Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5136results about "Multi-cylinder pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

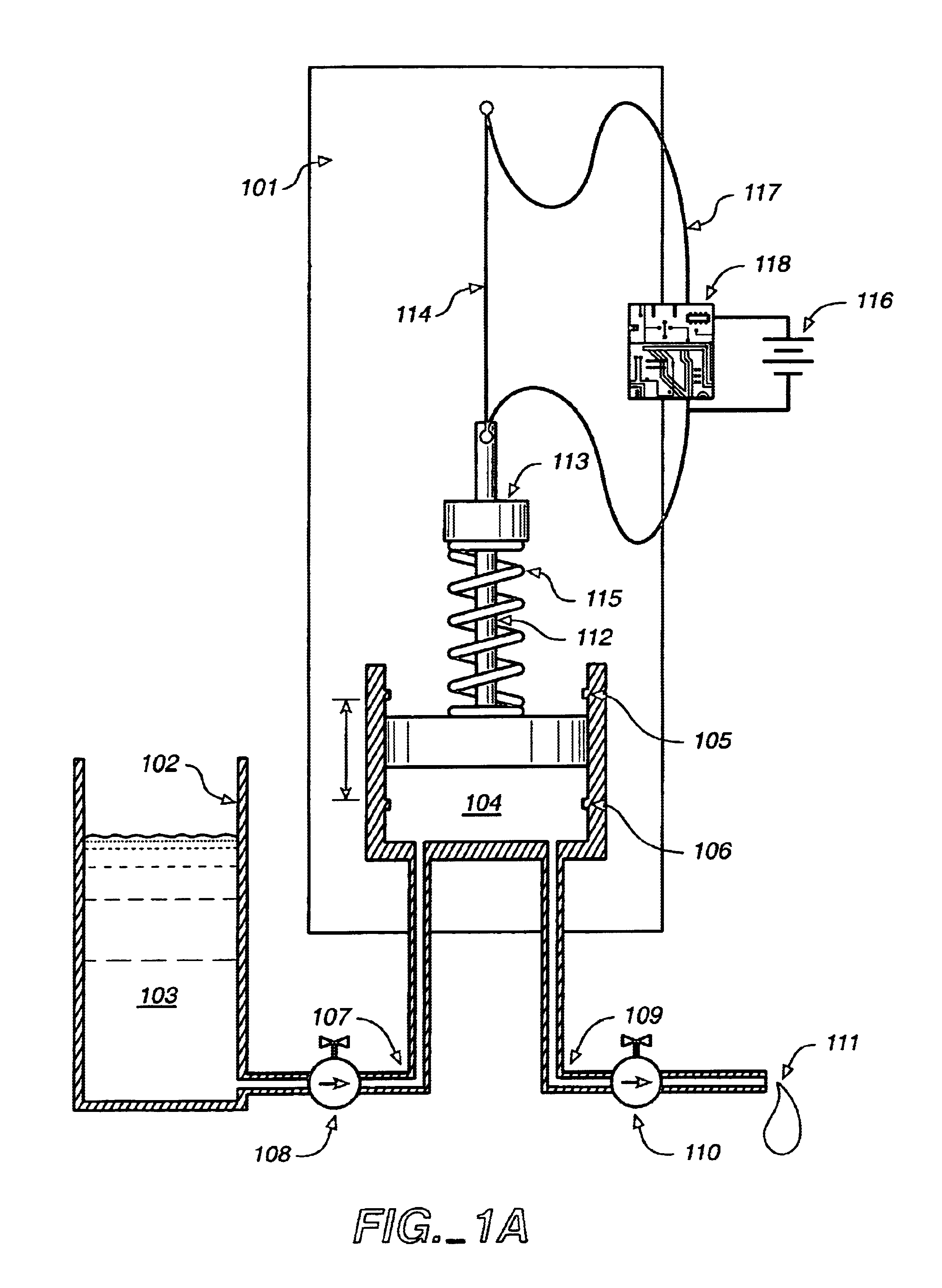

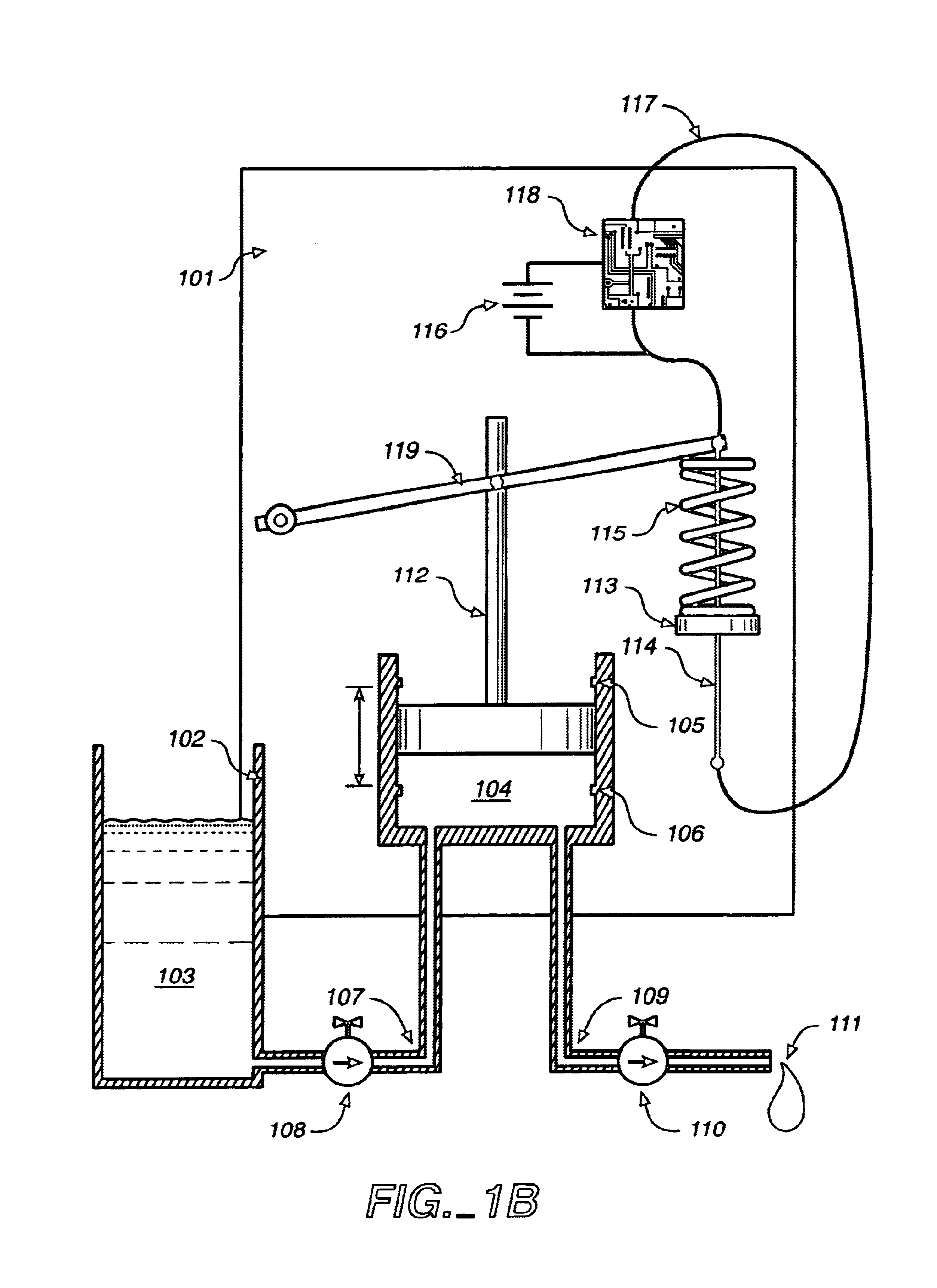

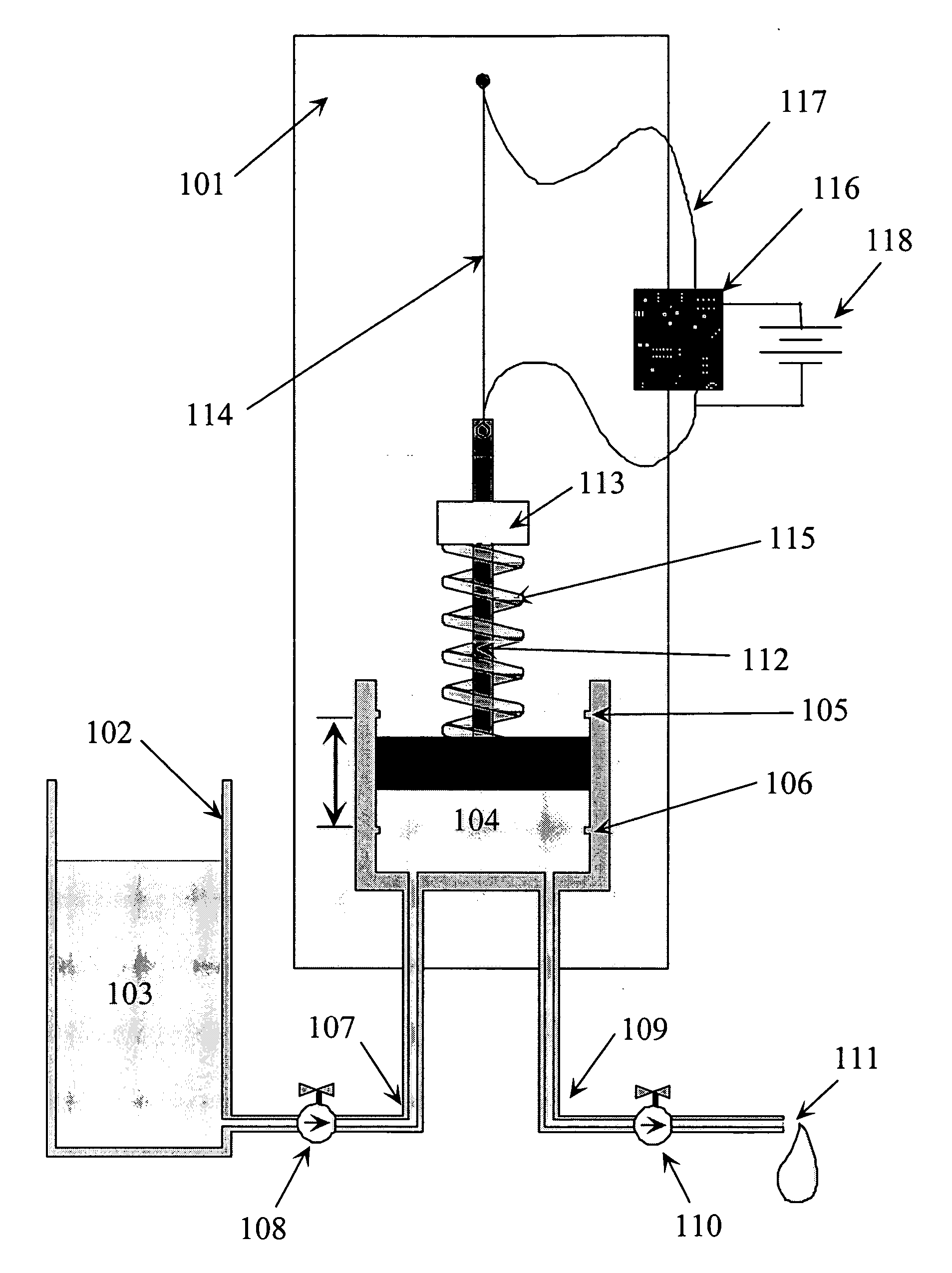

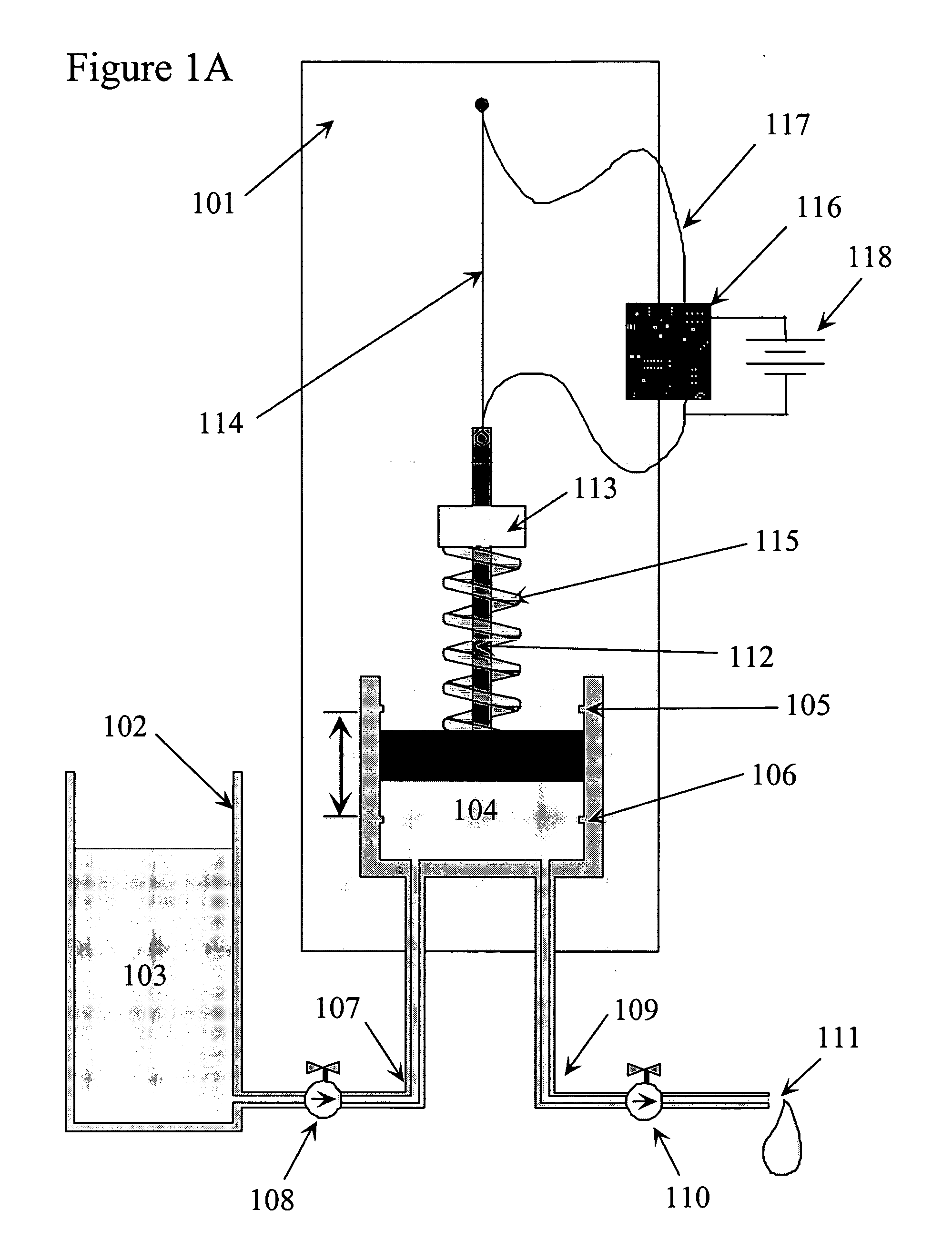

Device and method employing shape memory alloy

InactiveUS6916159B2Low costSmall size and weightTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyEngineering

Owner:THERASENSE

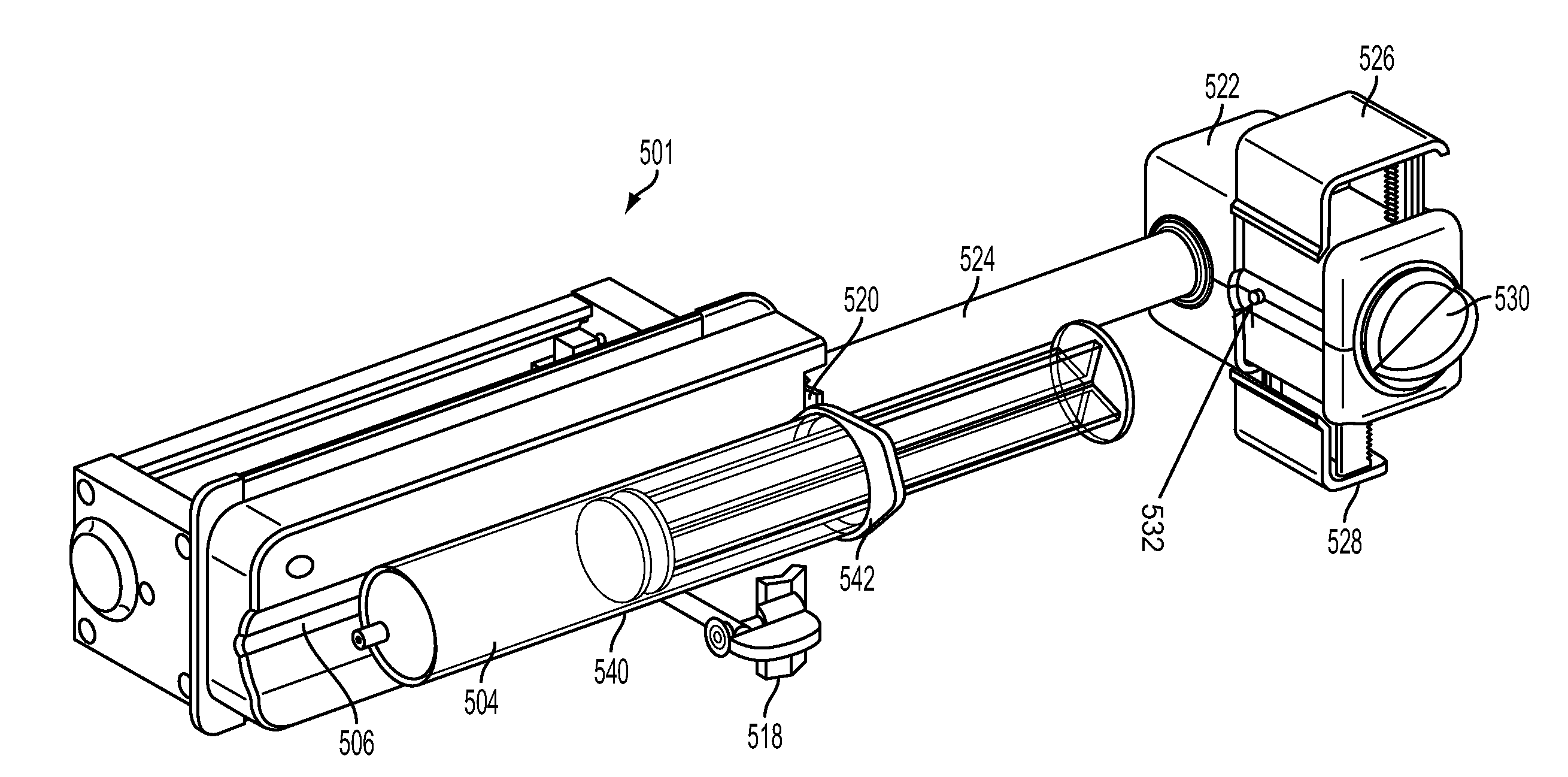

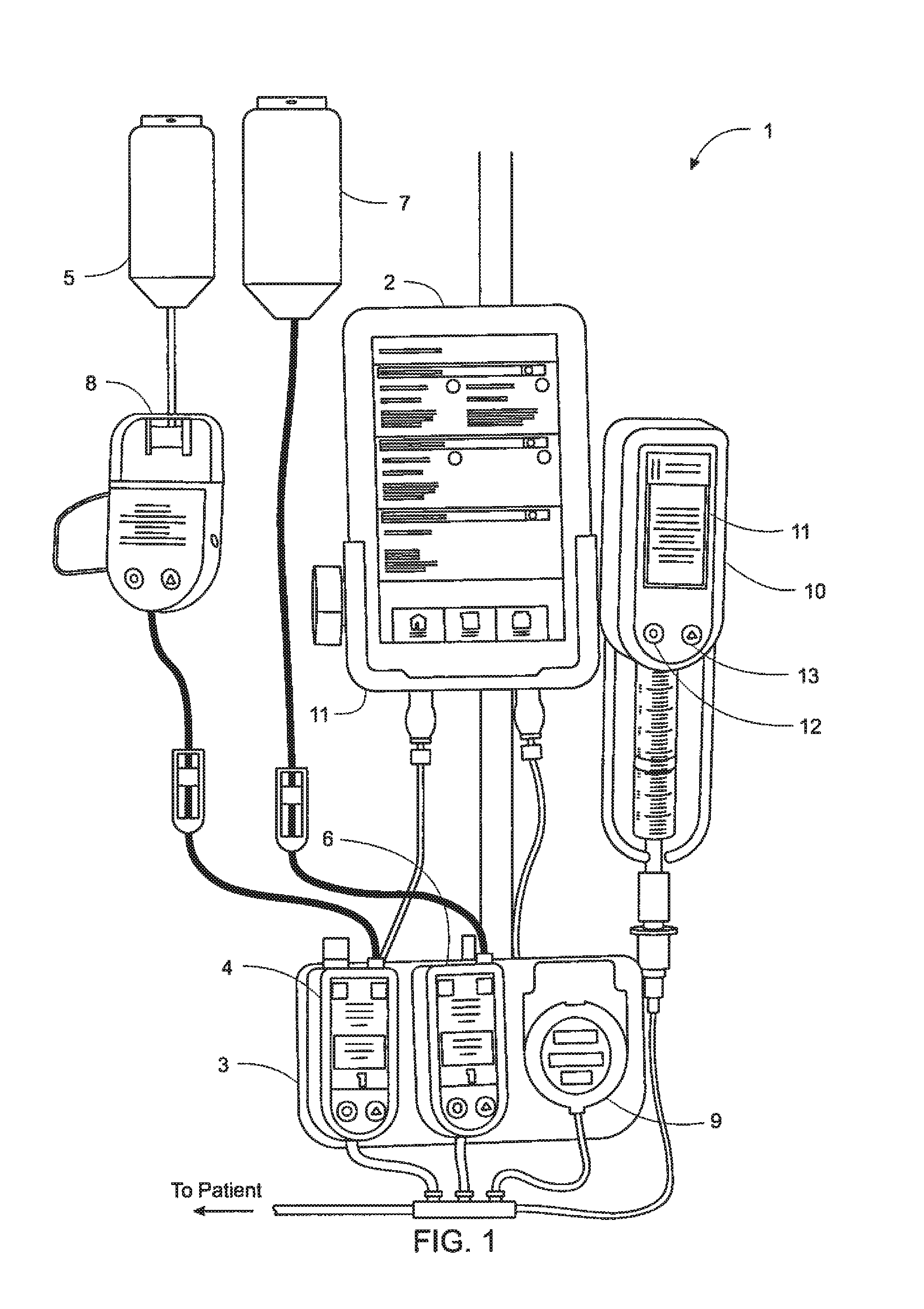

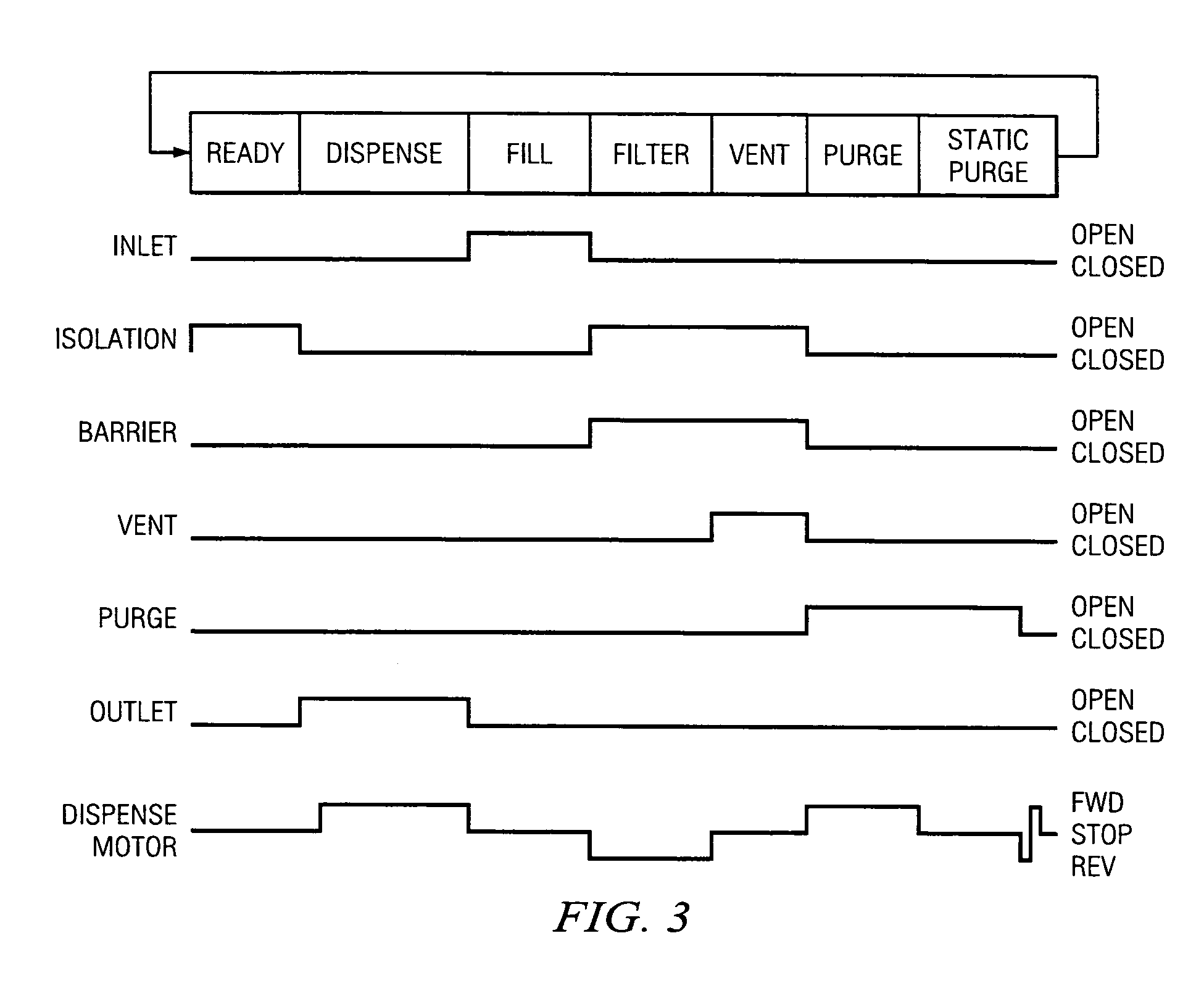

Syringe Pump, and Related Method and System

A method for discharging fluid from a syringe and for mitigating occlusion conditions includes actuating the plunger of a syringe into a barrel. The method monitors fluid pressure within the barrel of the syringe and determines that an occlusion exists when the fluid pressure exceeds a predetermined threshold. The method actuates the plunger out of the barrel by a predetermined amount in response to the detected occlusion and actuates the plunger of the syringe into the barrel until a measured fluid pressure within the barrel of the syringe exceeds another predetermined threshold.

Owner:DEKA PROD LLP

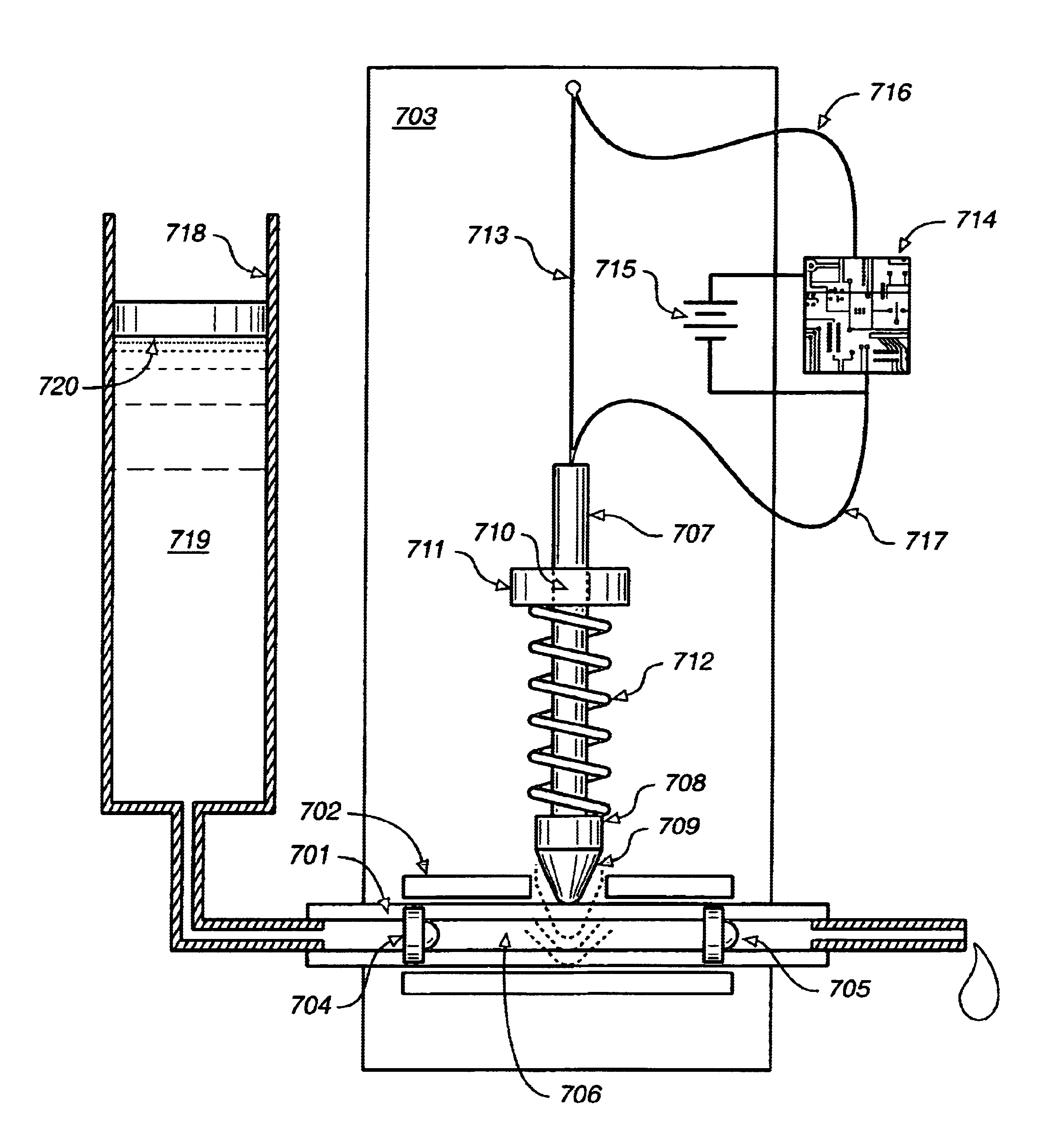

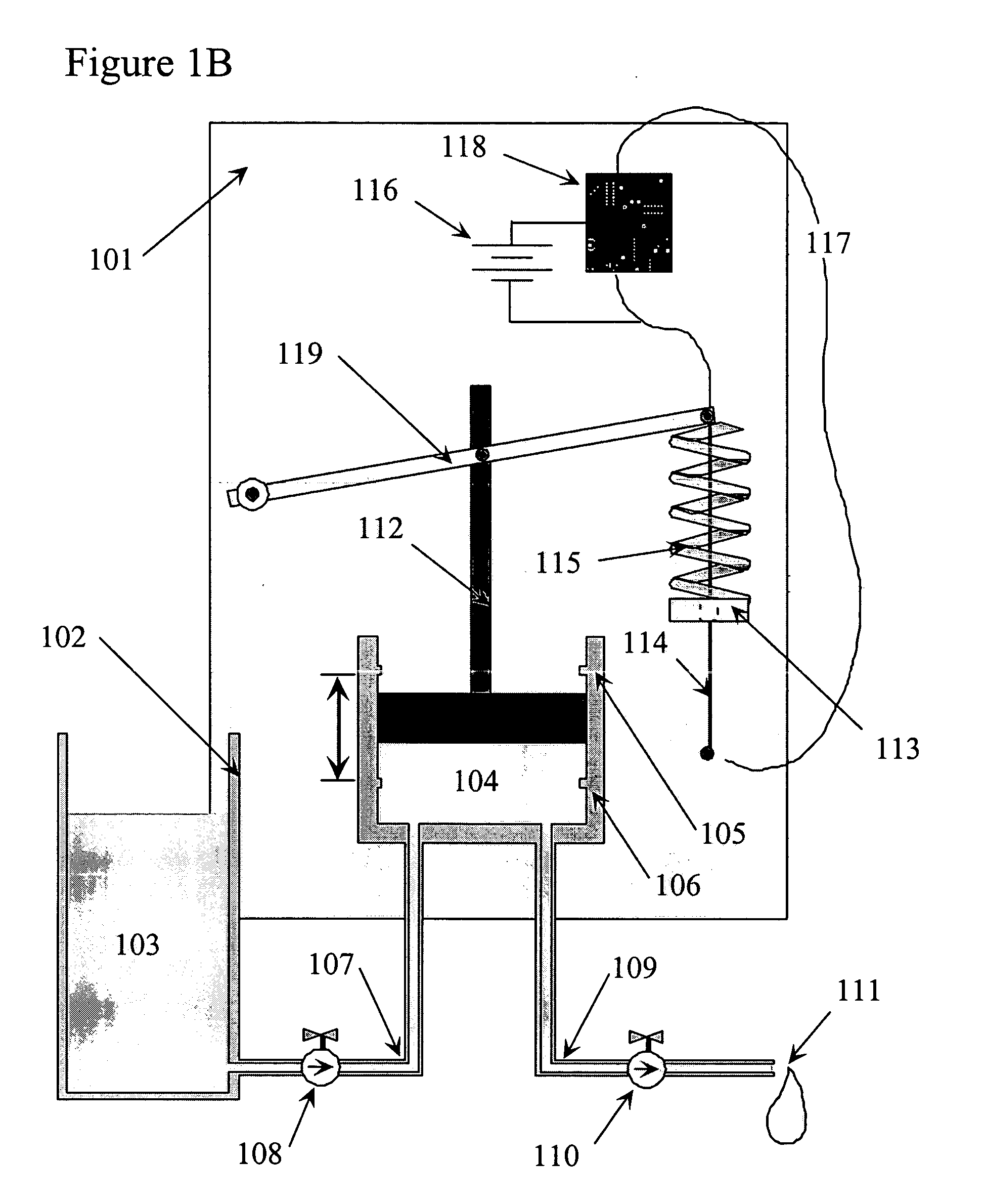

Fluid delivery device, system and method

ActiveUS20040115067A1Low costSmall sizeTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyAlloy

A system for the metering and delivery of small discrete volumes of liquid is comprised of a small or minimal number of inexpensive components. One such component is a movable member, such as a miniature precision reciprocating displacement pump head, which is driven by an actuator that comprises a shape memory alloy material. The operating mechanism of the system is of little or minimal complexity. The system facilitates the precise metering and delivery of the small discrete volumes of liquid. Potential applications for the system include subcutaneous, long-term, automated drug delivery, for example, the delivery of insulin to a person with diabetes. In such an application, the small, simple and inexpensive nature of the invention would allow for its use as both a portable and a disposable system.

