Method for preparing transitional metal carbides catalytic material and use

A transition metal and catalytic material technology, applied in the preparation and application of transition metal carbide catalytic materials, can solve problems such as difficult to remove, and achieve the effect of improving the efficiency of the catalytic process, high activity and selectivity, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of carbon nanotube-supported tungsten carbide catalytic material

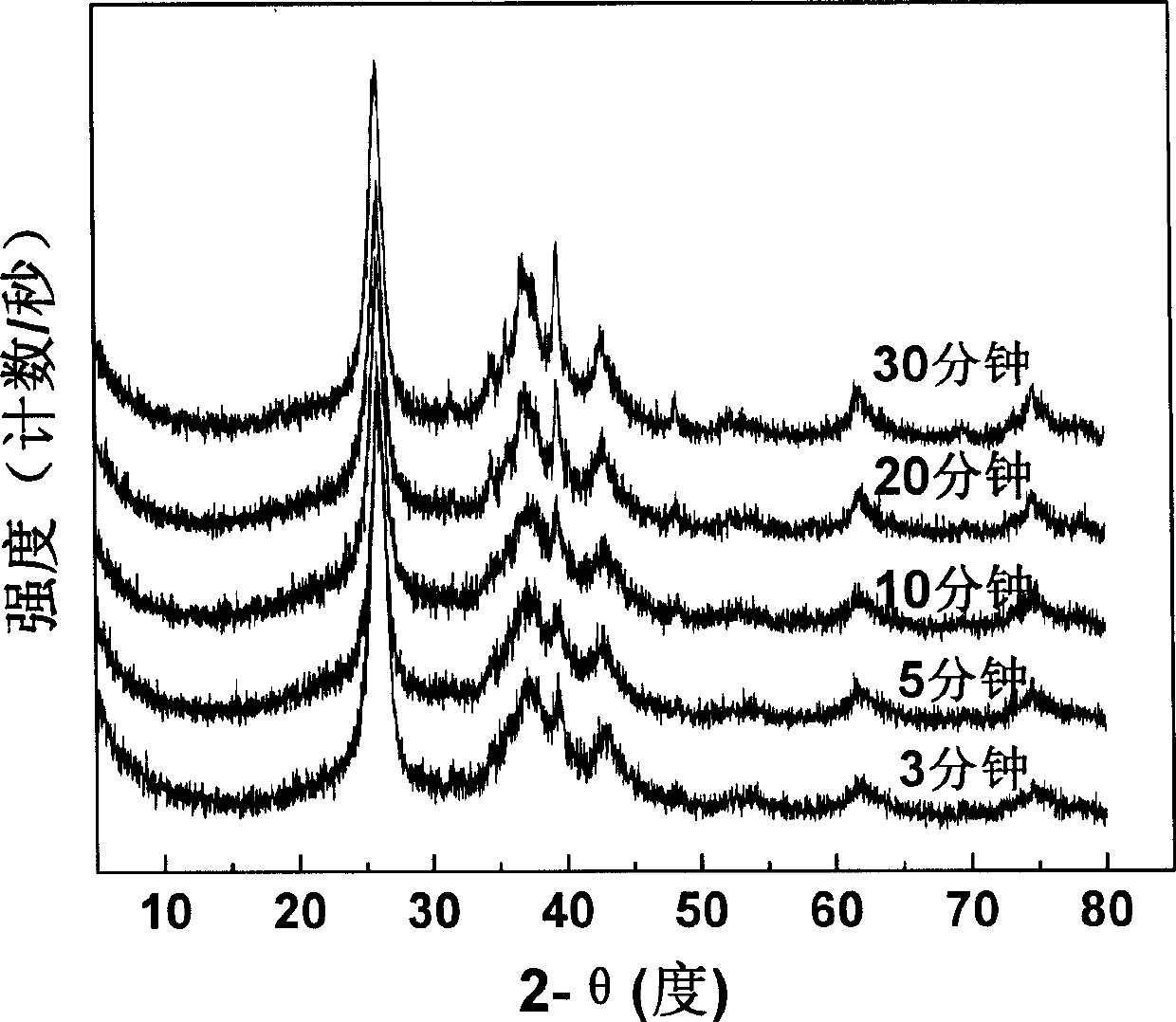

[0027] Weigh 0.1g carbon nanotube and 0.0383g W(CO) 6 Put it into a mortar, grind for 30min, so that the metal load is 20%, put it into a fluidized reaction tube, pass through argon gas to purge for 2h, turn on the microwave at 800W under an argon atmosphere and heat for 3, 5, 10 , 20, 30min, tungsten carbide is obtained after the sample is cooled. The XRD spectrum of the obtained tungsten carbide is as figure 1 shown. It was identified as tungsten carbide by X-ray powder diffraction. The specific surface area of the sample is 69.5653m 2 / g. The transmission electron micrographs of the obtained samples are shown in Figure 4 , 5 6.

