Preparation of tephthalyl intrile

A technology of terephthalonitrile and p-xylene, applied in the field of ammoxidation of p-xylene to prepare terephthalonitrile, which can solve the reactor engineering amplification effect, high yield of terephthalonitrile, and reactor engineering amplification and other problems, to achieve good reaction stability, improve reaction selectivity, and enhance the effect of oxygen adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Catalyst preparation:

[0048] 224g V 2 o 5 Add it into a solution at a temperature of 80-90° C. consisting of 490 milliliters of water and 468 grams of oxalic acid, stir well, and react to obtain a vanadium oxalate solution.

[0049] The concentration will be 40% SiO 2 1250 grams of silica sol are slowly added in the above-mentioned solution under stirring, then add respectively by 935 grams of Cr (NO 3 ) 3 9H 2 A solution of O and 300 ml of water, 76.3 g of H 3 BO 3 and 560 ml of water and 28.4 g of 85% H 3 PO 4 and 50 milliliters of water, then add 190 grams of 30% (by weight) TiCl 3 Hydrochloric acid solution, and containing 12.5 grams of KNO 3 and 88 g Mn(NO 3 ) 2 300 g of the aqueous solution was stirred, heated and evaporated to a solid content of 40% (weight), to obtain a thick slurry.

[0050] The catalyst formed by spray drying the above slurry was dried at 120°C for 12 hours and calcined at 650°C for 5 hours to obtain catalyst composition V 1.00 C...

Embodiment 2~4

[0058] Using the same catalyst preparation method and evaluation conditions as in Example 1 above, the composition of the catalyst was changed to prepare the catalyst, and the evaluation results are listed in Table 1.

[0059] Example

Embodiment 5

[0061] Prepare catalyst by each step of embodiment 1, change evaluation condition to be:

[0062] p-Xylene: NH 3 : Air = 1:5:50 (mol), catalyst weight loading (WWH) 0.10 hours -1 , the reaction temperature is 430°C, the reaction pressure is 0.01MPa, and the reaction results are as follows:

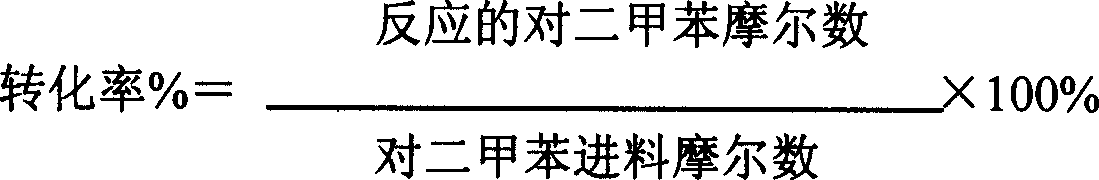

[0063] p-xylene conversion 98.4%

[0064] Terephthalonitrile selectivity 91.7%

[0065] Terephthalonitrile yield 90.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com