Owner:THERASENSE

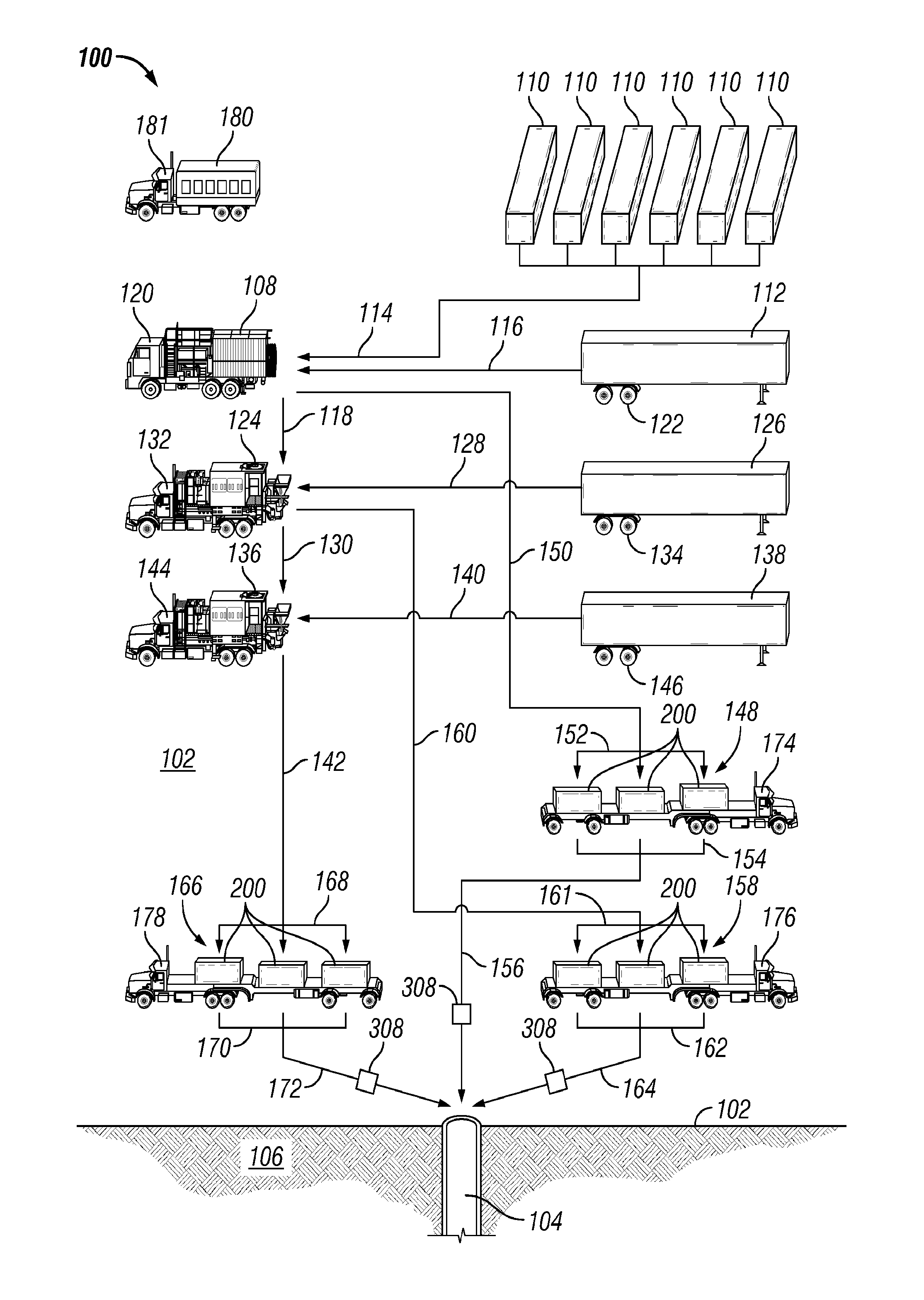

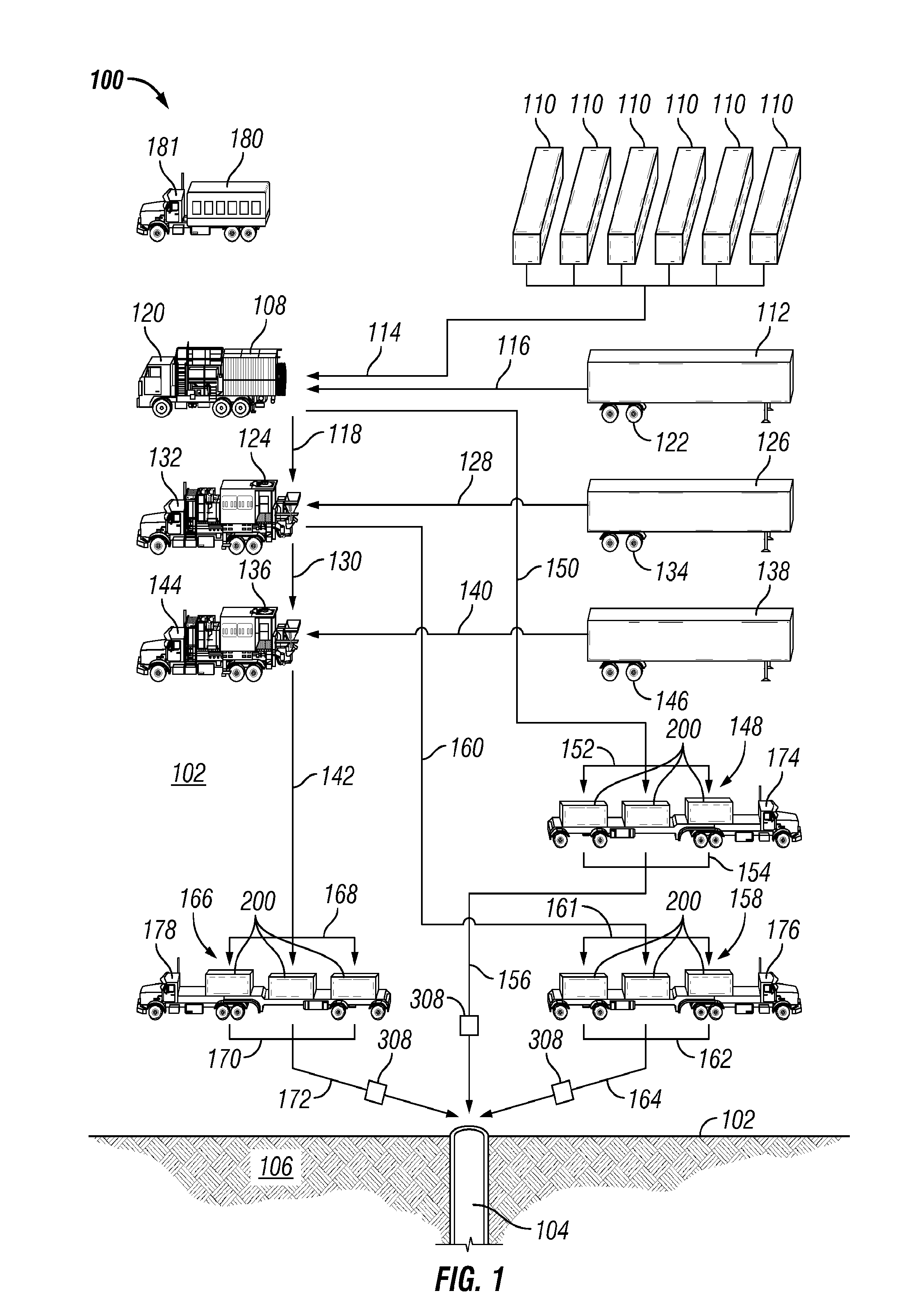

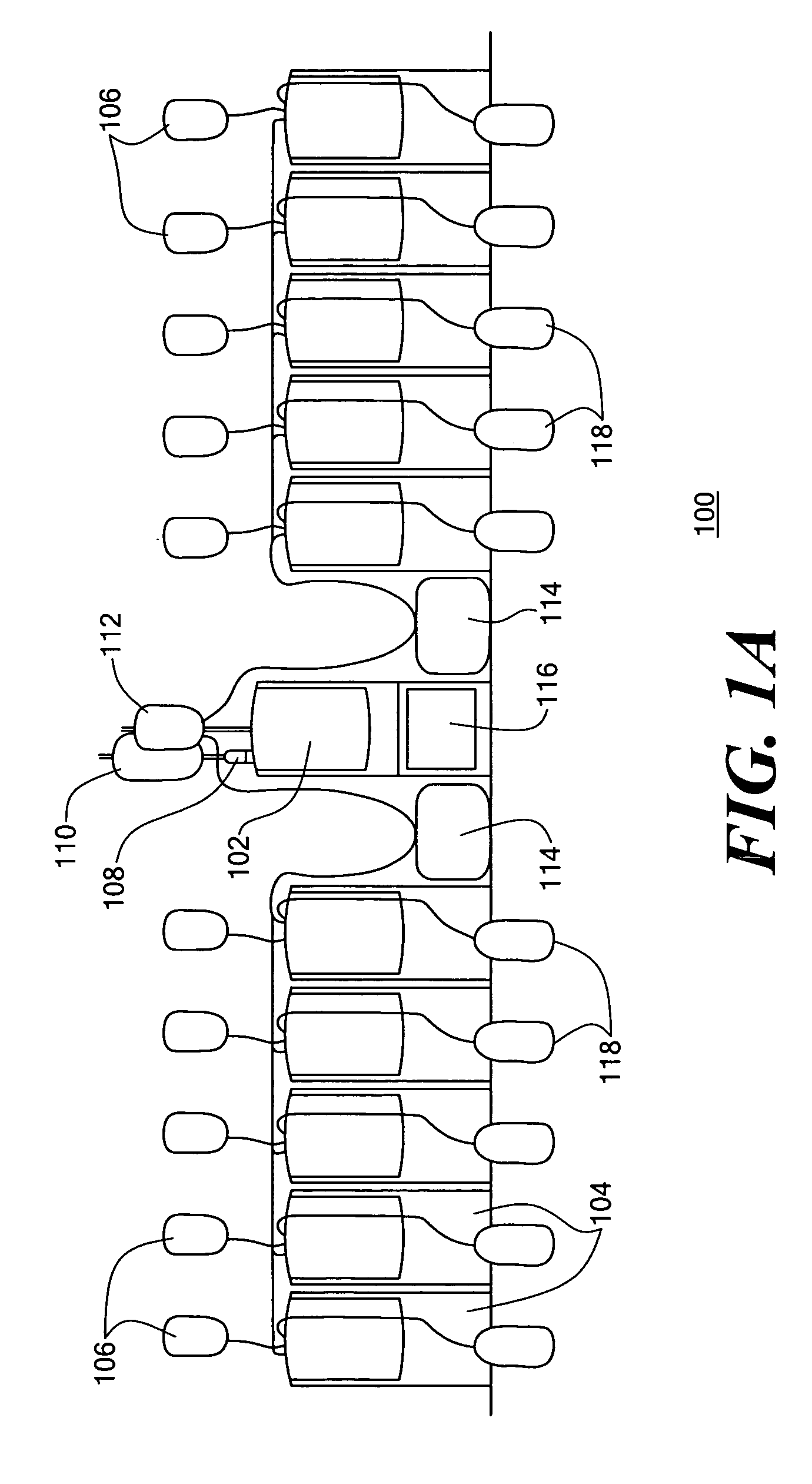

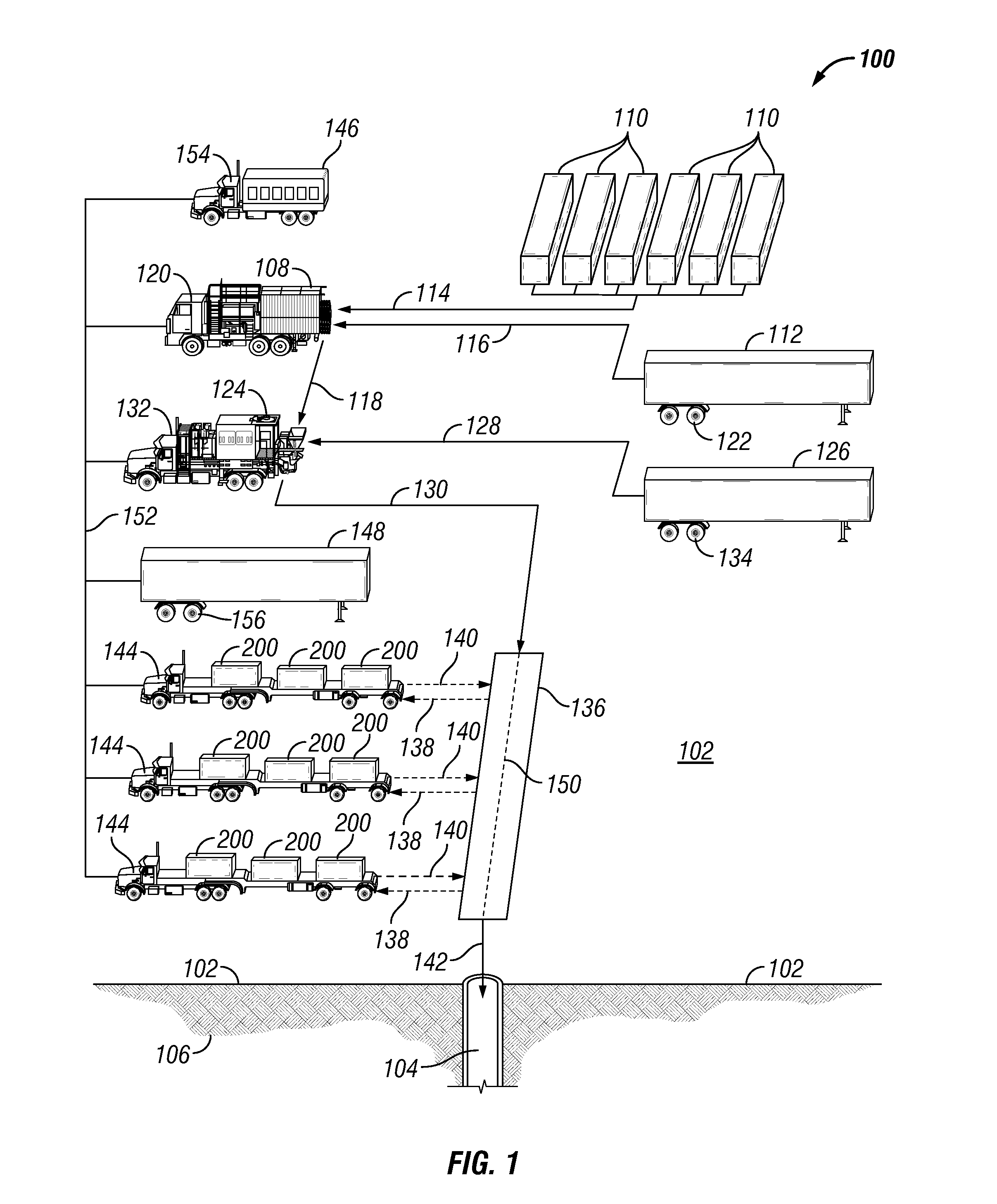

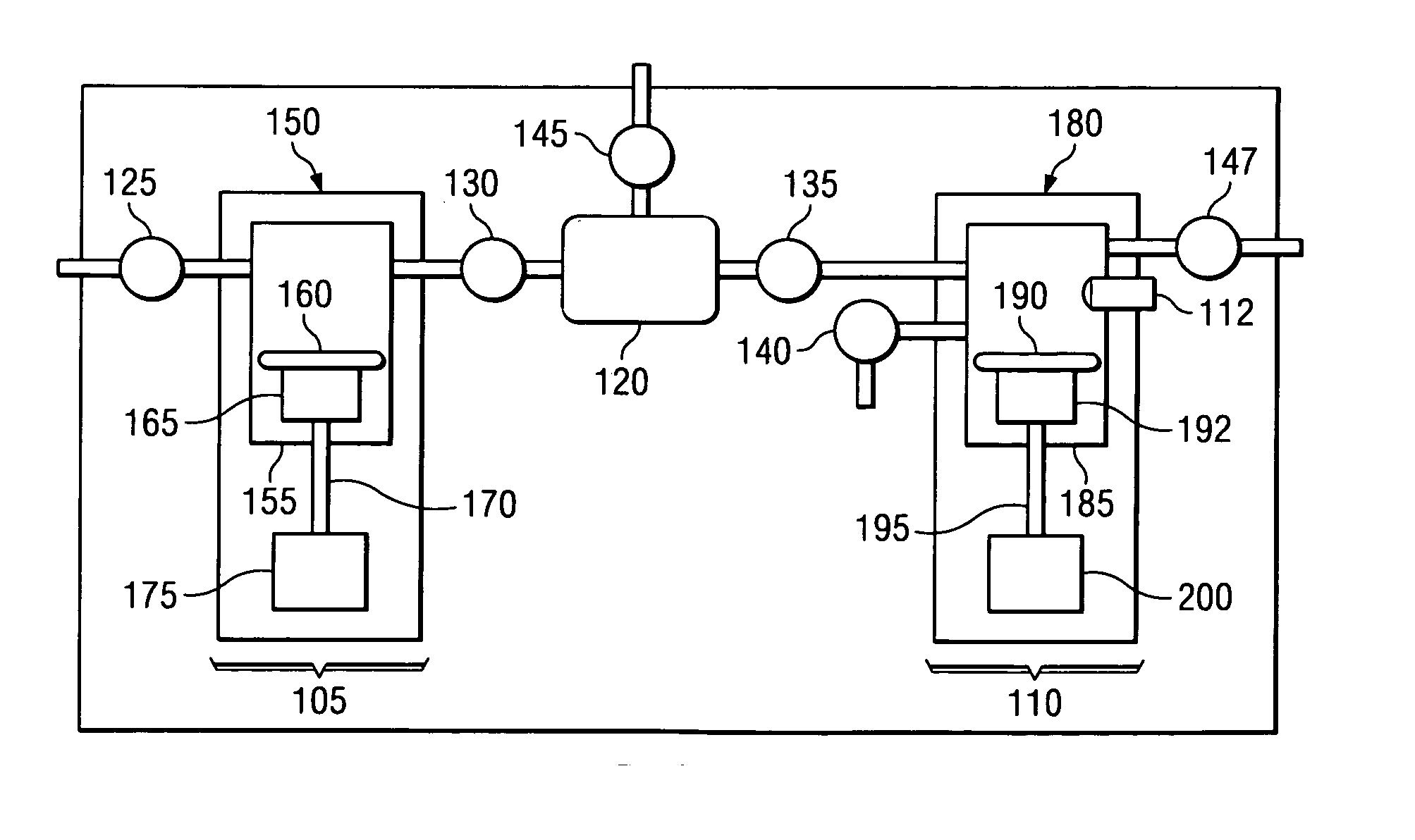

Reducing fluid pressure spikes in a pumping system

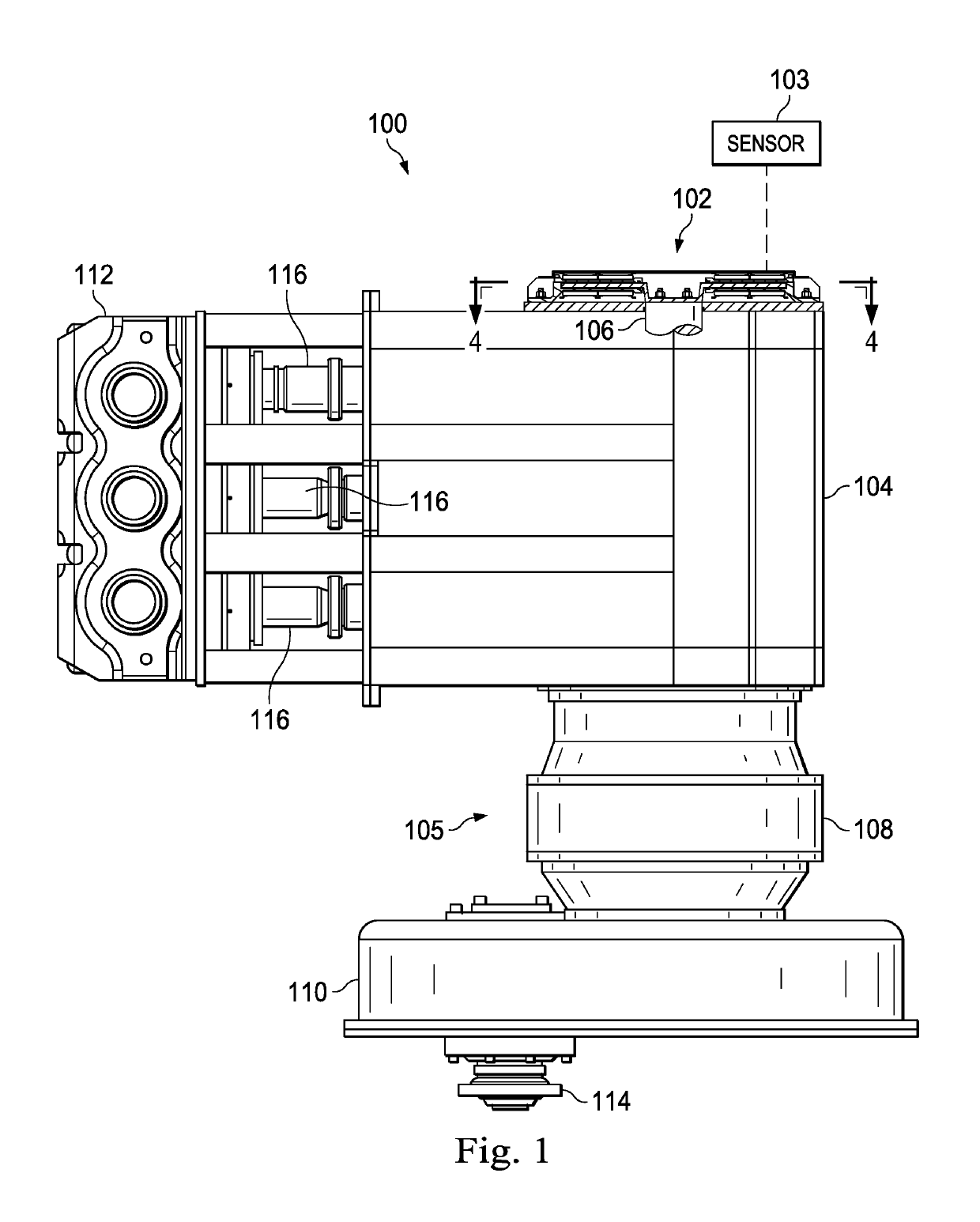

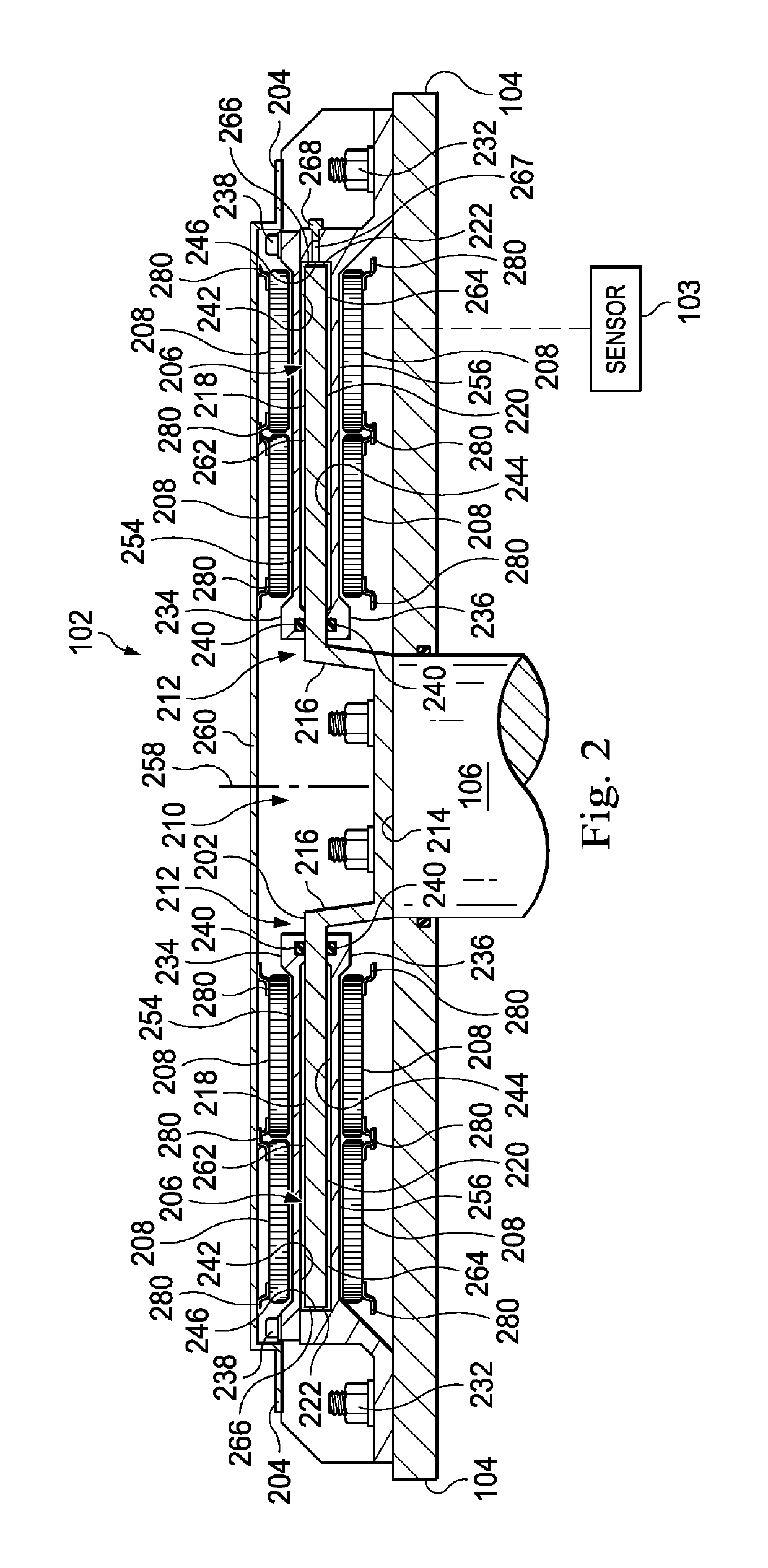

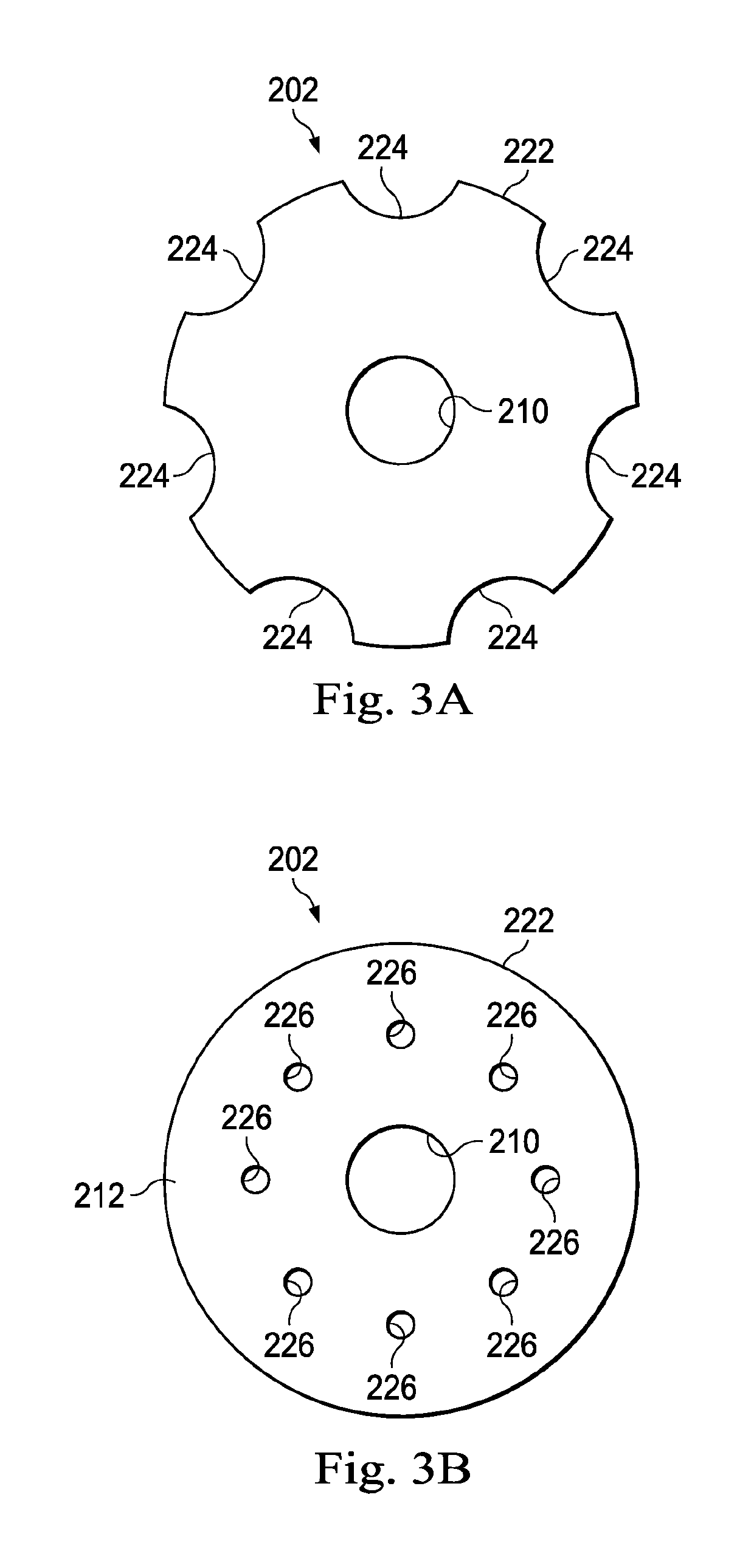

A pumping system including a plurality of pumps each having a pump fluid outlet, a drive shaft, a prime mover, and fluid displacing members operatively coupled with the drive shaft. A common fluid conduit may be fluidly coupled with each pump fluid outlet. A control system of the pumping system includes position sensors operable to generate information relating to phase and / or speed of each pump, pressure sensors operable to generate information relating to fluid pressure spikes, and a controller in communication with the position and pressure sensors. The controller is operable to cause the prime movers to adjust the phasing of the pumps with respect to each other, based on the information relating to fluid pressure spikes, and synchronize the speed of the pumps.

Owner:LIBERTY OILFIELD SERVICES LLC

Fluid End for Frac Pump

ActiveUS20190011051A1Reduce the cross-sectional areaReduce the possibilityPositive displacement pump componentsFlexible member pumpsEngineeringValve seat

Frac pumps have valve seats and bodies. The valve seats comprise a cylindrical body and an annular seat surface. The body has an axial passage and external threads adapted to engage internal threads in a fluid end block of the frac pump. The annular seat surface is at an end of the body and is adapted to engage a valve body. The valve bodies comprise a head and a compressible seal. The head provides a valve surface adapted to engage the valve seat. The compressible seal is carried on the head radially inward of the valve surface and is adapted to engage the valve seat.

Owner:BJ ENERGY SOLUTIONS LLC FORMERLY TES ASSET ACQUISITION LLC

Reducing fluid pressure spikes in a pumping system

A pumping system including a plurality of pumps each having a pump fluid outlet, a drive shaft, a prime mover, and fluid displacing members operatively coupled with the drive shaft. A common fluid conduit may be fluidly coupled with each pump fluid outlet. A control system of the pumping system includes position sensors operable to generate information relating to phase and / or speed of each pump, pressure sensors operable to generate information relating to fluid pressure spikes, and a controller in communication with the position and pressure sensors. The controller is operable to cause the prime movers to adjust the phasing of the pumps with respect to each other, based on the information relating to fluid pressure spikes, and synchronize the speed of the pumps.

Owner:LIBERTY OILFIELD SERVICES LLC

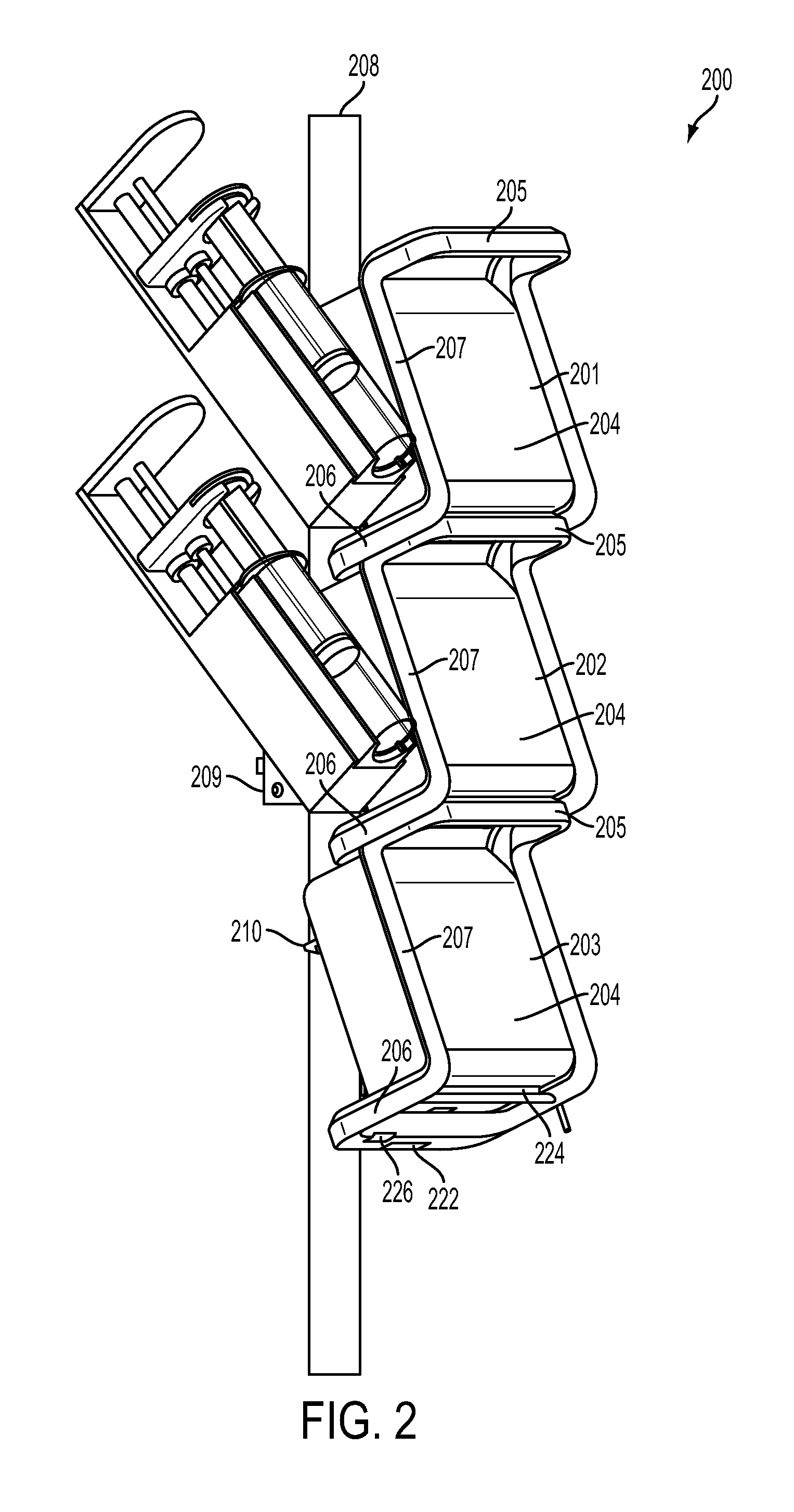

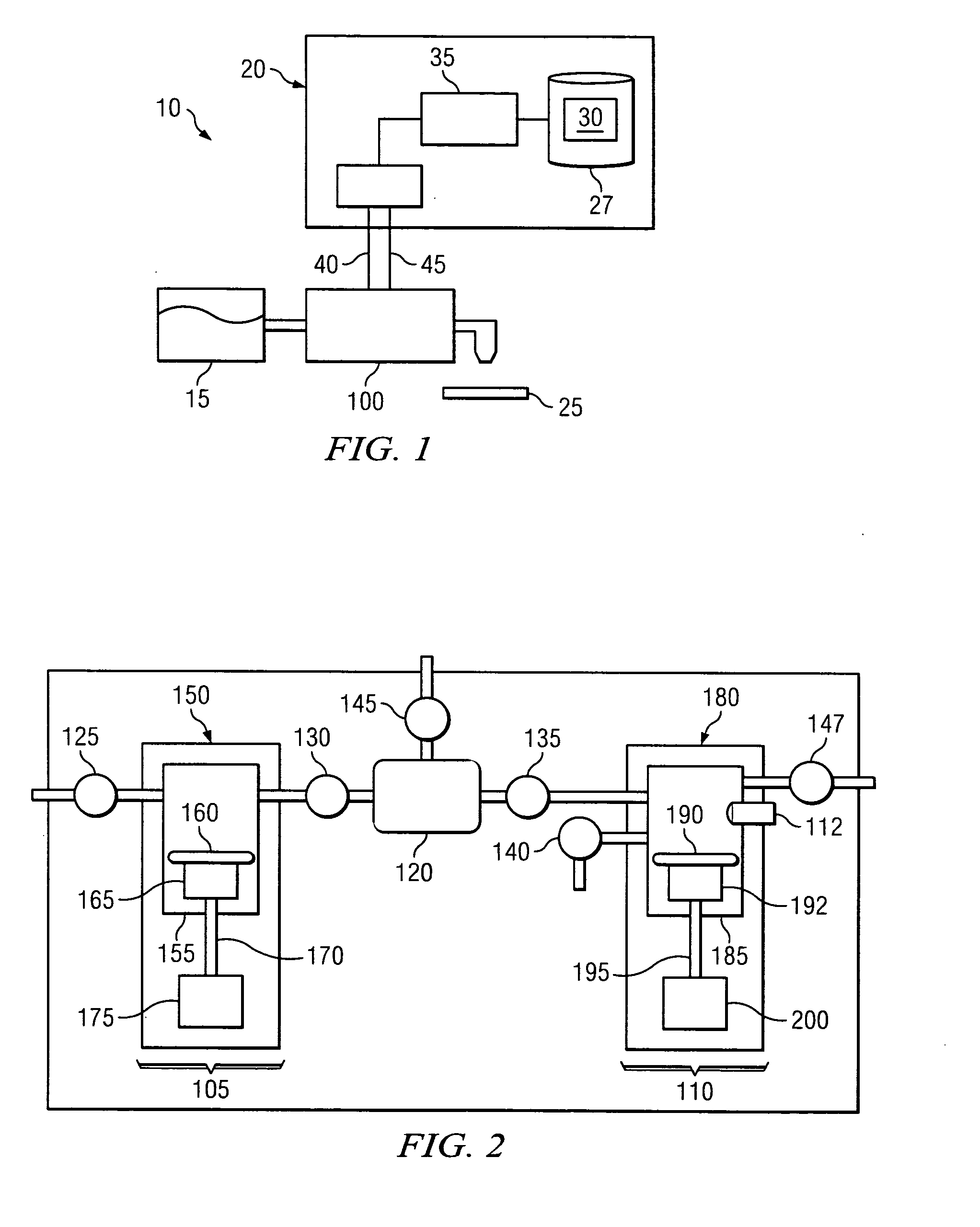

Bezel assembly for pneumatic control

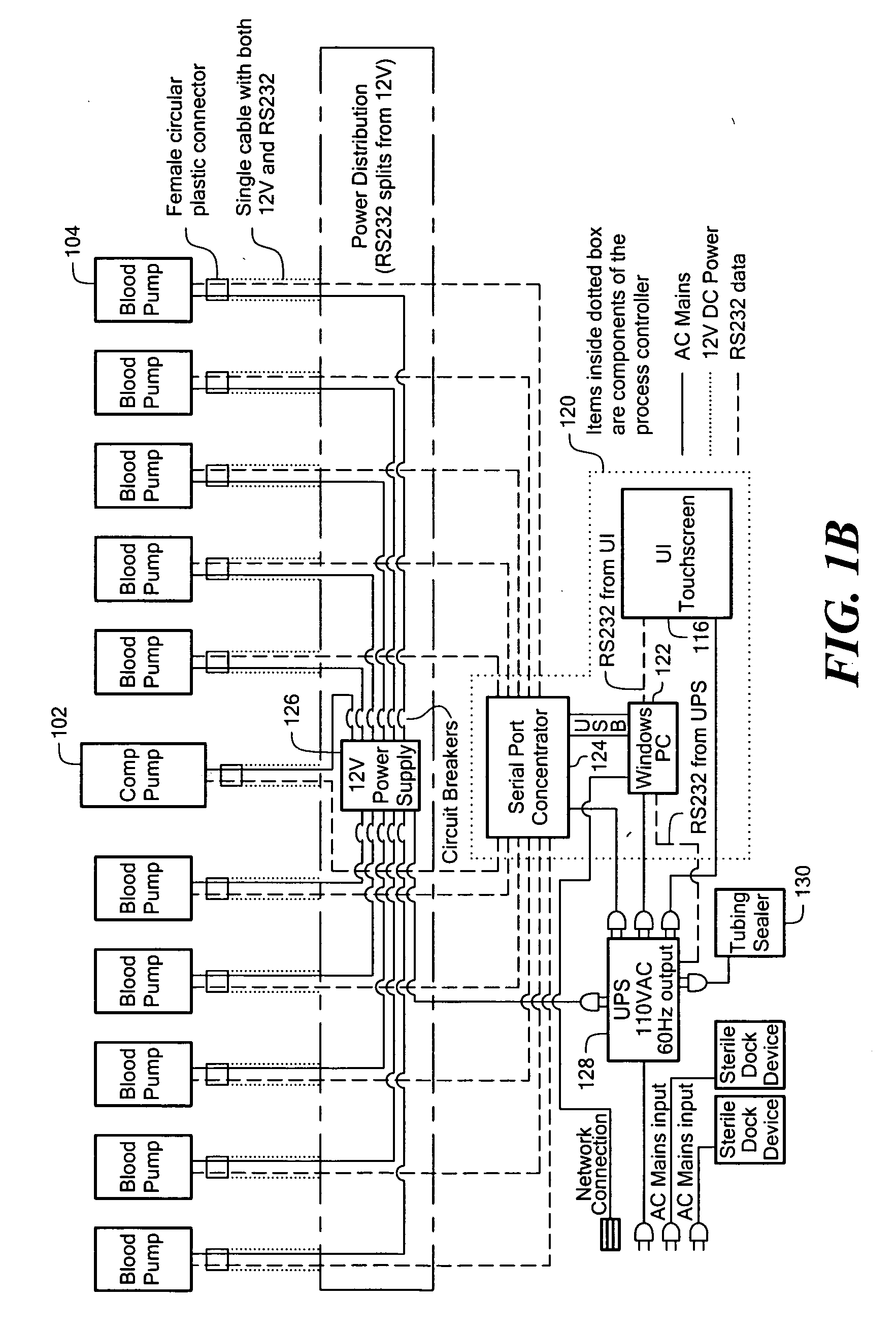

ActiveUS20050095154A1Reducing pump strokeReducing the pump strokeFlow mixersOther blood circulation devicesPositive pressureEngineering

A bezel and bezel assembly in which the bezel is a rigid block with a plurality of cavities. A depression in the block has ribs extending up therefrom to form an elevated contour. The depression includes at least one cavity therein for the application of air pressure into the depression and over the elevated contour. A gasket fits over the bezel so that positive pressure applied through the at least one cavity in the depression forces a gasket membrane to expand away from the pumping side and negative pressure applied through the at least one cavity in the depression pulls the gasket membrane against the elevated contour of the ribs. The bezel may include solvent bondable tubing connections for making pneumatic connections to the bezel.

