Method for reoving mercaptan from gasoline

A technology for removing mercaptan and gasoline, applied in gasoline stabilization and other directions, can solve the problems of affecting reaction efficiency, inconvenient filling, complex structure, etc., and achieve the effects of improving reaction efficiency, prolonging service life, and high mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] 1. Catalyst Preparation

[0021] Mix commercially available nickel oxide powder with alumina and diatomaceous earth at a weight ratio of 0.65:0.25:0.1, add 0.5 parts of water for kneading, and dry at 120°C for about 1 hour. Control the water content in the material to 5-10 %, after granulation, the ring-shaped carrier is formed, roasted at 550°C for 4 hours, and reduced with hydrogen at 450°C for 10 hours to obtain a ring-shaped bifunctional sweetening catalyst. The basic properties are shown in Table 1:

[0022] shape

circular

diameter, mm

16

height, mm

8

Ring thickness, mm

3.0

Lateral compressive strength, kg / cm

5.0

Pore volume, ml / g

0.35

Specific surface, m 2 / g

60

Nickel content, wt%

51.6

[0023] 2. Sweetening reaction

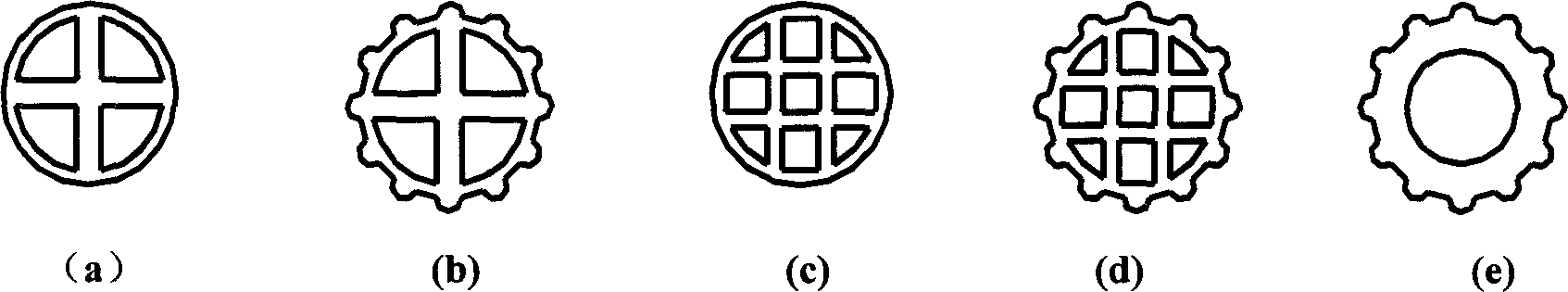

[0024] React by the technique shown in Fig. 1, and process condition is listed in table 2. The preparation of the cat...

example 2

[0027] 1. Catalyst Preparation

[0028] Add 1M nickel nitrate solution dropwise to 1M sodium carbonate solution to precipitate basic nickel carbonate, the precipitation temperature is 85°C, and the final pH value of the solution is 7.5. The obtained precipitate is washed with deionized water, and the sodium content in the material is less than 0.2%. The material was dried at 120°C for 2 hours, then calcined at 550°C for 5 hours, and the obtained nickel oxide was mixed with alumina and diatomaceous earth in a ratio of 0.50:0.40:0.1. The other processes were the same as in Example 1 to obtain a cyclic bifunctional The basic properties of the catalyst are shown in Table 3.

[0029] shape

circular

diameter, mm

16

height, mm

8

Ring thickness, mm

3.0

Lateral compressive strength, kg / cm

9.0

Pore volume, ml / g

0.35

Specific surface, m 2 / g

70

Nickel content, %(m / m)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com