Semitrailer-mounted turbine fracturing equipment

A semi-trailer and turbine technology, applied in the field of turbo fracturing, can solve the problems of engine exhaust pollution, noise, uneconomical, high fuel consumption cost, and achieve the effects of stability and safety assurance, investment cost reduction, and operating cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

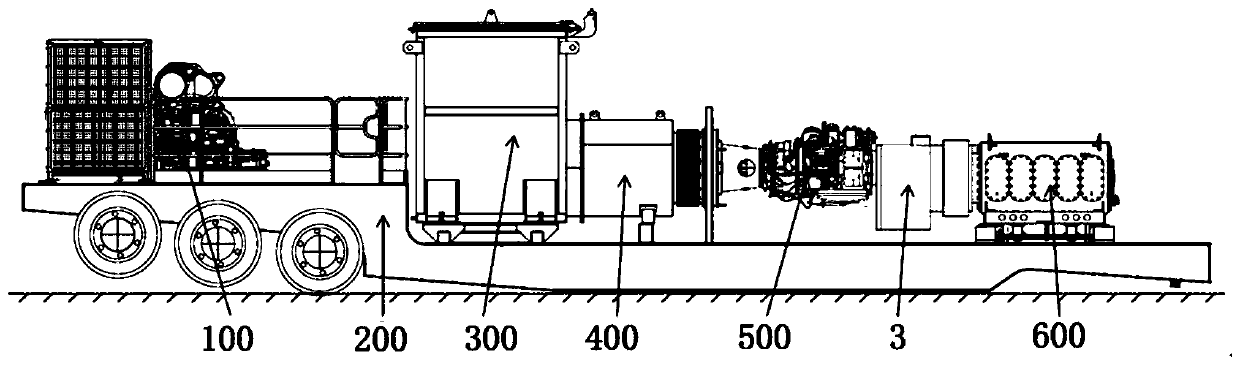

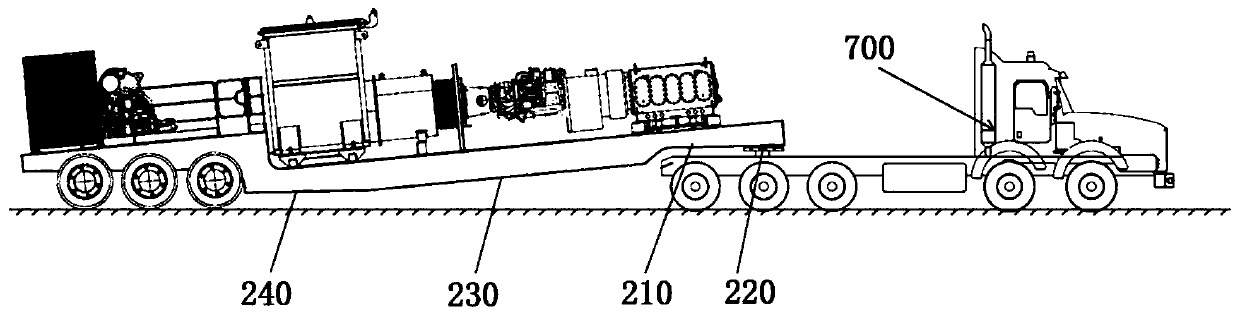

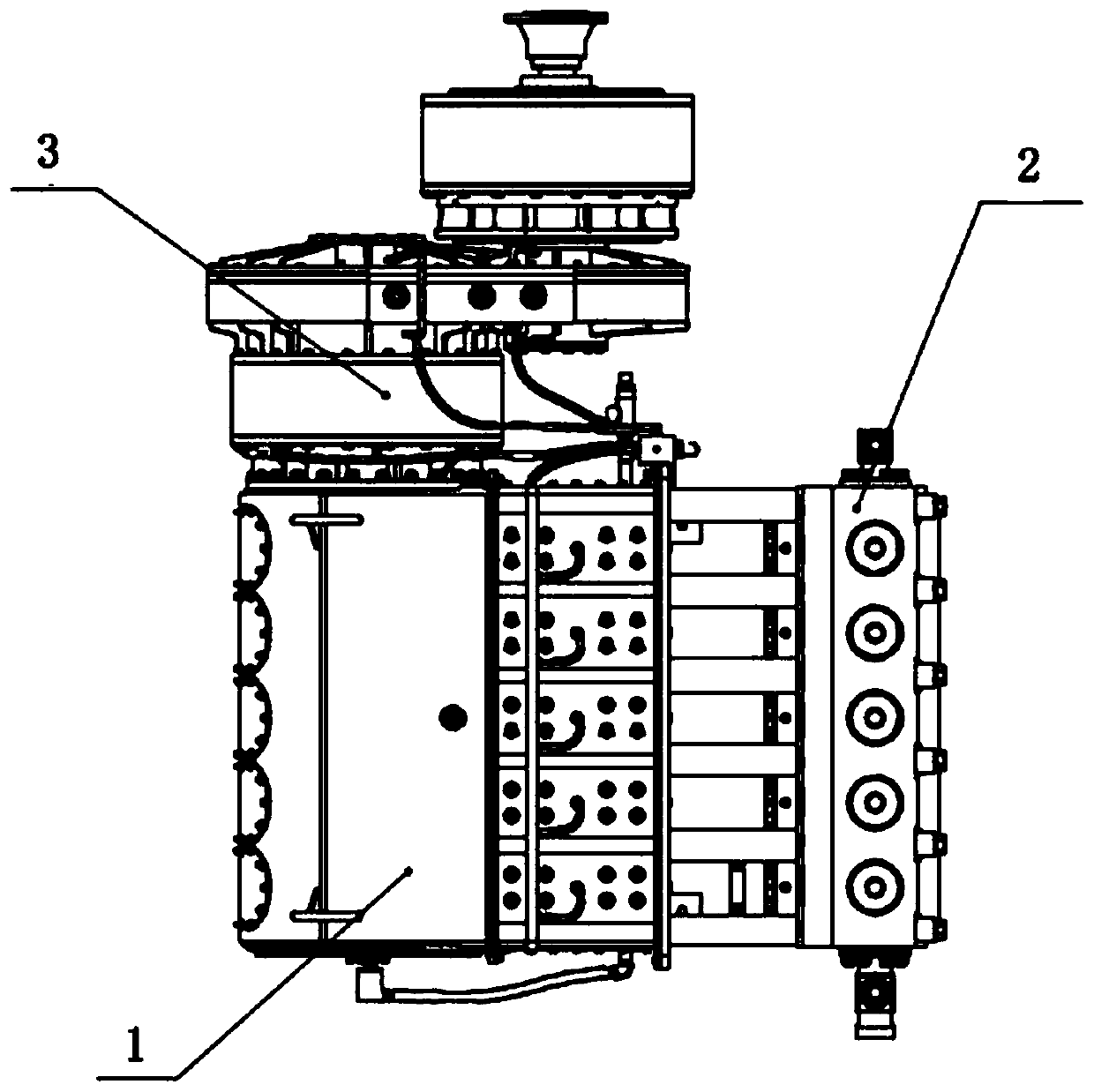

[0038] Examples such as Figures 1 to 8As shown, a semi-trailer-mounted turbo fracturing equipment, the turbo fracturing equipment includes a transport device 200, an exhaust system, a turbine engine 500 and a plunger pump 600, and the turbine engine 500 is the power transmission system of the entire equipment. As the power source, the turbine engine 500 can directly use 100% natural gas as fuel, which greatly reduces the cost of use compared with the diesel consumption in diesel drive and the investment in gas generator set in electric drive fracturing equipment. Of course, the turbine engine 500 can also use 100% fuel oil as fuel, preferably natural gas, which can reduce fuel cost more than fuel oil. The exhaust system is connected to the exhaust port of the turbine engine 500 , and the output end of the turbine engine 500 is connected to the plunger pump 600 . The exhaust system includes an exhaust muffler 300 and an exhaust pipe 400 , and the exhaust muffler 300 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com