Owner:DEKA PROD LLP

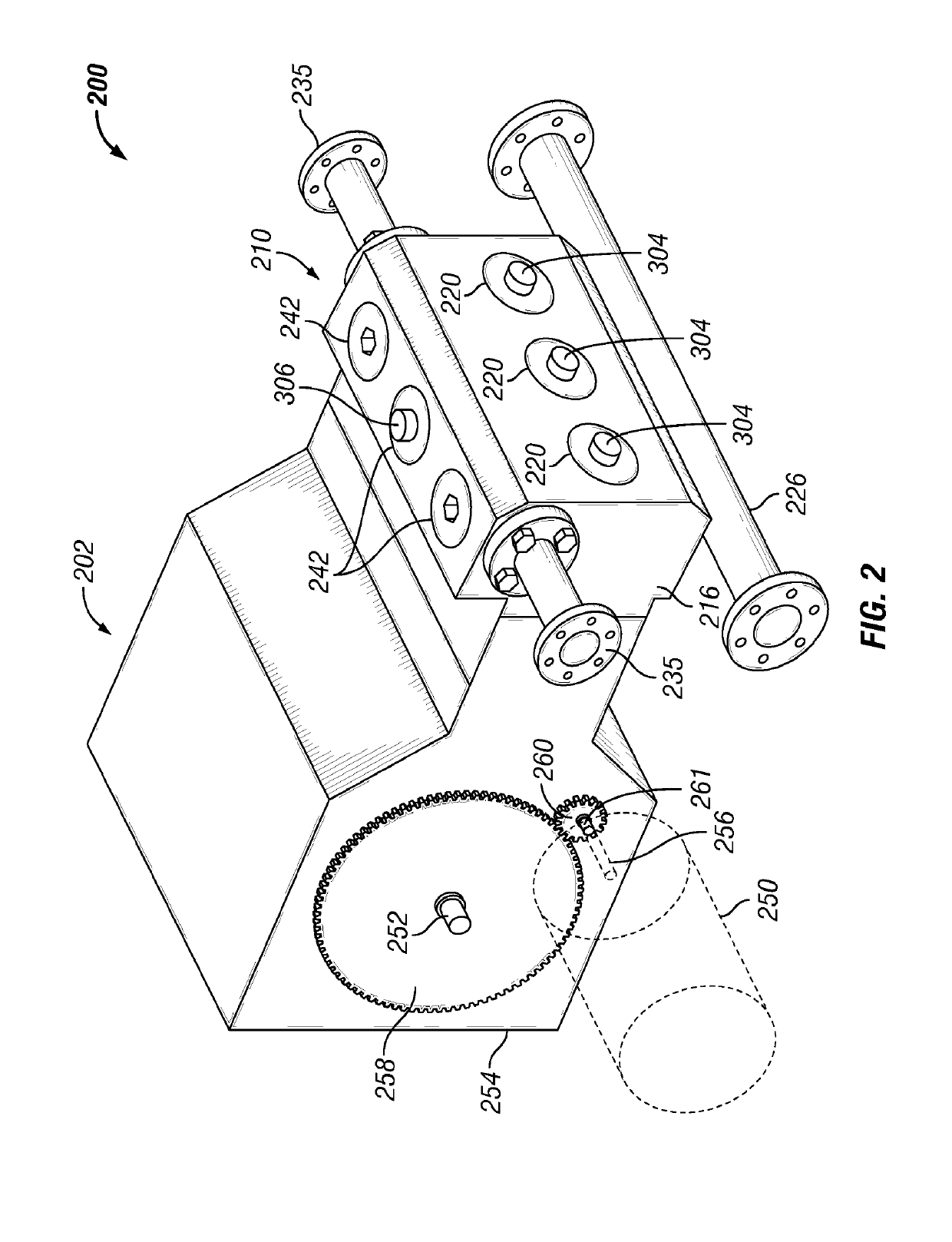

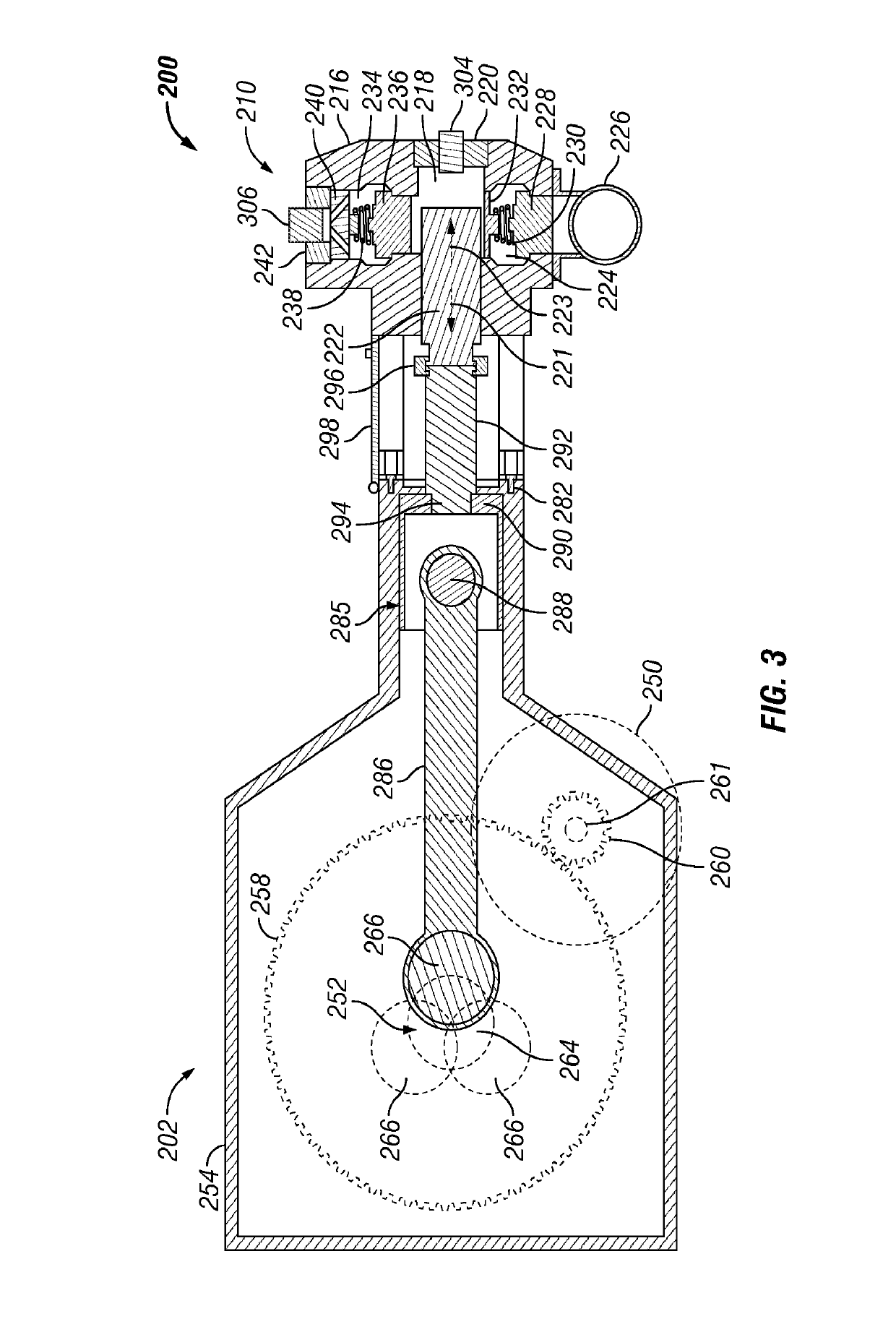

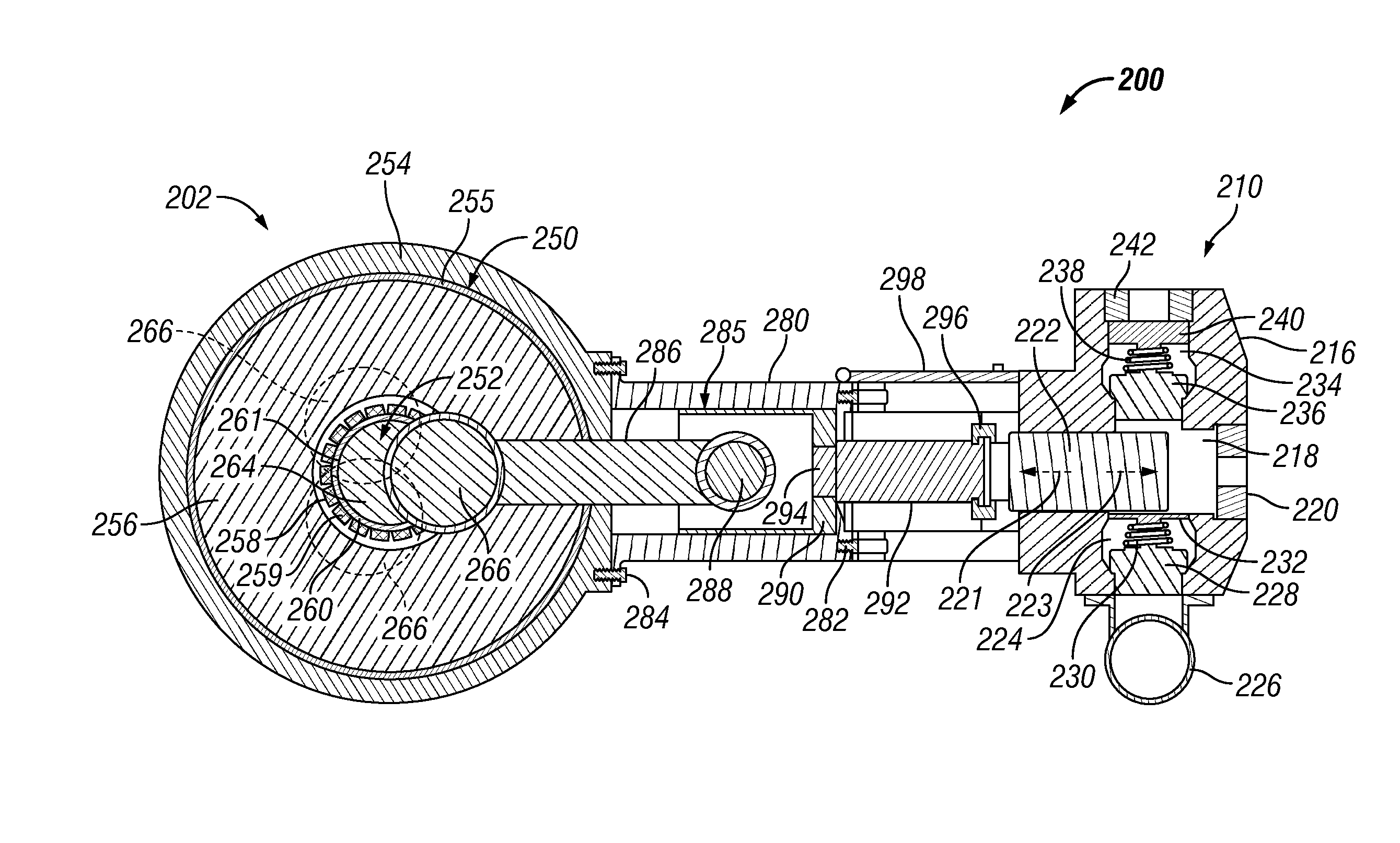

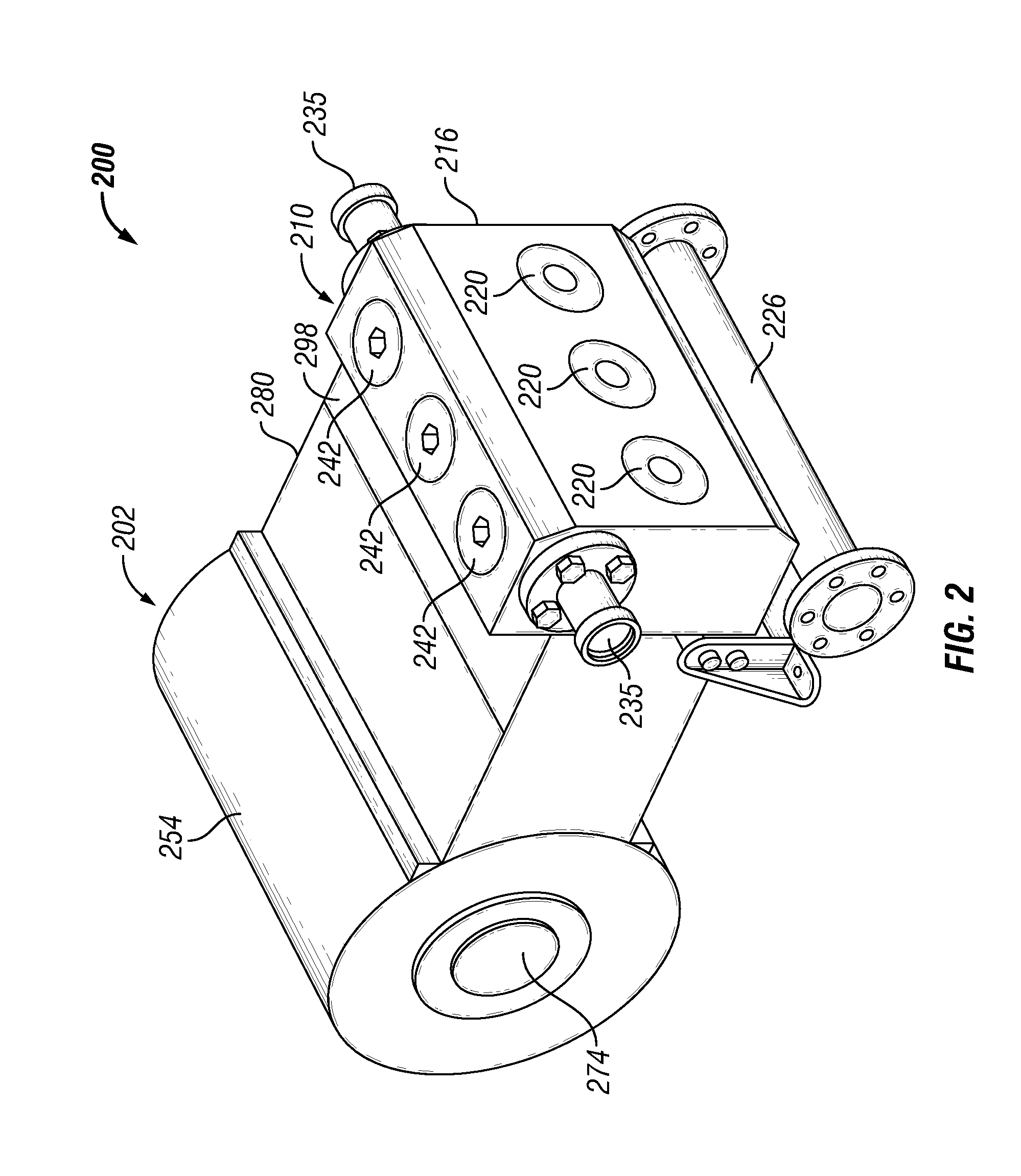

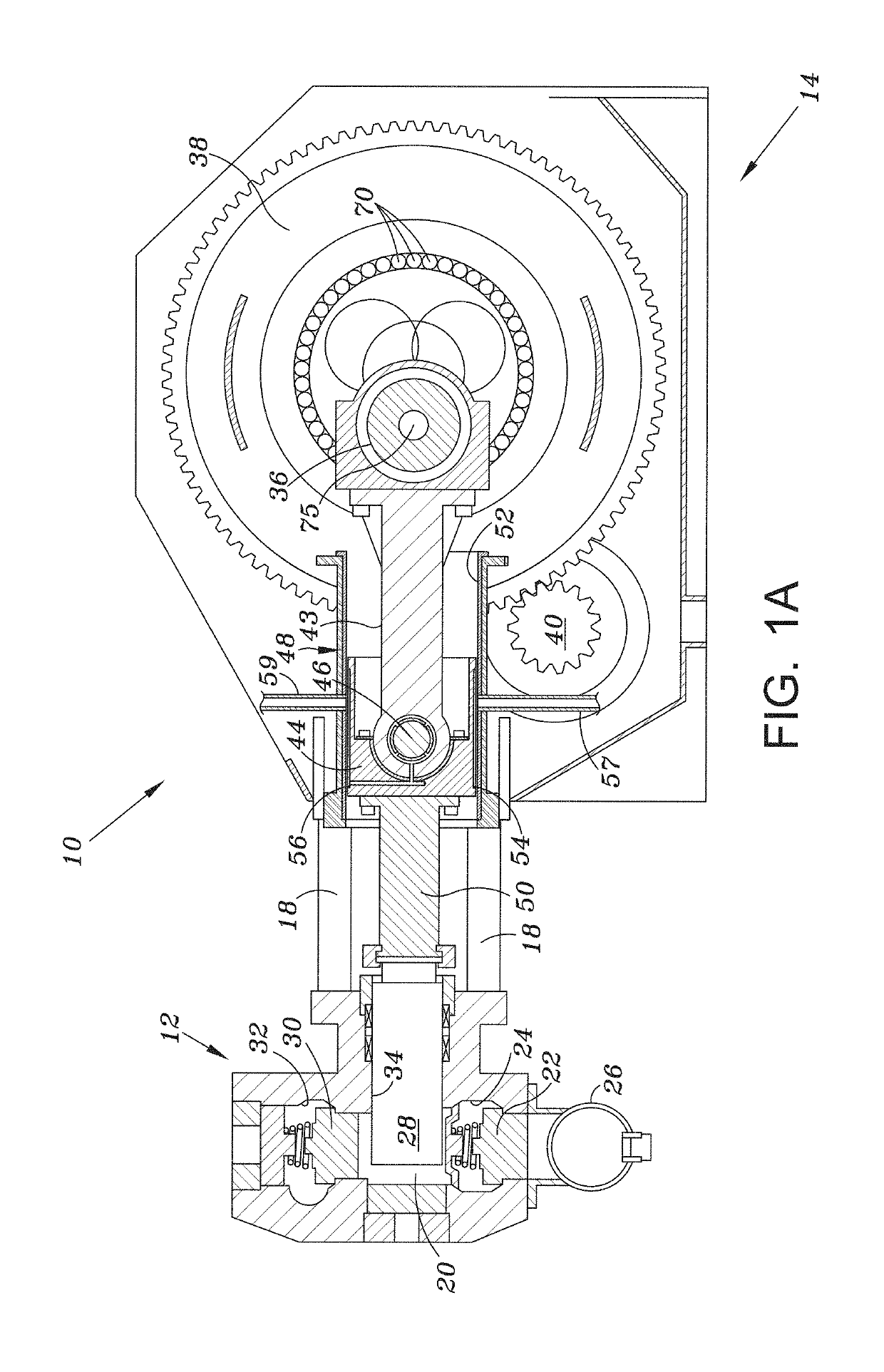

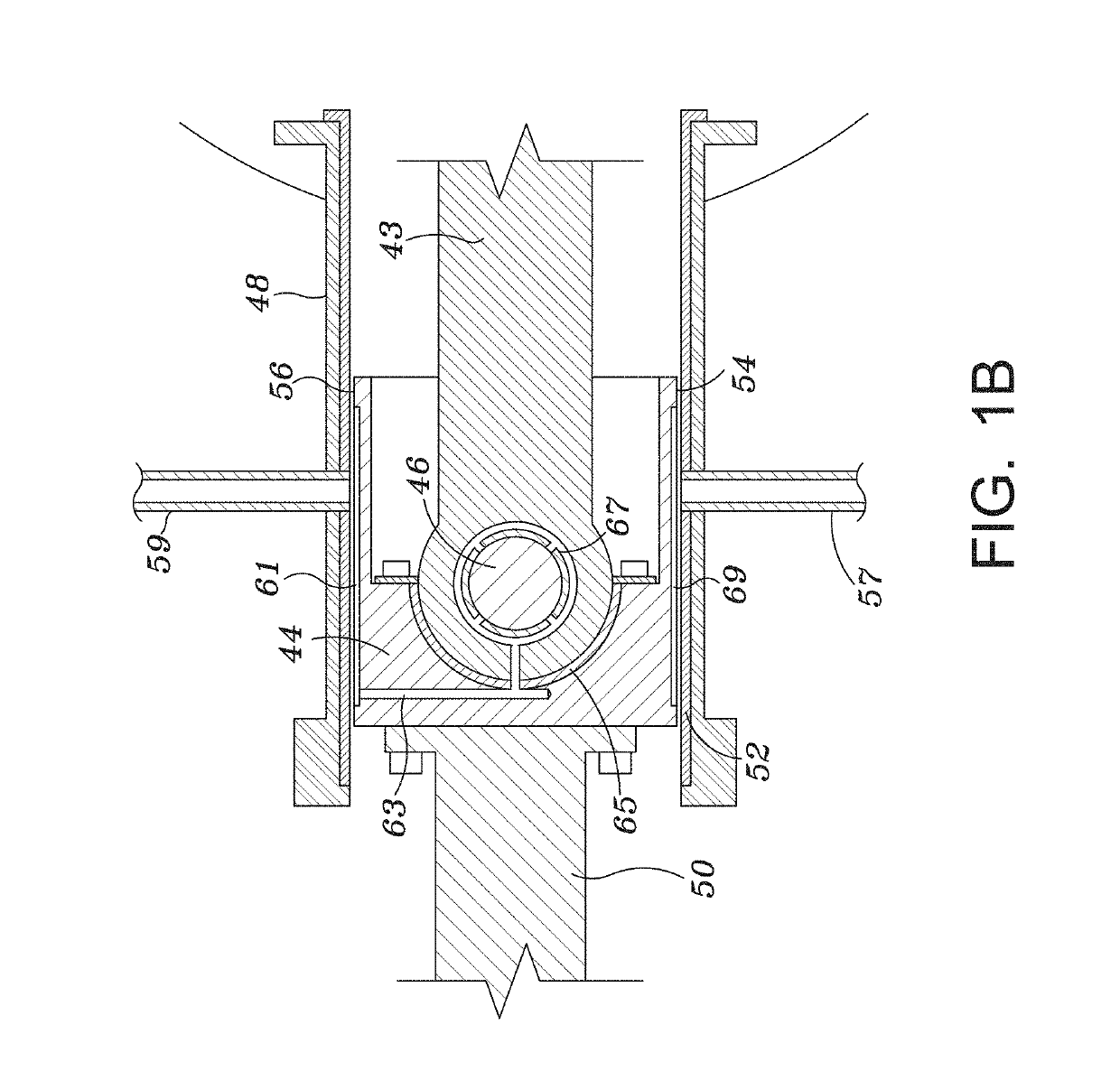

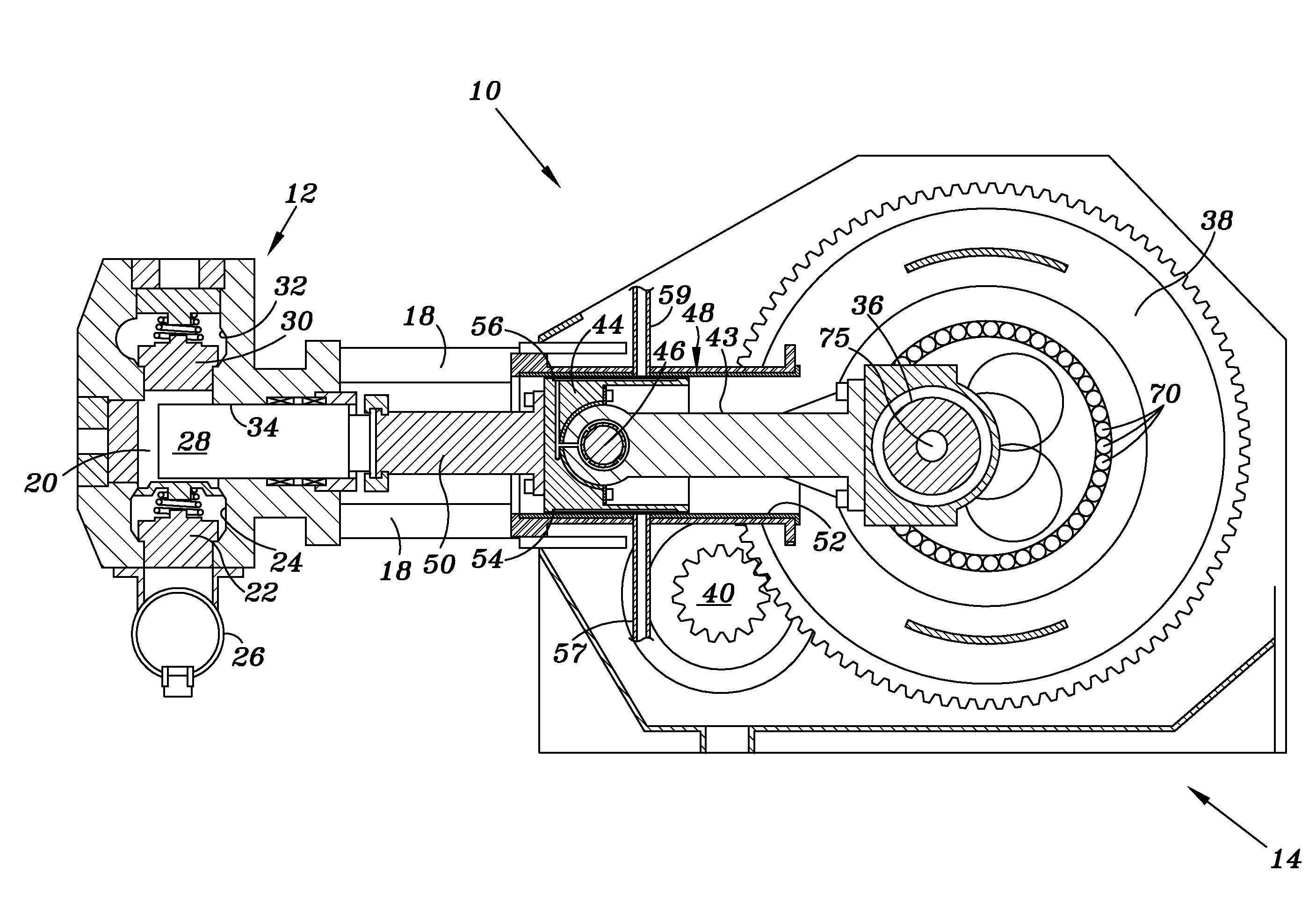

Integrated motor and pump assembly

InactiveUS20150275891A1Positive displacement pump componentsFlexible member pumpsEngineeringCrankpin

A pump assembly that includes a crankshaft having main journals and crankpin journals, rods operatively coupled with the crankpin journals, reciprocating members operatively coupled with the rods, and an electric motor operable to rotate the crankshaft. The electric motor includes a stator and a rotor. The rotor is directly connected with the crankshaft and is operable to rotate the crankshaft to move the plurality of rods and reciprocating members to move a fluid.

Owner:SCHLUMBERGER TECH CORP

Pump drivetrain damper system and control systems and methods for same

ActiveUS10316832B2Reduce vibrationLiquid resistance brakesPositive displacement pump componentsControl signalDrivetrain

