Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Maximize flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

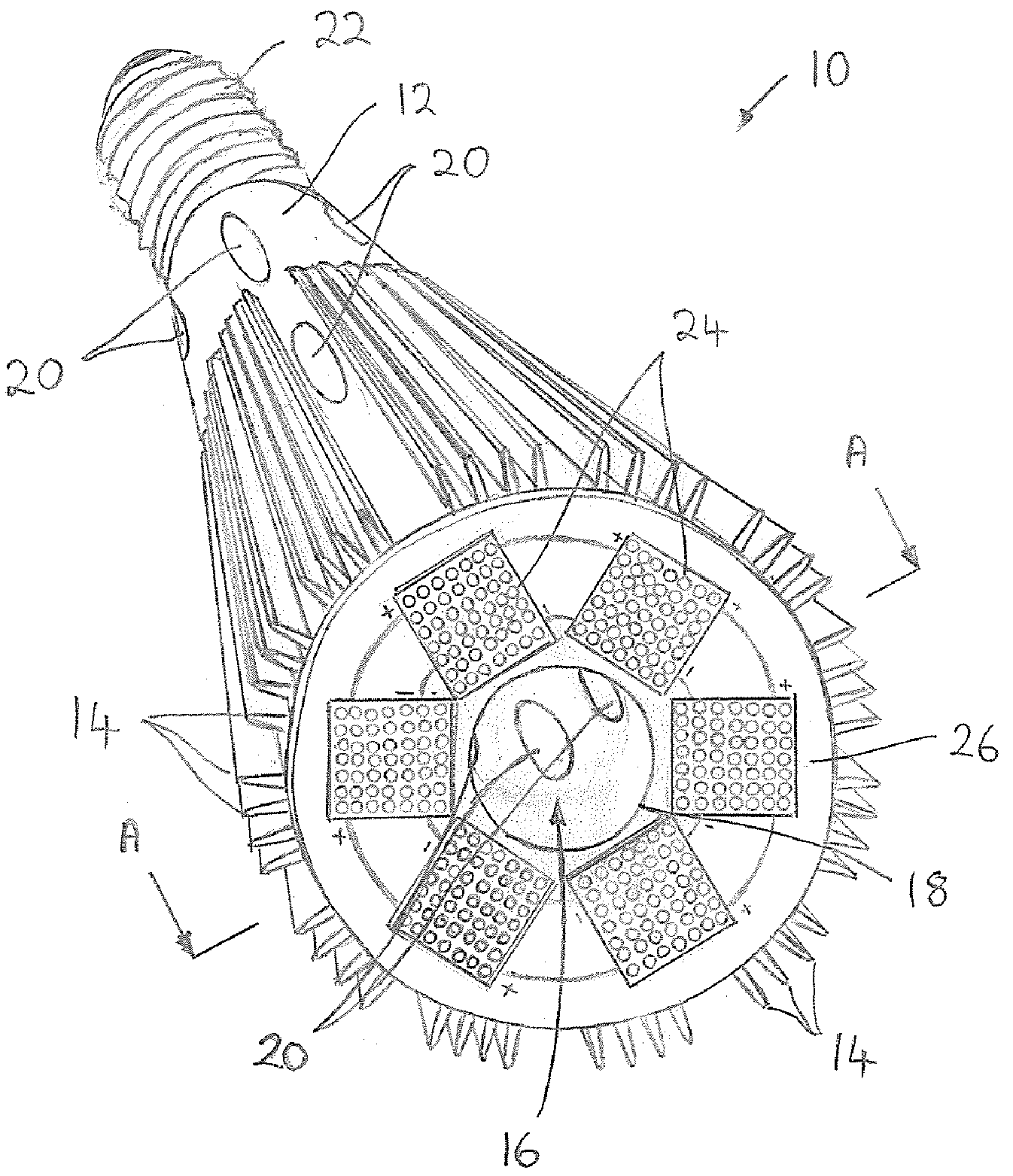

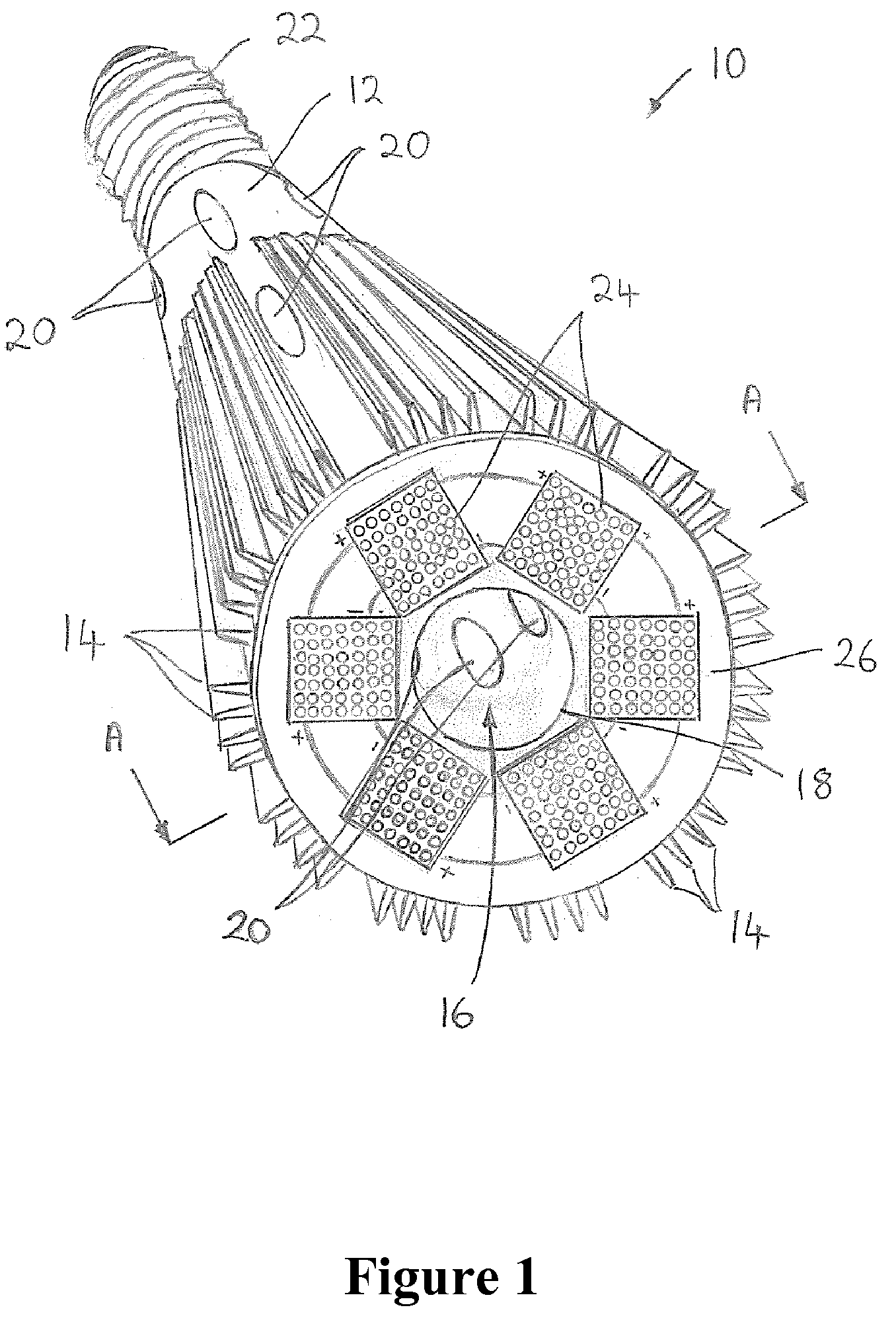

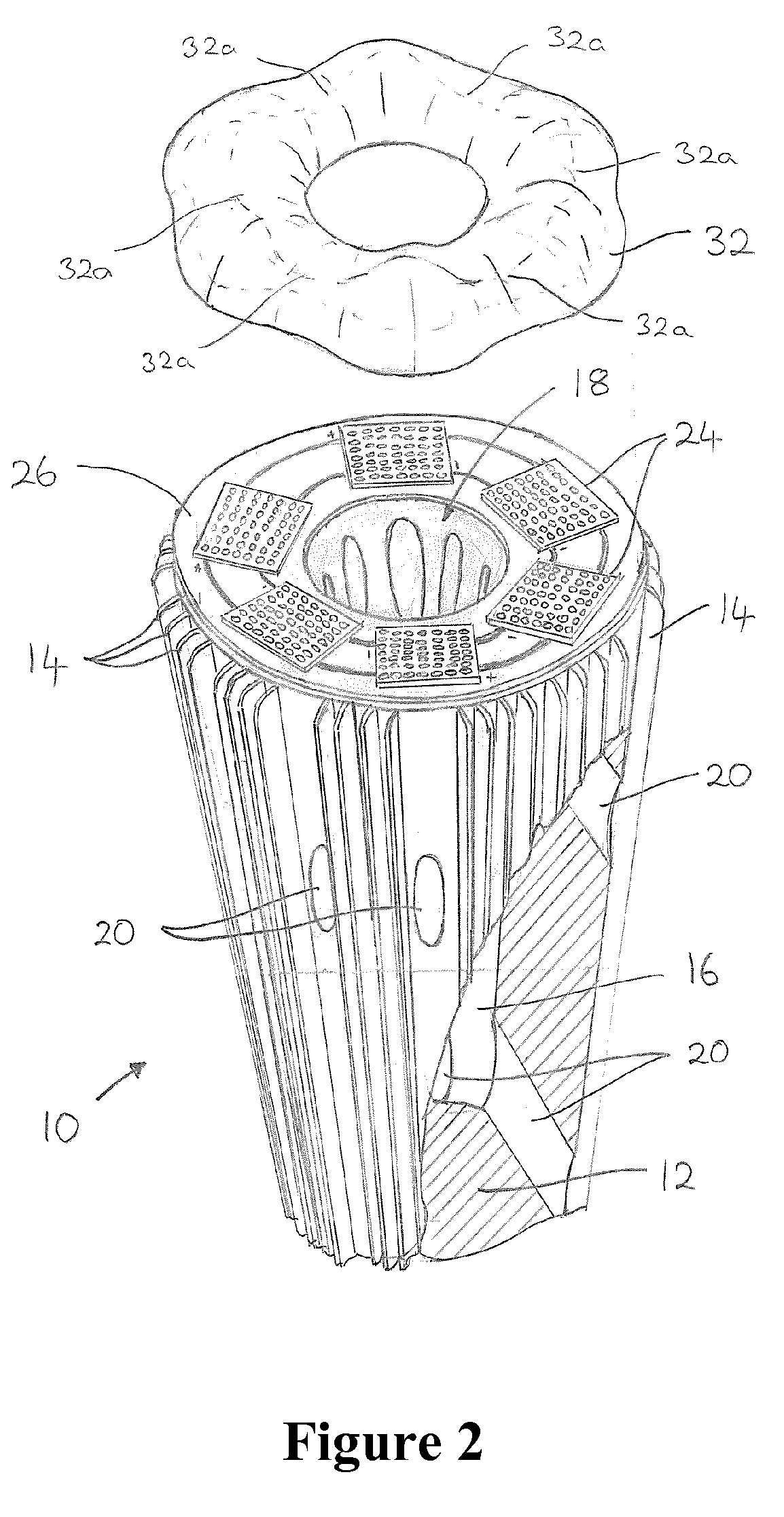

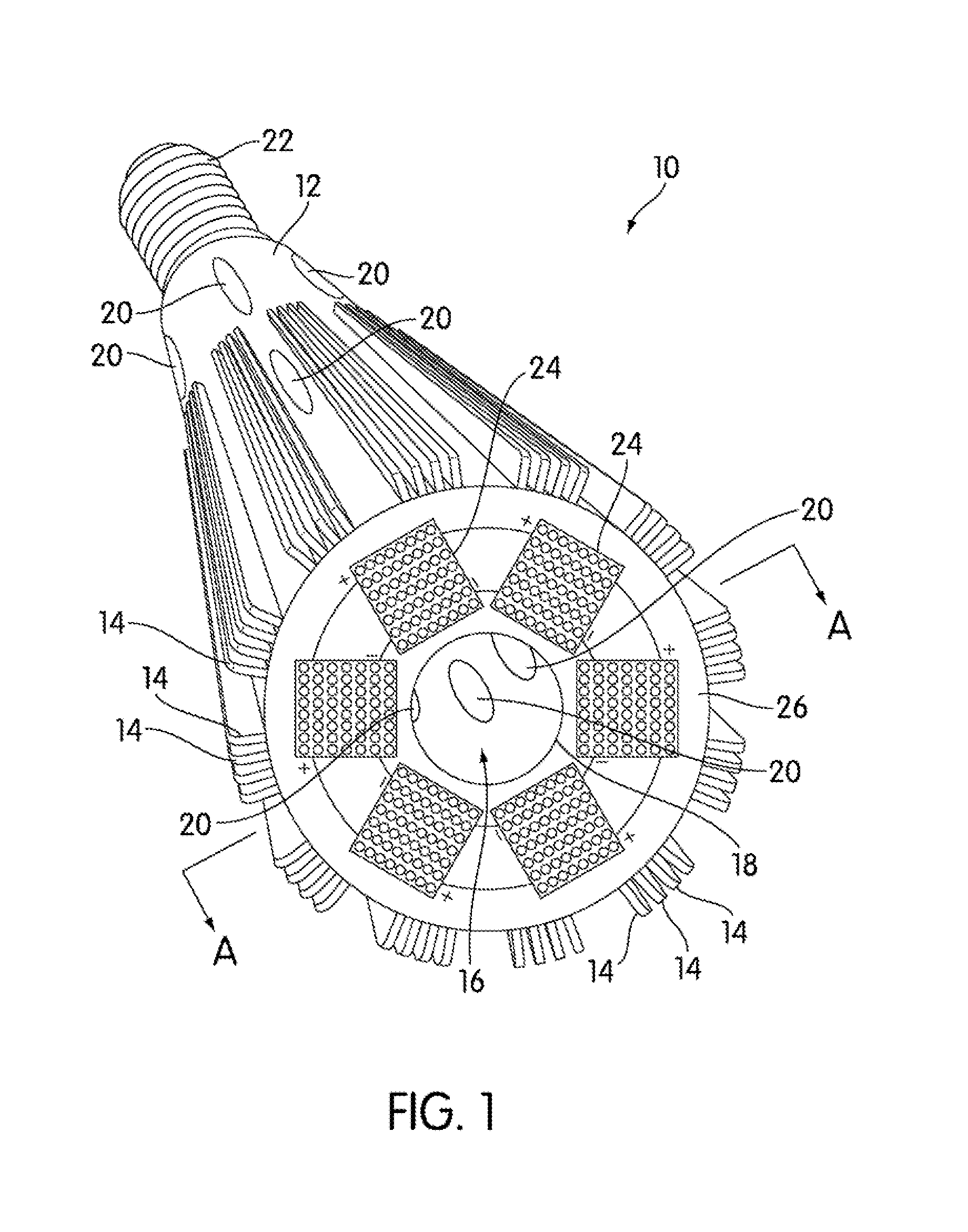

Light emitting diode (LED) lighting device

ActiveUS20100060130A1Increase air flowHigh trafficPoint-like light sourceElectric discharge tubesEffect lightEngineering

An LED lighting device comprises: a thermally conducting body having an at least one opening that connects with a cavity within the body and a plurality of LEDs mounted in thermal communication with a face of the body and positioned around the opening. One or more passages pass through the body from the cavity to an outer surface of the body and are configured such that in operation air moves through the cavity by thermal convection thereby to provide cooling of the body. Each passage is configured in a direction that extends in a direction at an angle of about 45° to a line that is parallel with the axis of the body toward the outer surface of the body away from the face. The body can be configured such that its outer surface has a form factor resembling an incandescent light bulb or halogen reflector lamp.

