Method for preparing manganese dioxide one-dimensional nanometer material

A nanomaterial, manganese dioxide technology, applied in the field of preparation of one-dimensional manganese dioxide nanomaterials, can solve the problems of product purity and yield reduction, cumbersomeness, etc., and achieve the effect of easy operation, convenient control and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

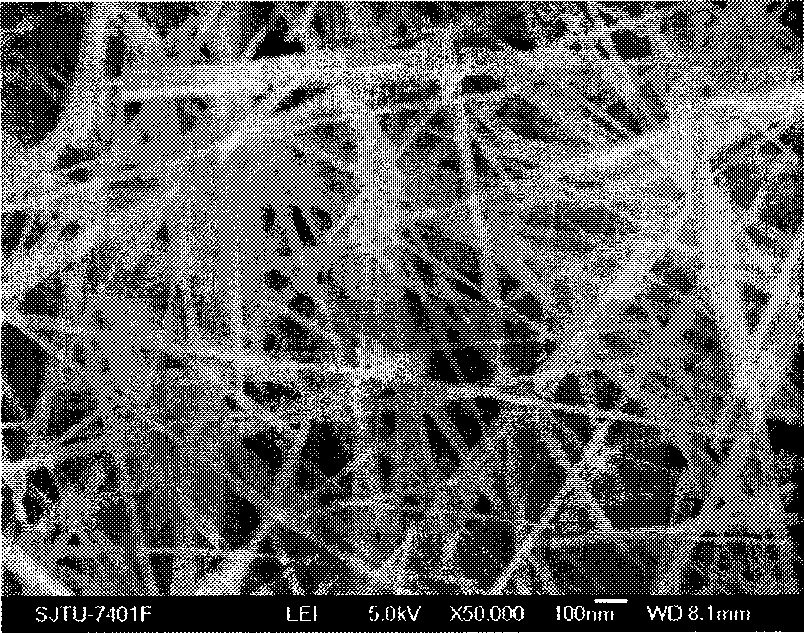

[0022] Inject 10 ml of pure water into a 50 ml beaker, dissolve 1.5 mmol of manganese chloride in water to form a clear solution, and then dissolve 3 mmol of sodium fluoride in it to obtain solution a. In addition, 10 ml of pure water was injected into a 50 ml beaker, and 1 mmol of potassium permanganate was dissolved in water to obtain solution b. Mix and stir solution a and solution b for 30 minutes, then transfer to a 35 ml stainless steel autoclave containing polytetrafluoroethylene liner, add pure water to 70% to 90% of the volume of the autoclave, seal the autoclave, and put React in a high-temperature oven at 180°C for 24 hours. After natural cooling, the obtained product was washed and centrifuged several times with pure water and ethanol, and then dried in an oven at 60°C for 6 hours to obtain α-MnO 2 One-dimensional nanomaterials. figure 1 It is a scanning electron microscope photo of the nanowires prepared in this embodiment.