Owner:SPM OIL & GAS INC

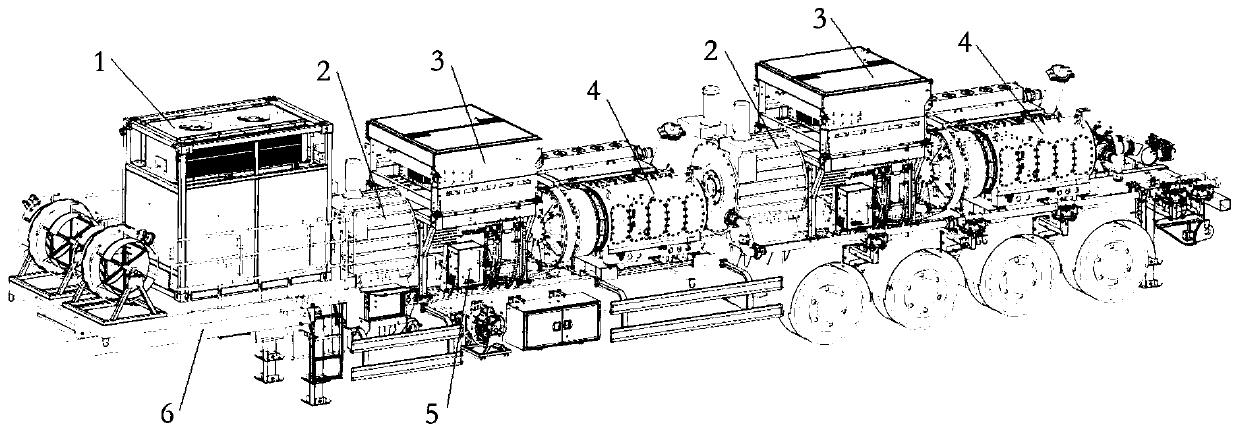

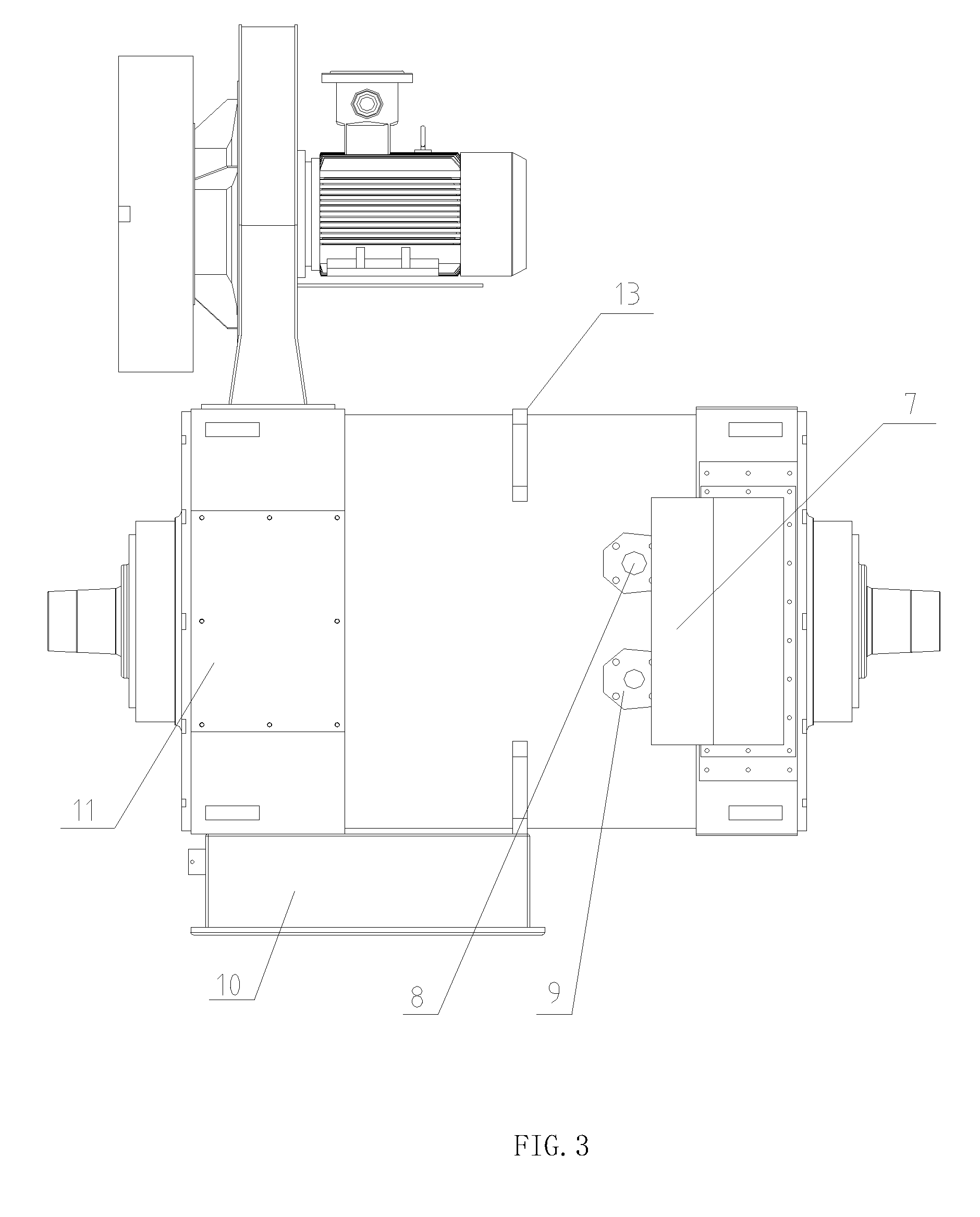

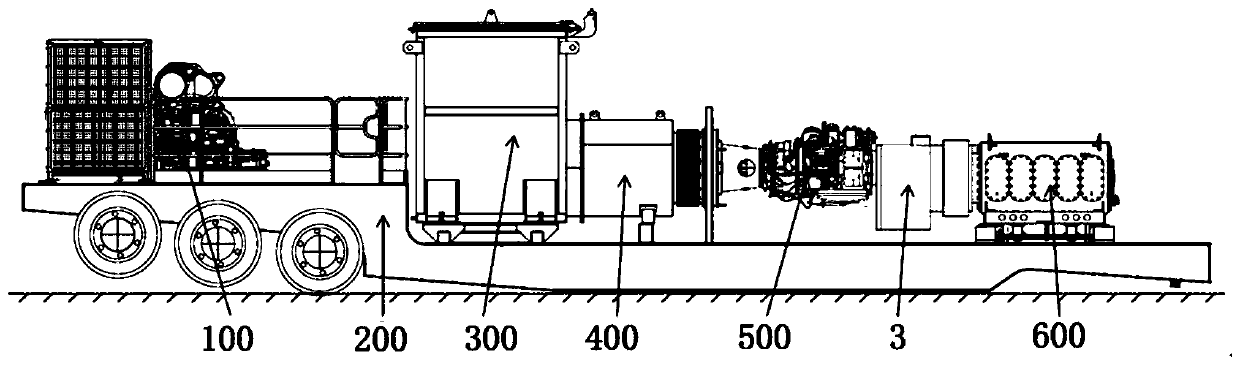

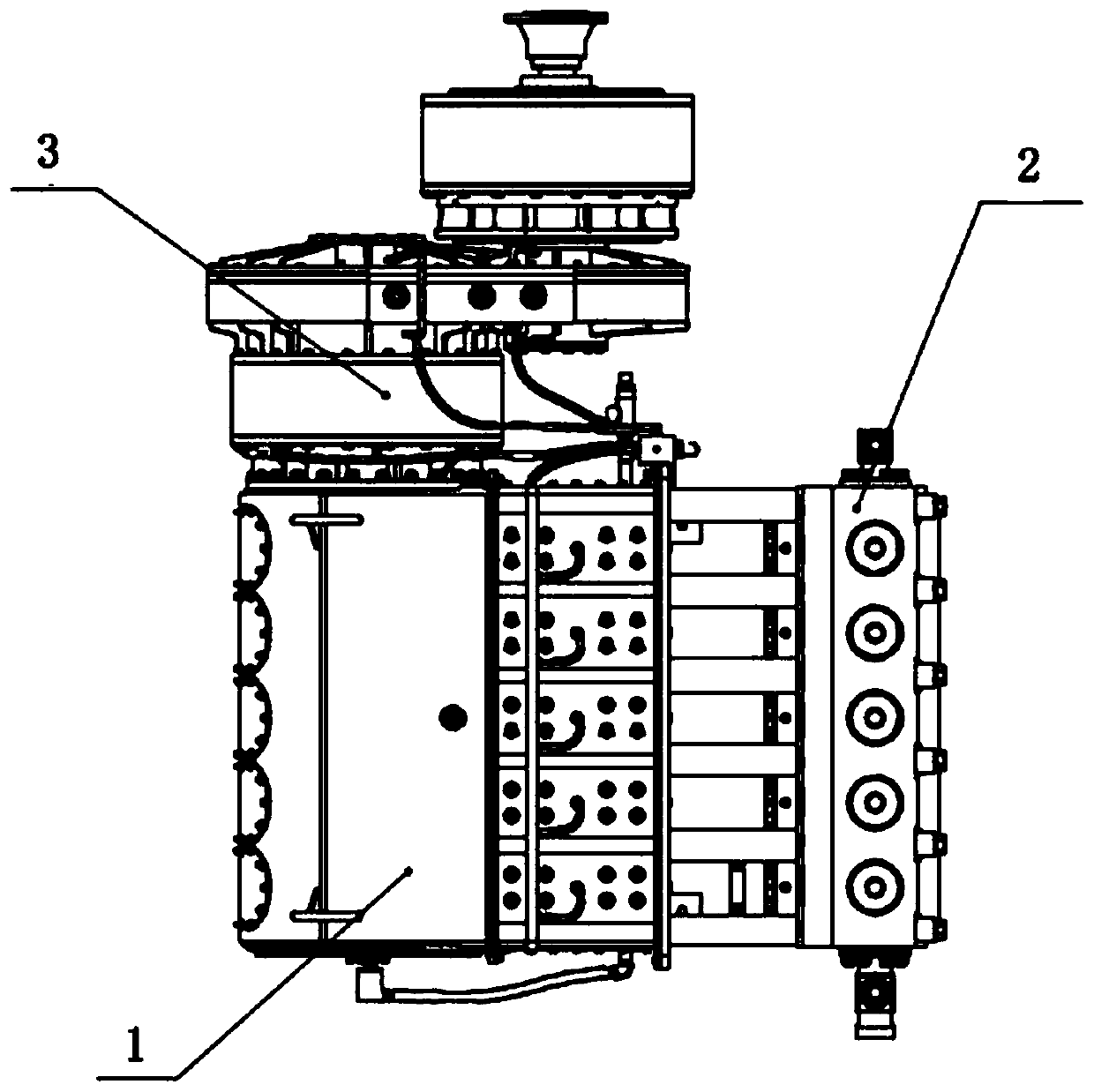

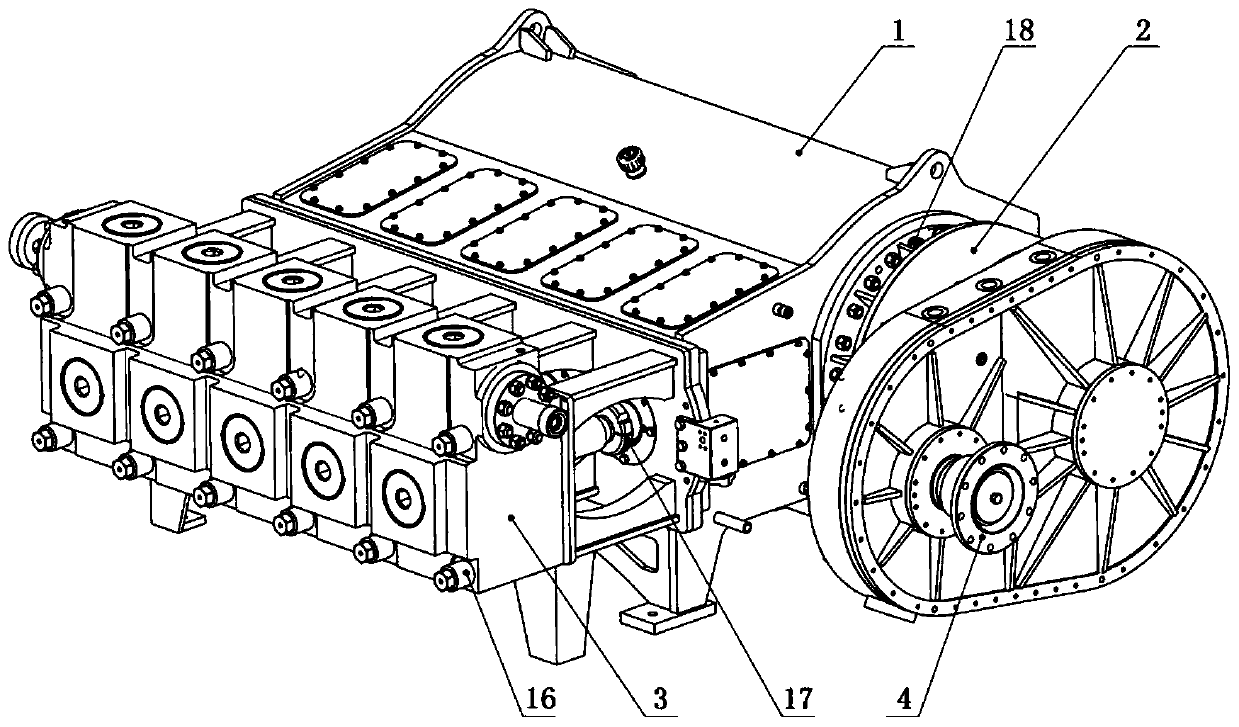

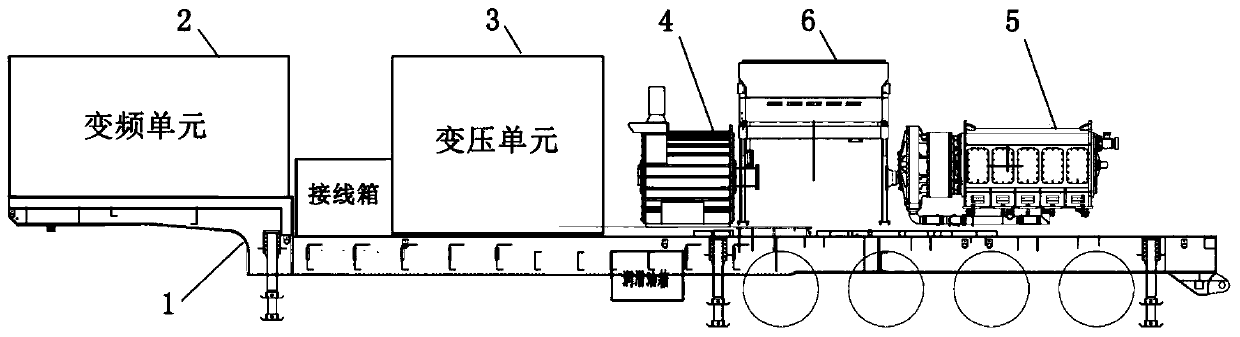

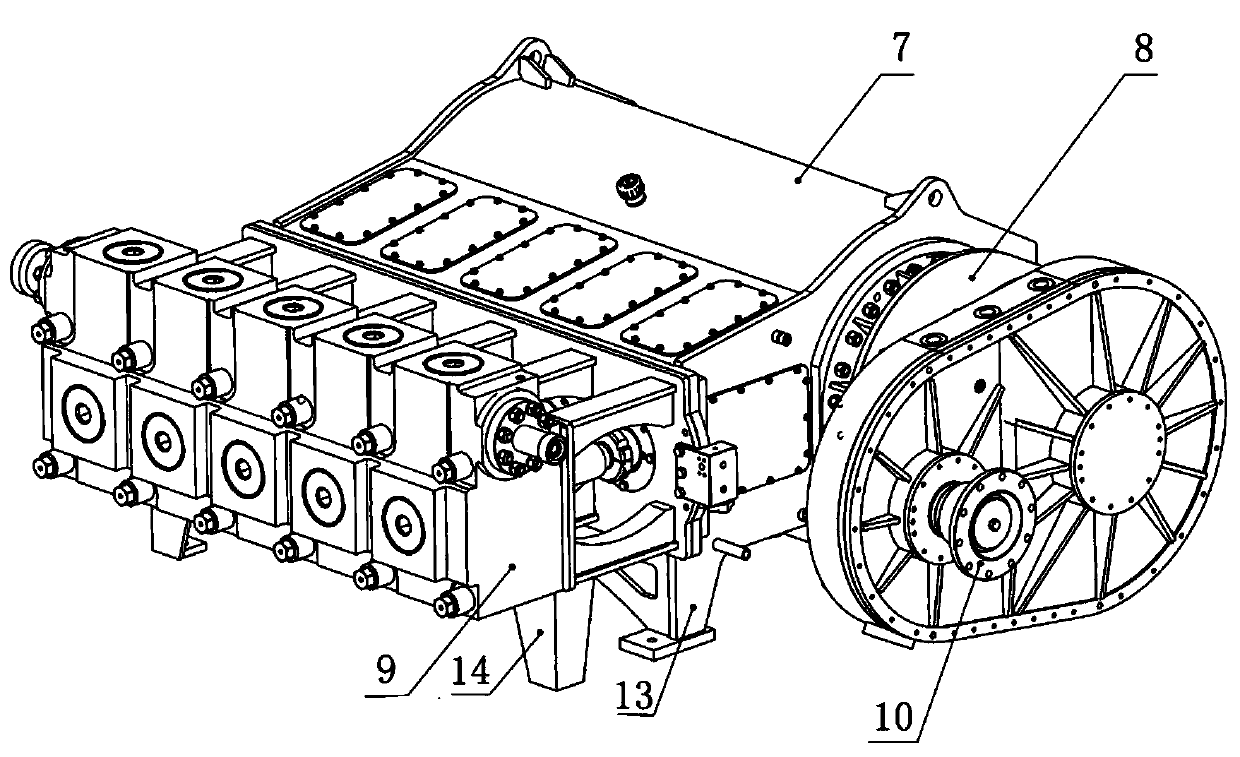

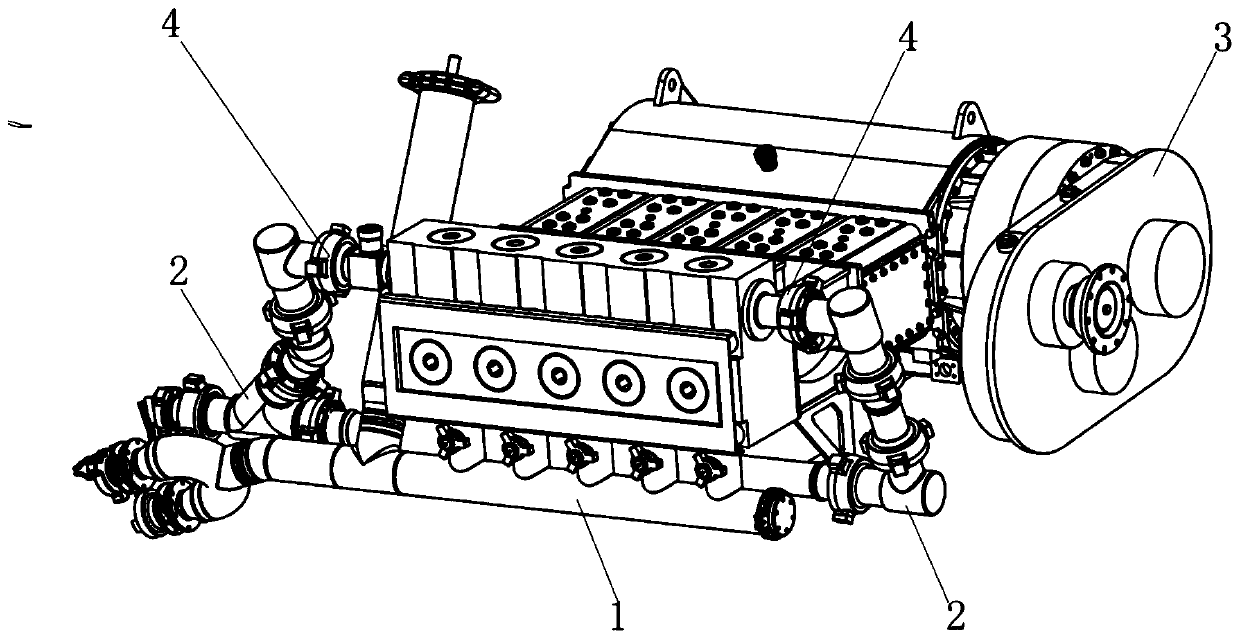

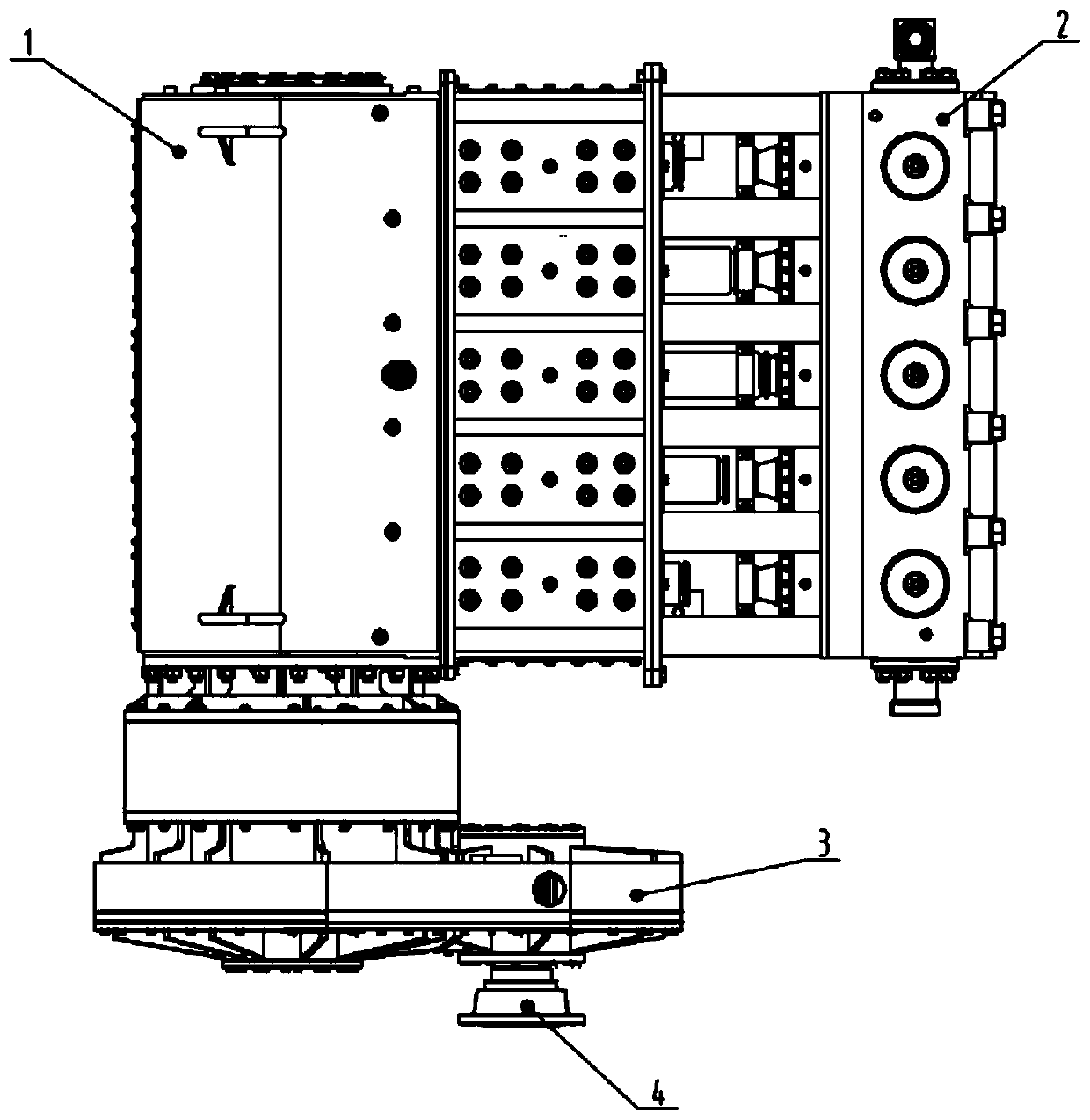

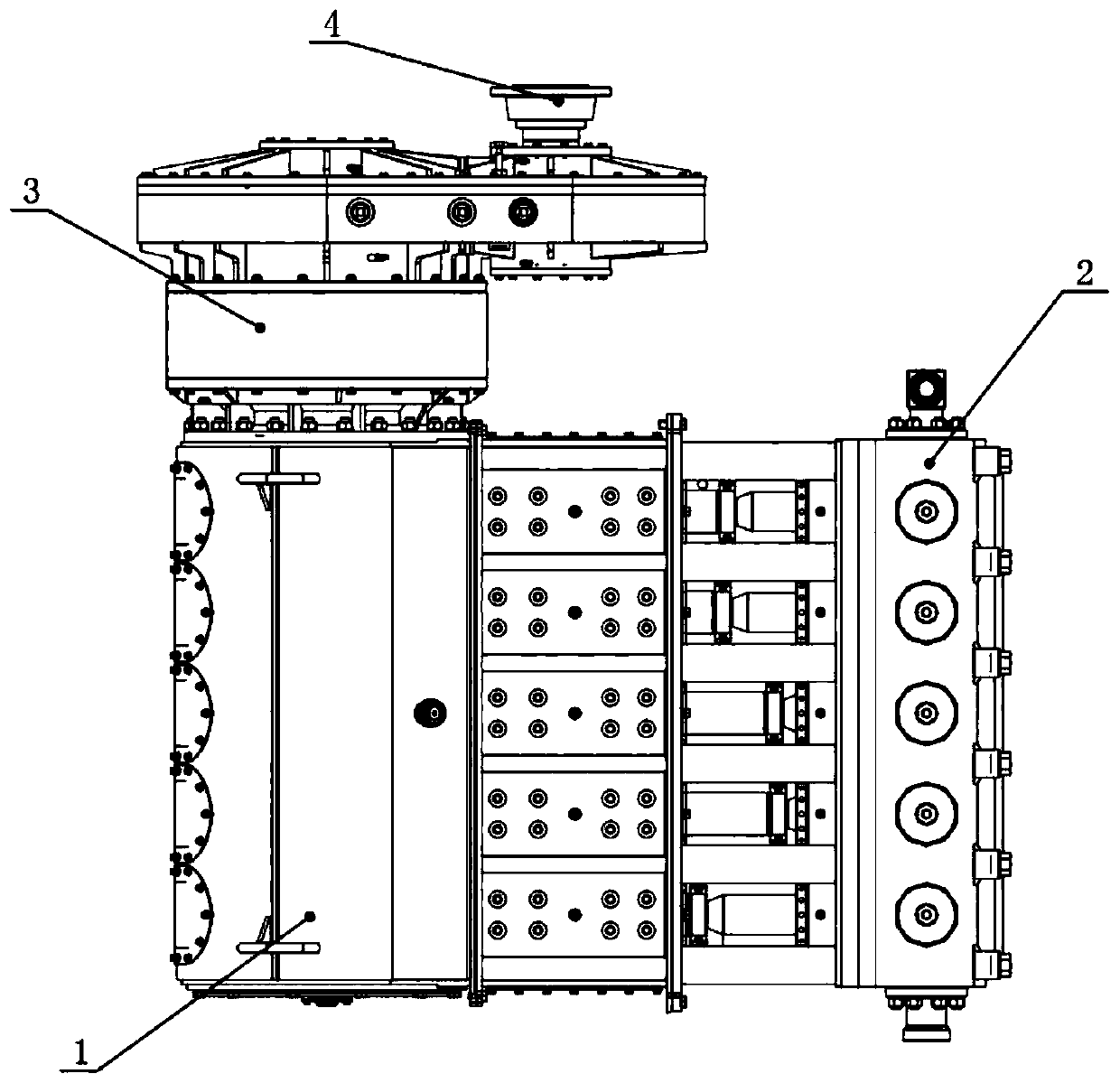

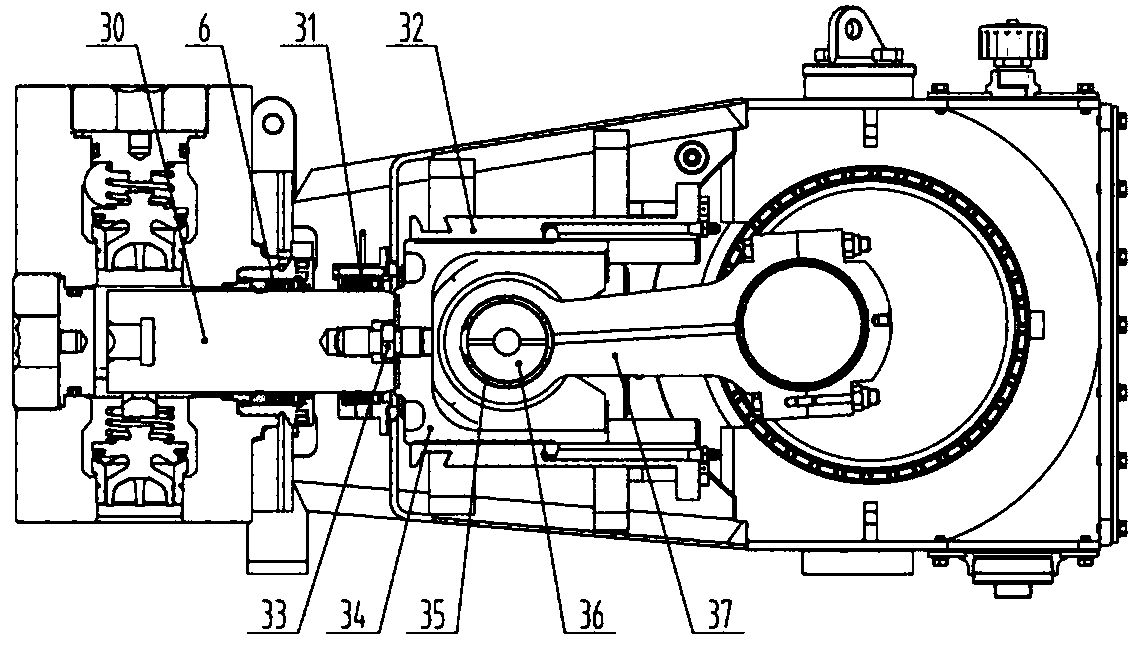

Electric drive fracturing semitrailer with dual engines and dual pumps

PendingCN109882144ARealized pump powerReduce investmentAssociation with control/drive circuitsPositive displacement pump componentsDrive shaftElectrical control

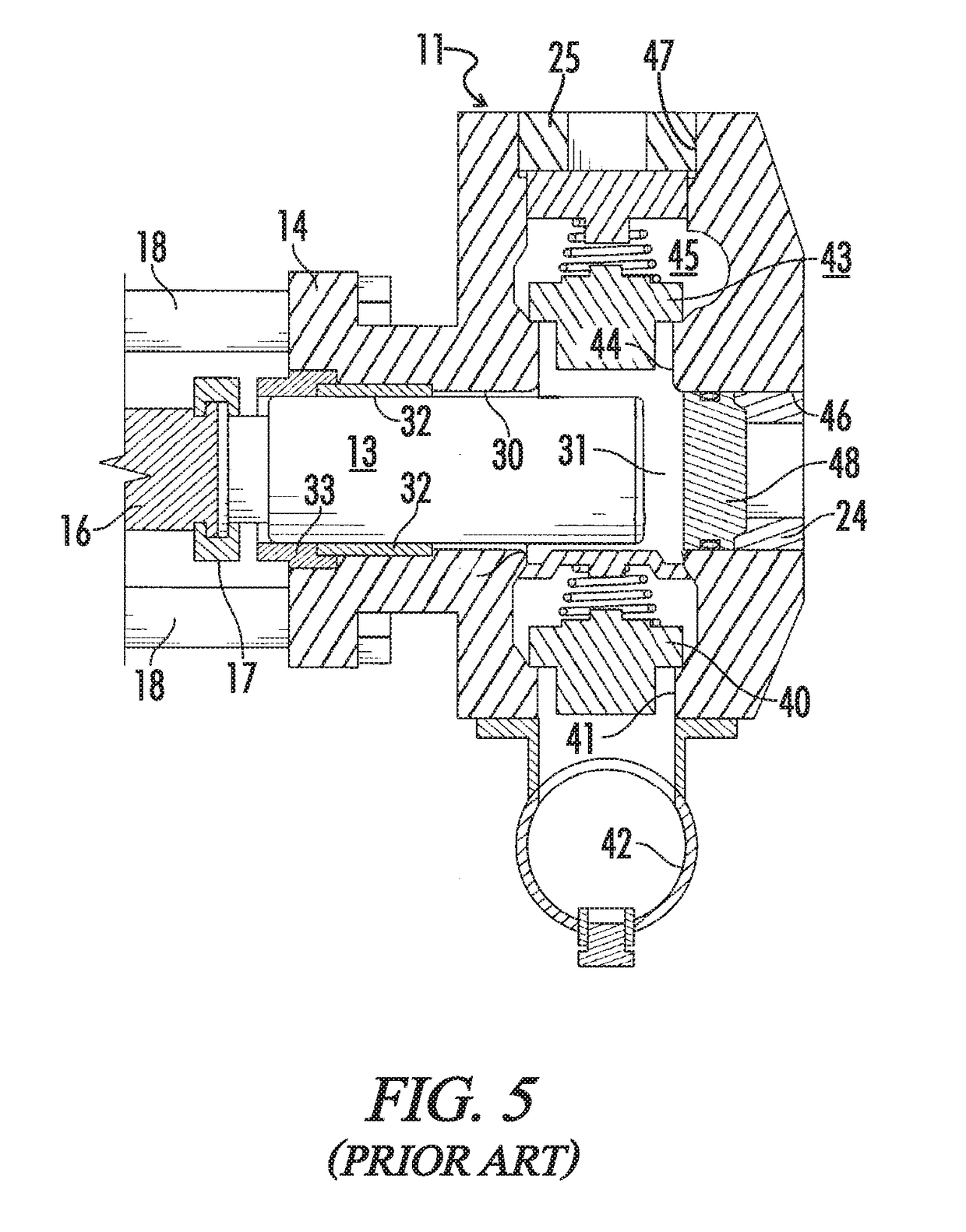

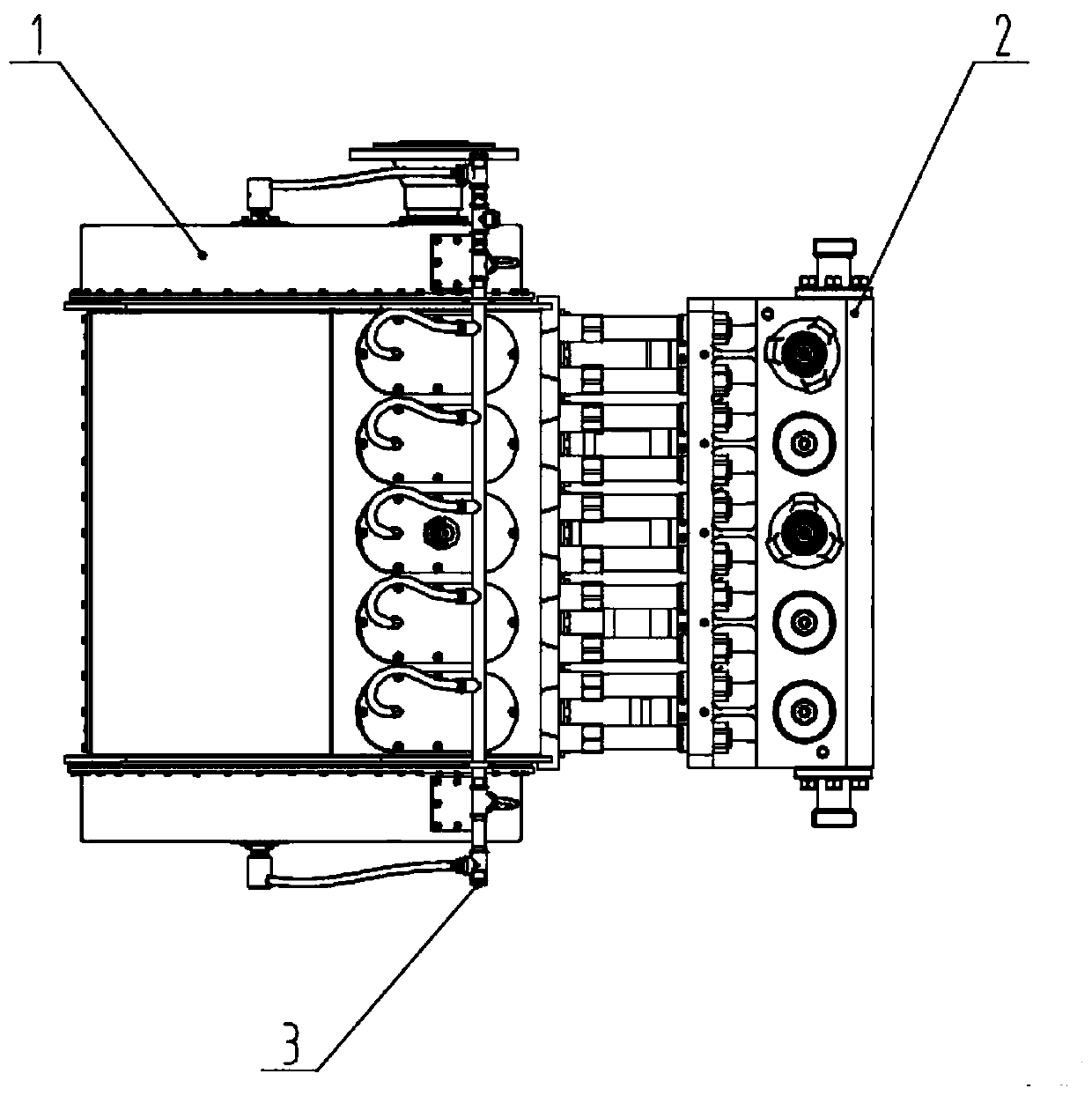

The invention discloses an electric drive fracturing semitrailer with dual engines and dual pumps. The electric drive fracturing semitrailer with the dual engines and the dual pumps comprises a semitrailer body, two plunger pumps, two radiators and an electrical control cabinet. The electric drive fracturing semitrailer with the dual engines and the dual pumps is characterized by further comprising two electromotorsand an inverter unit. The plunger pumps, the radiators, the electrical control cabinet, the electromotors and the inverter unit are integrated in the semitrailer body, the inverterunit is arranged on the gooseneck of the semitrailer body, the output end of the inverter unit individually drives the two electromotors, the other ends of the two electromotors are connected with theplunger pumps correspondingly, lubricating oil of the plunger pumps is cooled through the radiators, and local operation of the electric drive fracturing semitrailer with the dual engines and the dual pumps is realized through the electrical control cabinet. The electric drive fracturing semitrailer with the dual engine and the dual pump has the beneficial effects that the electromotors are adopted to drive the plunger pumps through a transmission shaft, the volume is small, and the economic efficiency, energy conservation and environment protection are achieved. The signal pump power of theplunder pumps is improved, design that the dual pumps are driven by the two electromotors is adopted by the whole fracturing device, the output power of the fracturing device is greatly improved, andthe using requirements are better met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

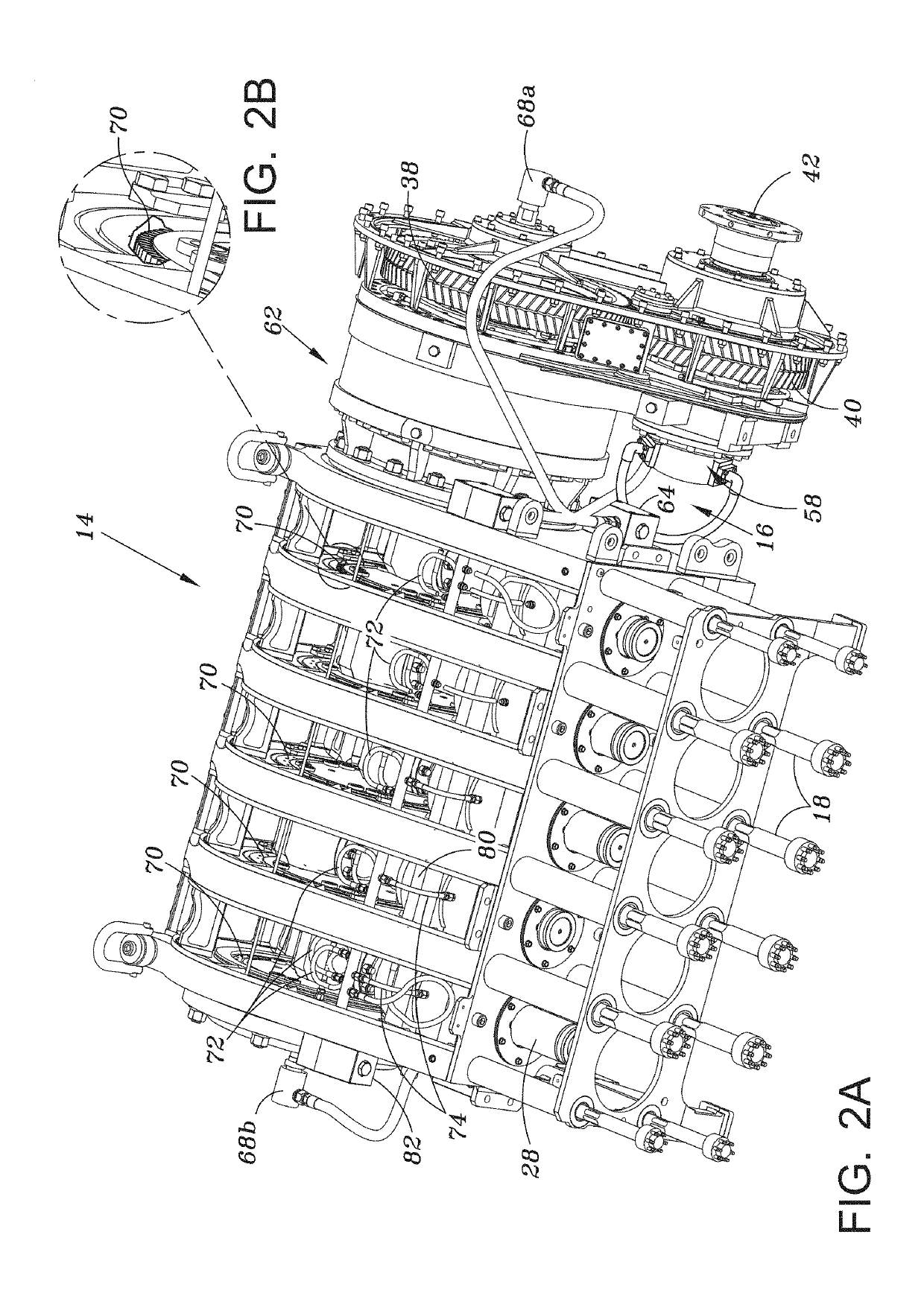

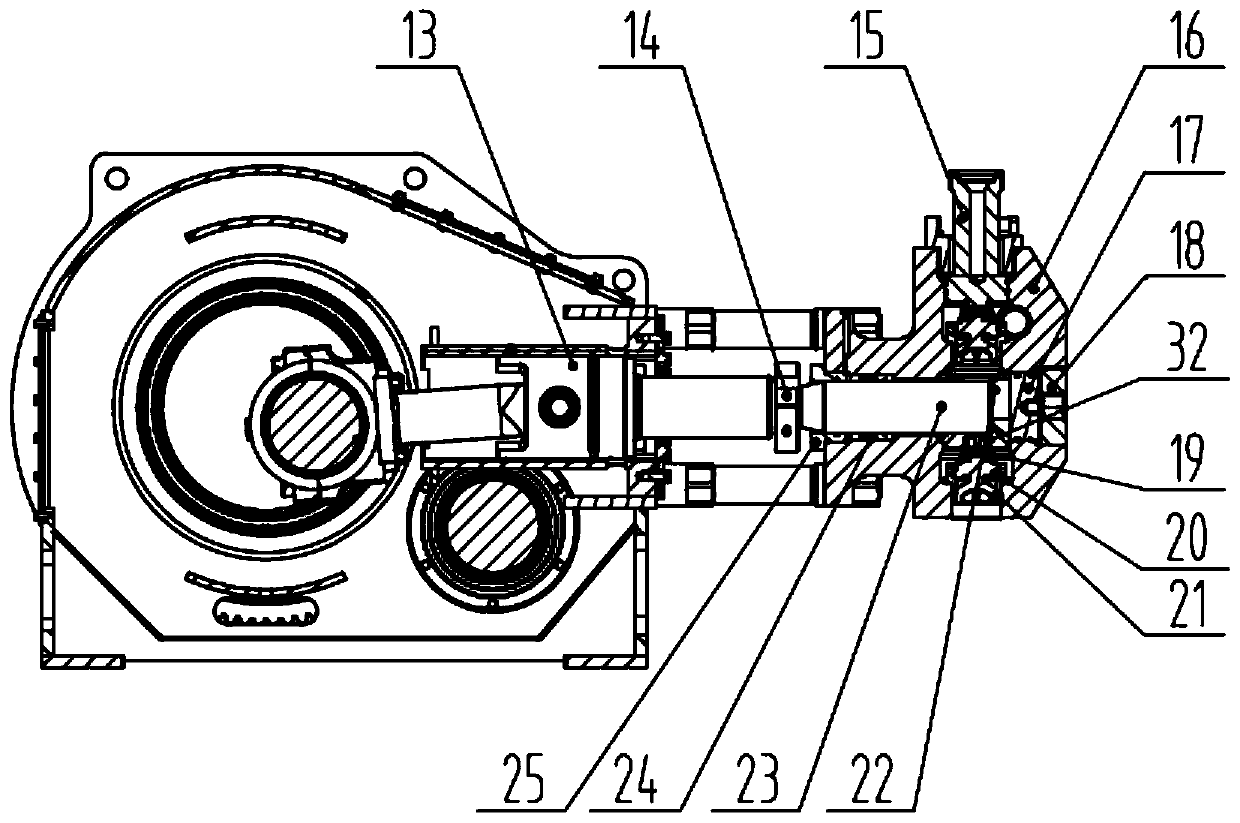

Fracturing Pump

InactiveUS20150078924A1Large single-machine powerWork at highPositive displacement pump componentsFlexible member pumpsEngineeringDiesel engine

The invention discloses a fracturing pump, comprising a cooling device and a control device, wherein a motor is connected on an shaft of the fracturing pump, the cooling device comprises an air-cooled device for cooling a rotor of the motor and a water-cooled device for cooling a stator of the motor, and the control device is connected with the motor and the cooling device, respectively. The fracturing pump in the invention adopts a structure directly driven by the motor, thus breaking the form of a transmission structure of a diesel engine of the conventional fracturing pump added with a transmission tank, simplifying the structure of the entire fracturing pump, reducing the apparatus mounted on a fracturing car, decreasing failure rate of the apparatus, and becoming more safe and reliable.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

Reciprocating pump with dual circuit power end lubrication system

ActiveUS20190277279A1Positive displacement pump componentsRotary/oscillating piston combinationsHigh pressureLubrication

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to journal surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of roller bearing surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