Embodiment 2

[0028] Example 2 Preparation of carbon nanotube-supported tungsten carbide catalytic material

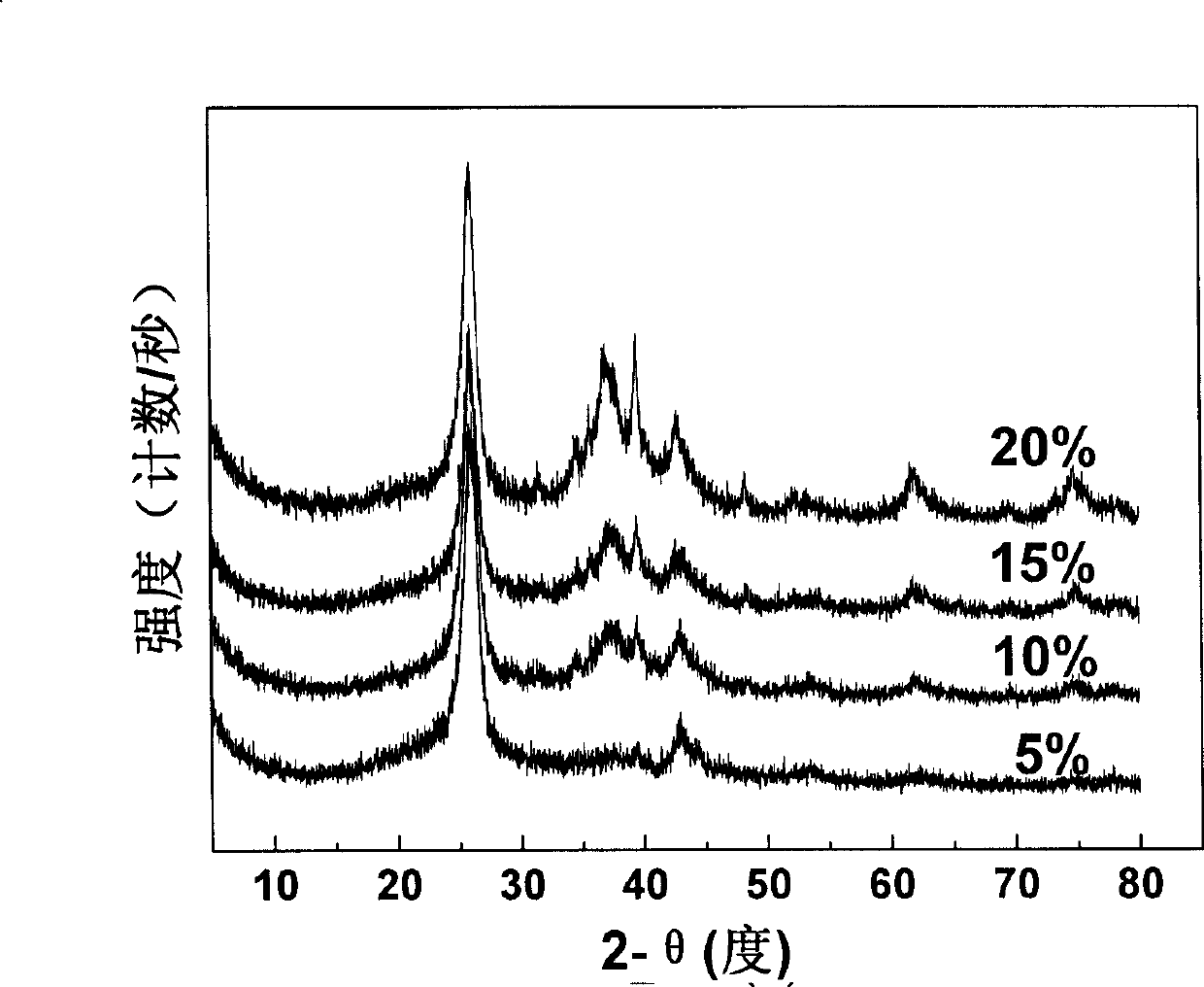

[0029] Weigh 0.1g carbon nanotube and 0.0287g W(CO) 6 Put it into a mortar, grind it for 30 minutes, so that the metal load is 15%, put it into a fluidized reaction tube, pass it into argon gas to purge for 2 hours, turn on the microwave at 800W and heat it for 30 minutes under an argon atmosphere, and wait for the sample to cool. That is, tungsten carbide is obtained. By changing the amount of carbonyl compound added, tungsten carbide catalytic materials with different loads can be prepared. The XRD spectrum of the obtained tungsten carbide is as figure 2 shown. It was identified as tungsten carbide by X-ray powder diffraction. The specific surface area of these samples is 74-86m 2 / g.

