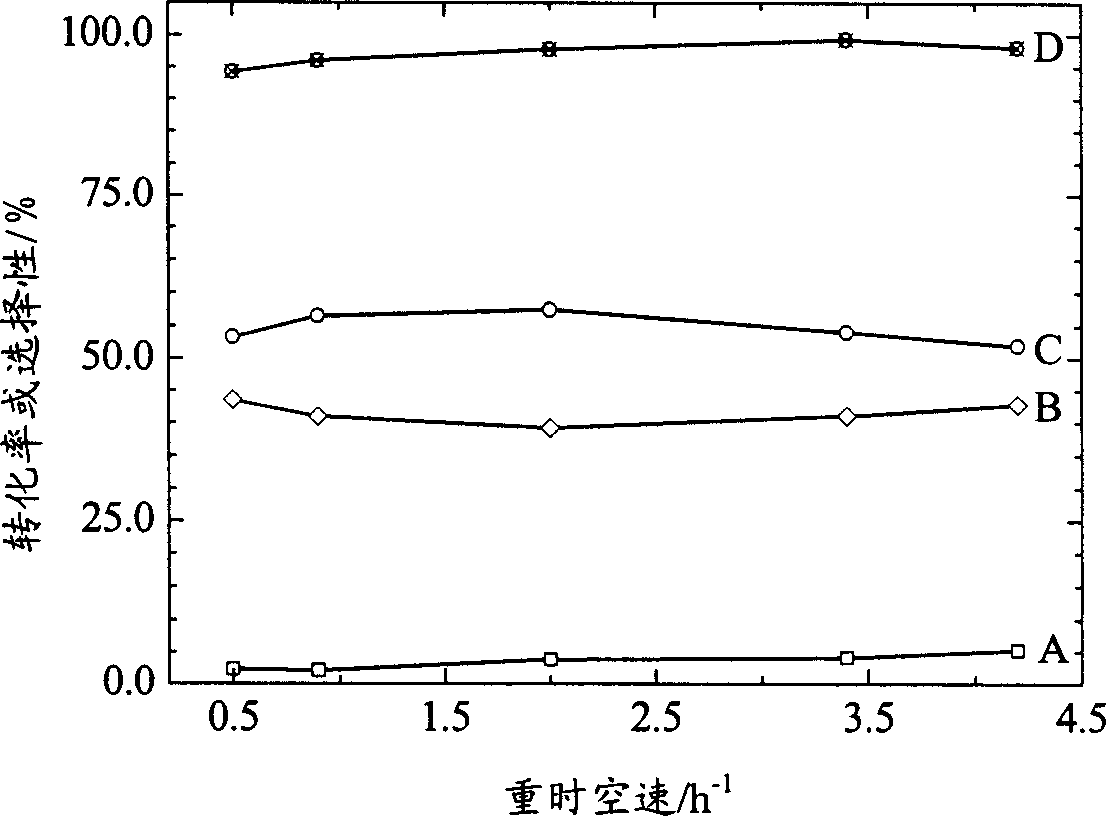

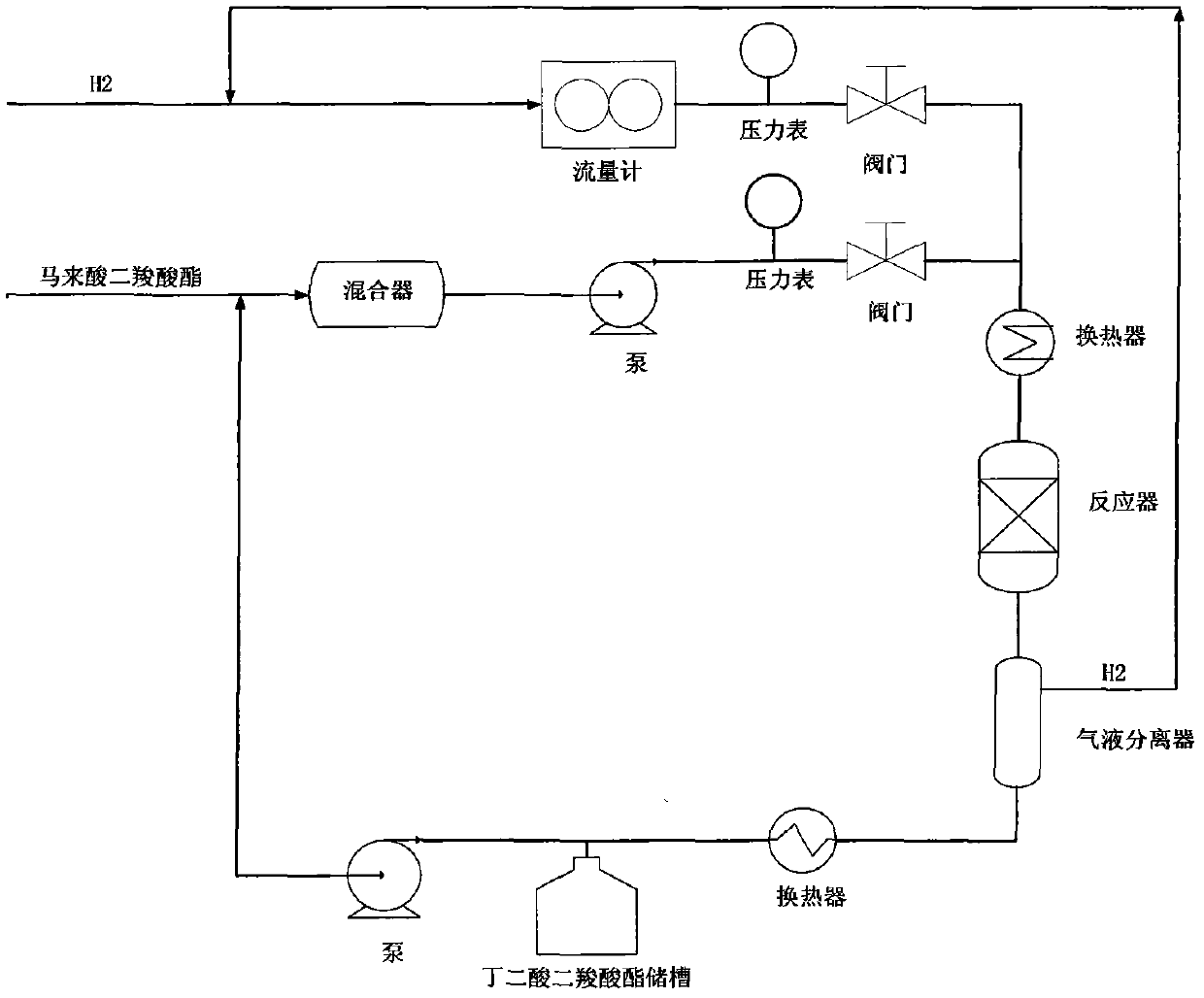

Method for preparing succinate

ActiveCN102001939AExtended service lifeHigh activity and selectivityOrganic compound preparationCarboxylic acid esters preparationBy-productFixed bed

The invention discloses a method for preparing succinate. The method comprises the following steps of: mixing hydrogen and maleic acid ester, and performing hydrogenation with a fixed bed reactor filled with a hydrogenation catalyst to obtain the succinate; and partially circulating the generated succinate, mixing with the maleic acid ester to obtain raw materials, and feeding a product subjectedto hydrogenation into a gas-liquid separator to obtain succinate with content of over 99.6 percent, wherein the separated hydrogen can be recycled. The method has the advantages that: raw materials are diluted in a reaction product circulation mode, so that temperature runaway caused by hydrogenation heat release can be effectively avoided, by-products of the reaction is very few, and the servicelife of the catalyst is prolonged and the stability of the catalyst is improved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Process of Catalytic Ammoxidation for Hydrogen Cyanide Production

ActiveUS20080317656A1Improve performanceGood choiceHeterogenous catalyst chemical elementsCatalyst activation/preparationHydrogenAlcohol

A process for the ammoxidation of an alcohol feed, such as methanol, or a nitrile feed, such as propionitrile, or a mixture thereof, to form hydrogen cyamide uses a modified Mn—P catalyst having the following empirical formula:MnaP1AbOx where A=one or more of K, Ca, Mo, Zn, Fe or mixtures thereof; a=1 to 1.5; b=0.01 to 1.0 and x is a total number of oxygen atoms determined by the oxidation states of the other elements present.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

Catalyst for hydrogenation to prepare isopropyl benzene

ActiveCN109092300AHigh activity and selectivityGood effectHydrocarbon by hydrogenationCatalyst activation/preparationAlpha-MethylstyreneChemistry

The invention relates to a catalyst for hydrogenation to prepare isopropyl benzene to mainly solve the technical problems of a low AMS conversion rate of catalysts and low selectivity of isopropyl benzene in the prior art. The adopted catalyst for the hydrogenation to prepare isopropyl benzene comprises a carrier and active components, and the active components include 0.01-10 g / L of metallic palladium or an oxide thereof and 0-60 g / L of alkaline earth metal or an oxide thereof. The technical scheme solves the technical problems well and can be used in a hydrogenation reaction of alpha-methylstyrene to prepare isopropyl benzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com