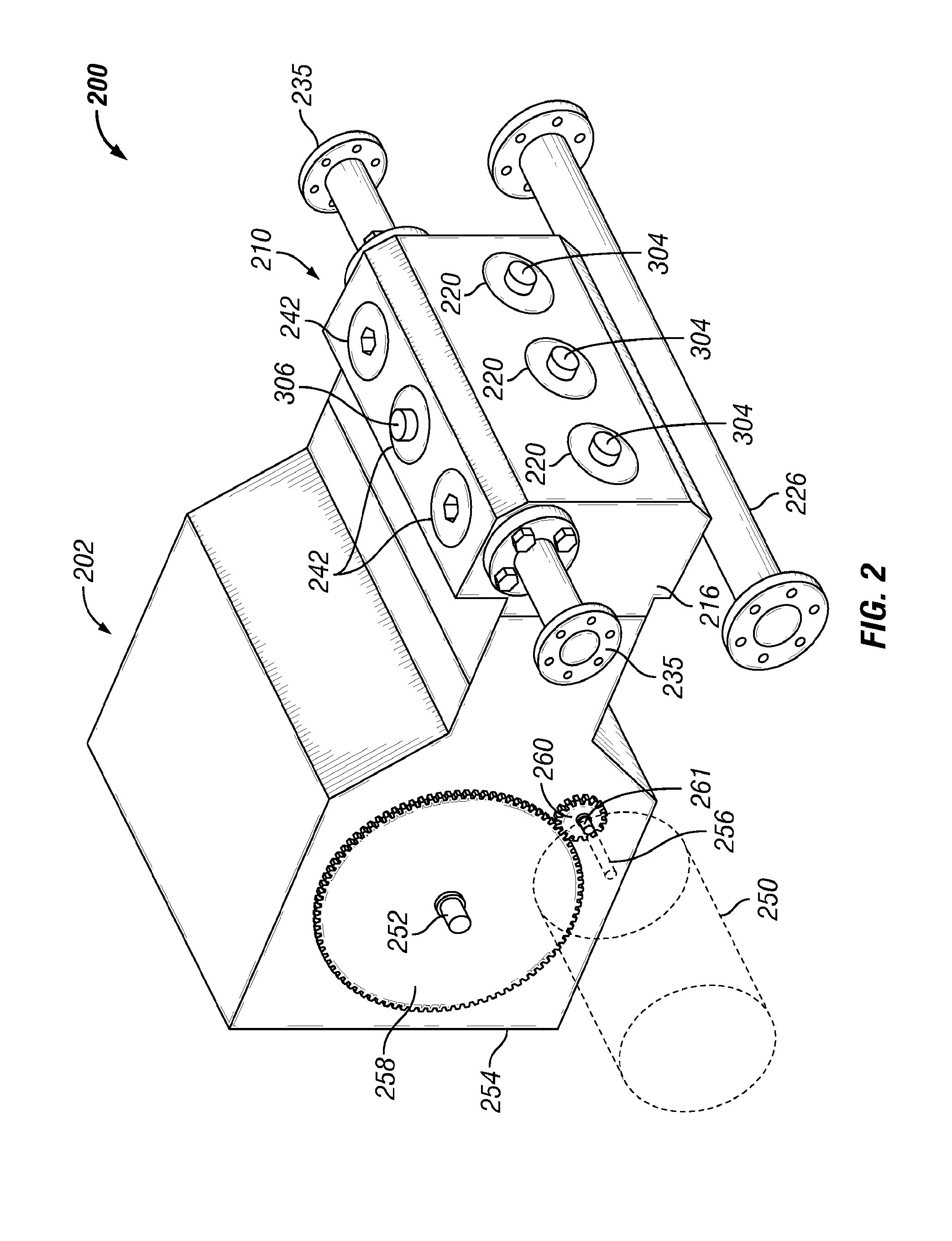

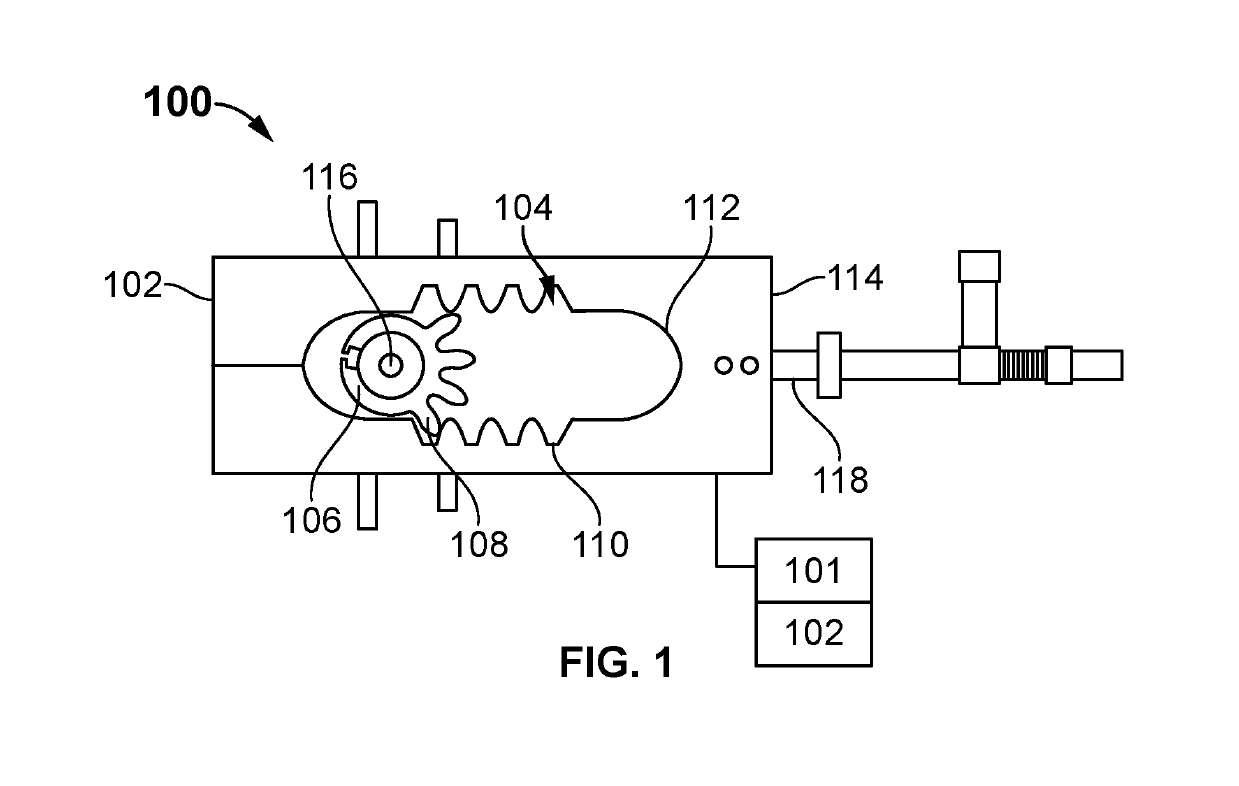

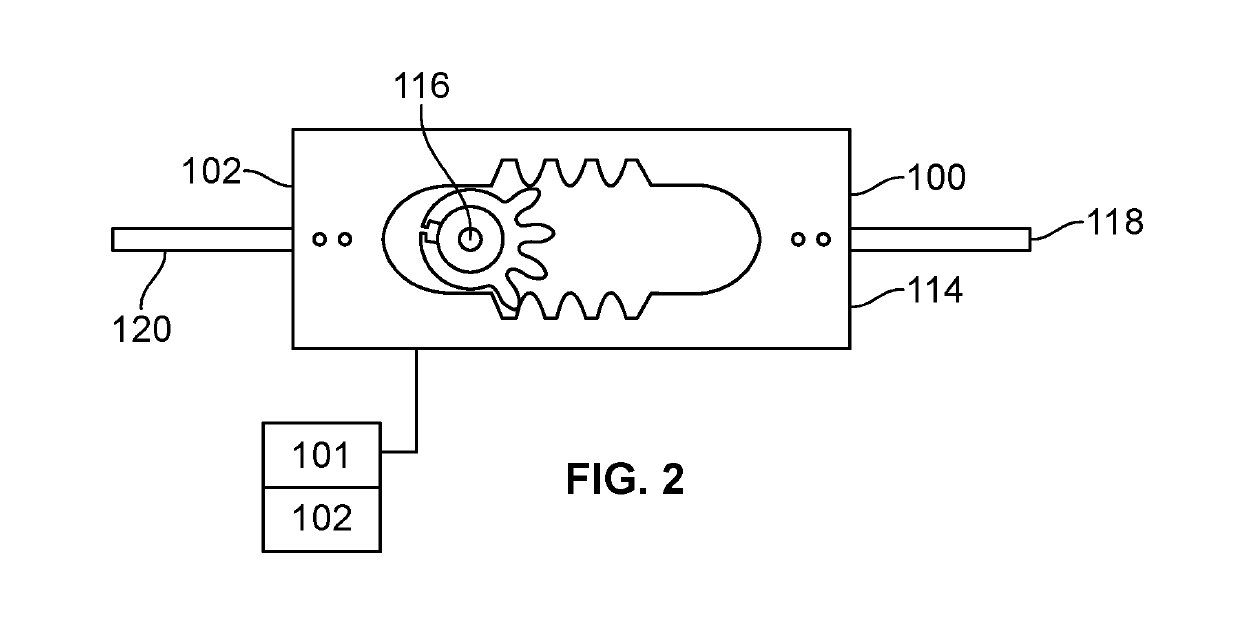

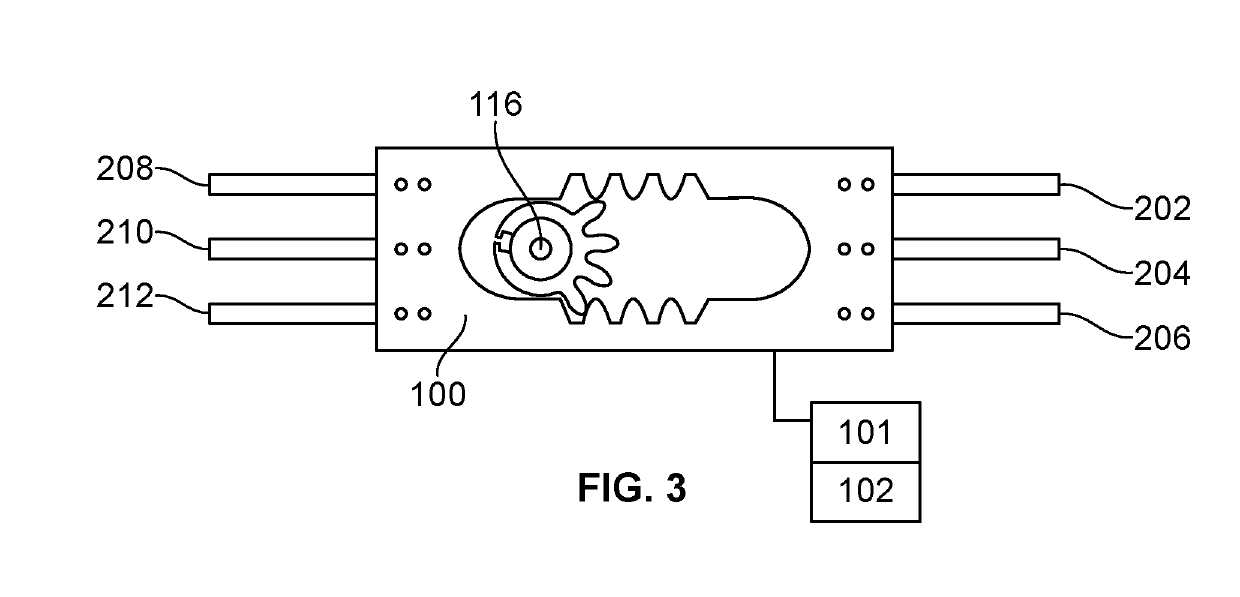

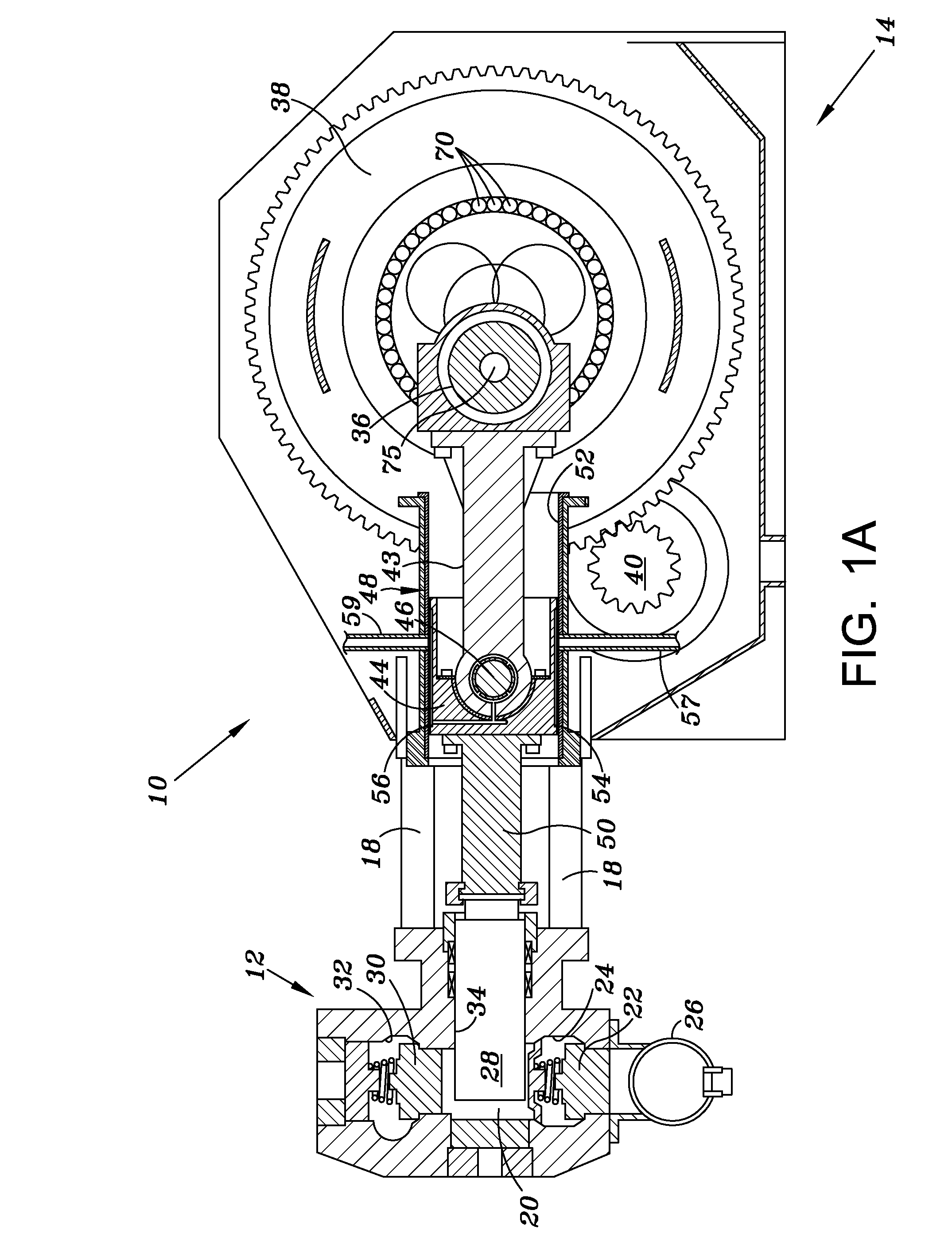

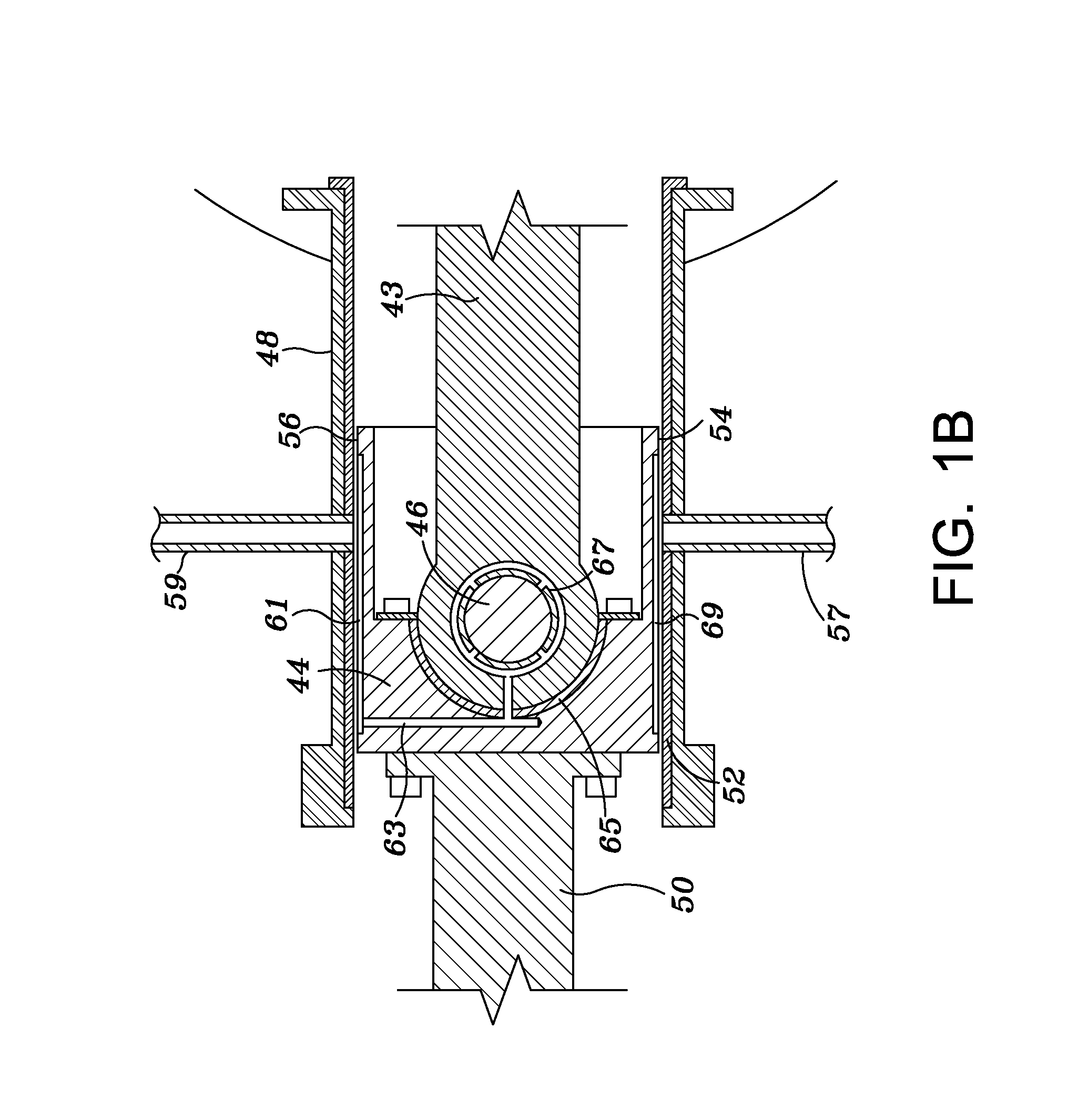

System and Method for a Reciprocating Injection Pump

A reciprocating injection pump is disclosed including but not limited to a reciprocating block driven by a rotating gear, the gear having a substantially circular shape with four gear teeth formed on the rotating gear along approximately one fourth of the substantially circular shape, the rotating gear is attached to a rotating motor, the rotating motor having a right-angle motor shaft.

Owner:PREDOMINANT PUMPS & AUTOMATION SOLUTIONS LLC

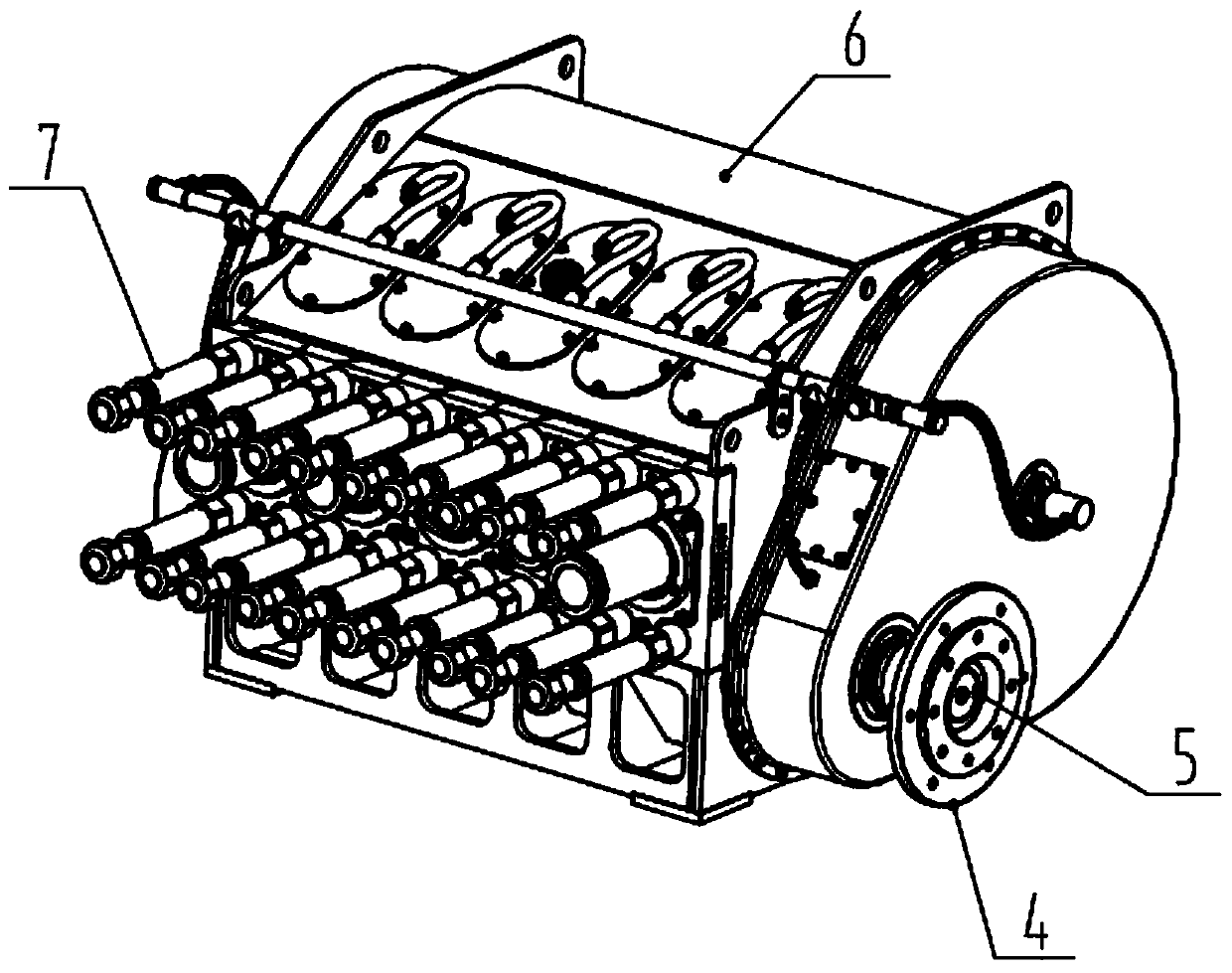

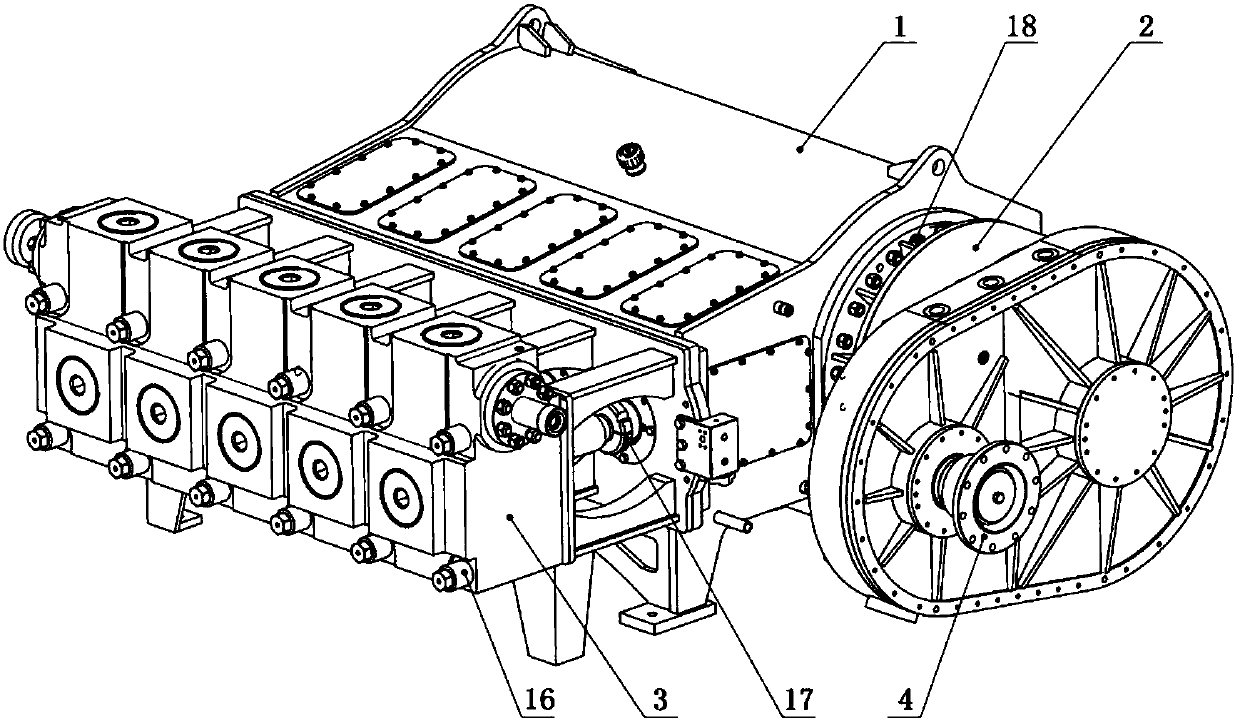

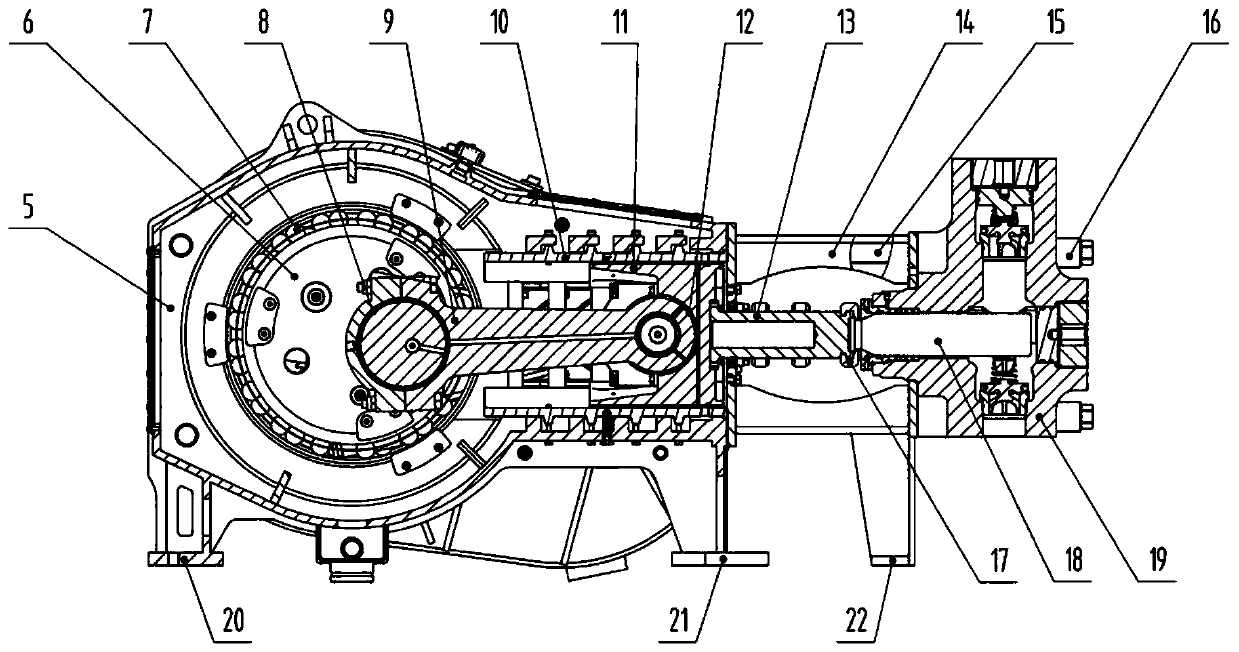

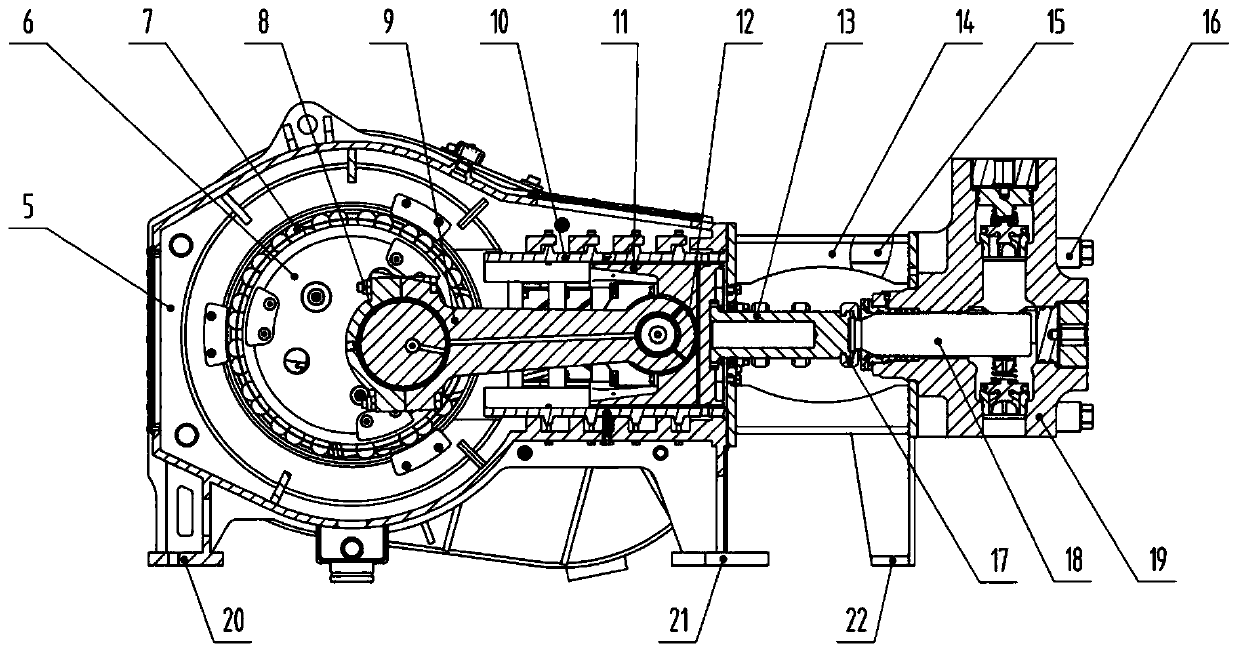

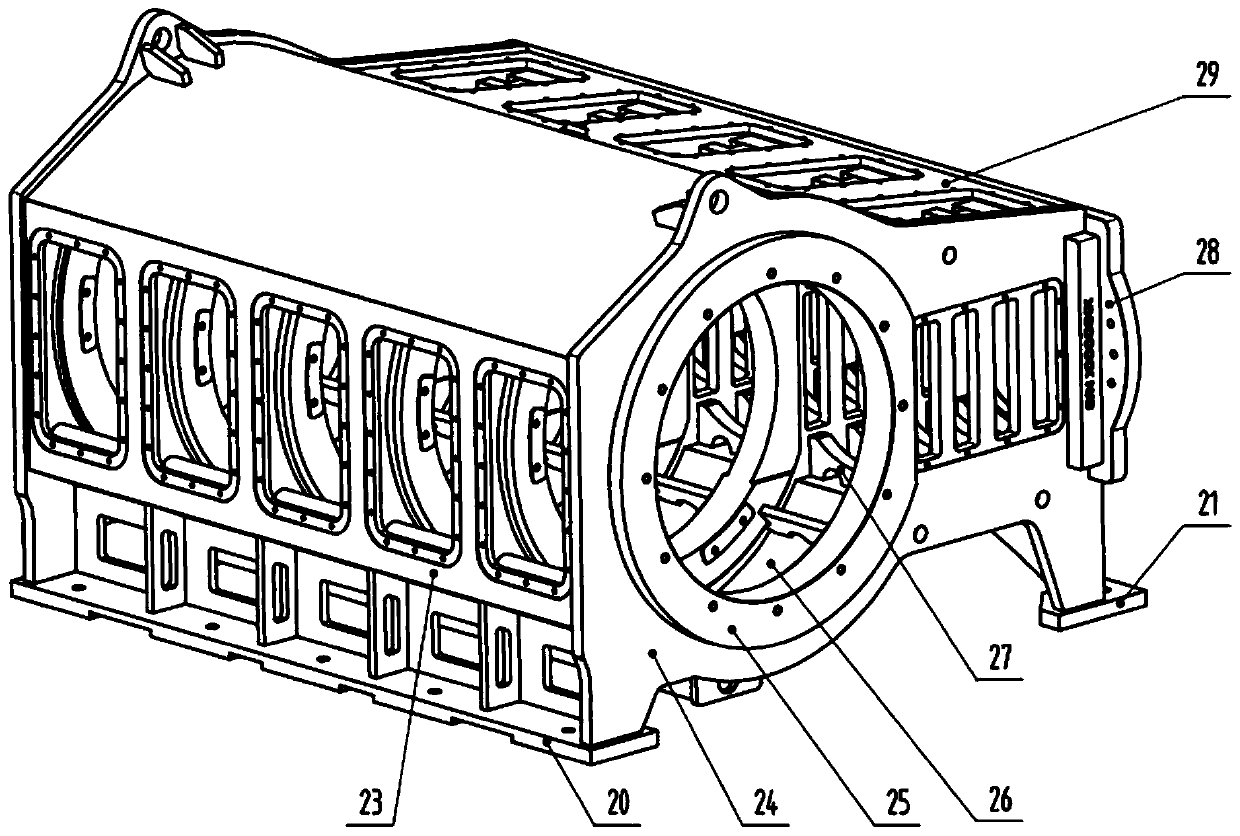

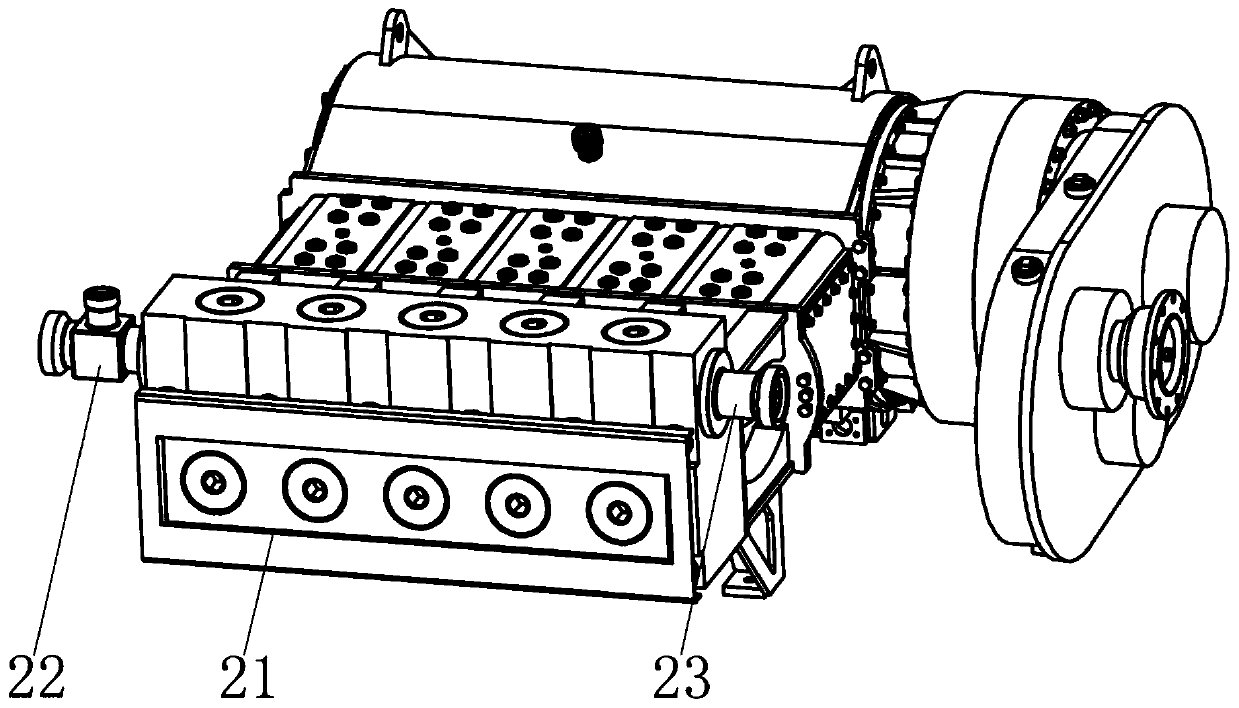

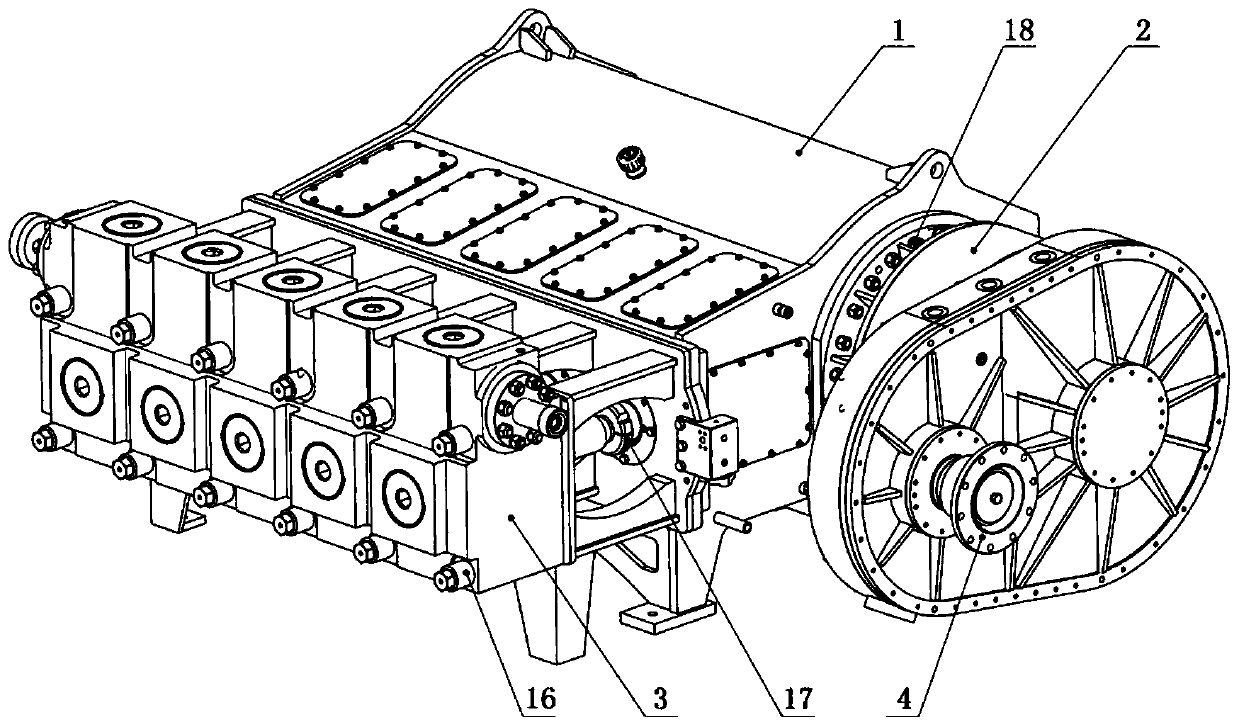

Light five-cylinder plunger pump

PendingCN111441925AIncreased stroke distanceIncrease rated input powerCrankshaftsPositive displacement pump componentsCrankGear wheel

The invention discloses a light five-cylinder plunger pump. The light five-cylinder plunger pump comprises a power end assembly and a hydraulic end assembly, wherein the power end assembly is connected with the hydraulic end assembly; the cylinder spacing of the light five-cylinder plunger pump is 9in; the power end assembly comprises a crank shaft, the crank shaft comprises six crank necks and five crank throws, the crank necks and the crank throws are fixedly connected, the distance between rotating centers of the crank necks and the crank throws is 101.6 mm, and the stroke distance of the light five-cylinder plunger pump is 203.2 mm. According to the light five-cylinder plunger pump, power is increased by increasing stroke, reducing transmission ratio and improving bearing capacity, andmeanwhile, dead weight is reduced by reducing the cylinder spacing, the tooth number of a big gear and the tooth thickness of the big gear and a pinion. The light five-cylinder plunger pump meets conditions of working in the area with severe well cementing operation conditions in aspects of weight and power simultaneously, and working efficiency is increased.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

