Suspended bed reactor and method for realizing liquid phase self circulation by using same

A liquid phase circulation and reactor technology, which is applied in chemical instruments and methods, hydrocarbon oil treatment, chemical/physical processes, etc., can solve the problems of difficult coking and coking, and achieve the effect of avoiding coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

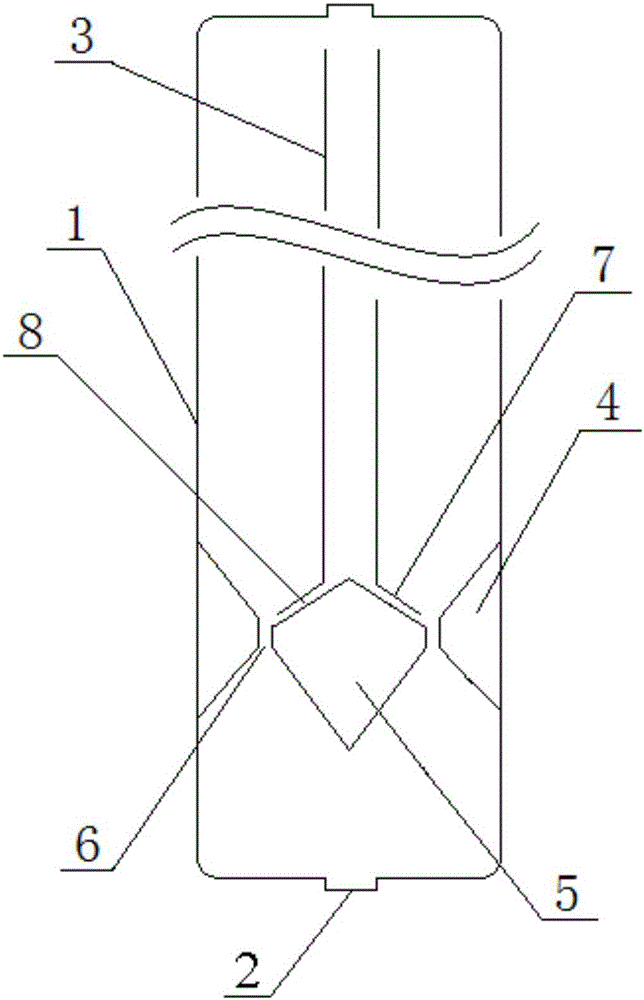

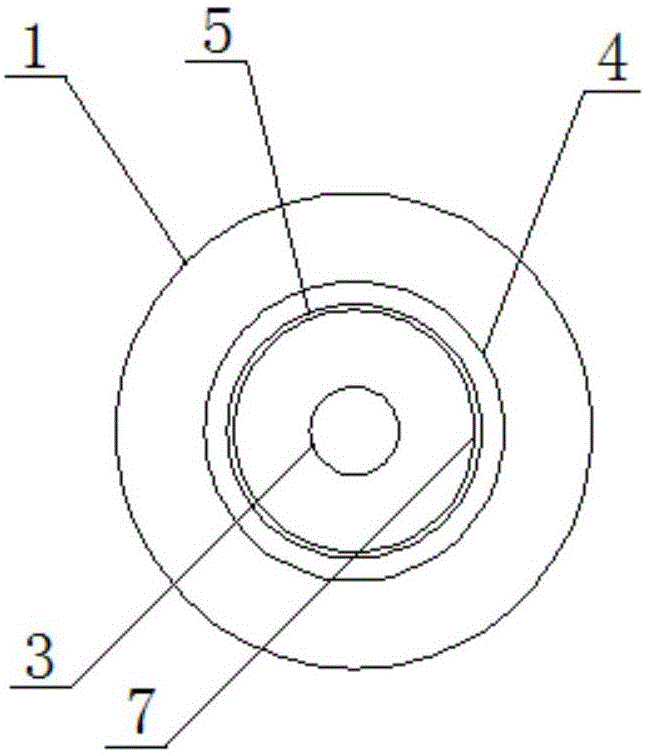

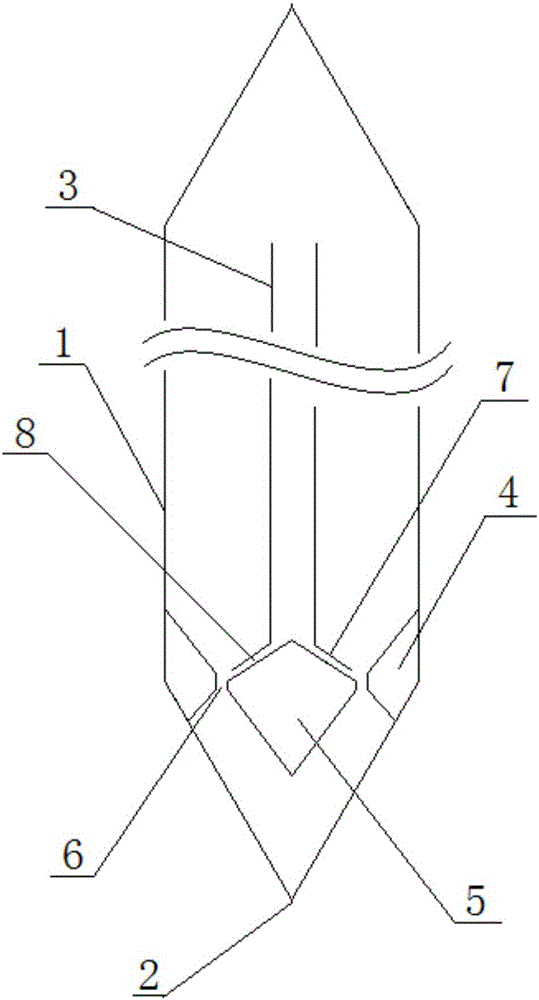

[0041] Such as figure 1 As shown, the suspended bed reactor capable of realizing liquid phase self-circulation described in this embodiment includes a reactor shell 1, a liquid phase circulation pipe 3 and an inlet jet distributor arranged in the reactor shell 1, wherein:

[0042] The reactor shell 1 is vertically arranged in the horizontal direction, the liquid inflow inlet 2 is set at the bottom of the reactor shell 1, and the liquid outflow outlet is set at the top of the reactor shell; the two ends of the liquid phase circulation pipe 3 Both openings, the upper end of the liquid phase circulation pipe 3 extends to the top of the reactor shell 1, and the lower end is close to the liquid inlet 2; the inlet jet distributor includes an annular boss 4 and a guide body 5, wherein, The annular boss 4 is arranged on the inner side wall of the reactor housing 1 close to the liquid inlet 2, and the inner diameter of the annular boss 4 first decreases and then increases along the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com