Embodiment 3

[0030] Example 3 Preparation of carbon nanotube-supported molybdenum carbide catalytic material

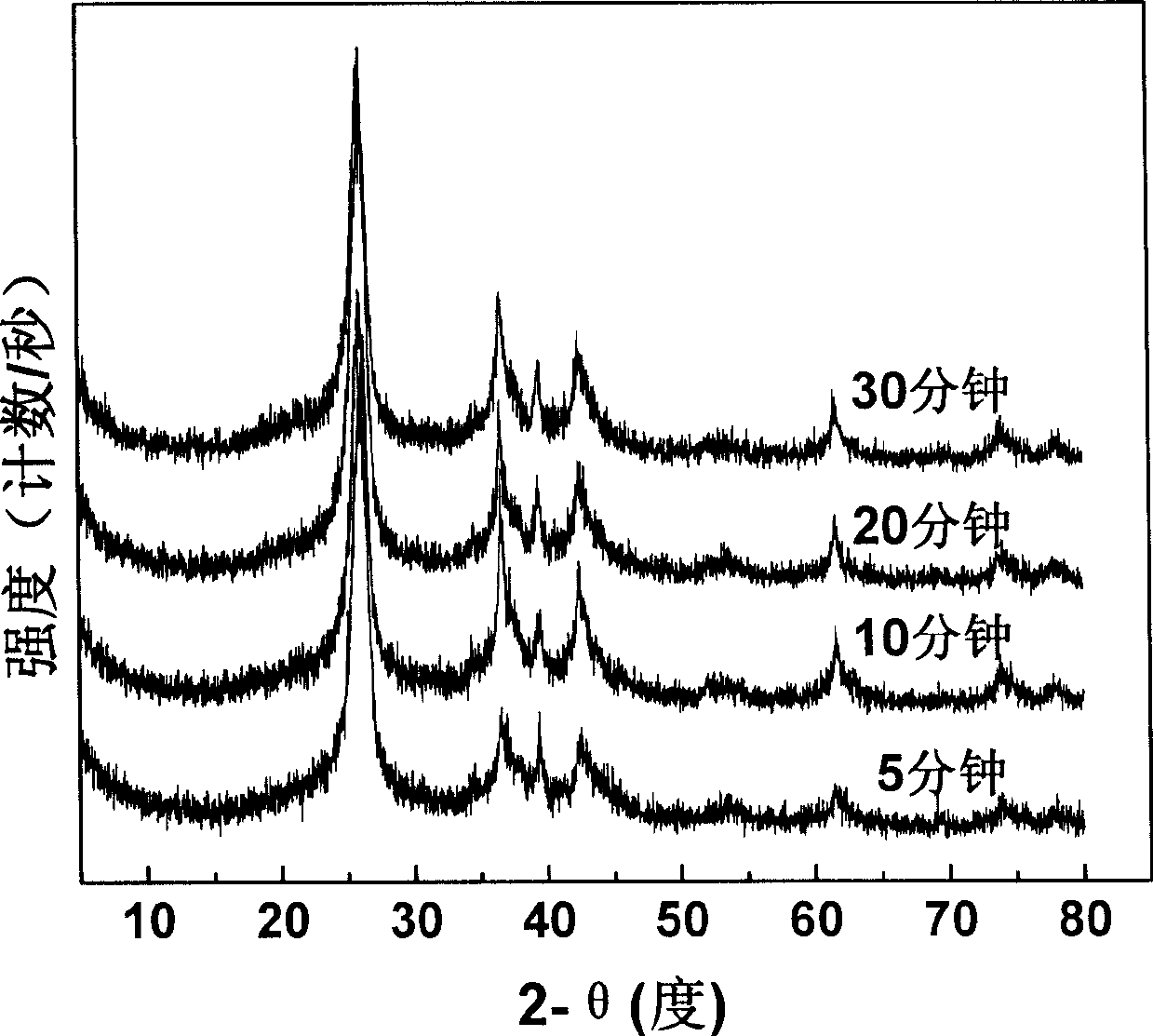

[0031] Weigh 0.1g carbon nanotube and 0.055g Mo(CO) 6 Put it into a mortar, grind for 30min, so that the metal load is 20%, put it into a fluidized reaction tube, pass through argon gas to purge for 2h, and turn on the microwave 800W under the argon atmosphere to heat for 5, 10, 20 respectively. , 30min, molybdenum carbide is obtained after the sample is cooled. The XRD pattern of the obtained molybdenum carbide is as follows image 3 shown. It was identified as molybdenum carbide by X-ray powder diffraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com