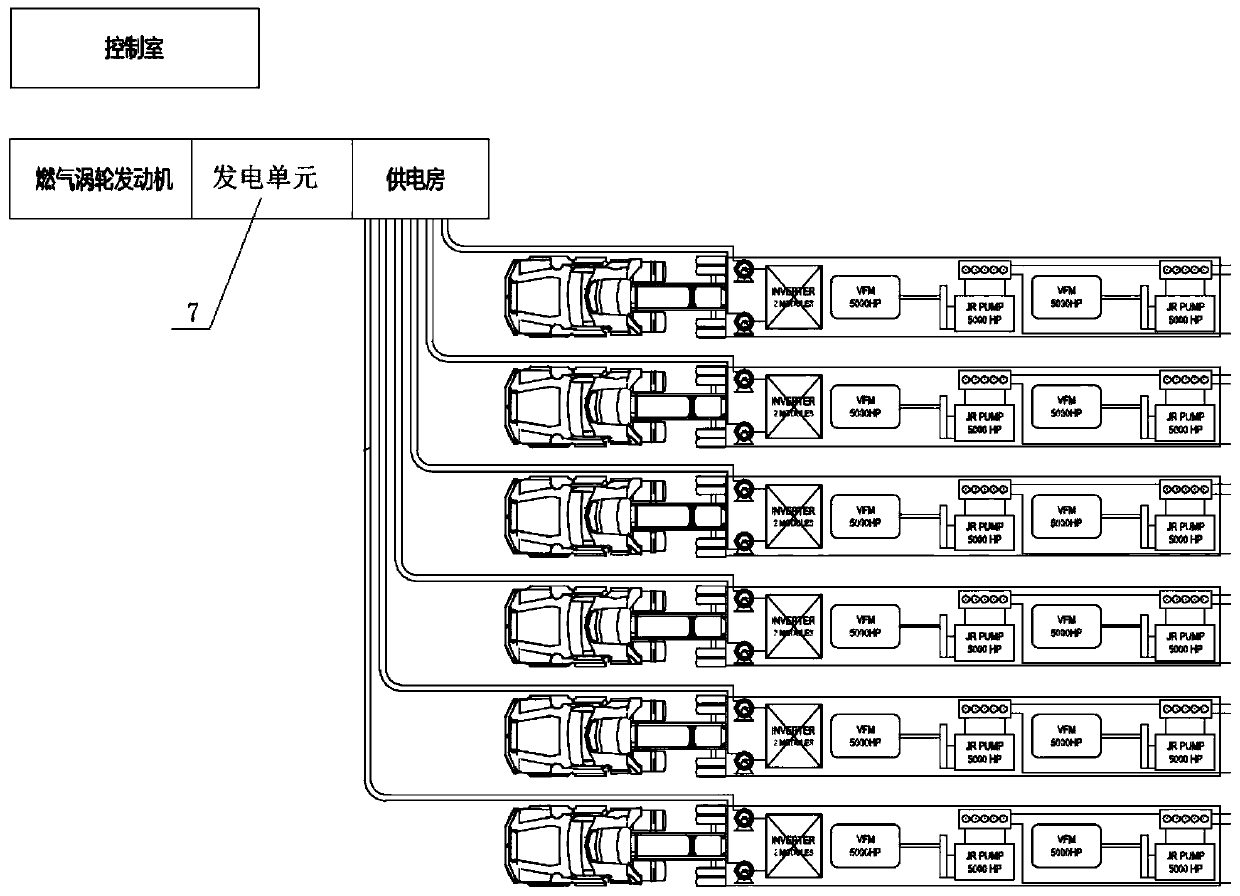

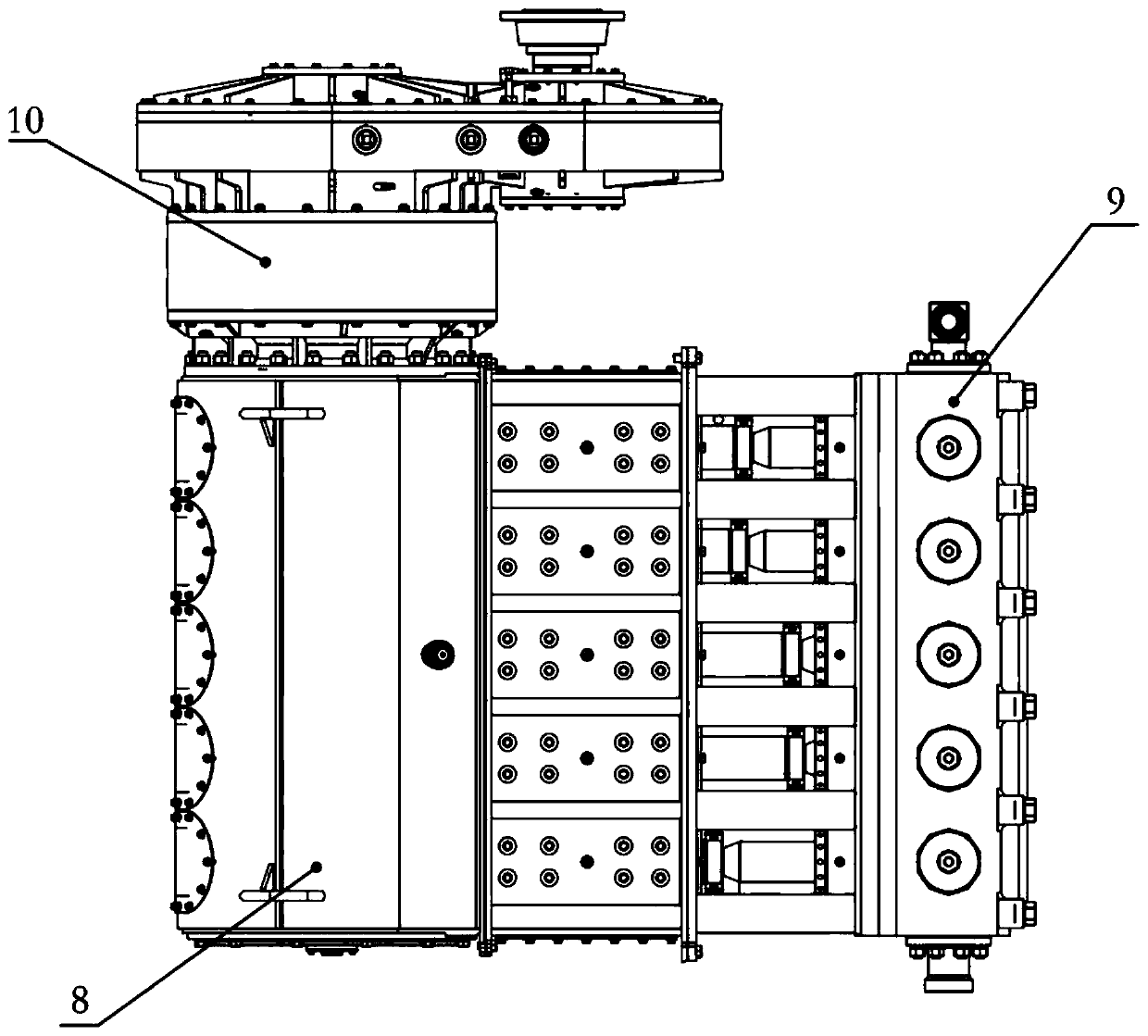

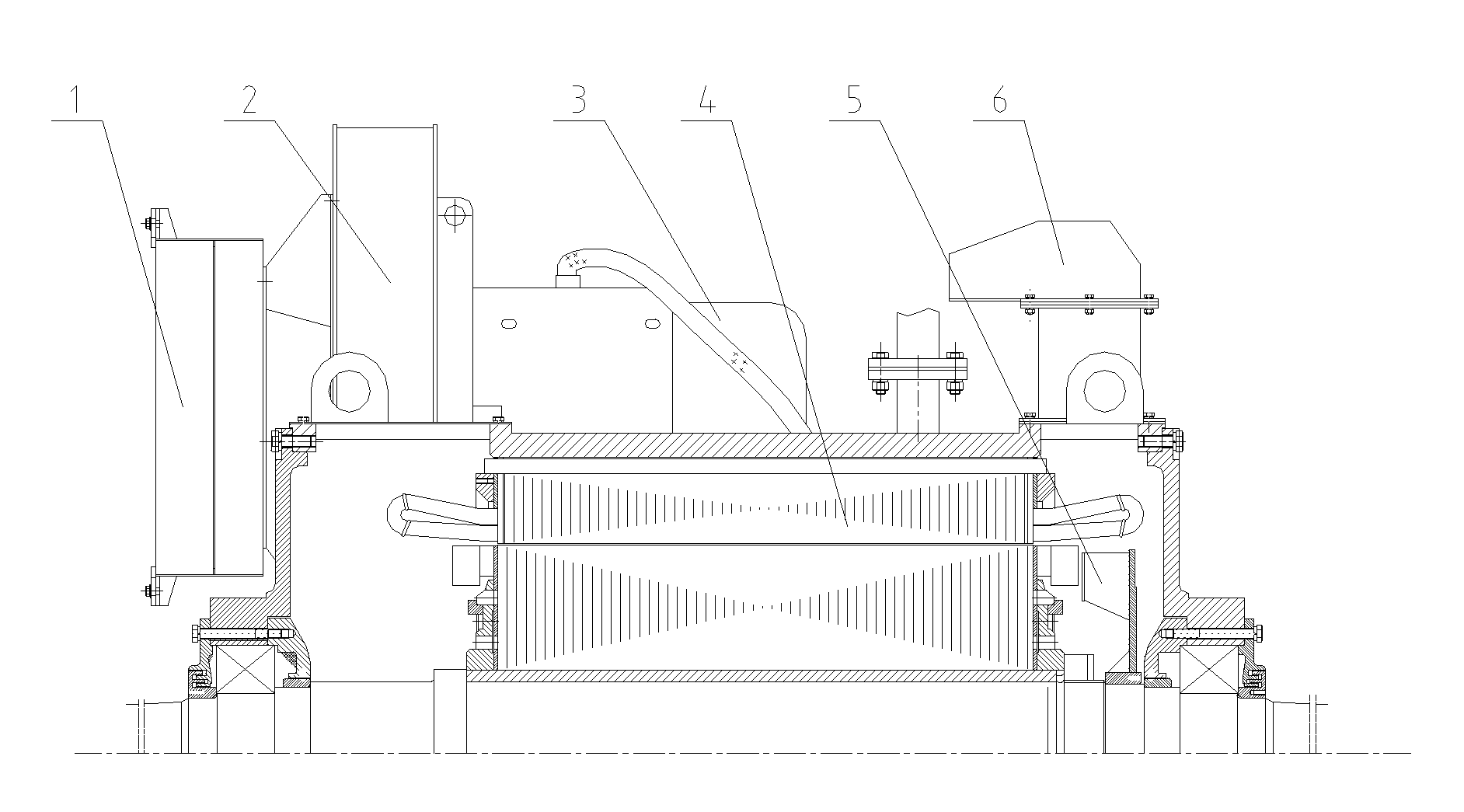

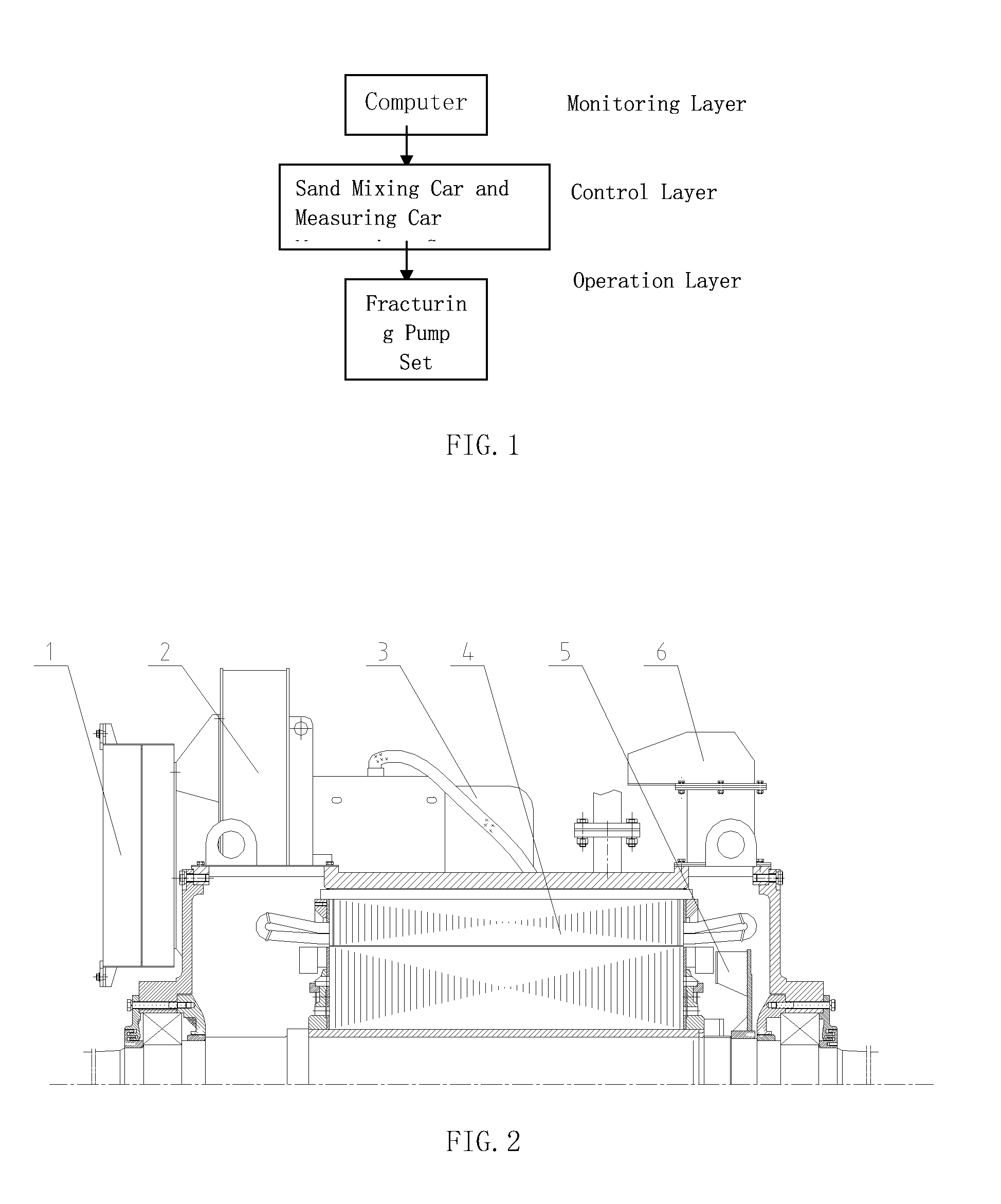

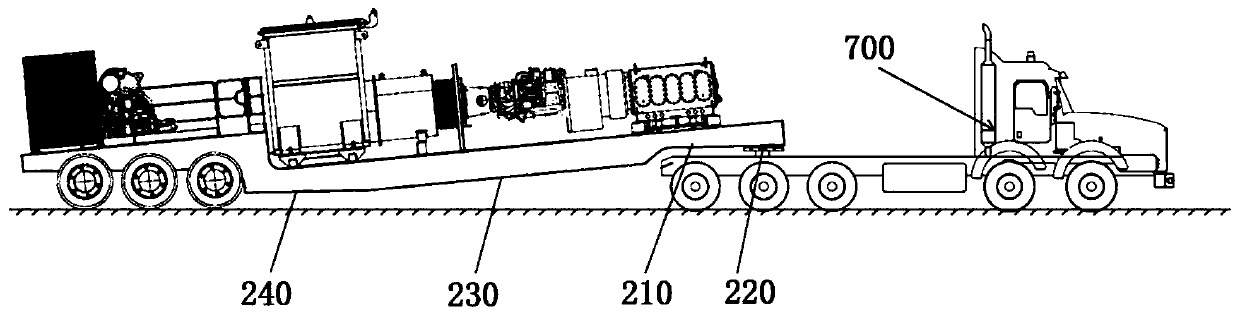

Semitrailer-mounted turbine fracturing equipment

PendingCN110485984AReduce weightLower center of gravityPositive displacement pump componentsFlexible member pumpsOperational costsGravity center

The invention discloses semitrailer-mounted turbine fracturing equipment. Straight-line connection and special chassis design of the whole equipment can double reduce center of gravity of the equipment, stability and safety are better ensured, the structure is simpler, the investment cost and the operation cost are lowered, risks of the whole breakdown of fracturing sites are reduced, transmissionis better, and the semitrailer-mounted turbine fracturing equipment is suitable for continuous operation working conditions with long time and large load. By improving a plunger pump, optimization ofrotating center distances of a crank throw and a crankshaft makes rated power input of the crank throw and the crankshaft increase to 5000-7000 hp, optimization of the transmission ratio of an integrated reduction gearbox on the plunger pump makes the maximum input speed of the integrated reduction gearbox reach 16000 rpm, and ultra-high speed enables reduction gearboxes to be directly connectedwith a turbine engine so as to the solve the problems that turbine fracturing equipment slows down depending on the two reduction gearboxes, and weight of the whole semitrailer is reduced, and boundary dimension of the semitrailer-mounted turbine fracturing equipment is reduced.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

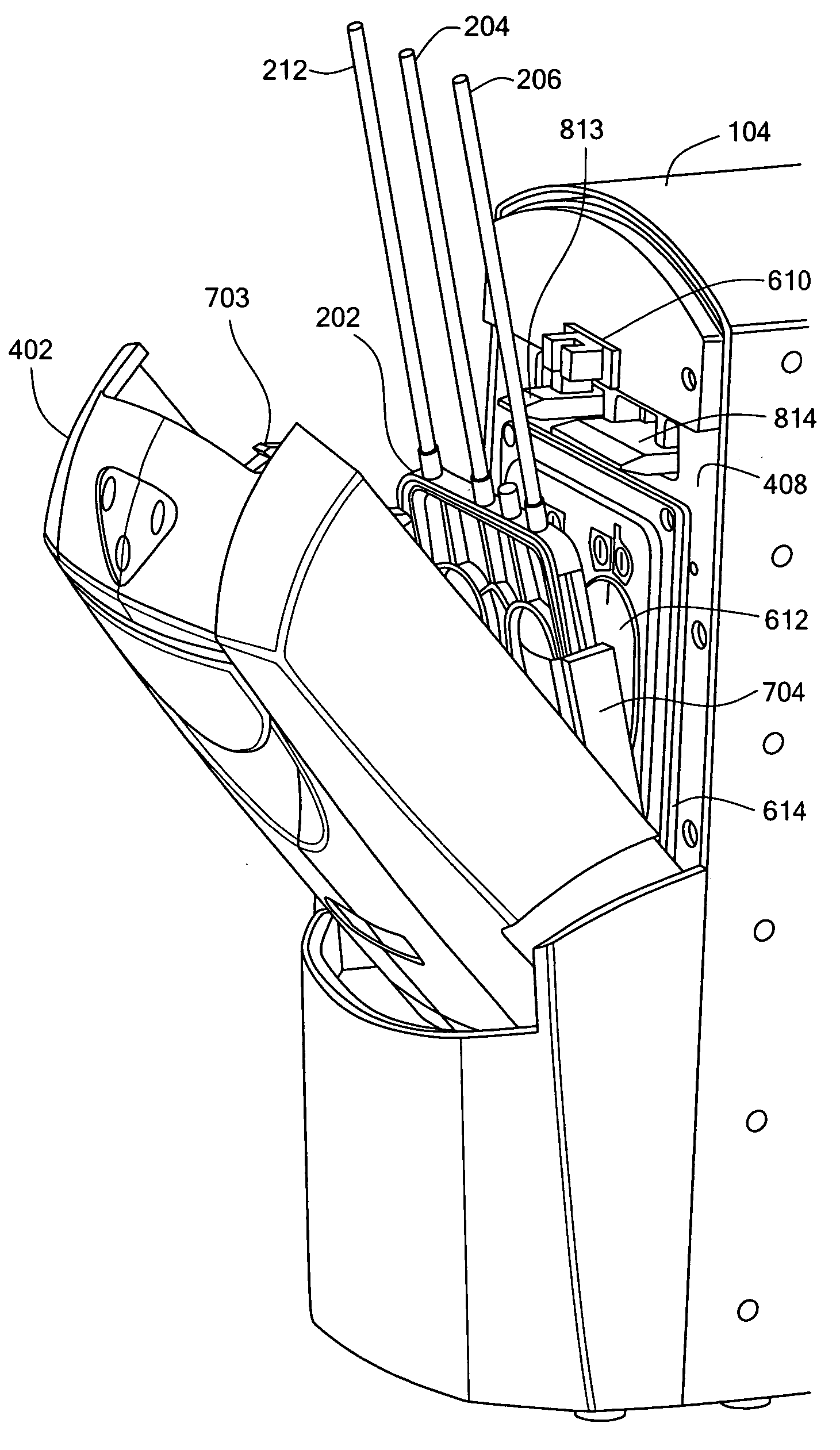

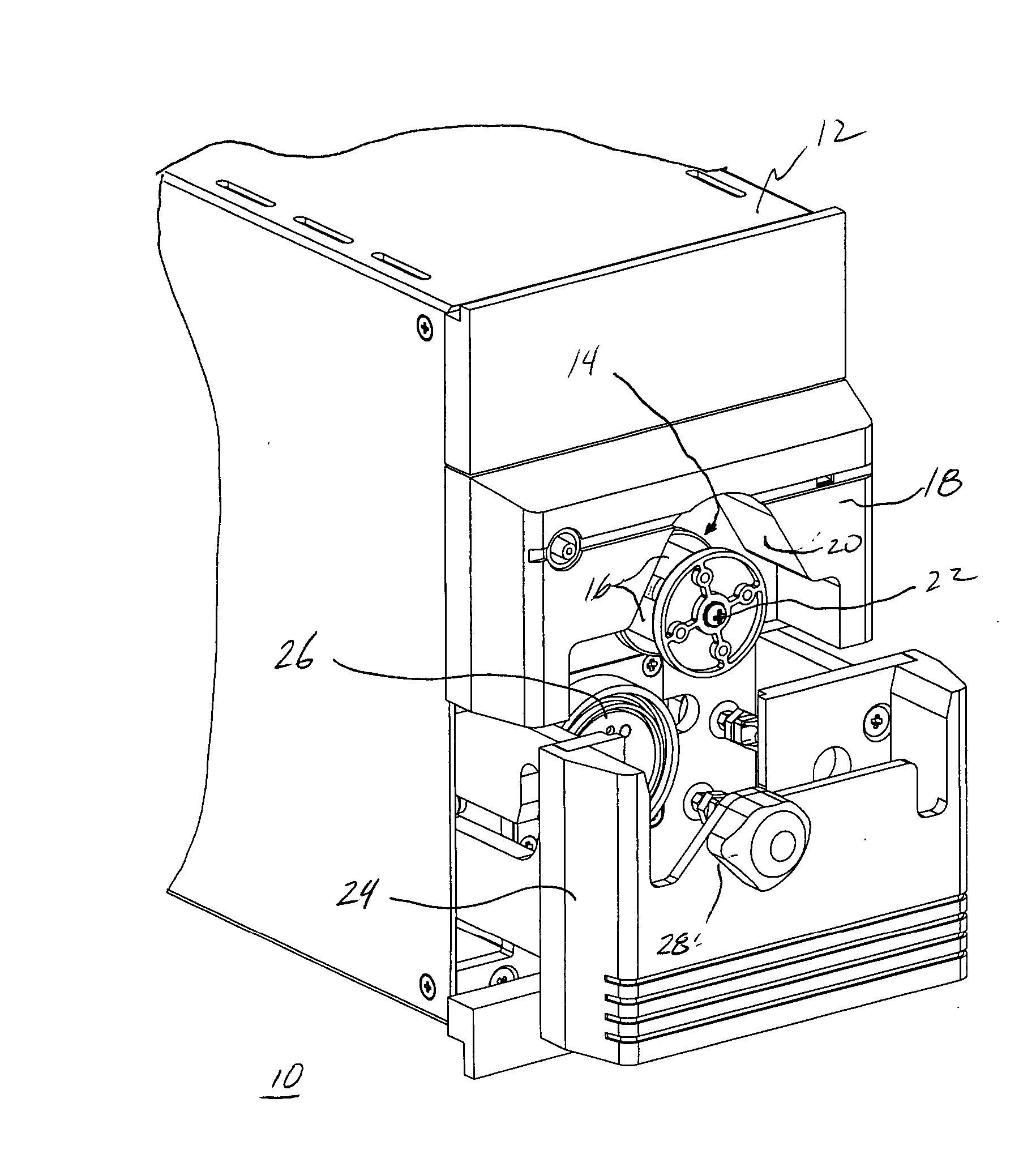

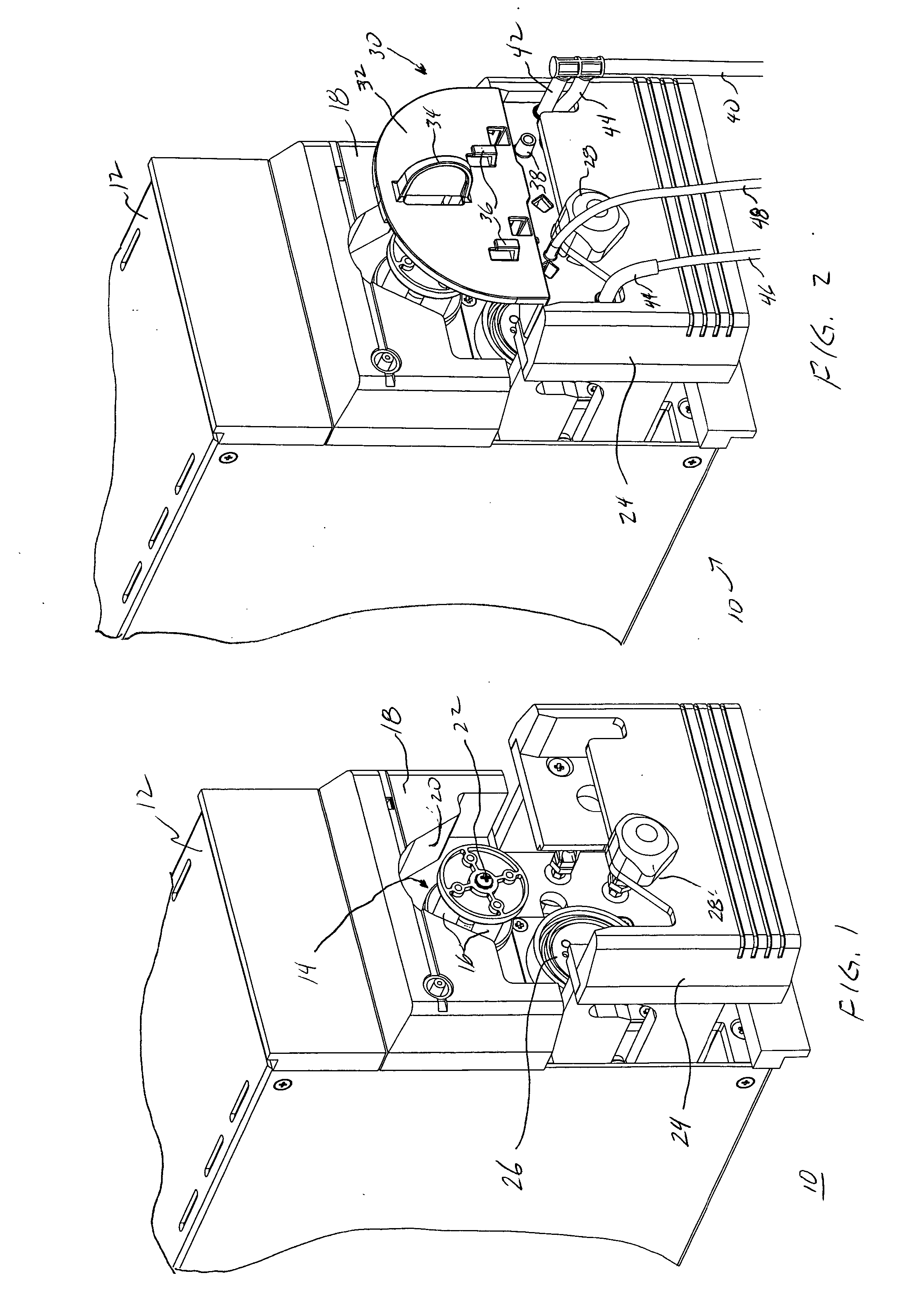

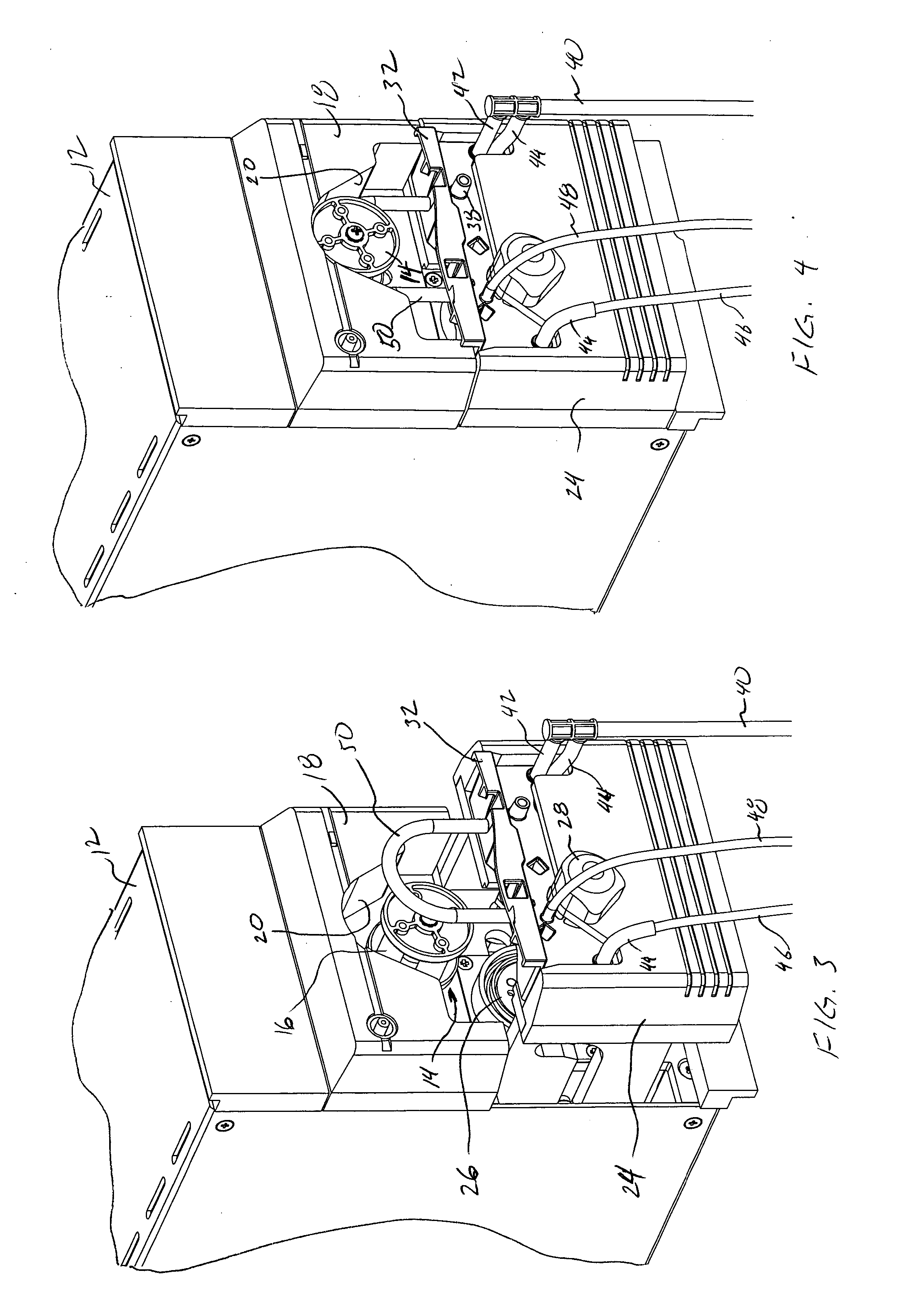

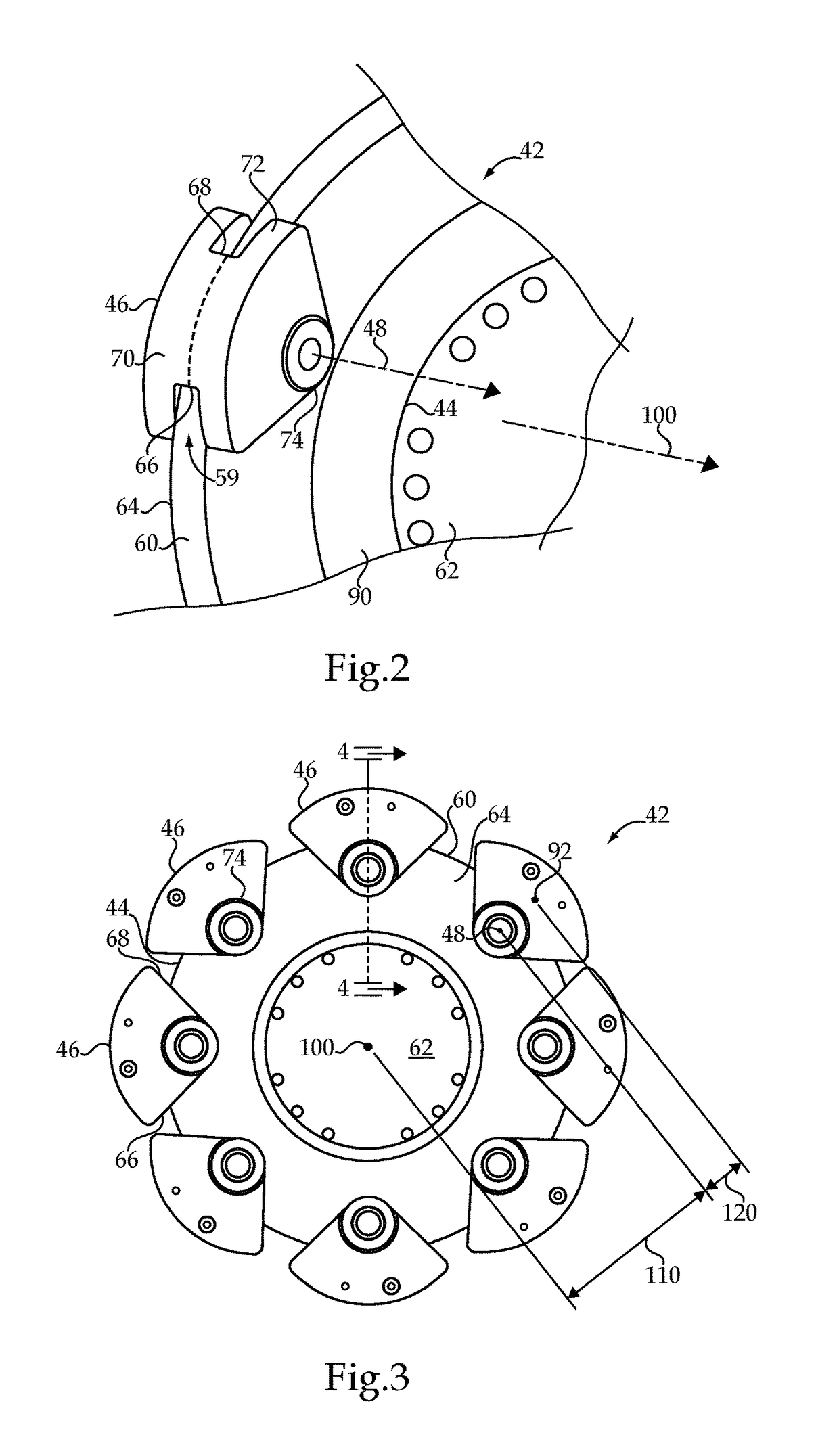

Peristaltic pump with air venting via the movement of a pump head or a backing plate during surgery

ActiveUS20050069419A1Low costShort timePositive displacement pump componentsFlexible member pumpsPeristaltic pumpEngineering

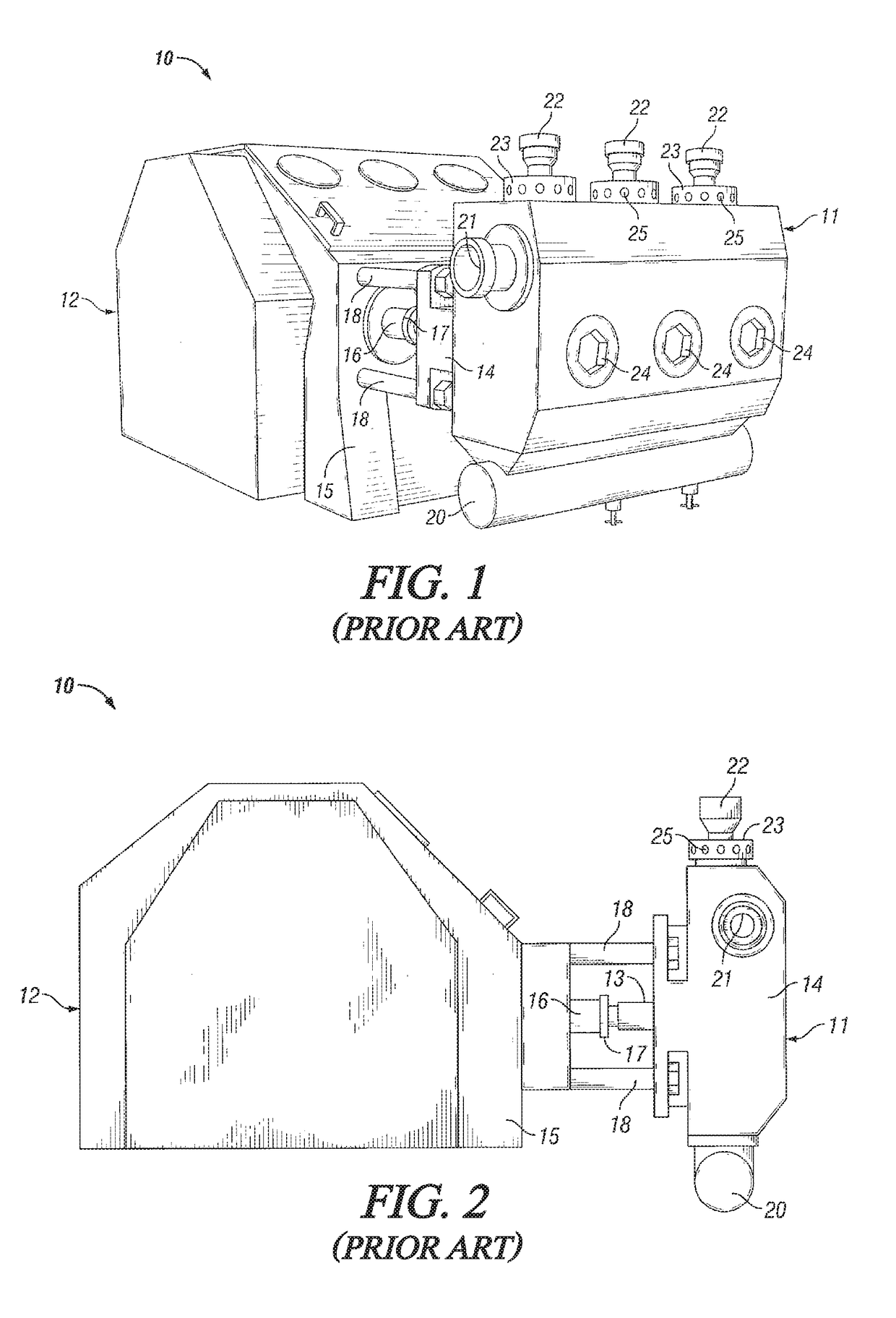

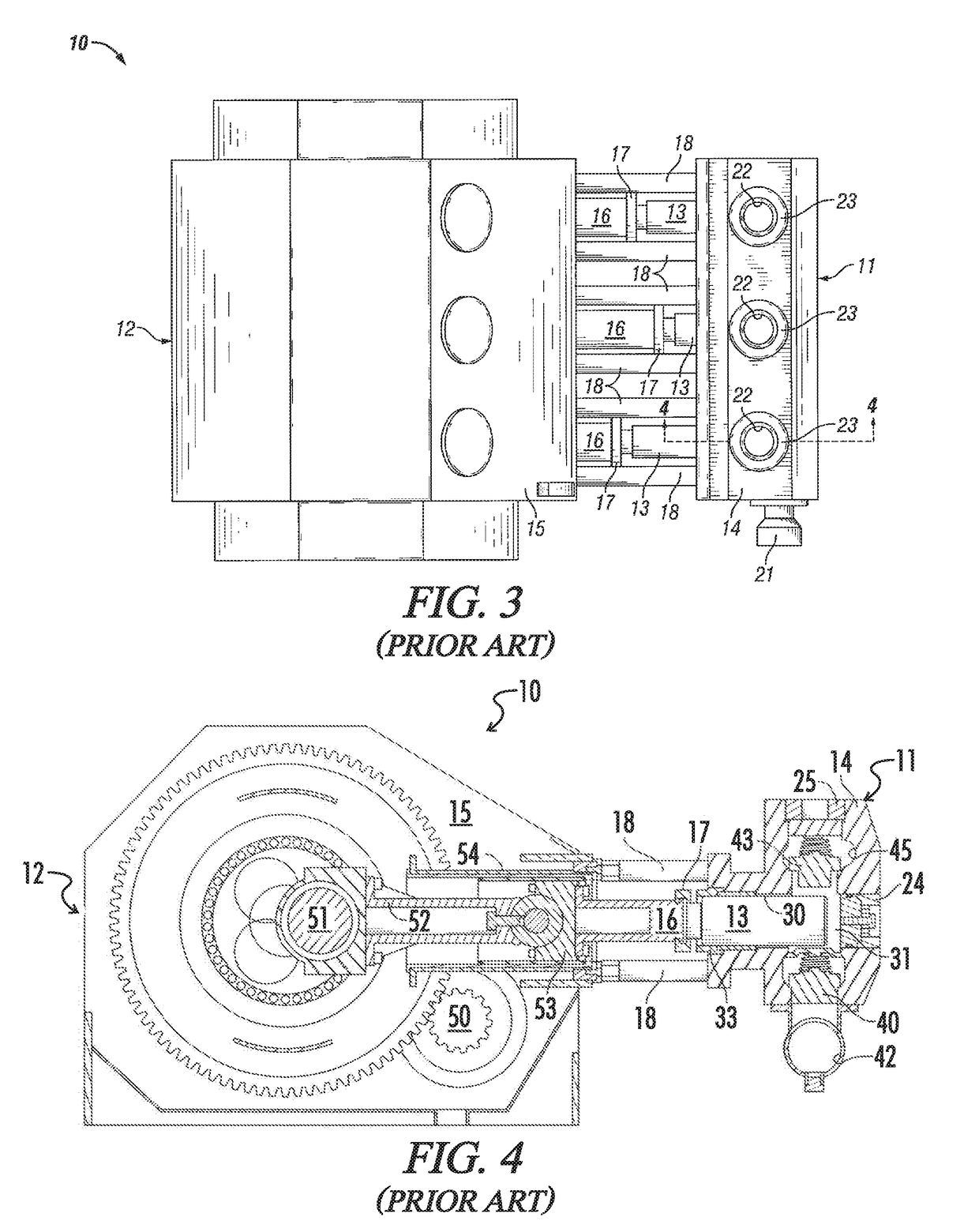

A peristaltic pump 10 for use in ophthalmic surgery includes a housing 12, a pump head 14 having plurality of rollers 16, a backing plate 18 attached to the housing 12, and a length of surgical tubing 50. The rollers 16 and backing plate 18 cooperate to pinch the length of surgical tubing 50 to peristaltically pump fluids from a surgical site to a collection bag 64. At least one of the pump head 14 and the backing plate 18 is moveable, during operation of the pump 10, from a tubing pinched position to a tubing vent position. This movement allows the tubing 50 to be vented by removing the pinched closure of the tubing 50.