Owner:BX LED LLC

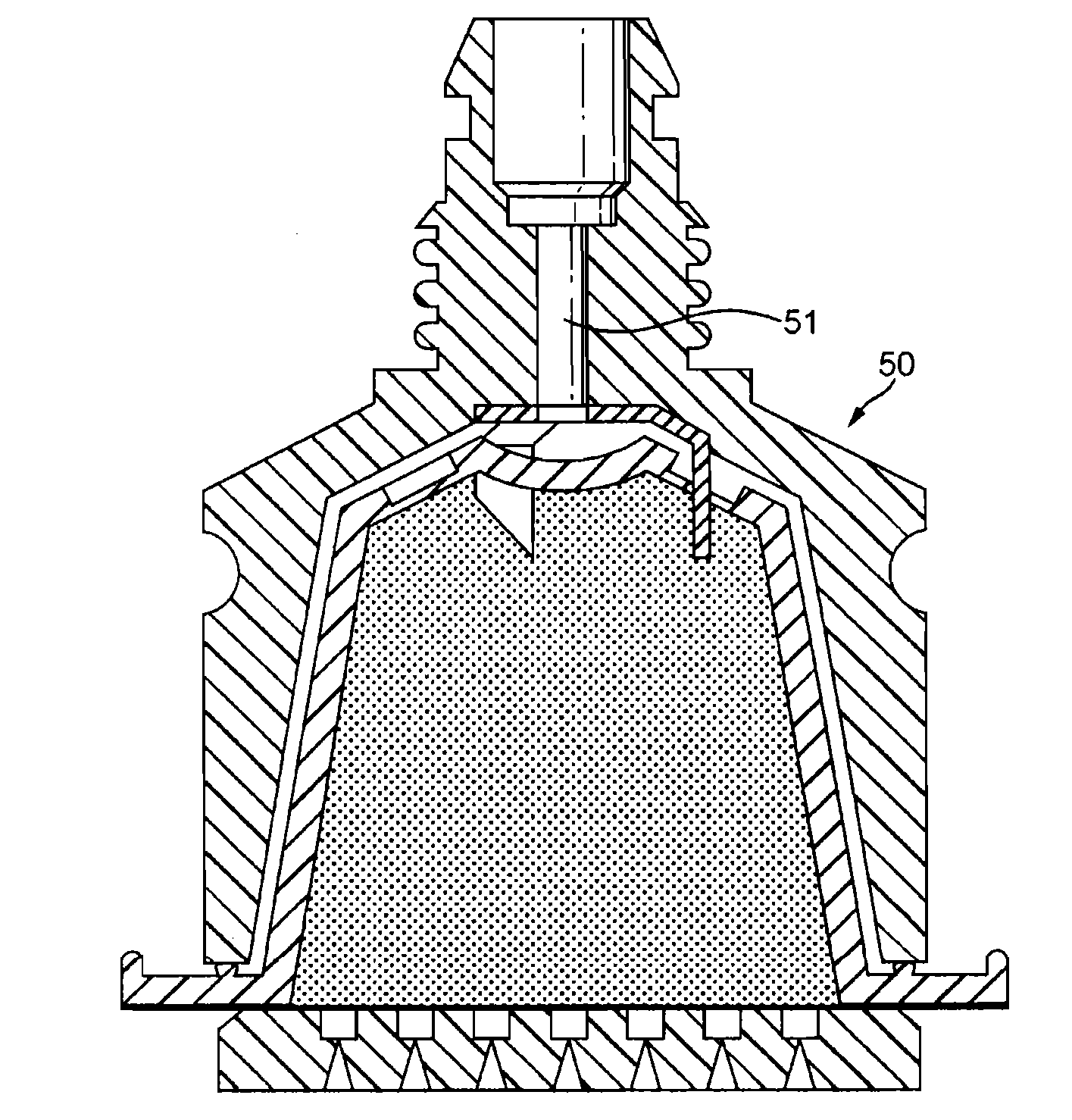

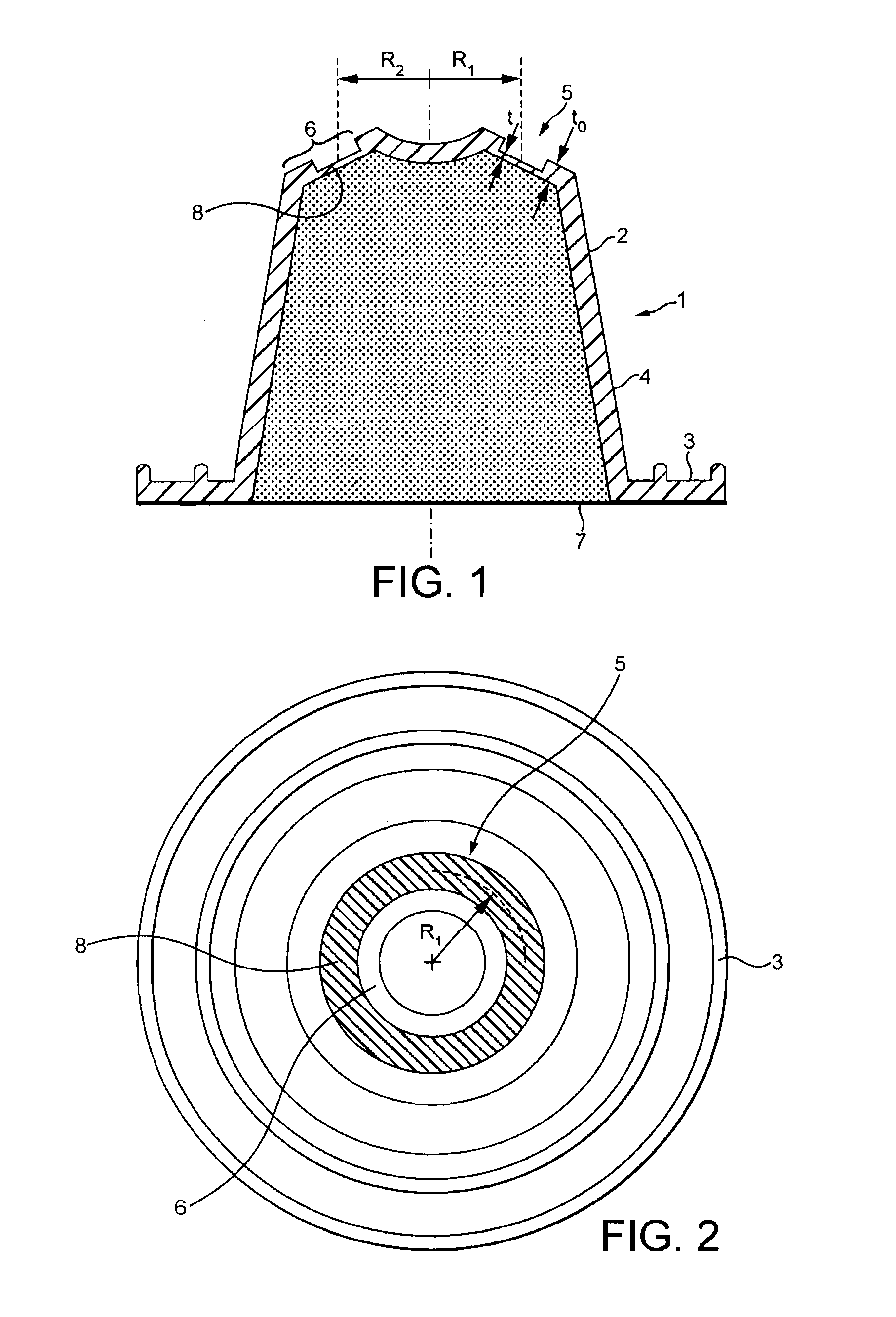

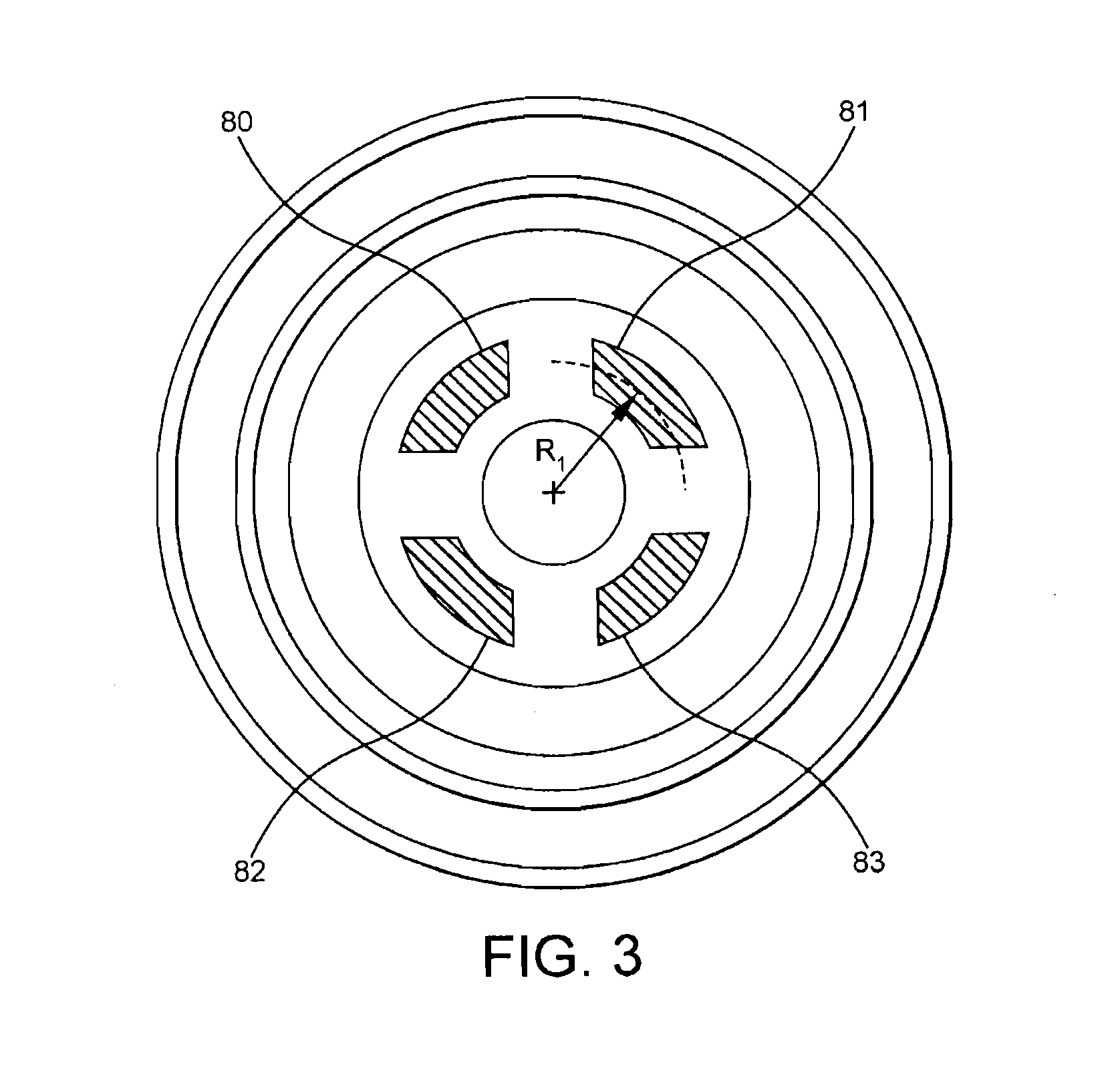

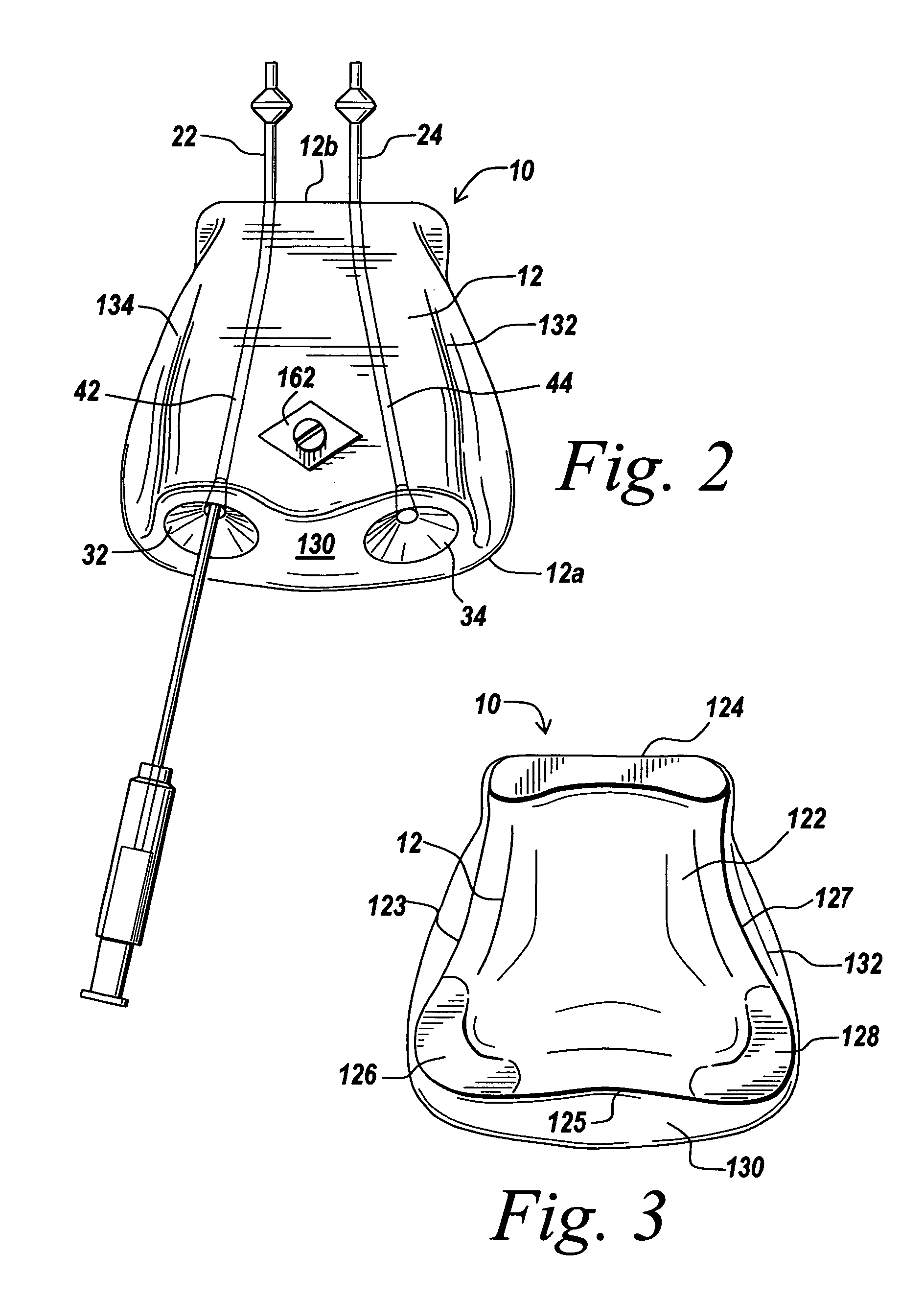

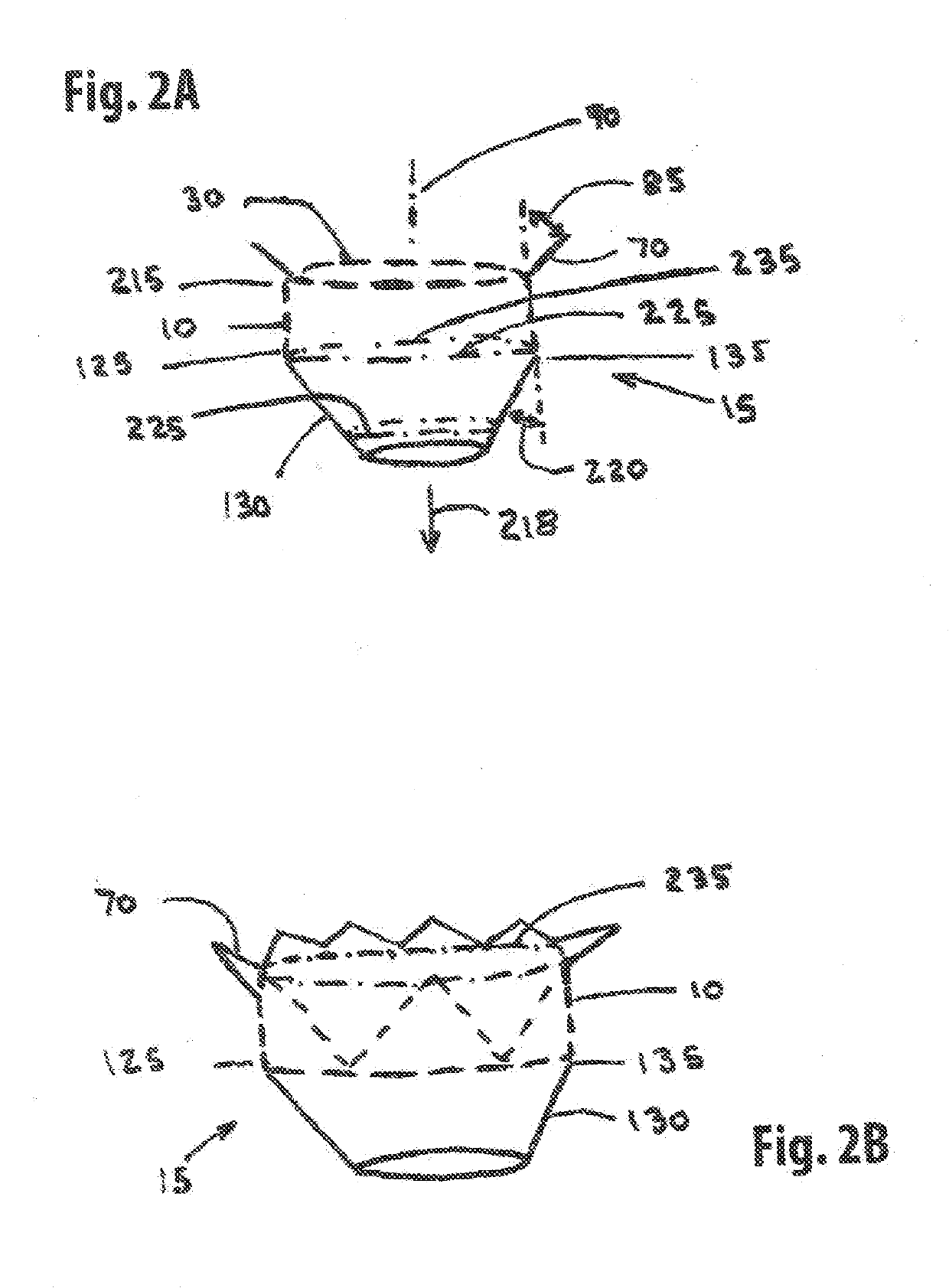

Capsule for the preparation of a coffee extract having a structure facilitating perforation for injection of water

ActiveUS20110041702A1Improve permeabilityReduce thicknessFlexible coversWrappersEngineeringMaterial Perforation

A capsule for the preparation of a coffee extract from coffee contained therein and hot water injected under pressure in the capsule by a water injection device. The capsule has a frusto-conical body with a rim, sidewall, and an inlet wall and a lower delivery wall sealed to the rim and contains a predosed amount of coffee. The inlet wall may have a flat or convex portion and a structure in relief or in recess arranged for facilitating penetration of blades belonging to the injection device and extending on a substantially circular path of predetermined radius R1 equal to the radius R2 of the circular path along which the blades of the injection device extend.