Embodiment 2

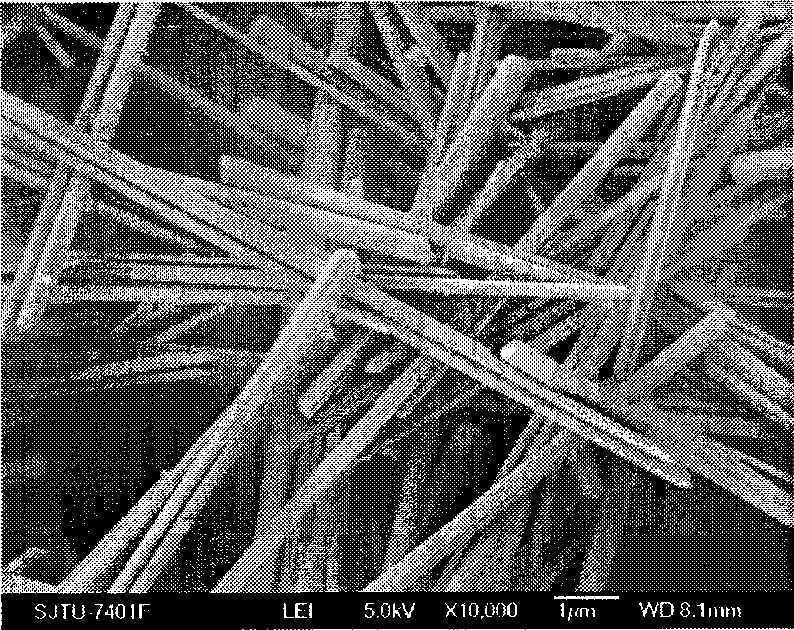

[0024] Inject 10 ml of pure water into a 50 ml beaker, dissolve 1.5 mmol of manganese chloride in water to form a clear solution, and then dissolve 1 mmol of sodium fluoride in it to obtain solution a. In addition, 10 ml of pure water was injected into a 50 ml beaker, and 1 mmol of potassium permanganate was dissolved in water to obtain solution b. Solution a and solution b were mixed and stirred for 30 minutes and then transferred to a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 35 milliliters, and pure water was added to 70% to 90% of the volume of the kettle. The kettle was sealed and put into a high-temperature oven at 180° C. to react for 24 hours. After natural cooling, the obtained product was washed and centrifuged several times with pure water and ethanol, and then dried in an oven at 60°C for 6 hours to obtain β-MnO 2 One-dimensional nanomaterials. figure 2 It is a scanning electron microscope photo of the nanowires prepared in ...

Embodiment 3

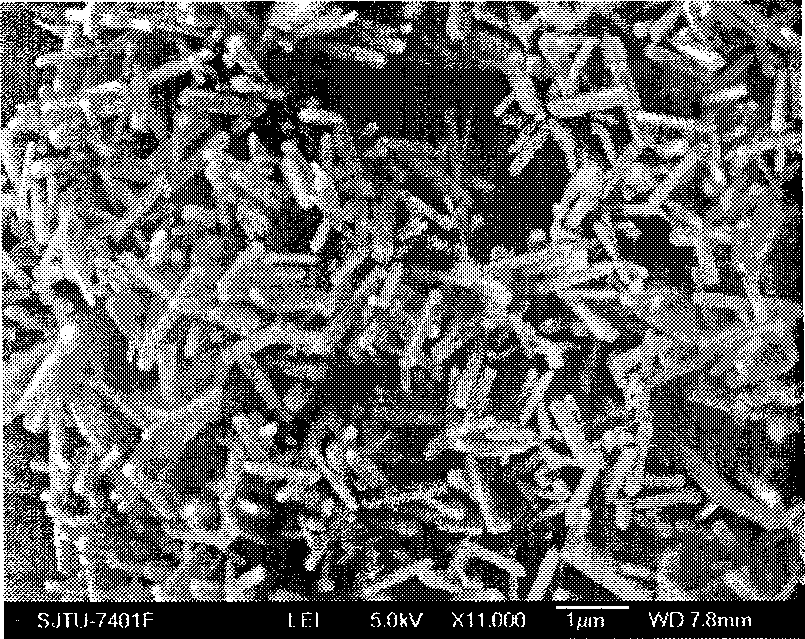

[0026] Inject 10 ml of pure water into a 50 ml beaker, dissolve 1.5 mmol of manganese chloride in water to form a clear solution, and then dissolve 1 mmol of sodium sulfate therein to obtain solution a. In addition, 10 ml of pure water was injected into a 50 ml beaker, and 1 mmol of potassium permanganate was dissolved in water to obtain solution b. Solution a and solution b were mixed and stirred for 30 minutes and then transferred to a stainless steel autoclave with a polytetrafluoroethylene liner with a volume of 35 milliliters, and pure water was added to 70% to 90% of the volume of the kettle. The kettle was sealed and put into a high-temperature oven at 180° C. to react for 24 hours. After natural cooling, the obtained product was washed and centrifuged several times with pure water and ethanol, and then dried in an oven at 60°C for 6 hours to obtain β-MnO 2 One-dimensional nanomaterials. image 3 It is a scanning electron microscope photo of the nanowires prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com