Owner:BAUSCH & LOMB INC

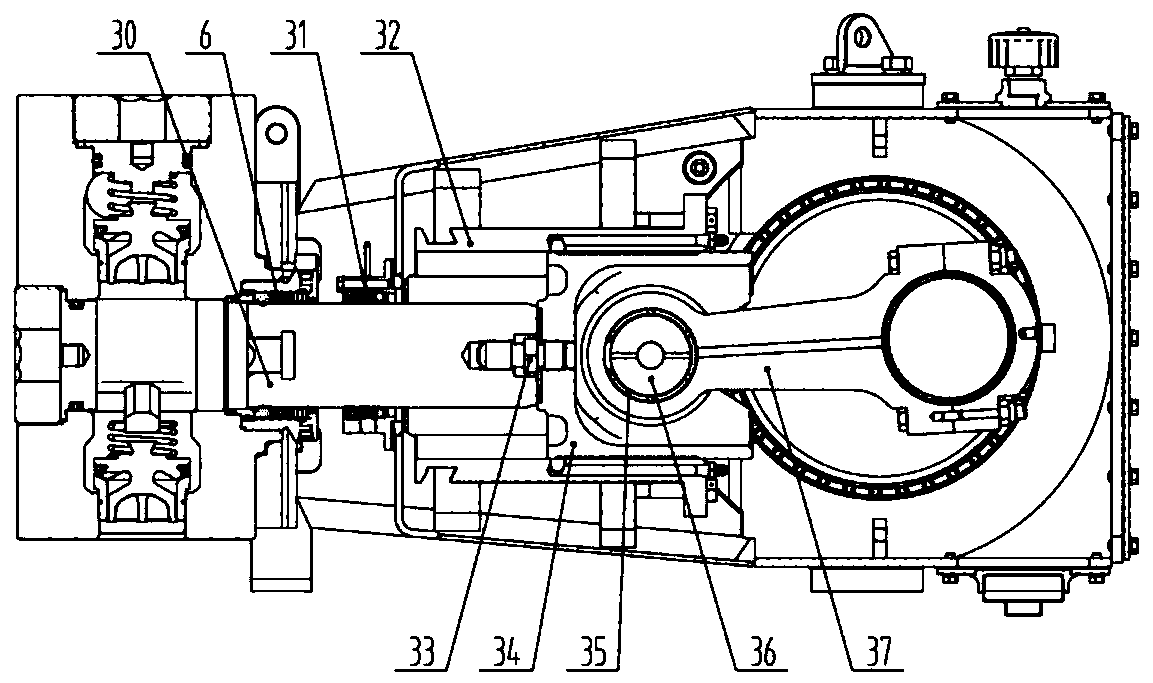

High-power five-cylinder plunger pump

PendingCN110617187AIncrease the carrying areaOptimize layoutPositive displacement pump componentsFluid removalEngineeringMechanical engineering

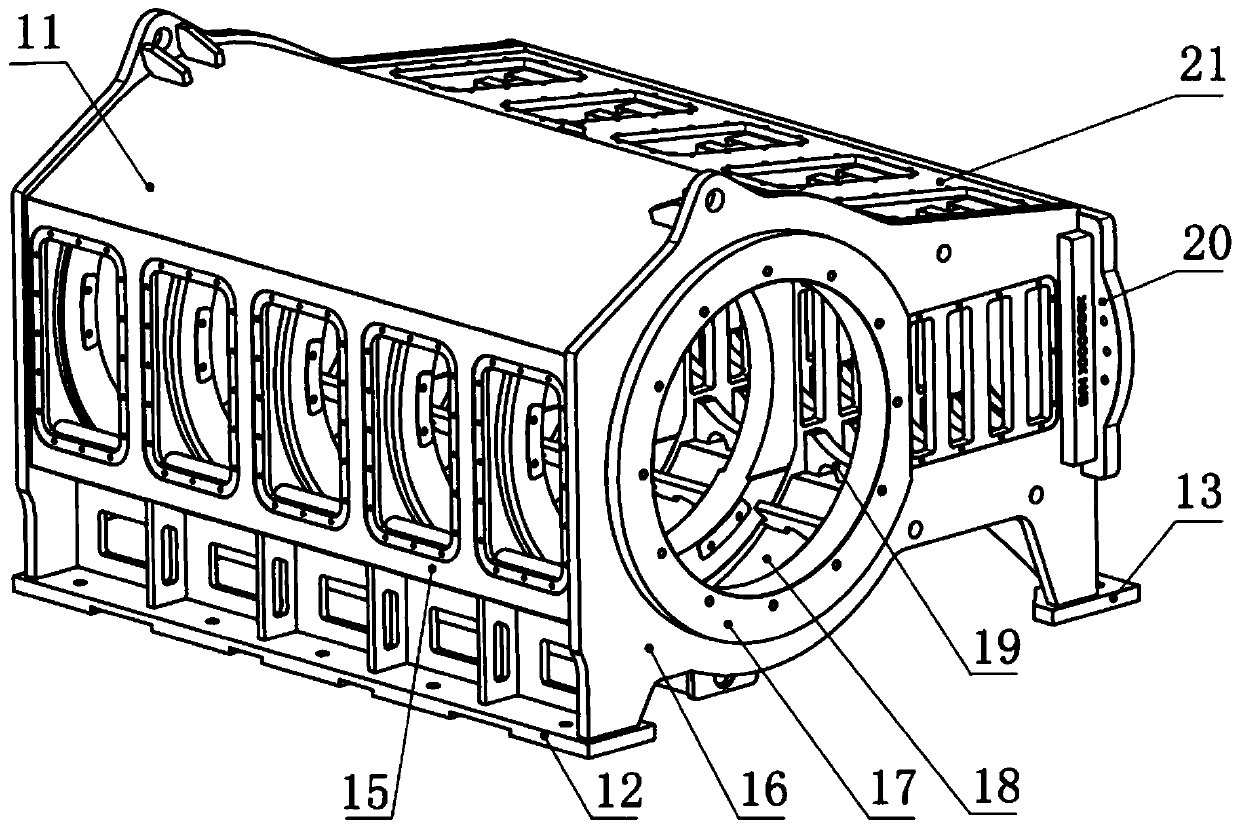

The invention discloses a high-power five-cylinder plunger pump. The plunger pump comprises a power end assembly, a hydraulic end assembly and a reduction gearbox assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a spacer frame; the crankshaft box body, the crosshead box body and the spacer frame are sequentially connected; the hydraulic end assembly is fixed on the spacer frame; the reduction gearbox assembly is fixed on the crankshaft box body; and the cylinder spacing of the five-cylinder plunger pump is 13-14 inches, so that a guarantee is provided for the output of high power of the five-cylinder plunger pump. According to the high-power five-cylinder plunger pump, the problems that the area of a shale gas fracturing well site is narrowand the number of required fracturing equipment is relatively large are effectively solved, thus reducing the use of equipment, and facilitating the arrangement of the well site.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

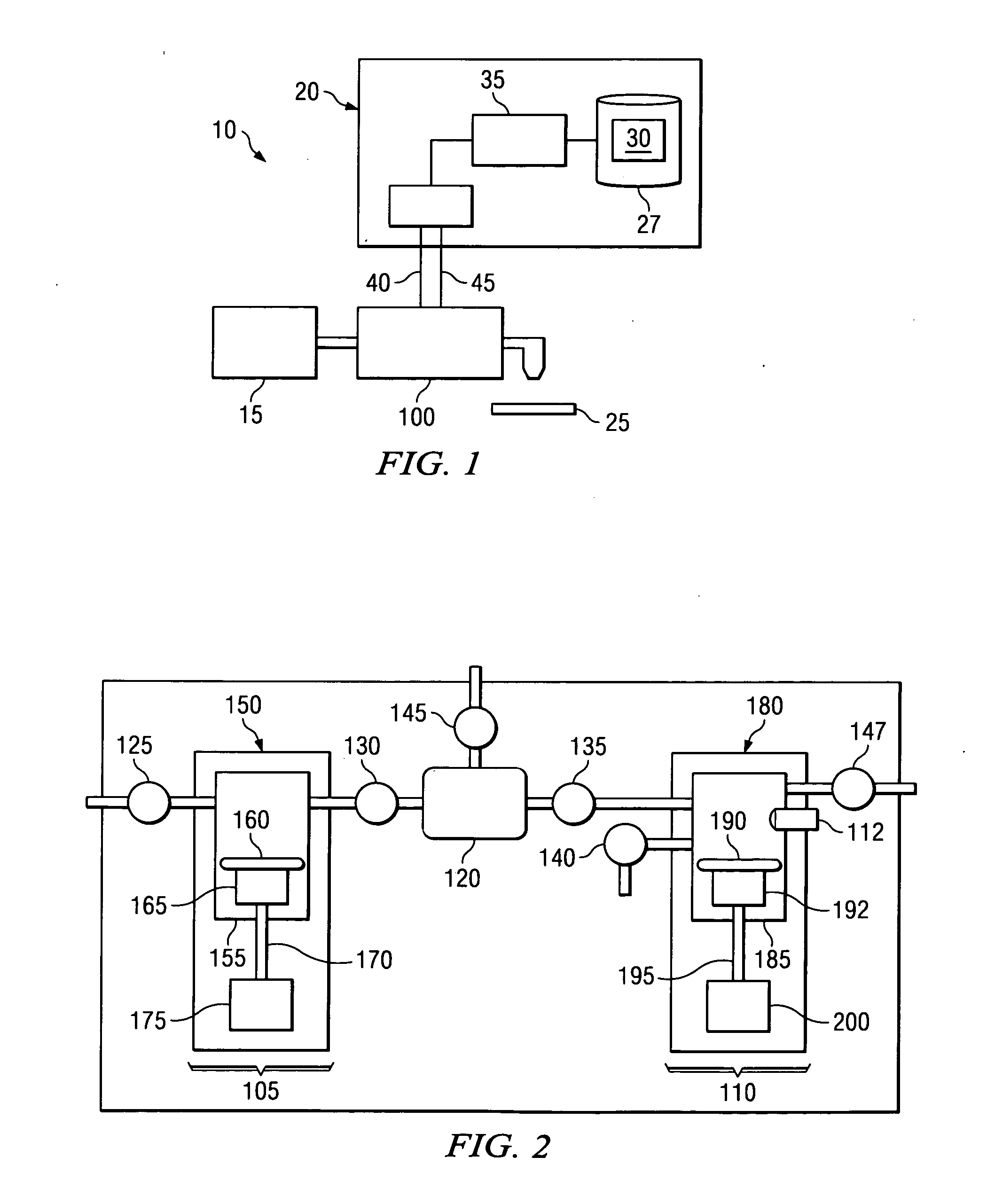

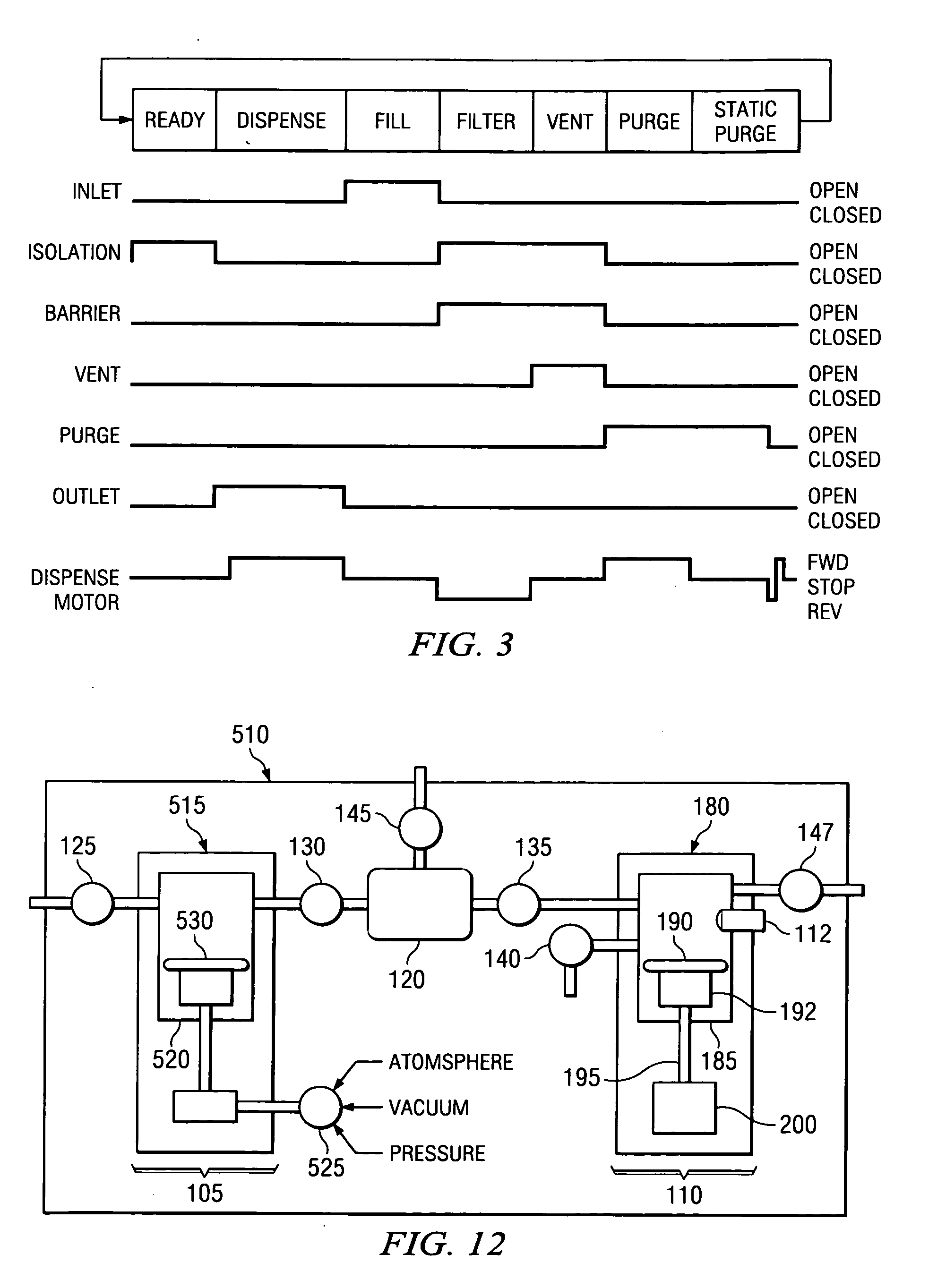

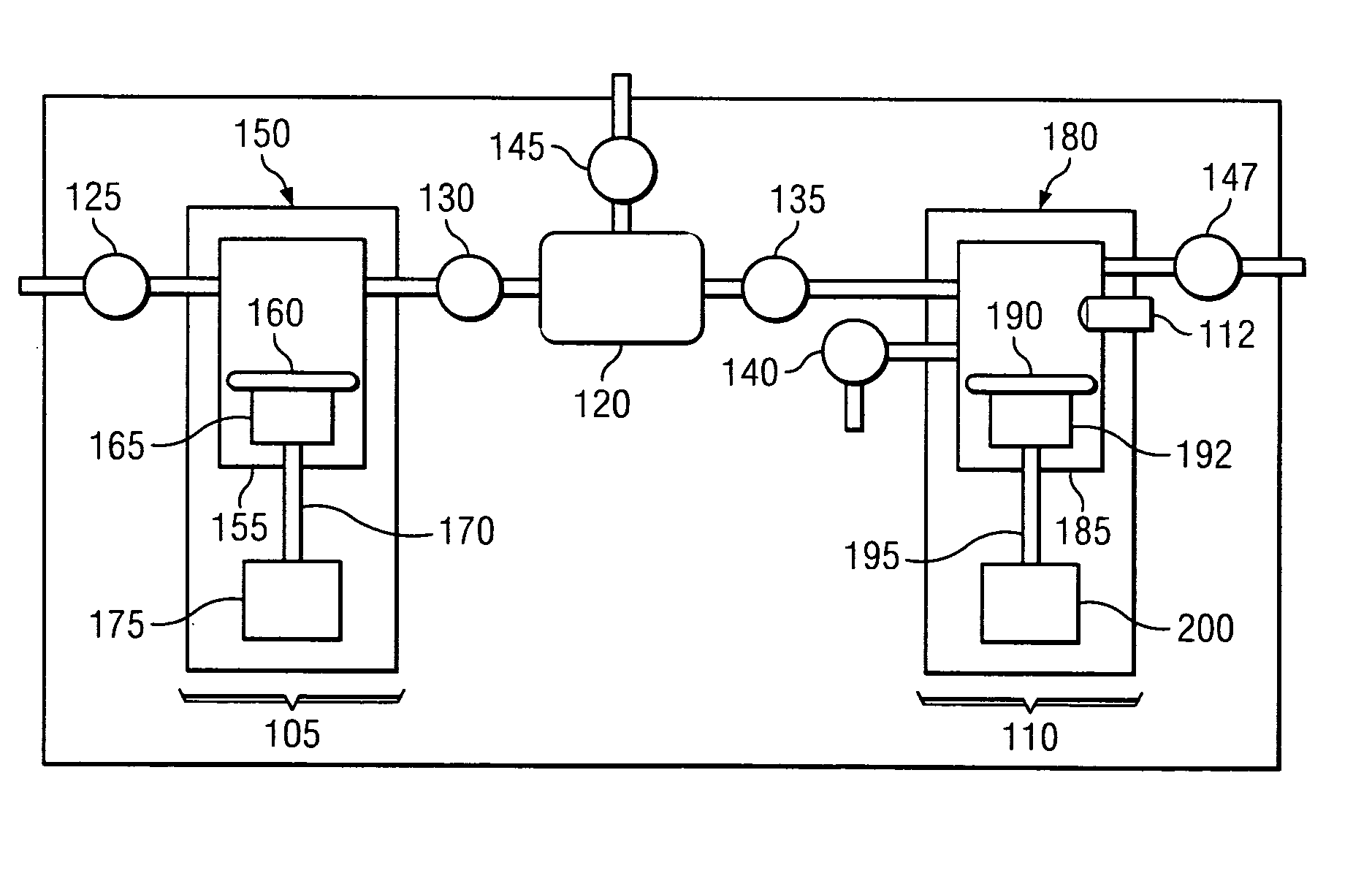

System and method for control of fluid pressure

ActiveUS20070128046A1Gentler handlingEliminates and reduces disadvantageFluid parameterFlexible member pumpsPressure decreaseEngineering

Embodiments of the present invention are related to a pumping system that accurately dispenses fluid using a multiple stage (“multi-stage”) pump. More particularly, embodiments of the present invention provide for control of a feed stage pump to regulate fluid pressure at a downstream dispense stage pump. According to one embodiment of the present invention, a pressure sensor at the dispense stage pump determines the pressure in a dispense chamber. When the pressure reaches a predefined threshold, the dispense stage pump can begin to increase the available volume of the dispense chamber, thereby causing the pressure in the dispense chamber to drop. As the pressure decreases / increases at the downstream pump, the pressure applied by the upstream pump can bed increased / decreased.

Owner:ENTEGRIS INC

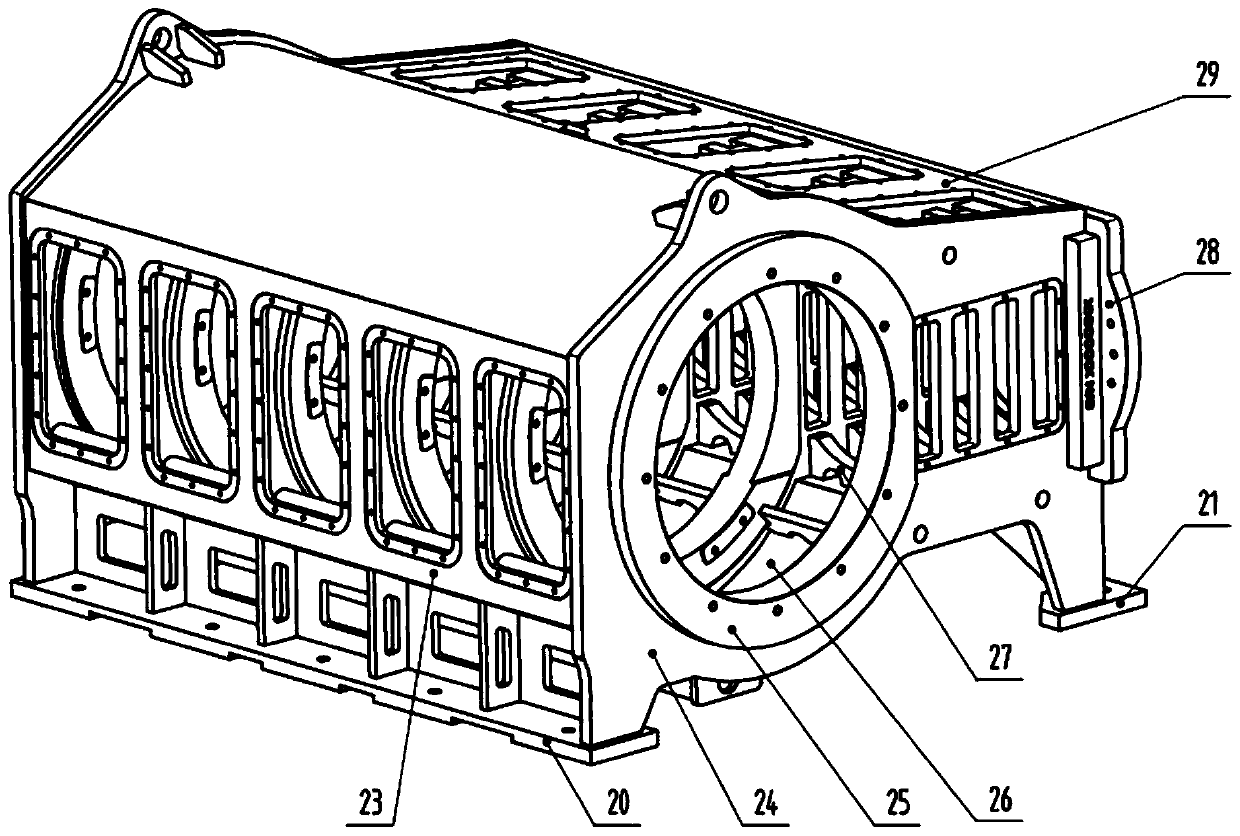

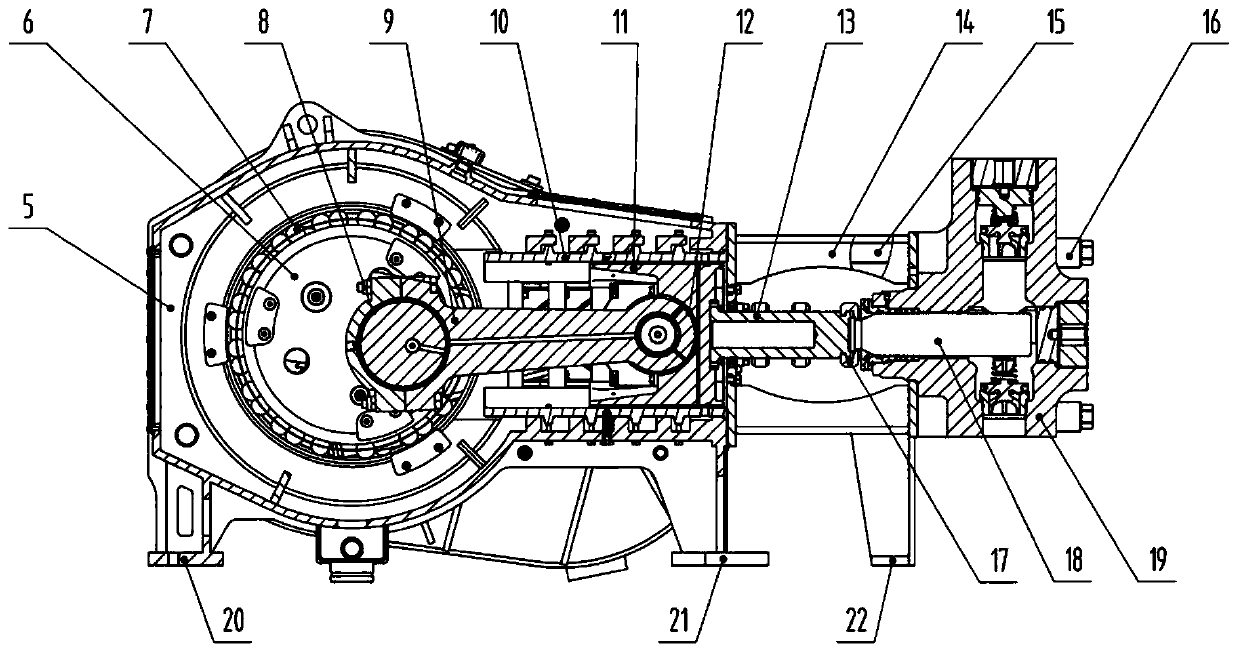

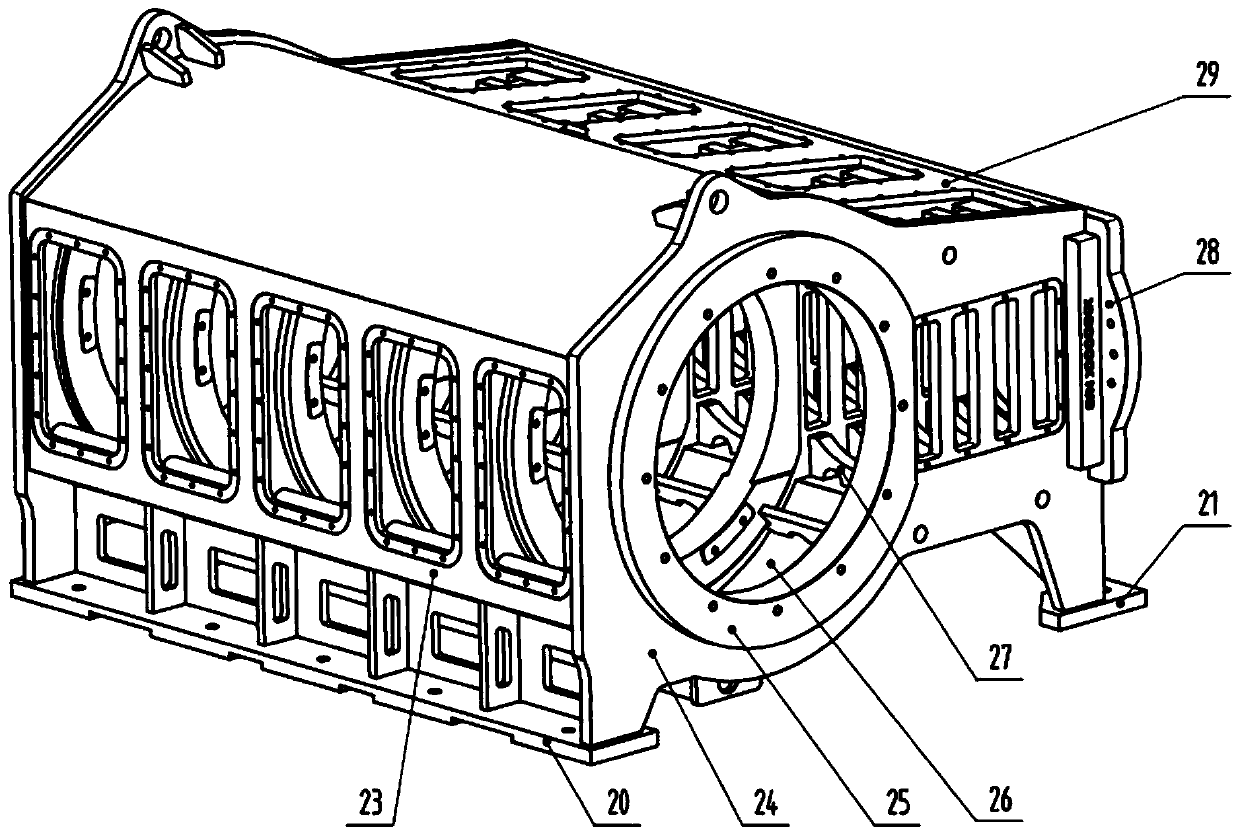

Five-cylinder plunger pump with integral power end structure

PendingCN110617318AExtended service lifeLow strokeCrankshaftsConnecting rod bearingsCrankcaseHigh load

The invention discloses a five-cylinder plunger pump with an integral power end structure. According to the five-cylinder plunger pump, an integral welding structure is adopted for a crankshaft box body and a crosshead box body in a five-cylinder plunger pump power end assembly, so that the structural strength of the power end assembly is higher, the supporting stability is better, and the whole pump vibration can be reduced; the cylinder spacing is 13-14 inches, the bearing area of connecting rods, crossheads and bearing bushes is increased, a guarantee is provided for the output of the high-power of the five-cylinder plunger pump, the high-power five-cylinder plunger pump can effectively solve the problem that the shale gas fracturing well site area is narrow and the required fracturingequipment is relatively large, the use of equipment can be reduced, and the wellsite arrangement is facilitated; the 11-inches long-stroke design can better realize large-displacement operation requirements and improve the operation efficiency; and according to the multi-point supporting design of crankcase bodies, crosshead box bodies and the hydraulic end assembly, the supporting strength of thefive-cylinder plunger pump can be improved, the vibration is reduced, the high-load operation is better guaranteed, and the operation is more stable.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

System and method for monitoring operation of a pump

Systems and methods for monitoring operation of a pump, including verifying operation or actions of a pump, are disclosed. A baseline profile for one or more parameters of a pump may be established. An operating profile may then be created by recording one or more values for the same set of parameters during subsequent operation of the pump. The values of the baseline profile and the operating profile may then be compared at one or more points or sets of points. If the operating profile differs from the baseline profile by more than a certain tolerance an alarm may be sent or another action taken, for example the pumping system may shut down, etc.

Owner:ENTEGRIS INC

Pumping system, vibration limiting device, and method

ActiveUS20170335842A1Positive displacement pump componentsPiston pumpsVibration amplitudeEngineering

A mechanism for limiting vibration amplitudes in a pumping system includes a plurality of pendulum absorbers coupled with a carrier and each having a pivoting range. The pendulum absorbers each further include a first and a second contact surface that contacts an outer peripheral surface of the carrier at limit stop positions, and each having a shape that is conforming with a shape of the outer peripheral surface. The pumping system may be used for pumping liquid nitrogen.

Owner:CATERPILLAR INC

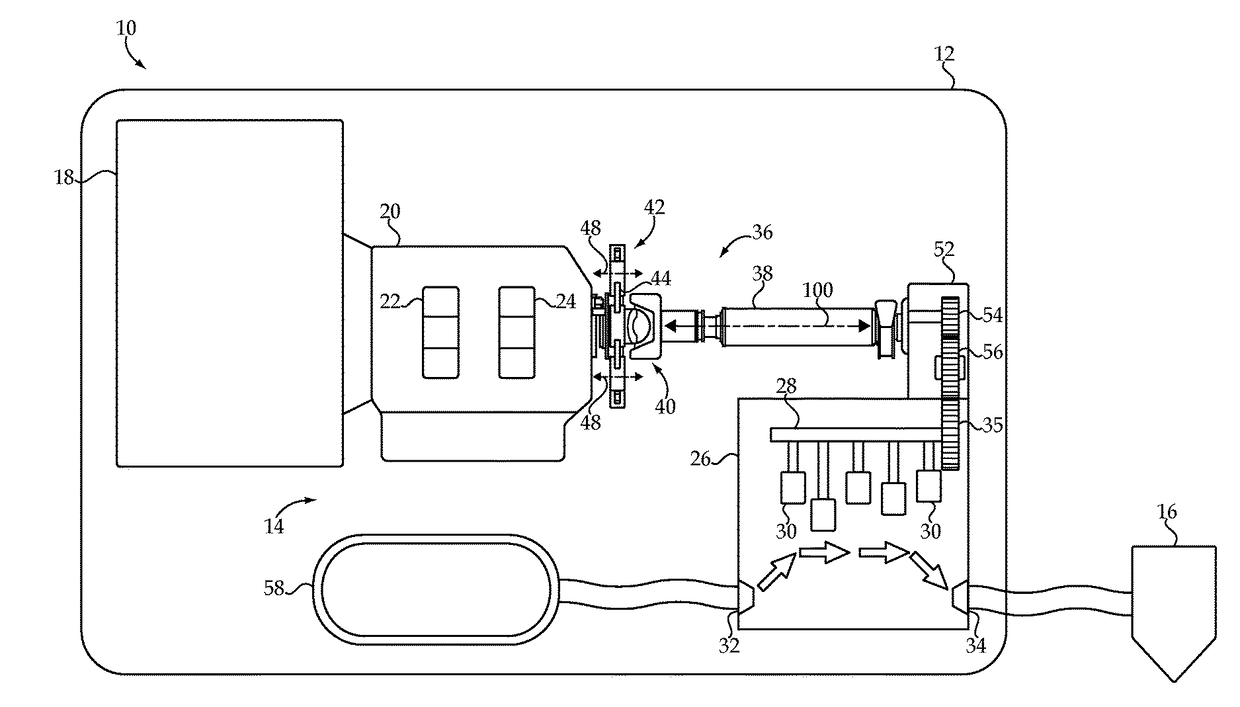

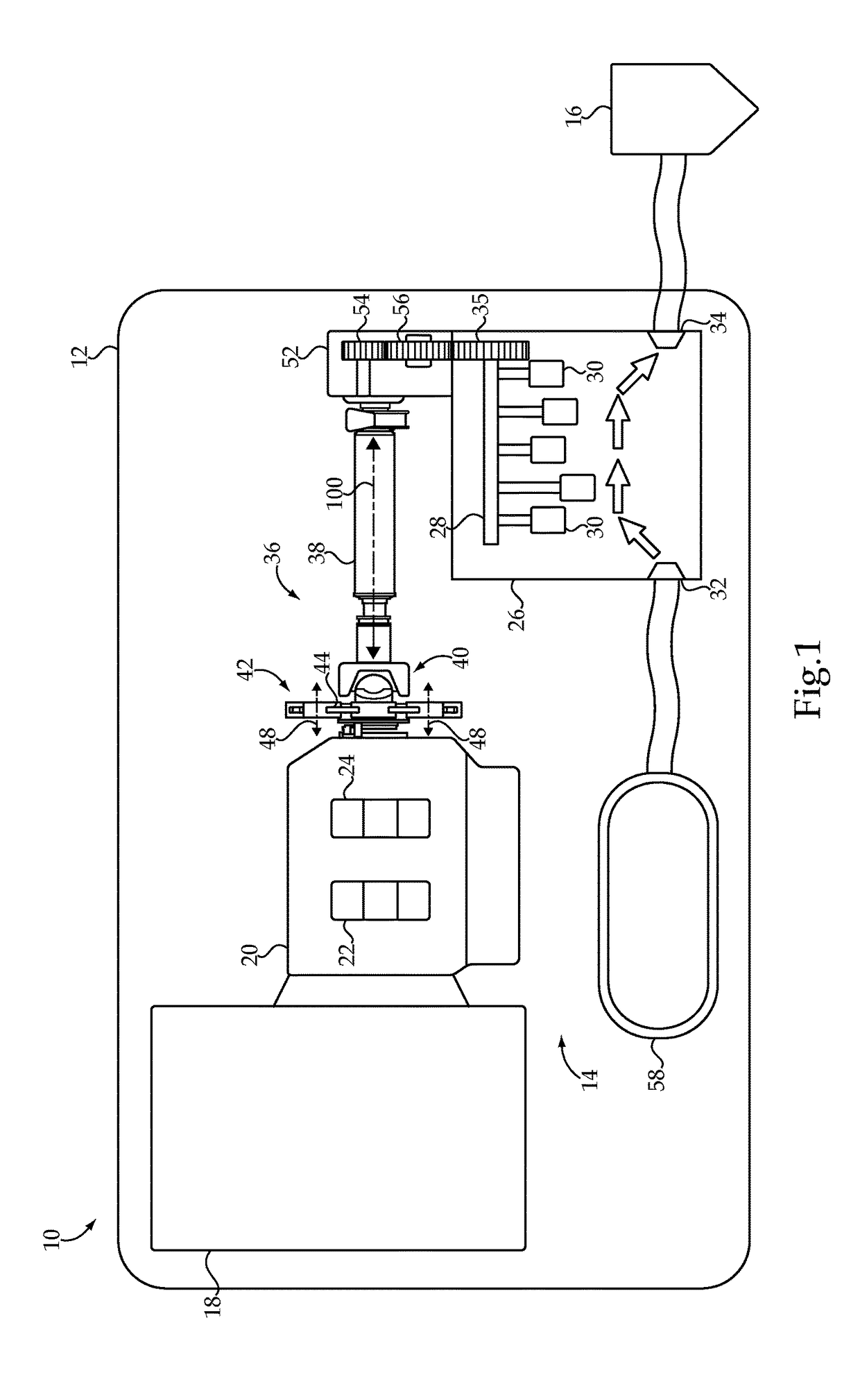

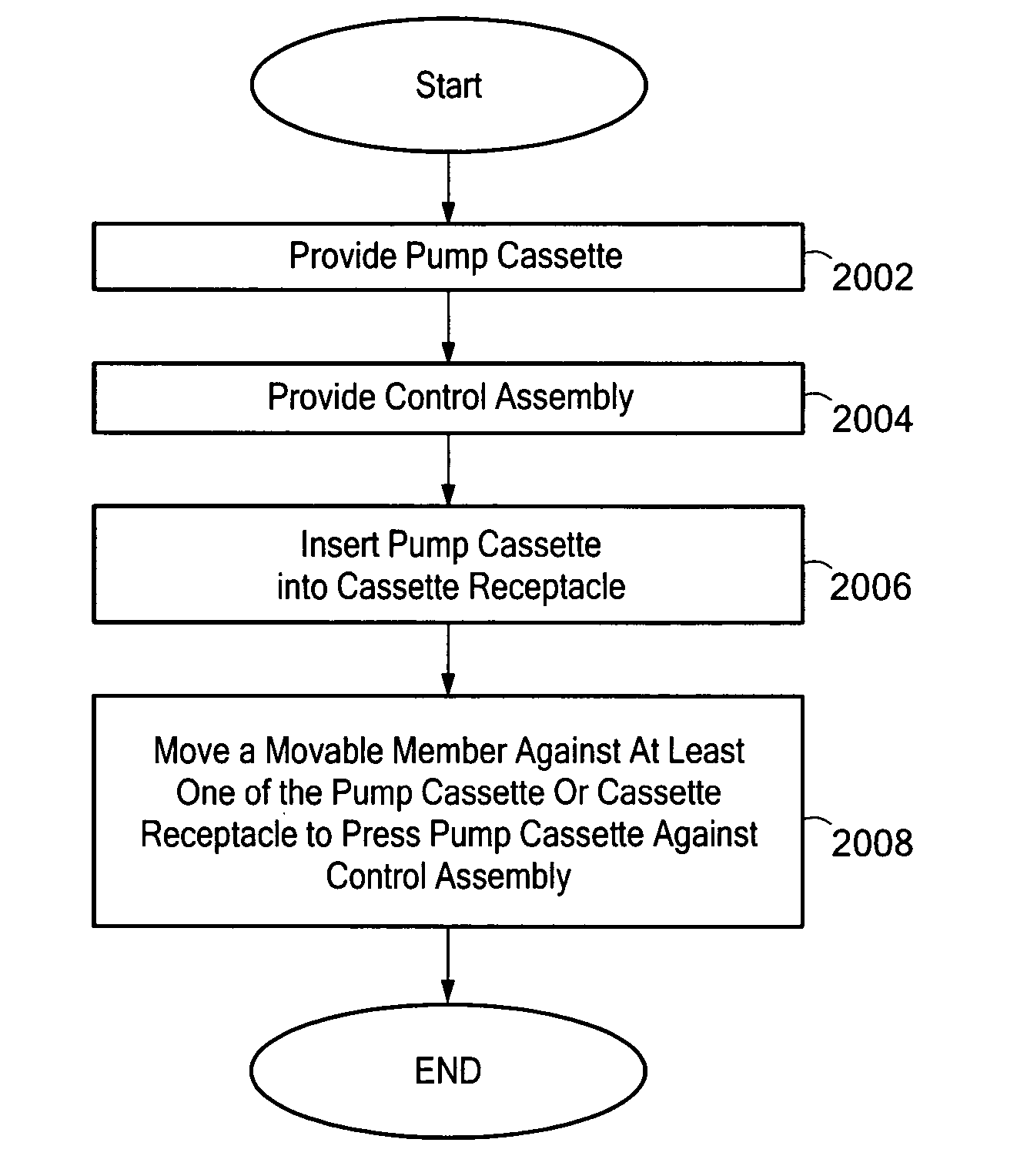

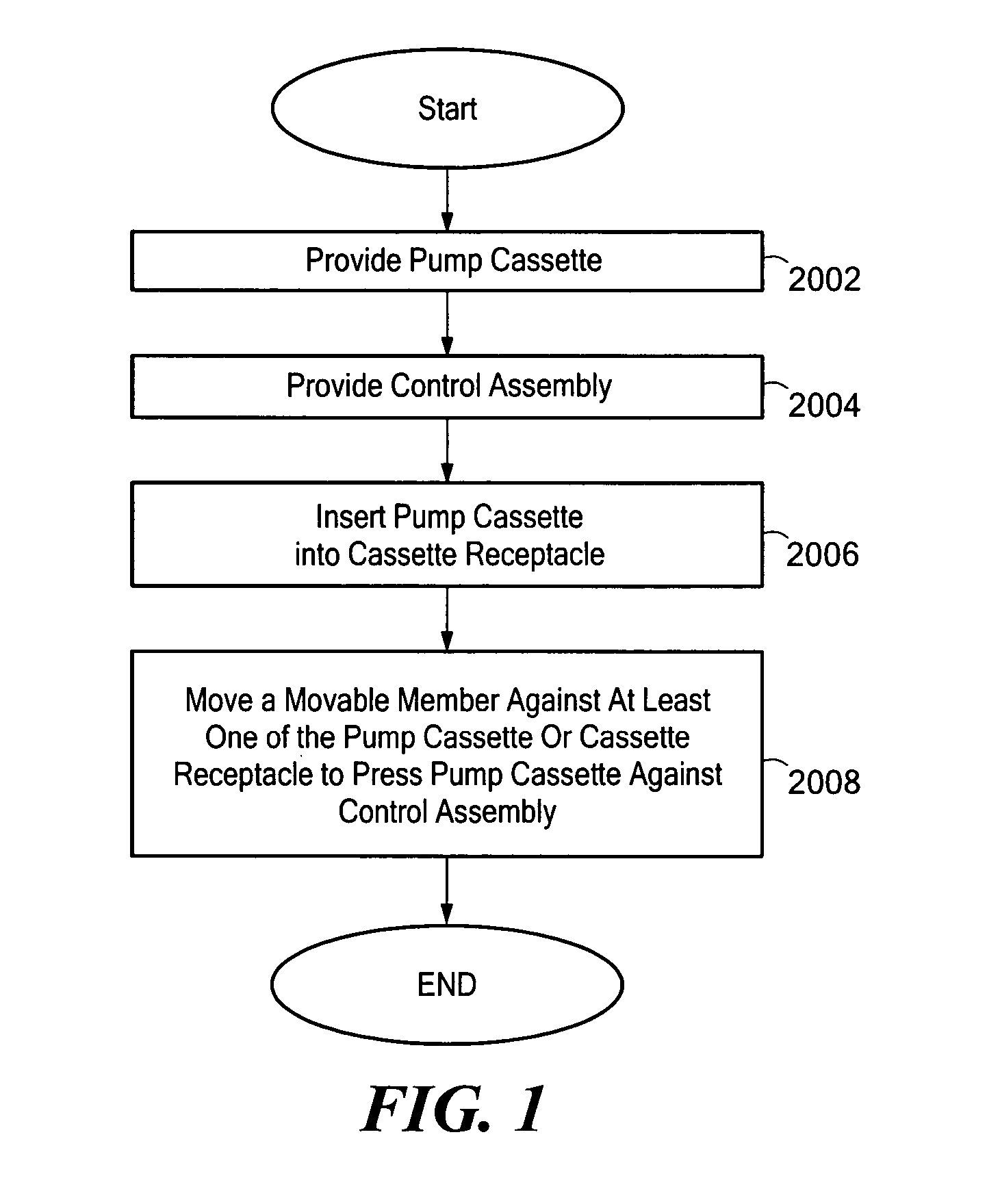

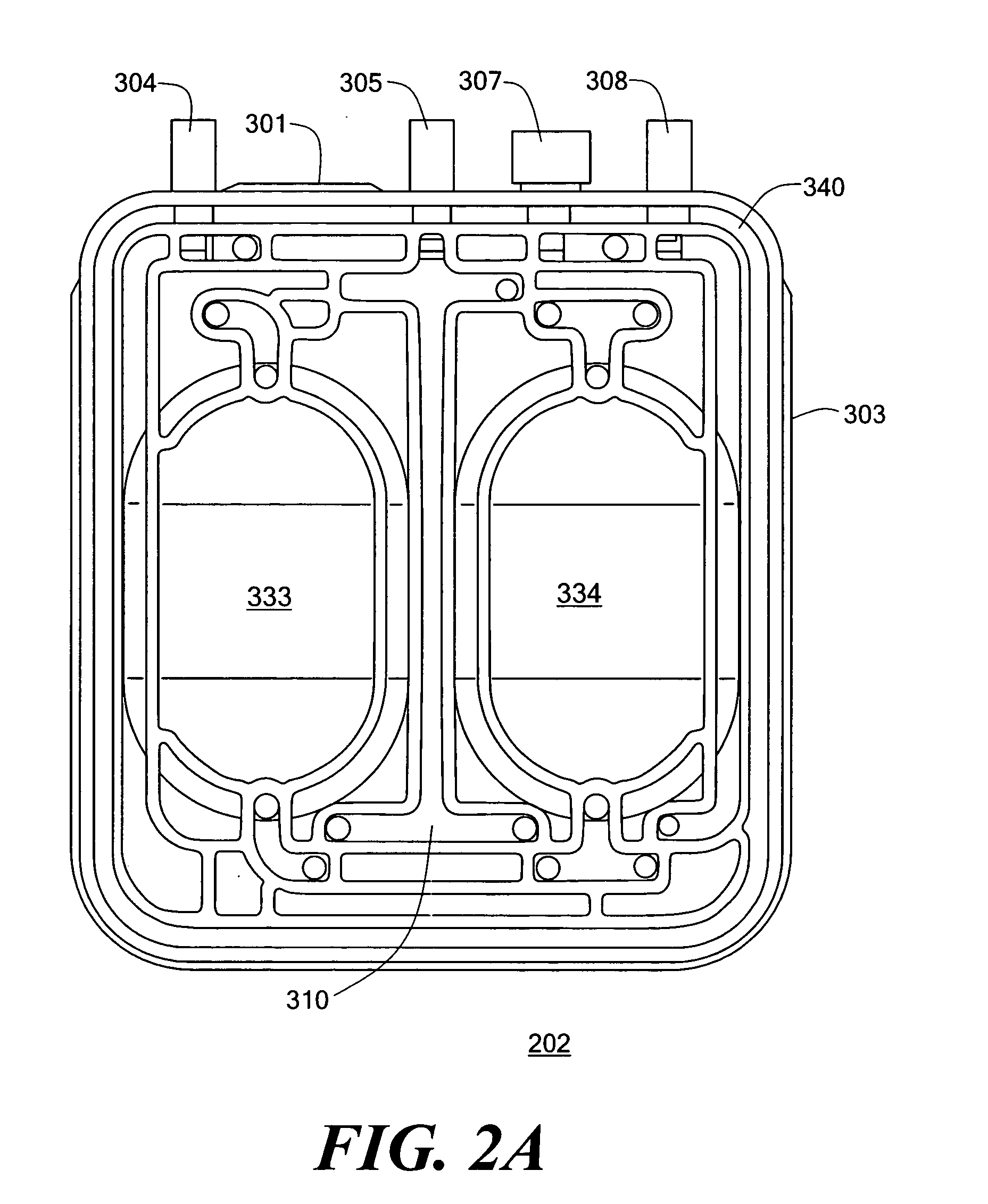

System and method for pumping fluid using a pump cassette

A system and method for pumping fluid using a pump cassette. The system includes a control assembly for operating the pump cassette. A force assembly having a movable member is capable of applying force to the pump cassette to press the pump cassette against the control assembly. The movable member may be an expandable member, such as a bladder.