Owner:SOC DES PROD NESTLE SA

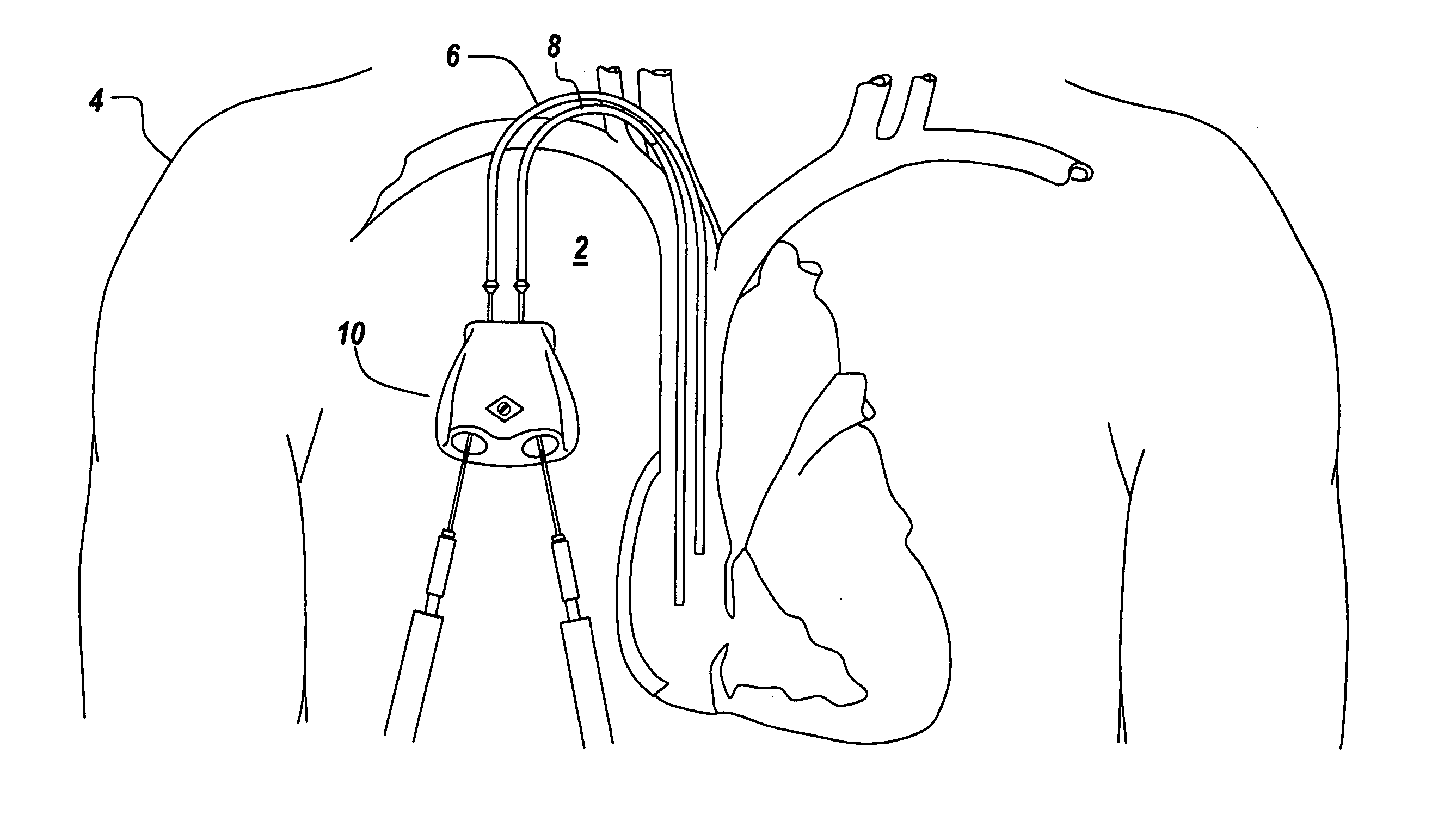

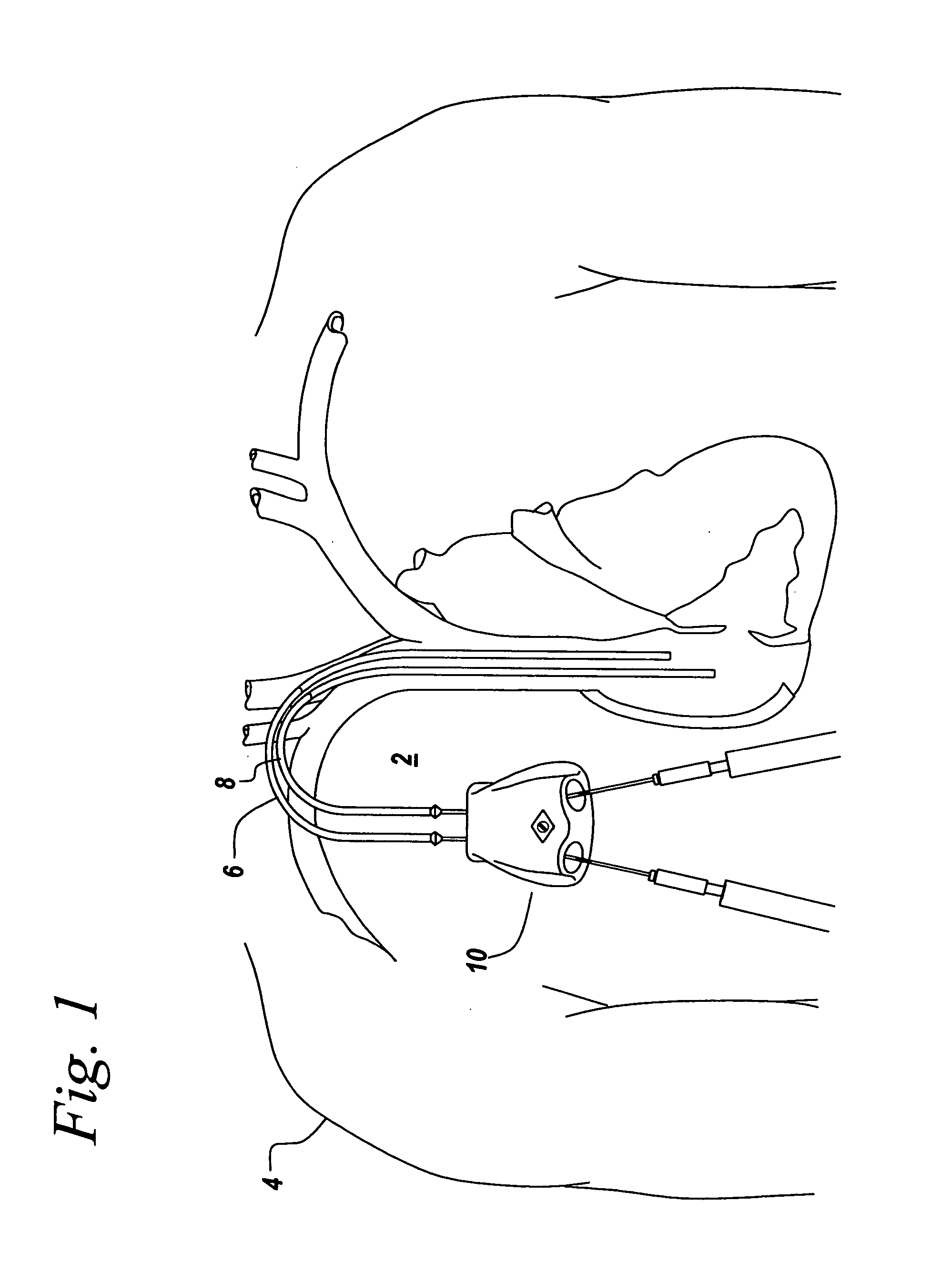

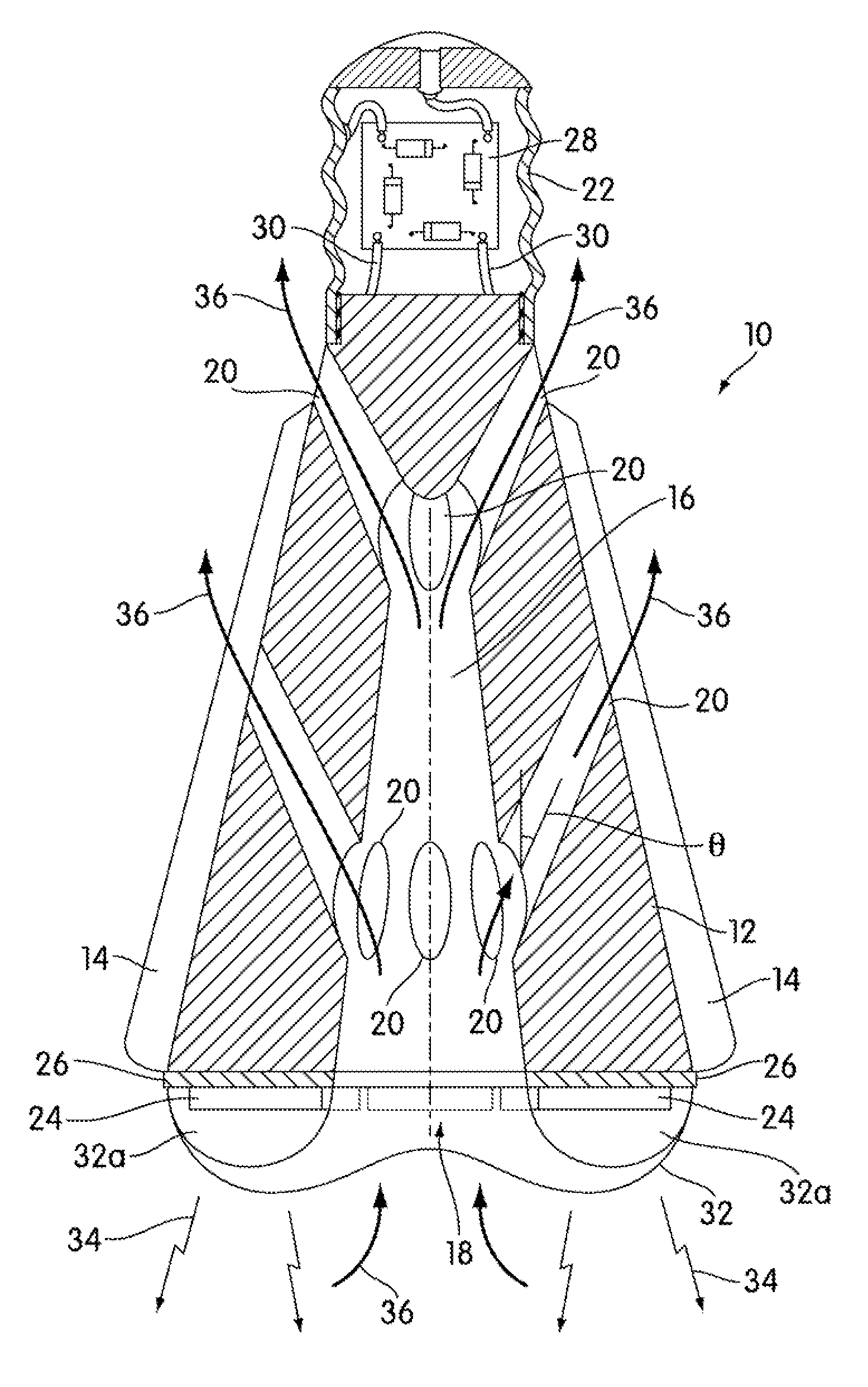

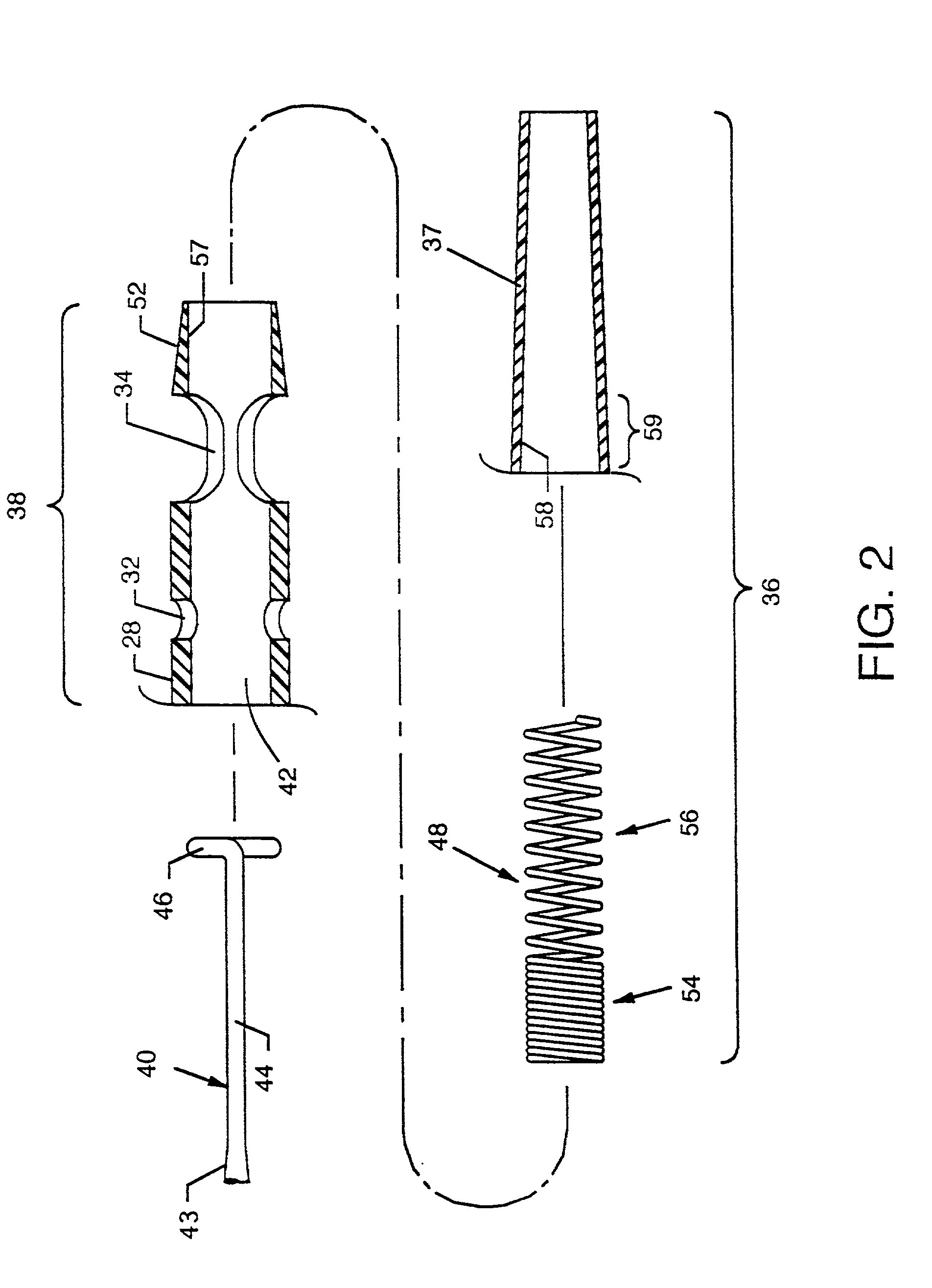

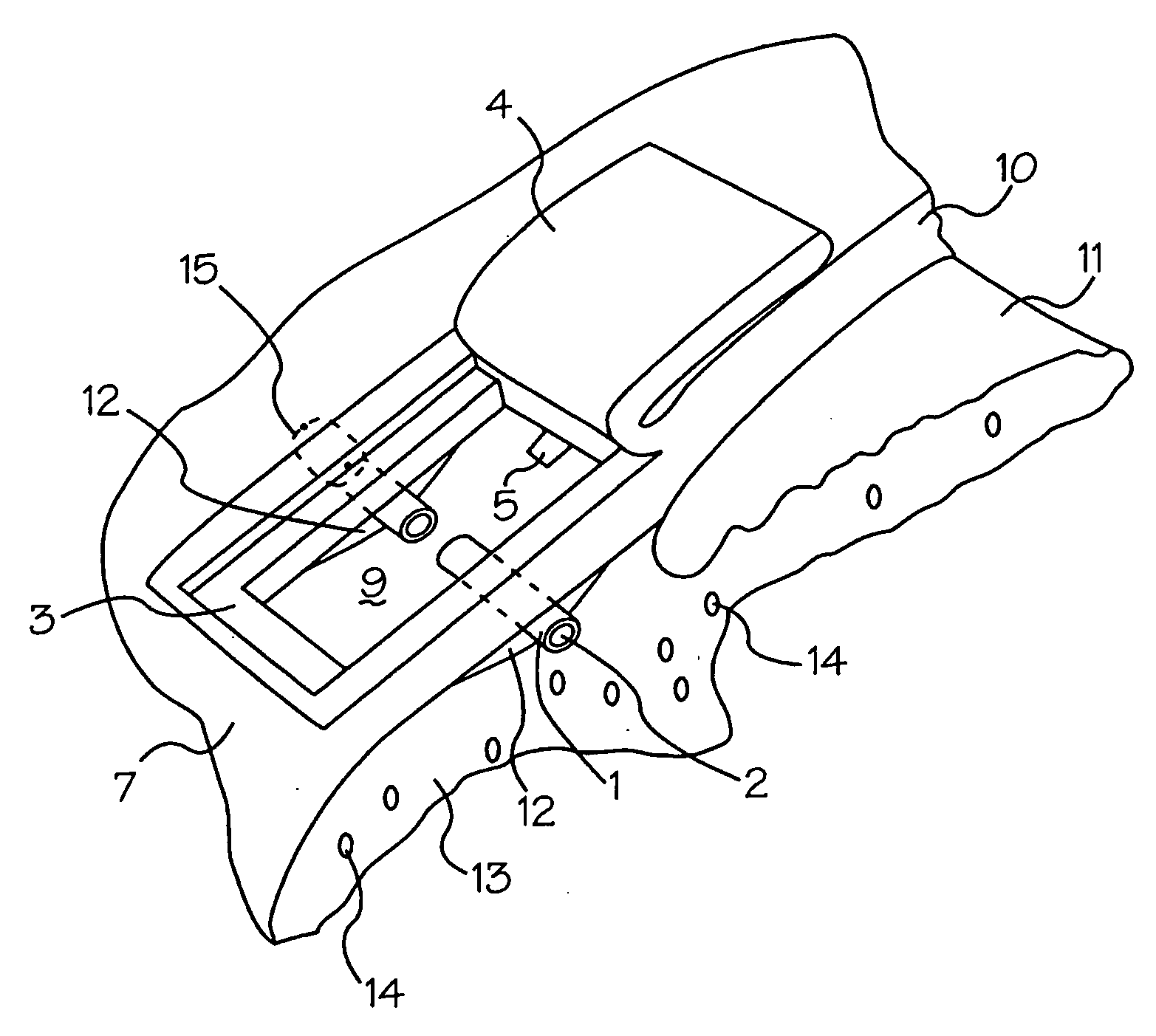

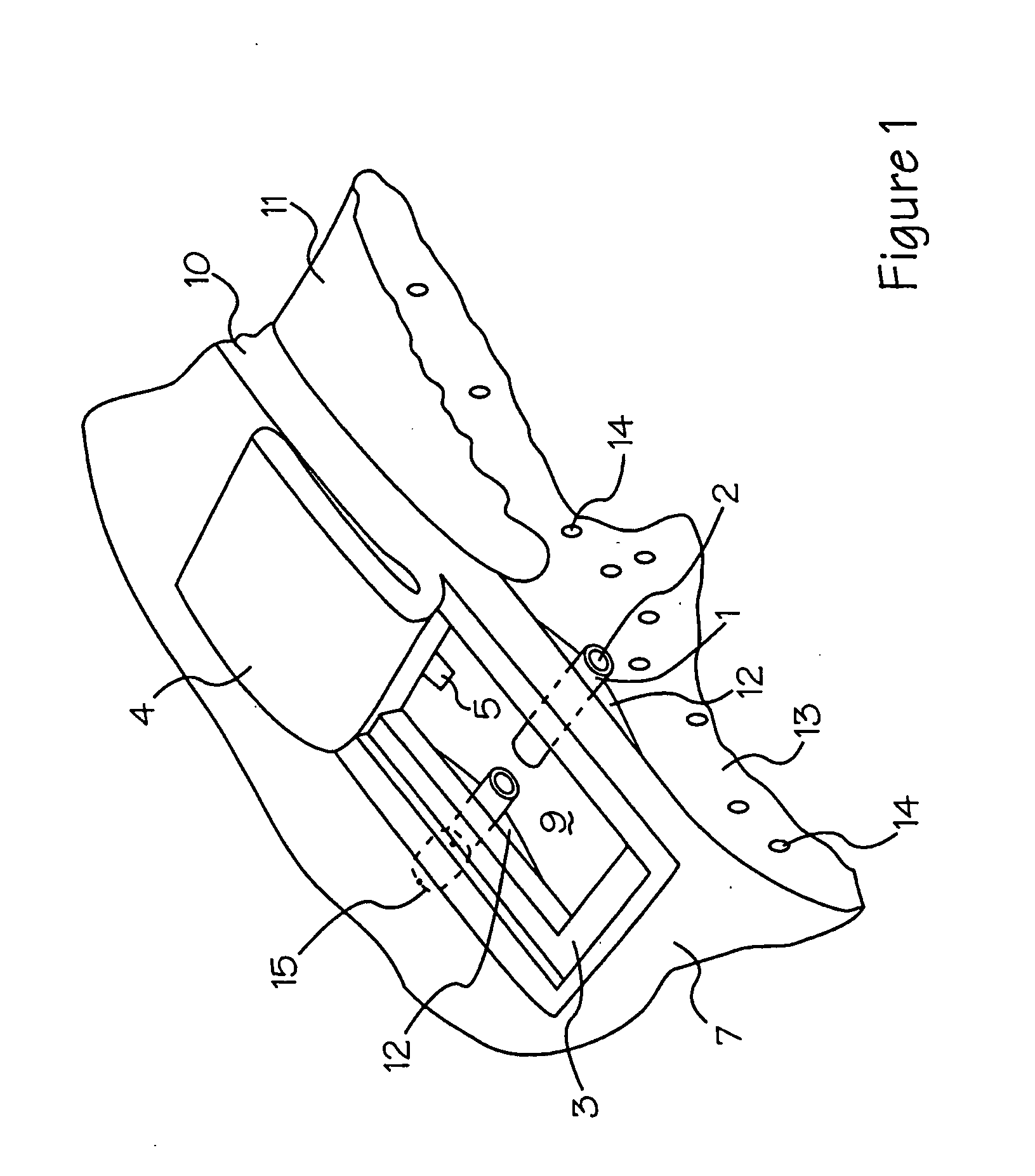

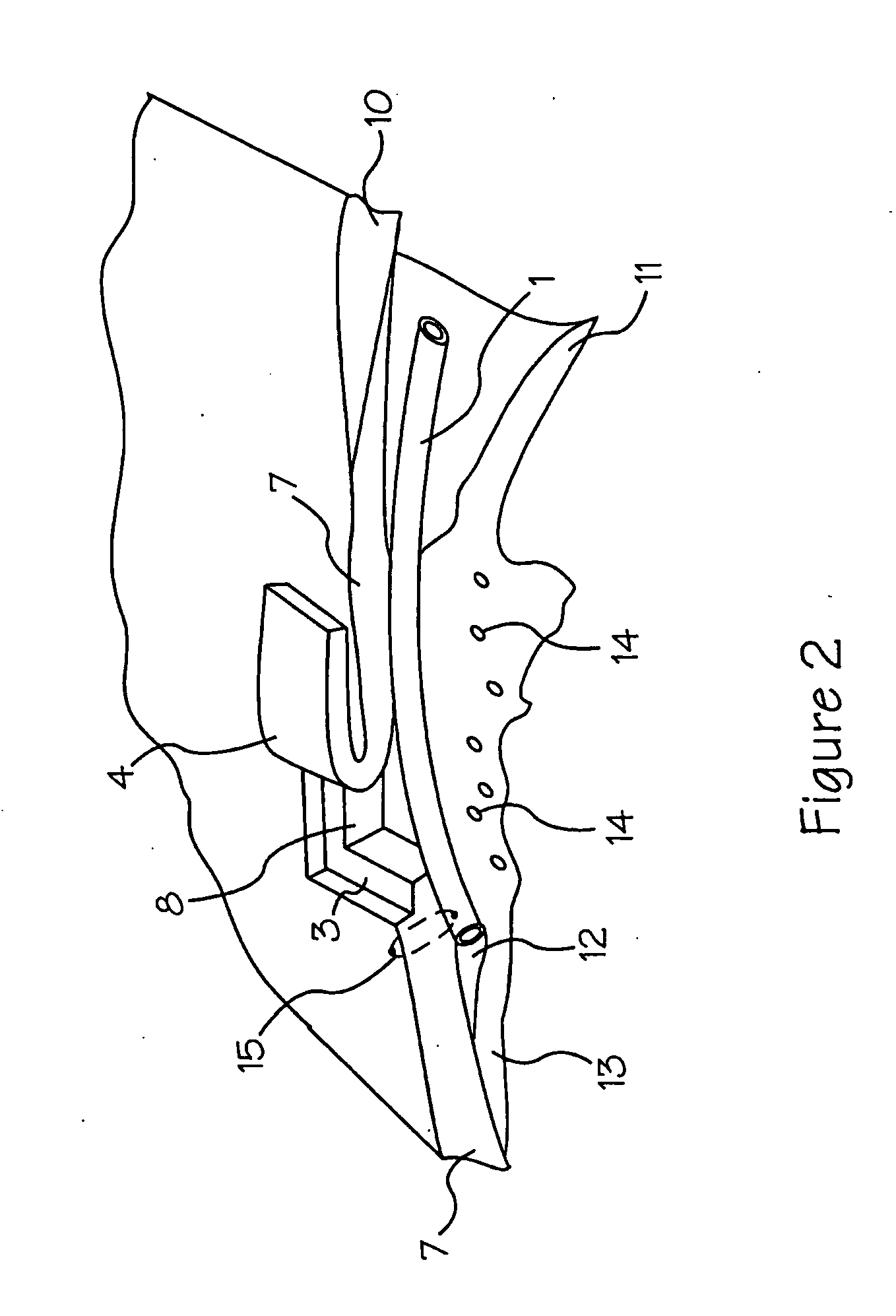

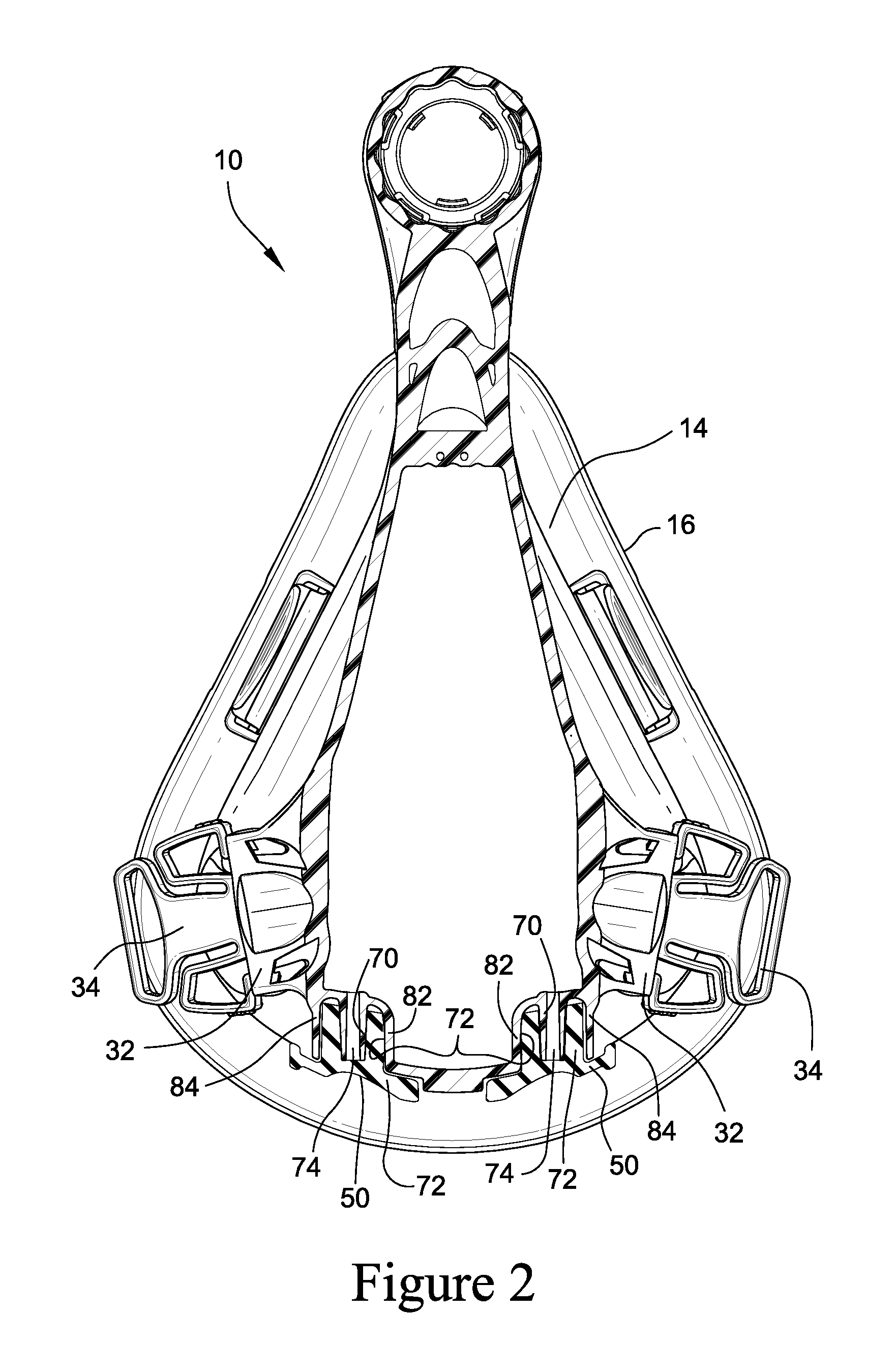

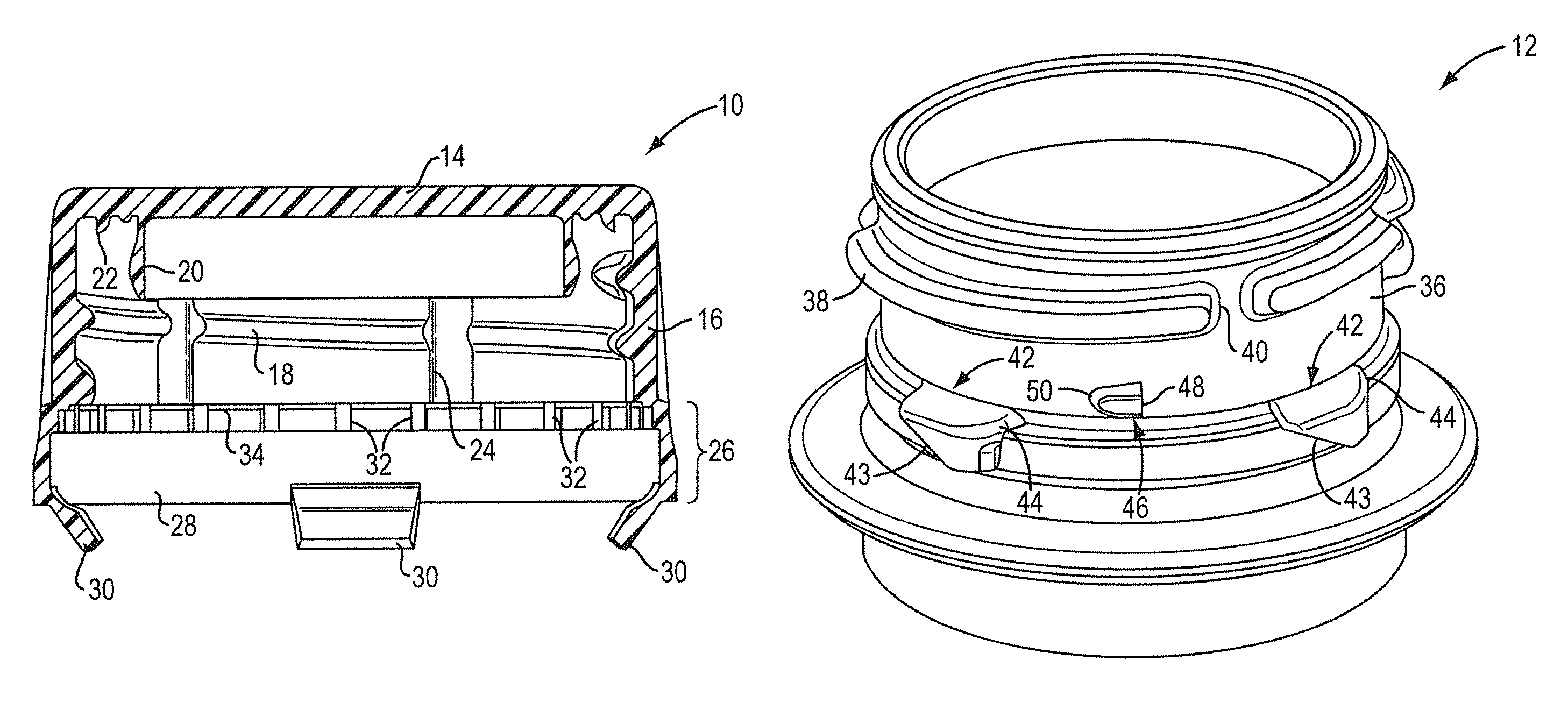

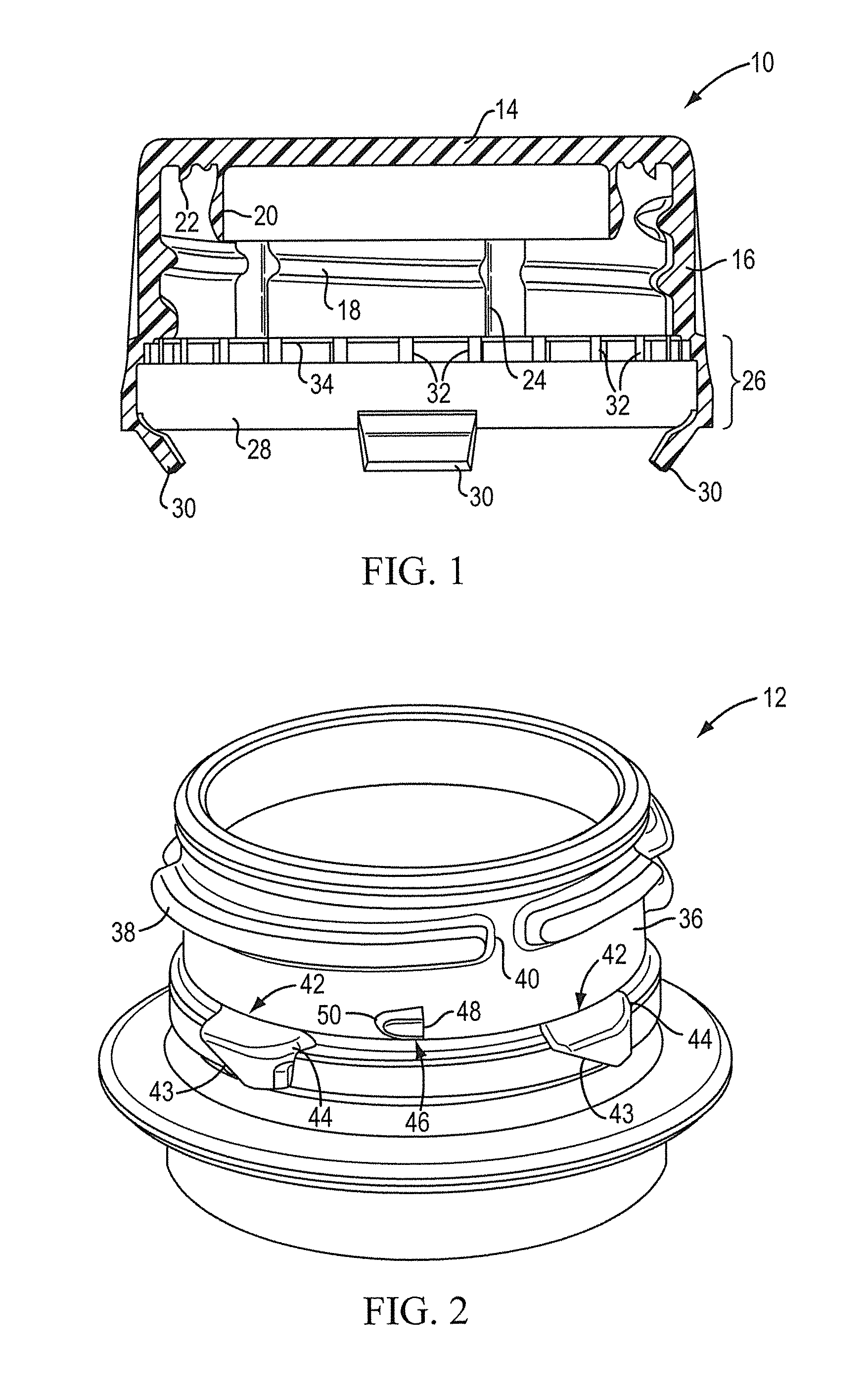

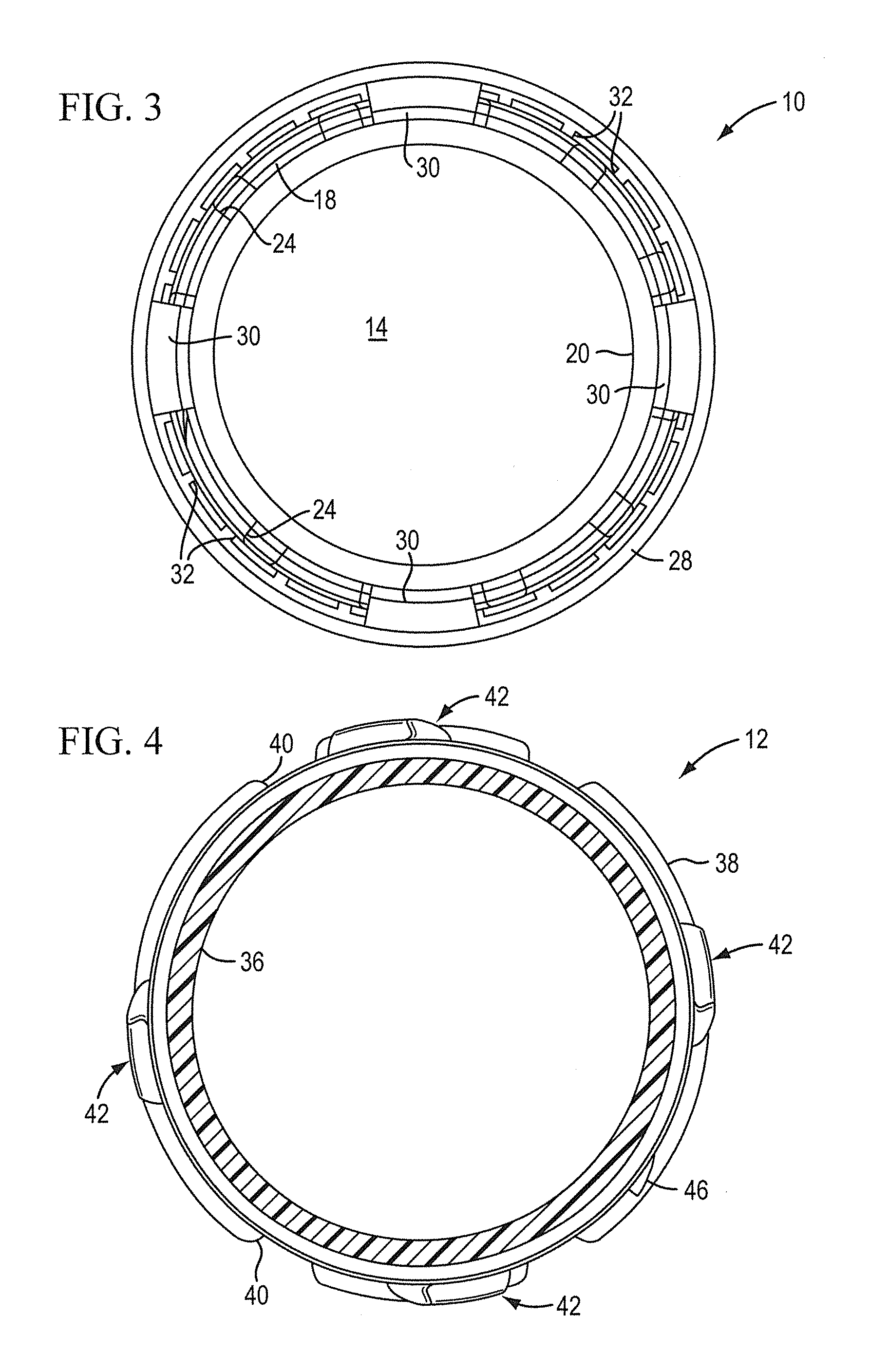

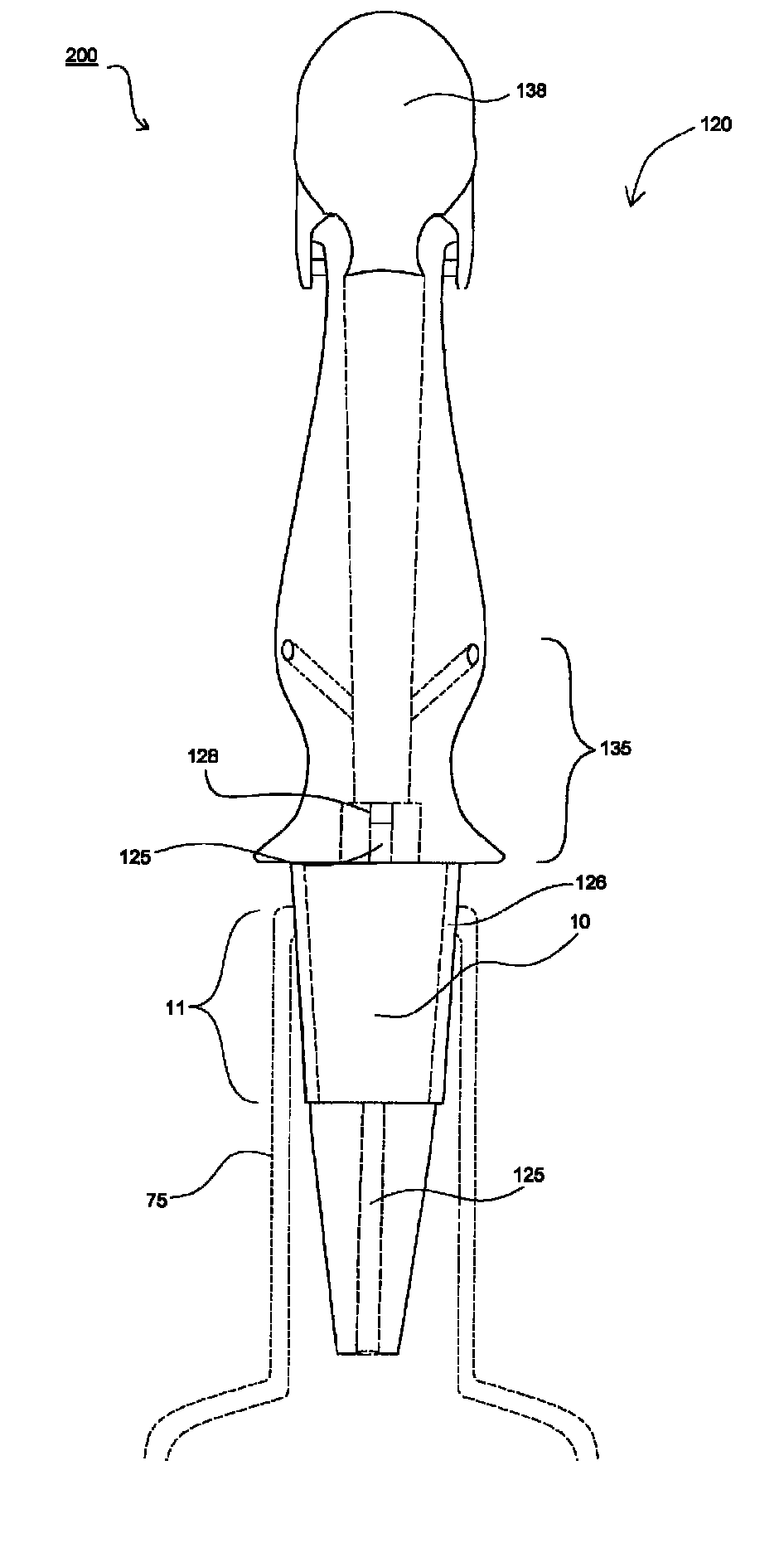

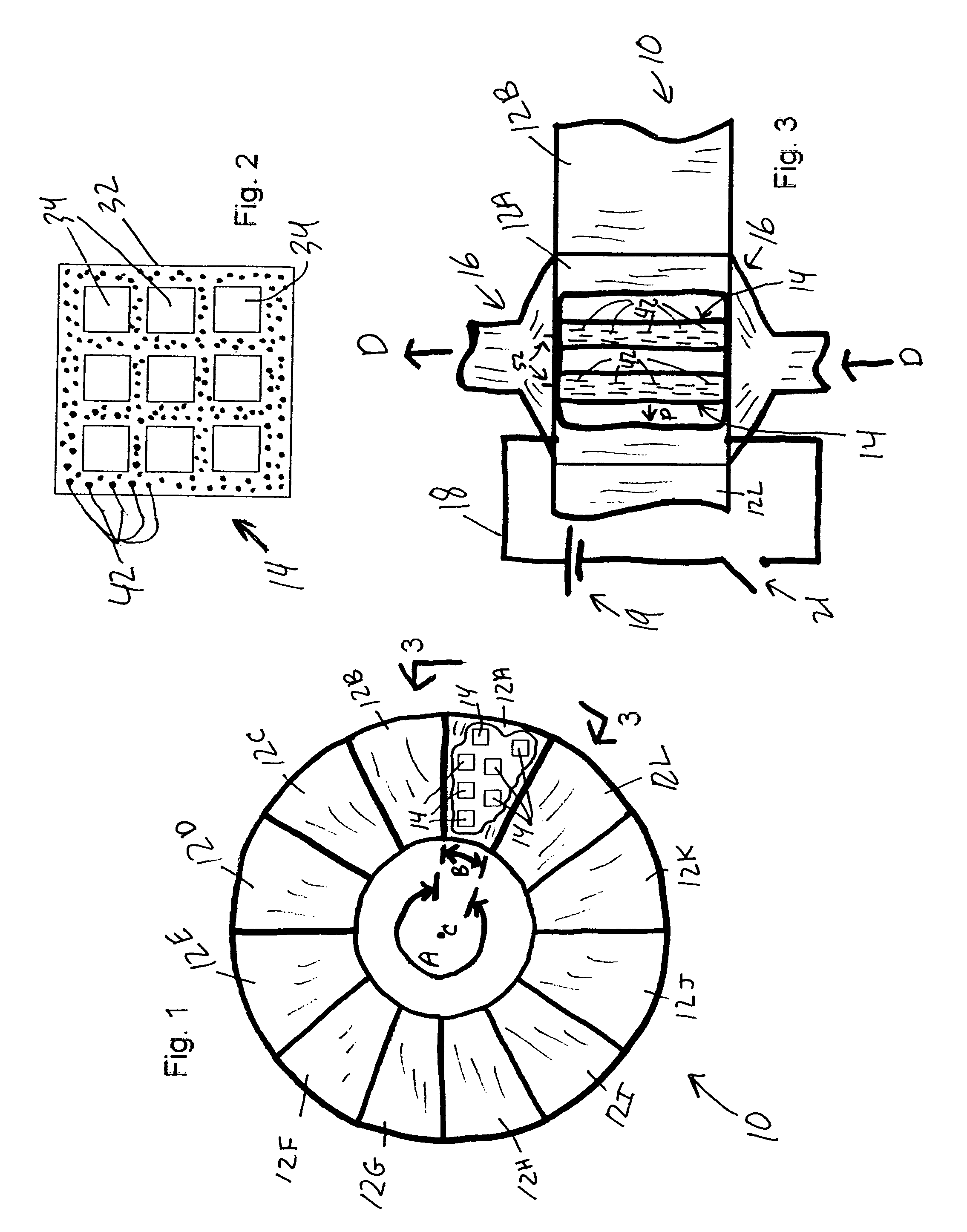

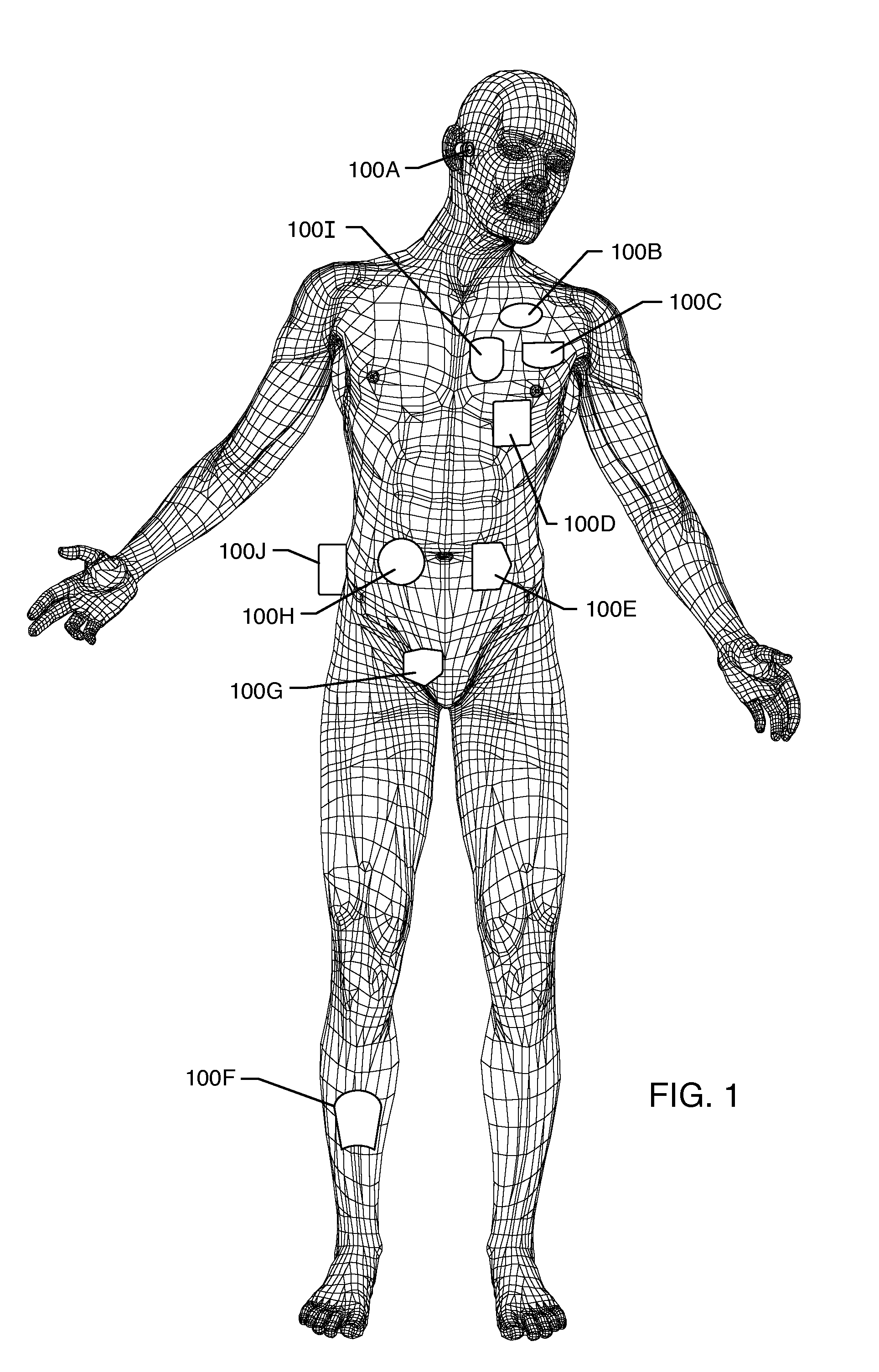

Subcutaneous needle connection system

InactiveUS20070083156A1Improve mechanical stabilityImprove sealingMedical devicesCatheterHemodialysisHaemodialysis machine

An apparatus for establishing a re-usable, recurring, mechanical connection to an organ within a patient is provided. A subcutaneous needle connection system for providing bidirectional, straight and turbulent-free fluid flow access to a vascular system of a patient includes a housing defining a needle access opening for receiving a needle, a cannula opening in communication with the vascular system and a passageway connecting the needle access opening to the cannula opening. The housing can additionally have a second needle access opening connected to a second cannula opening via a second passageway. The subcutaneous needle connection system allows for blood to be removed from the vascular system via one cannula opening, passed to a hemodialysis system via a needle inserted in an associated needle access opening, treated using the hemodialysis system, and returned to the vascular system via the other needle access opening and associated cannula opening. The implantable needle connection system provides enhanced mechanical stability under the skin, improved fluid flow dynamics, improved needle hole healing potential of the skin, and improved needle edge interfacing to minimize flow turbulence and blood cell trauma during use.

Owner:ATRIUM MEDICAL

Light emitting diode (LED) lighting device

ActiveUS8143769B2Increase air flowHigh trafficPoint-like light sourceElectric discharge tubesEffect lightEngineering

An LED lighting device comprises: a thermally conducting body having an at least one opening that connects with a cavity within the body and a plurality of LEDs mounted in thermal communication with a face of the body and positioned around the opening. One or more passages pass through the body