Owner:DEKA PROD LLP

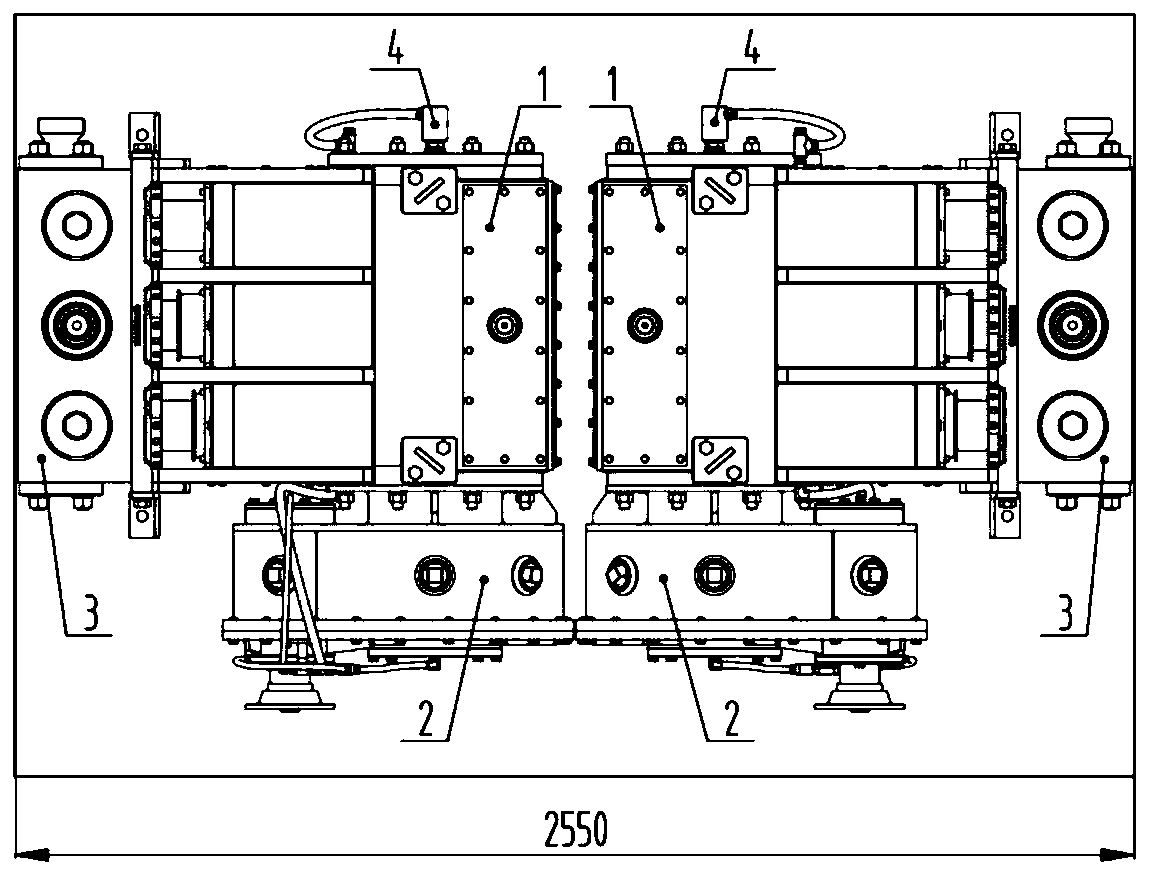

Single-machine single-pump electric drive fracturing semitrailer

PendingCN110656919AOptimize layoutNo emission pollutionPositive displacement pump componentsFluid removalExhaust gas emissionsElectric drive

The invention discloses a single-machine single-pump electric drive fracturing semitrailer. A traditional power supply semitrailer and a fracturing semitrailer are integrated in an optimized manner torealize a semitrailer simultaneously having power supply and fracturing functions; the power supply semitrailer and the fracturing semitrailer do not need to be used in a matched manner so that the single-machine single-pump electric drive fracturing semitrailer is more flexible in actual use and the oil and gas field well site layout is greatly optimized; the transportation is convenient; a working state can be reached only by using one group of high voltage cables to be connected with high voltage power supply so that the wiring mounting is faster; compared with diesel oil drive fracturing,electric drive fracturing has the advantages of small noise and no waste gas exhaust pollution; and as a driving source is electric power, compared with the diesel oil, the electric power has the advantage of lower use cost.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

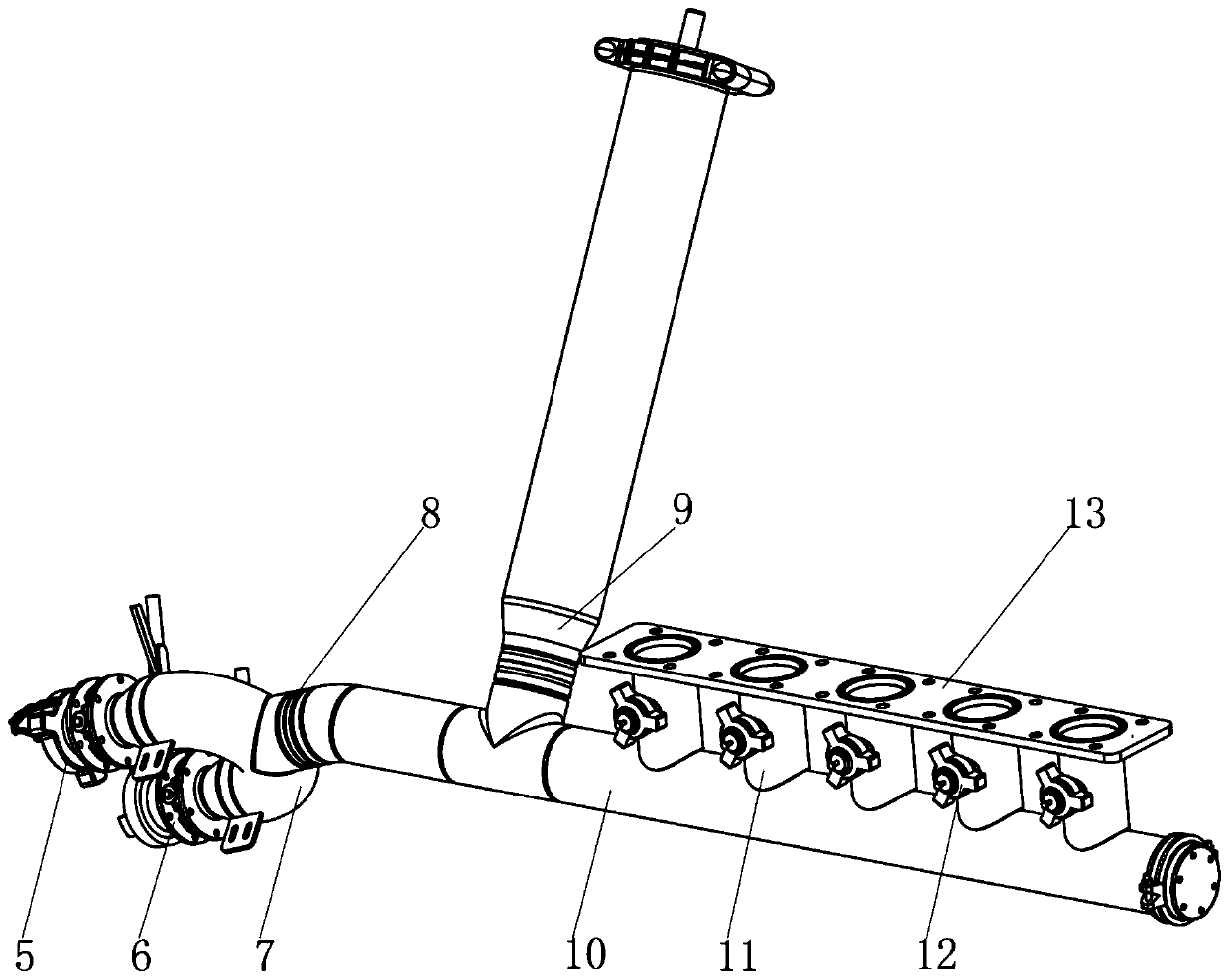

Manifold system capable of realizing low-pressure suction and high-pressure discharge

PendingCN111219326AGuaranteed large displacementLarge displacementPositive displacement pump componentsFluid removalEngineeringPlunger pump

The invention discloses a manifold system capable of realizing low-pressure suction and high-pressure discharge. The manifold system capable of realizing low-pressure suction and high-pressure discharge comprises a low-pressure manifold, a high-pressure manifold and a plunger pump, wherein the low-pressure manifold inputs a medium to a fluid end of the plunger pump; discharge ports are formed in the fluid end of the plunger pump; and two discharge ports are formed, and connected into the high-pressure manifold. The manifold system capable of realizing low-pressure suction and high-pressure discharge has the following beneficial effects: the five-cylinder plunger pump with a power of 5000 and above guarantees a high-pressure and large-displacement power source of fracturing equipment. A double-discharge form of the five-cylinder plunger pump realizes smooth liquid discharge of the five-cylinder plunger pump, avoids sand accumulation in the low-pressure manifold, and guarantees a large displacement of the fracturing equipment. A large-drift-diameter manifold with a size of 10 inches is adopted as the low-pressure manifold; and double-suction of a U-shaped pipe realizes enough fluid supply for the large displacement of the five-cylinder plunger pump.

Owner:美国杰瑞国际有限公司

Multi-point-support five-cylinder plunger pump

PendingCN110617188AImprove structural strengthImprove support strengthPositive displacement pump componentsPiston pumpsSoftware engineeringHigh load

The invention discloses a multi-point-support five-cylinder plunger pump. The multi-point-support five-cylinder plunger pump comprises a power end assembly, a hydraulic end assembly and a speed reduction box assembly, wherein the power end assembly comprises a crankshaft box body, a crosshead box body and a space rack, and the crankshaft box body, the crosshead box body and the space rack are connected in sequence; the hydraulic end assembly is fixed on the space rack, the speed reduction box assembly is fixed to the crankshaft box body, the bottom of the crankshaft box body is provided with acrankshaft supporting body, and the crankshaft supporting body is used for supporting the crankshaft supporting box body; the bottom of the crosshead box body is provided with a crosshead supportingbody, the crosshead supporting body is used for supporting the crosshead box body, the bottom of the space rack is provided with a hydraulic supporting body, and the hydraulic supporting body is usedfor supporting the hydraulic end assembly. The multi-point-support five-cylinder plunger pump has the advantages that through the multi-point-support design on the crankshaft box body, the crosshead box body and the hydraulic end assembly, the support strength of the plunger pump can be improved, vibration is reduced, high-load work is better guaranteed, and the plunger pump runs more stably.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

High-power five-cylinder plunger pump

PendingCN111441923AIncrease the carrying areaImplementation drivePositive displacement pump componentsFluid removalEngineeringElectric drive

The invention discloses a high-power five-cylinder plunger pump. The stroke of the high-power five-cylinder plunger pump is 10 in, the cylinder spacing is 11.5 in, and the braking power is 5000 HP. The plunger pump has the beneficial effects that the power is large, and the displacement is large; the pump is suitable for electric drive fracturing and turbine fracturing; the integral power end assembly or the split type power end assembly can be selected according to specific operation working conditions, so that the arrangement mode of a fracturing unit or a fracturing vehicle is better realized; and the stable operation with the long stroke and the braking power of 5000 HP is guaranteed by means of the size of the cylinder spacing.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

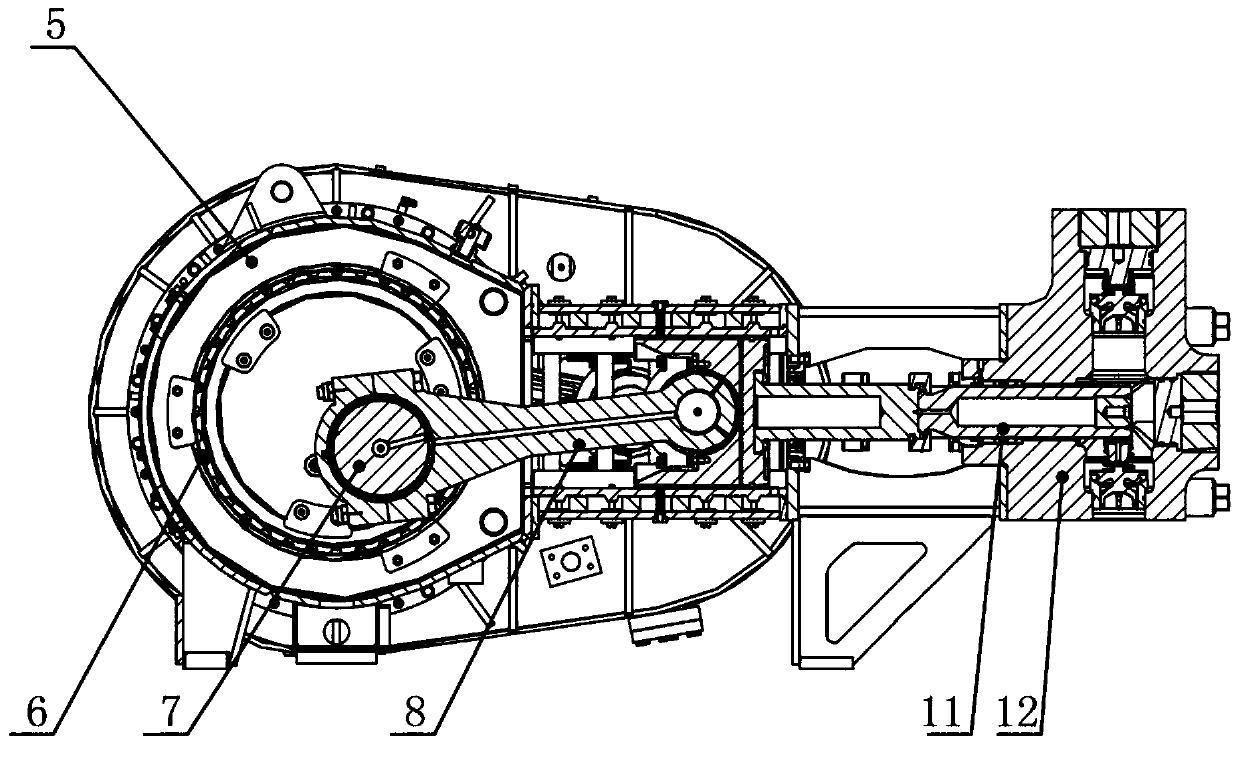

Reciprocating type three-cylinder plunger pump for oil and gas field

PendingCN109882372AExtend your lifeFully lubricatedPositive displacement pump componentsPositive-displacement liquid enginesEngineeringLubrication

The invention provides a reciprocating type three-cylinder plunger pump for an oil and gas field. The reciprocating type three-cylinder plunger pump comprises a gear box assembly, a power end assemblyand a hydraulic end assembly which are transmitted in sequence; and the hydraulic end assembly comprises a disc root and a plunger, the power end assembly comprises a crankshaft, a connecting rod, asliding rail and a crosshead, power is transmitted from the crosshead to the plunger, a pull rod and a fender are arranged between the plunger and the crosshead, the pull rod is fixed on the cross head, the plunger is fixed to the pull rod, the fender is located between the pull rod and the plunger and fixed with the plunger, and the outer diameter of the fender is larger than that of the plungerand the pull rod. The reciprocating type three-cylinder plunger pump can solve the problems that a working medium in a hydraulic end assembly in the prior art is poured into a power end assembly alongthe plunger, a packing is inconvenient to replace, and a connecting rod large-head bearing bush is insufficient in lubrication and the like.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

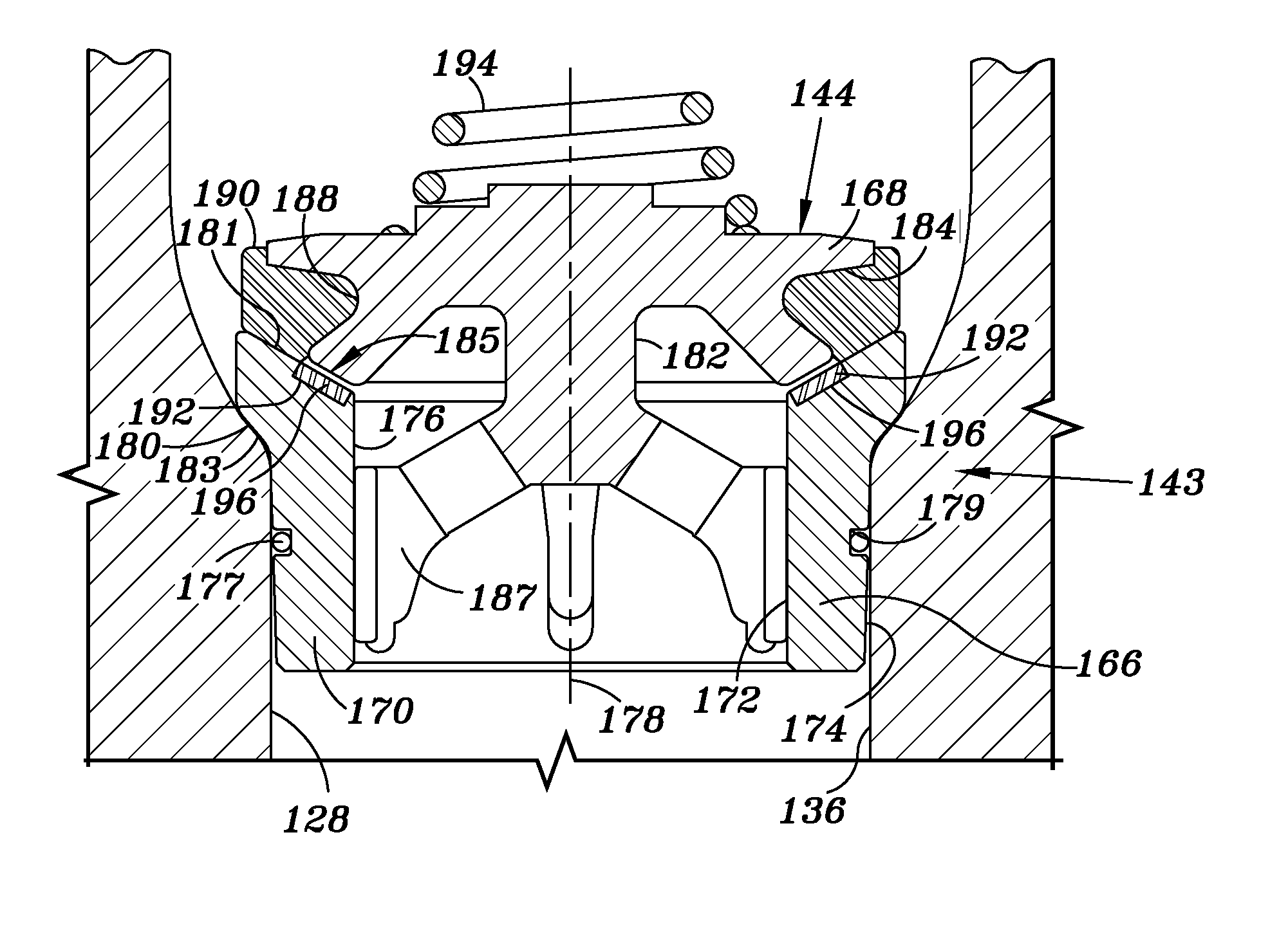

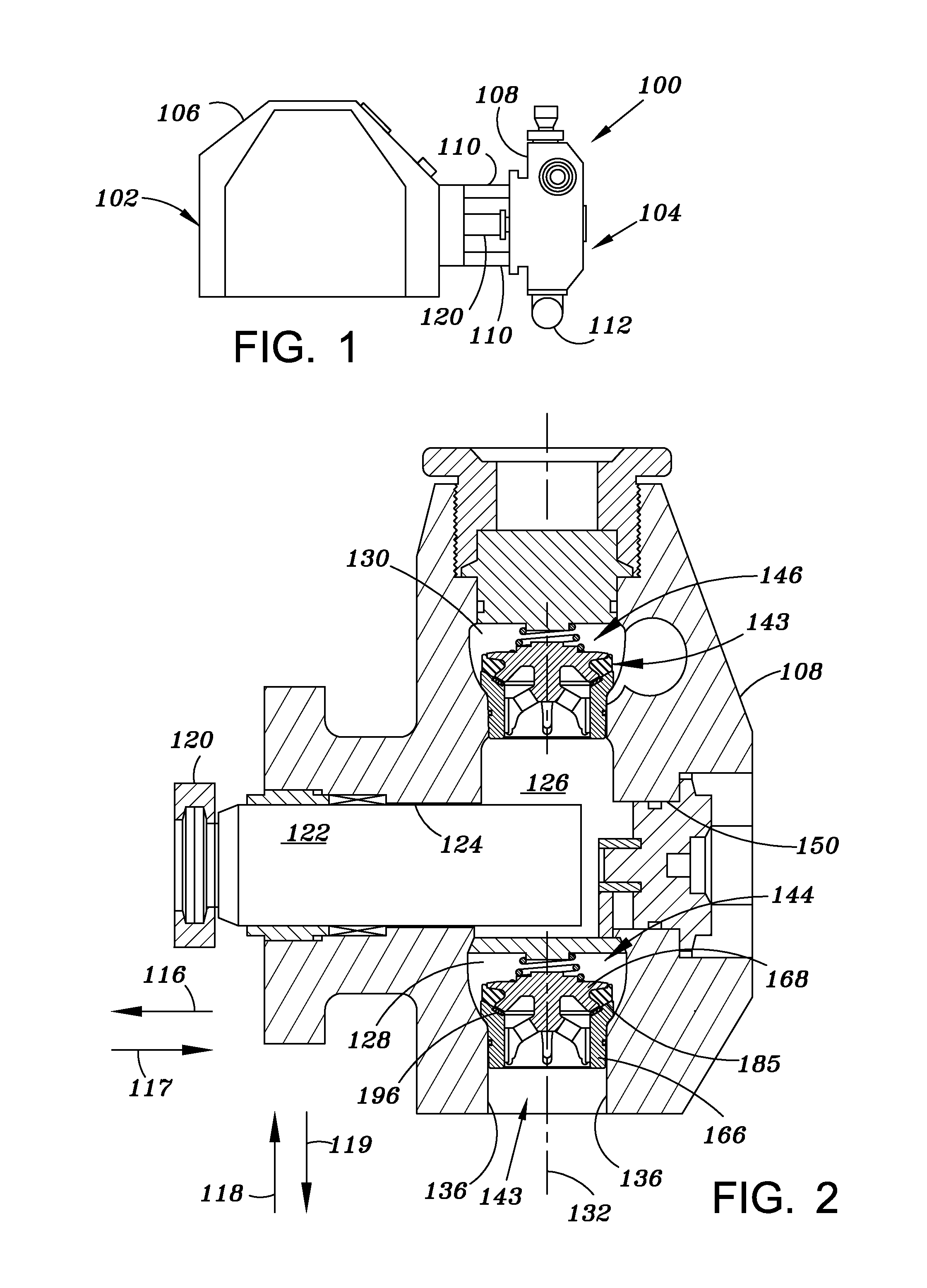

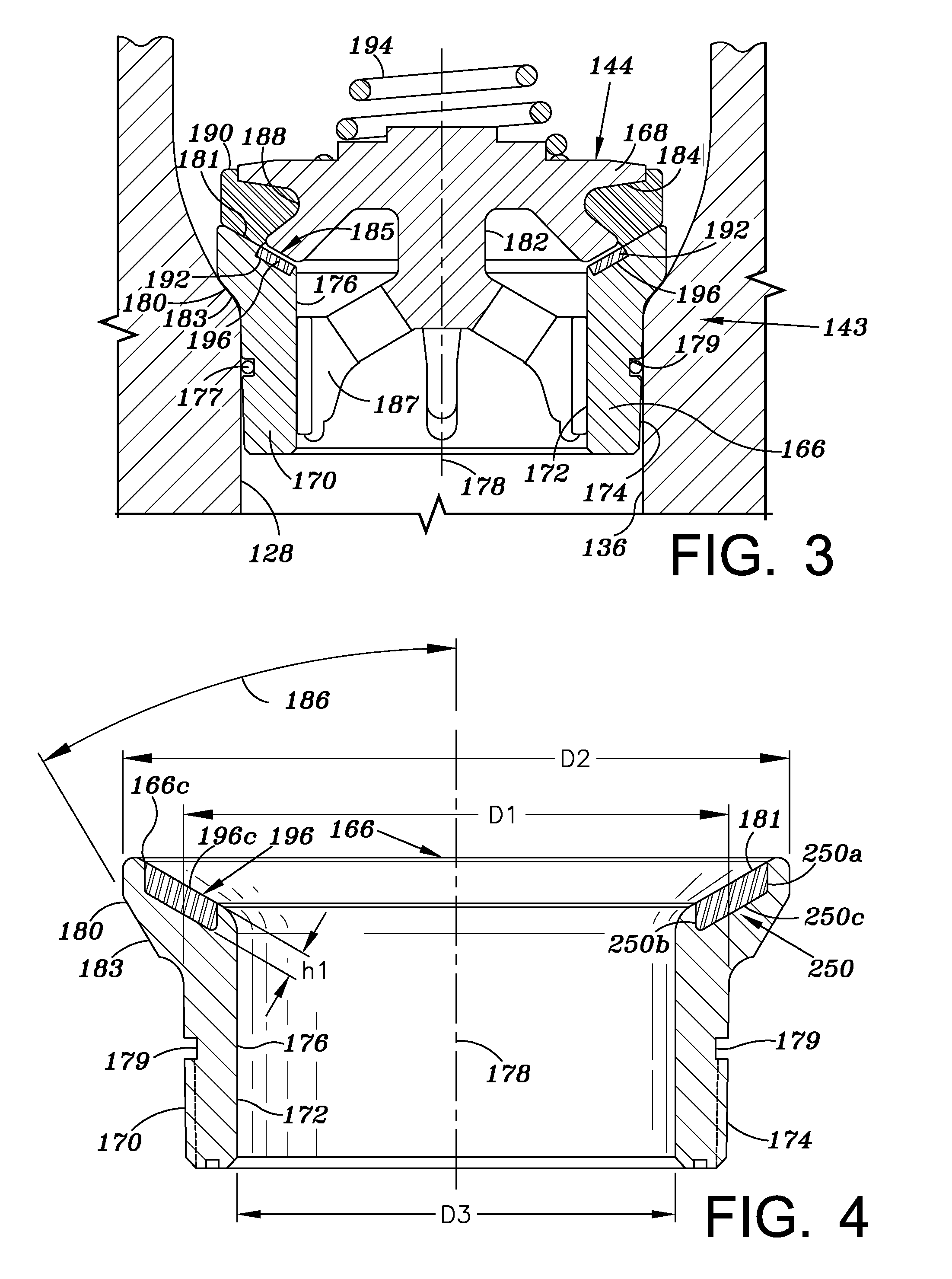

Valve seats for use in fracturing pumps

A valve seat at least partially formed of a ceramic material for use in a fracturing pump includes a first body and a second body. The first body is configured to be inserted into a fluid passageway of the fracturing pump. The first body has an outer diameter, D1. The second body extends radially from the first body and has an outer diameter, D2, greater than the outer diameter, D1, of the first body. The second body is at least partially formed of the ceramic material.

Owner:SPM OIL & GAS INC

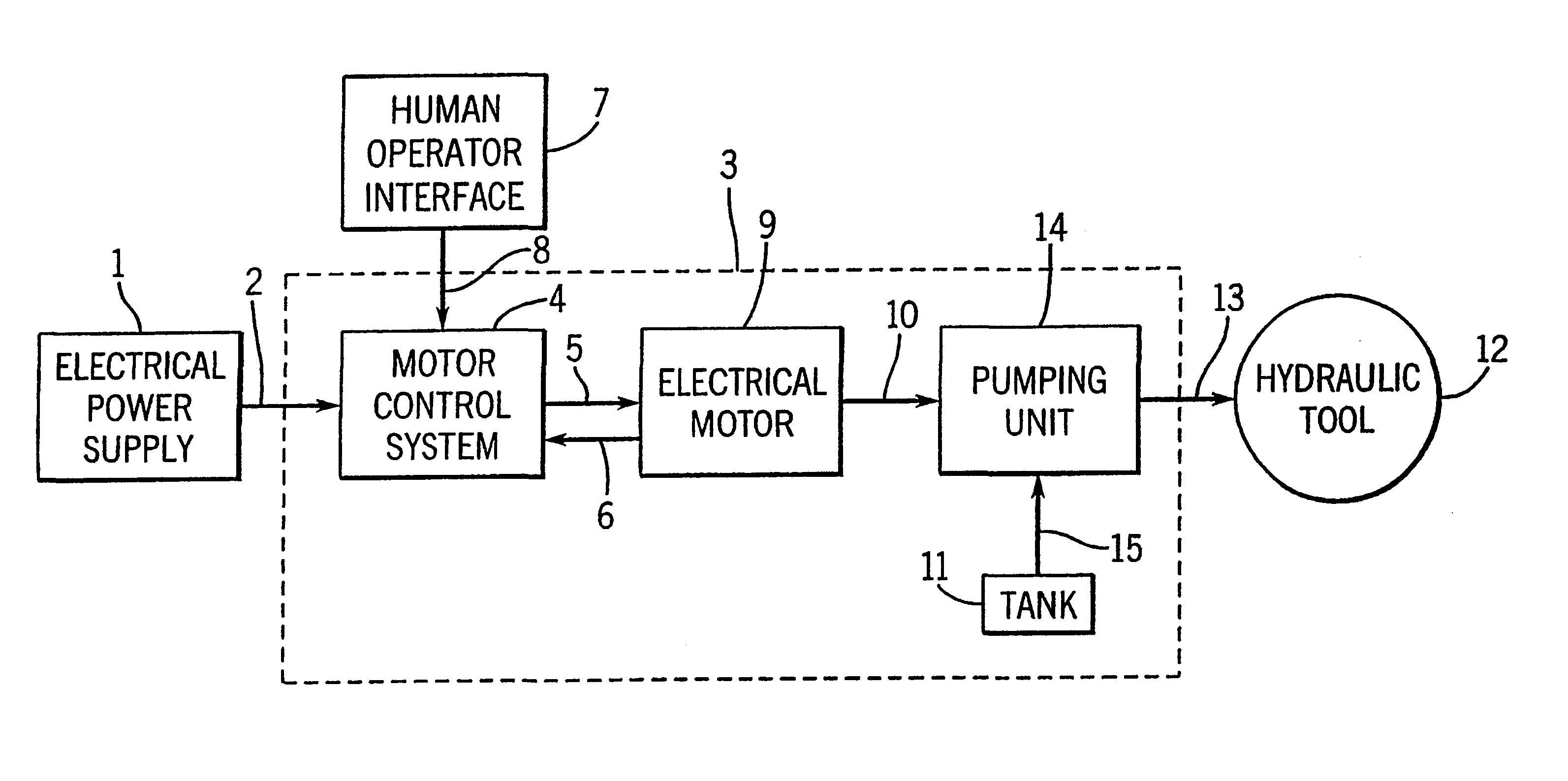

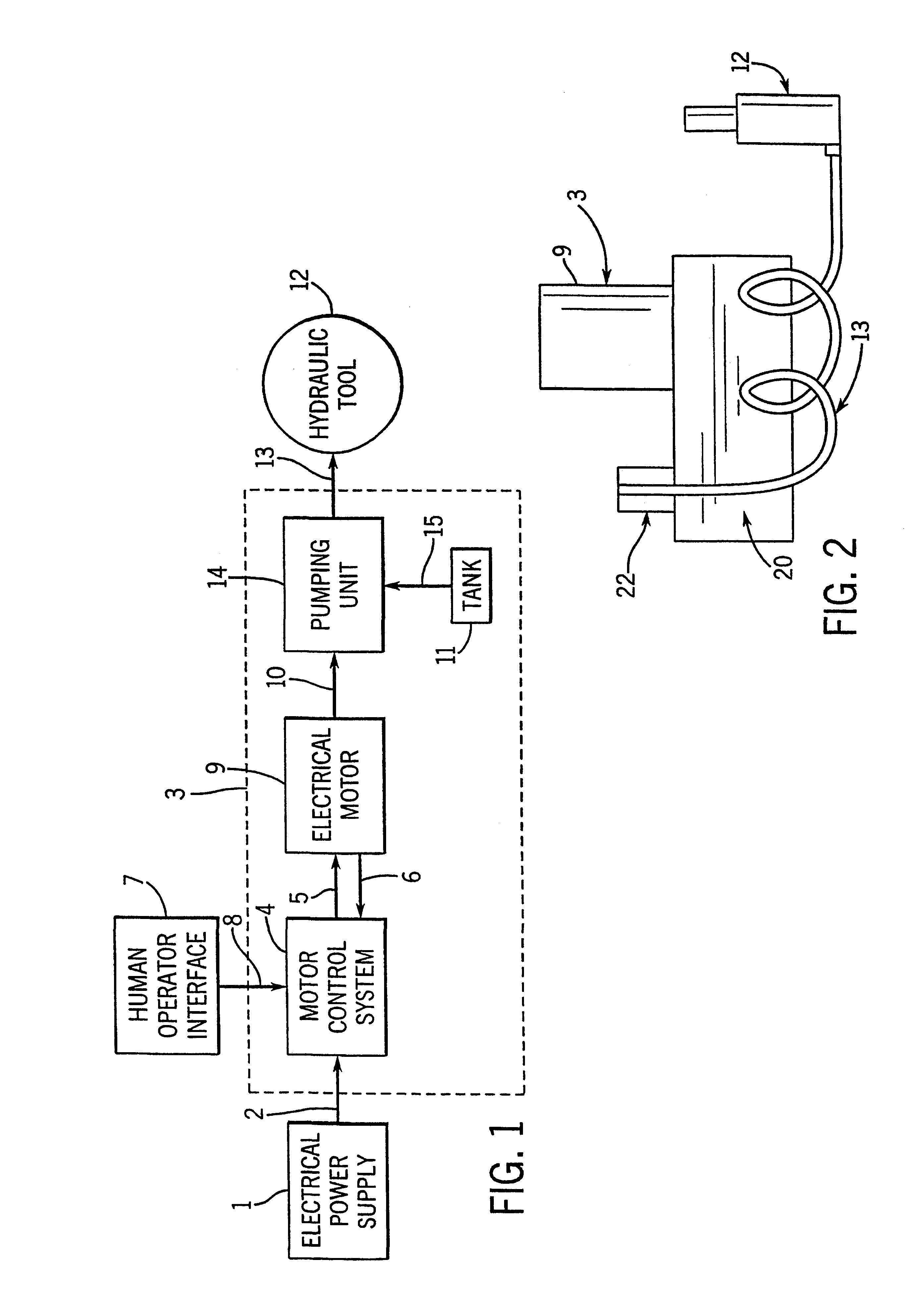

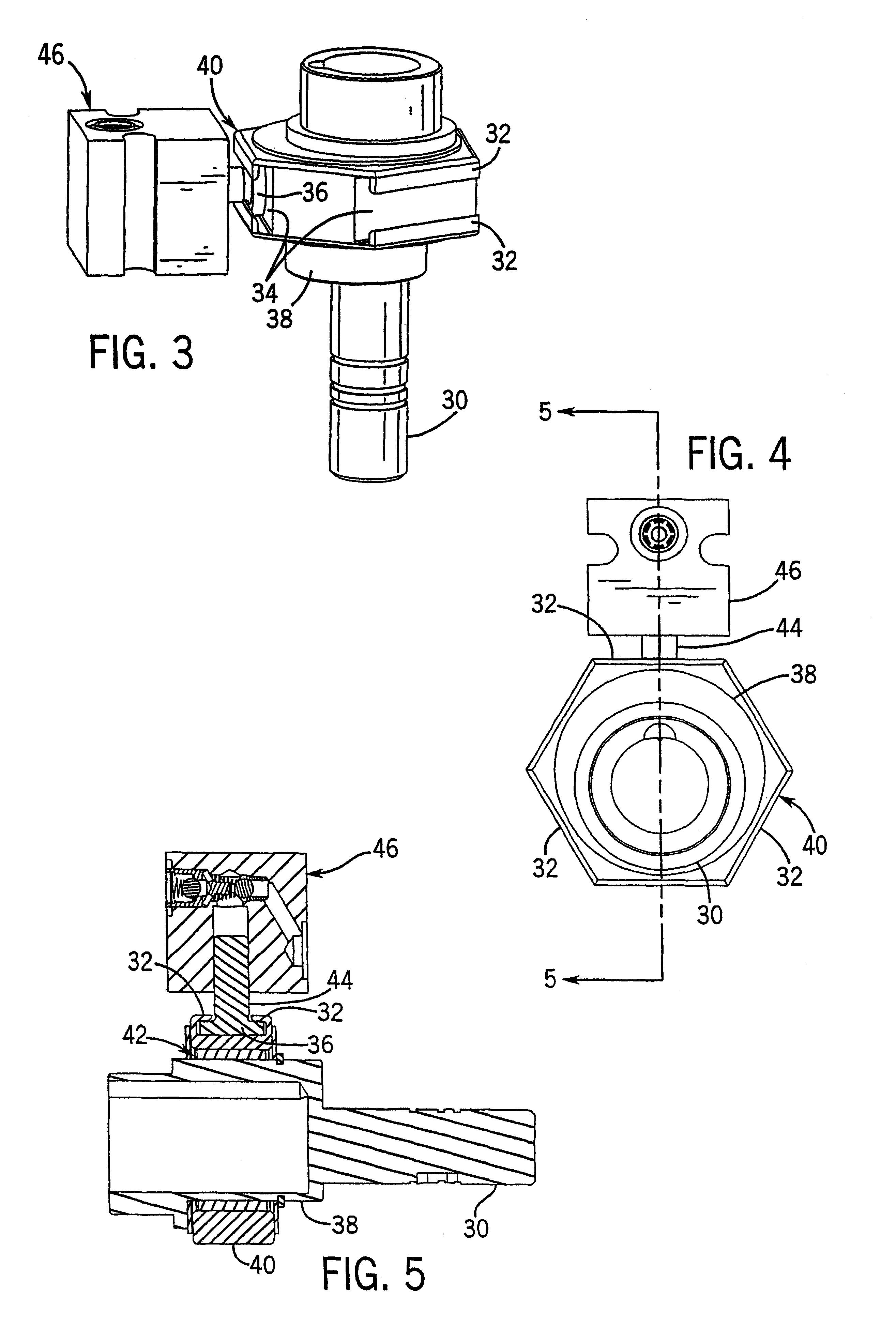

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

Reciprocating pump with dual circuit power end lubrication system

ActiveUS20160177945A1Positive displacement pump componentsRotary/oscillating piston combinationsEngineeringHigh pressure

A dual circuit lubrication system for a power end of a reciprocating pump that includes a lubrication pump that supplies lubrication fluid to a high pressure lubrication circuit and a low pressure lubrication circuit. The high pressure lubrication circuit is fluidly coupled to a crankshaft to supply lubrication fluid to sliding surfaces associated with the crankshaft at a first lubrication fluid pressure. The crankshaft drives a crosshead coupled to a plunger to displace fluid from a fluid end of the reciprocating pump. The low pressure lubrication circuit is fluidly coupled to supply the lubrication fluid to a plurality of rolling surfaces associated with the crankshaft at a second lubrication fluid pressure. The first lubrication fluid pressure is greater than the second lubrication fluid pressure.

Owner:SPM OIL & GAS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com