from the cavity to an outer surface of the body and are configured such that in operation air moves through the cavity by thermal convection thereby to provide cooling of the body. Each passage is configured in a direction that extends in a direction at an angle of about 45° to a line that is parallel with the axis of the body toward the outer surface of the body away from the face. The body can be configured such that its outer surface has a form factor resembling an incandescent light bulb or halogen reflector lamp.

Owner:BX LED LLC

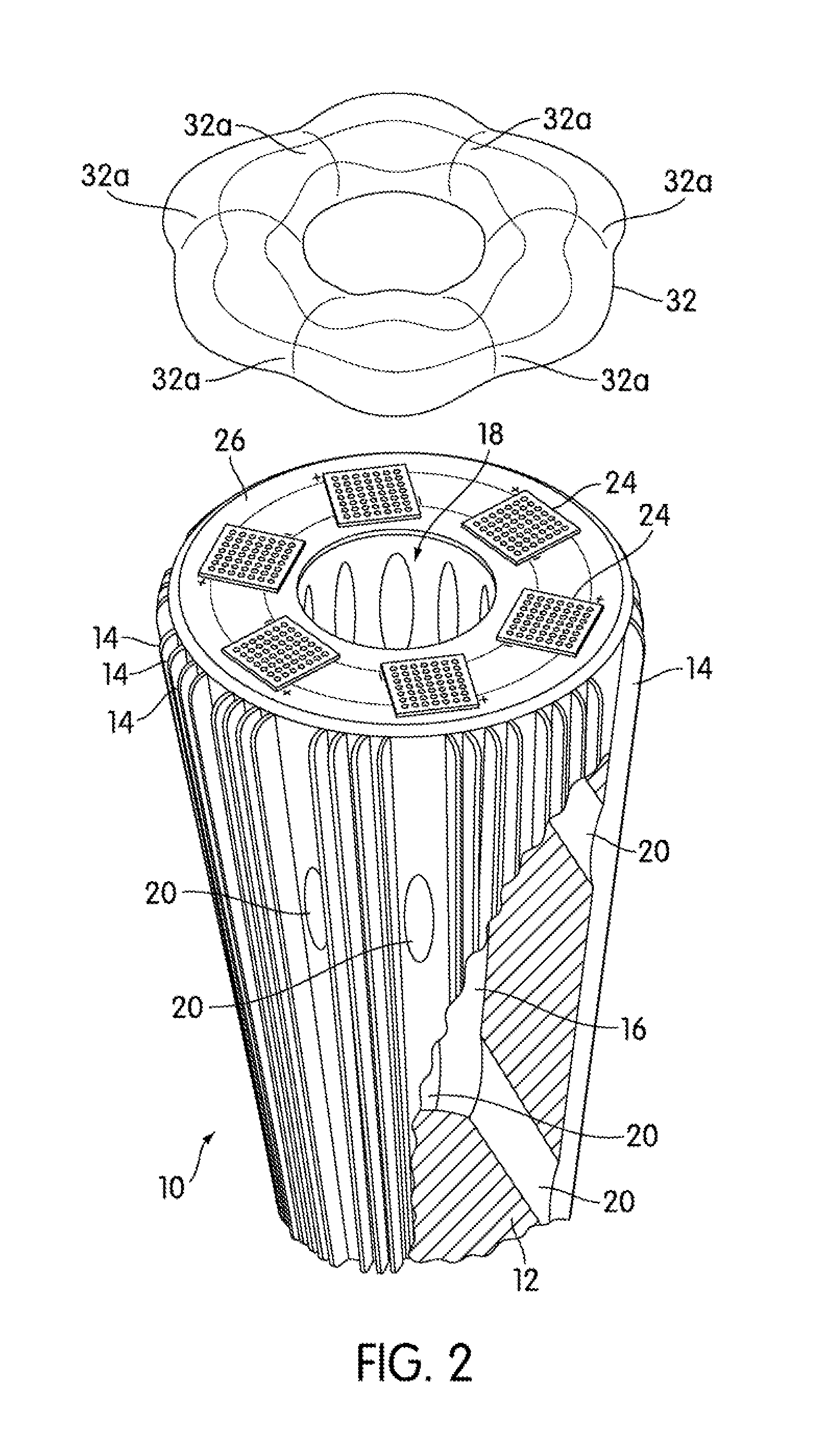

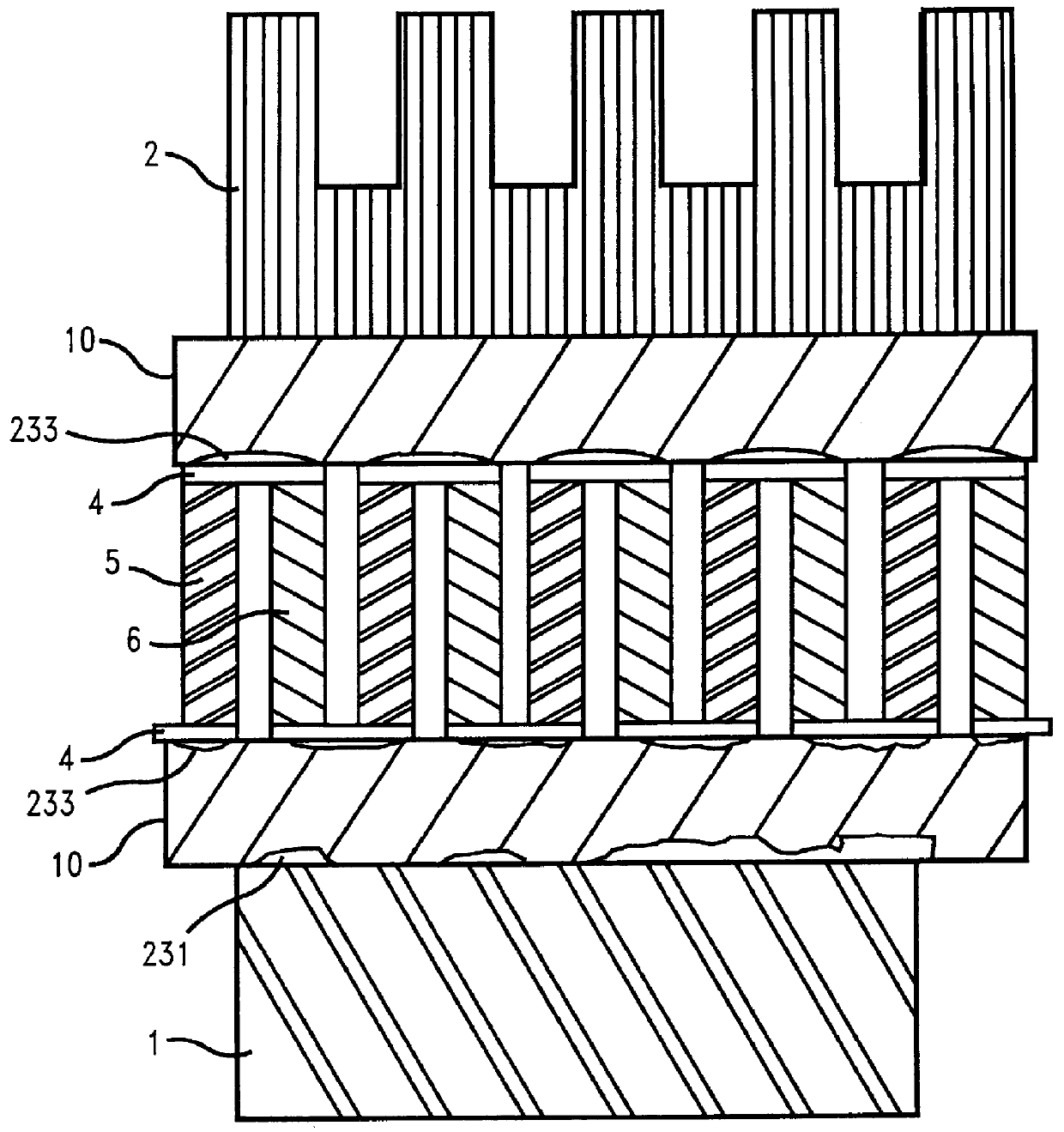

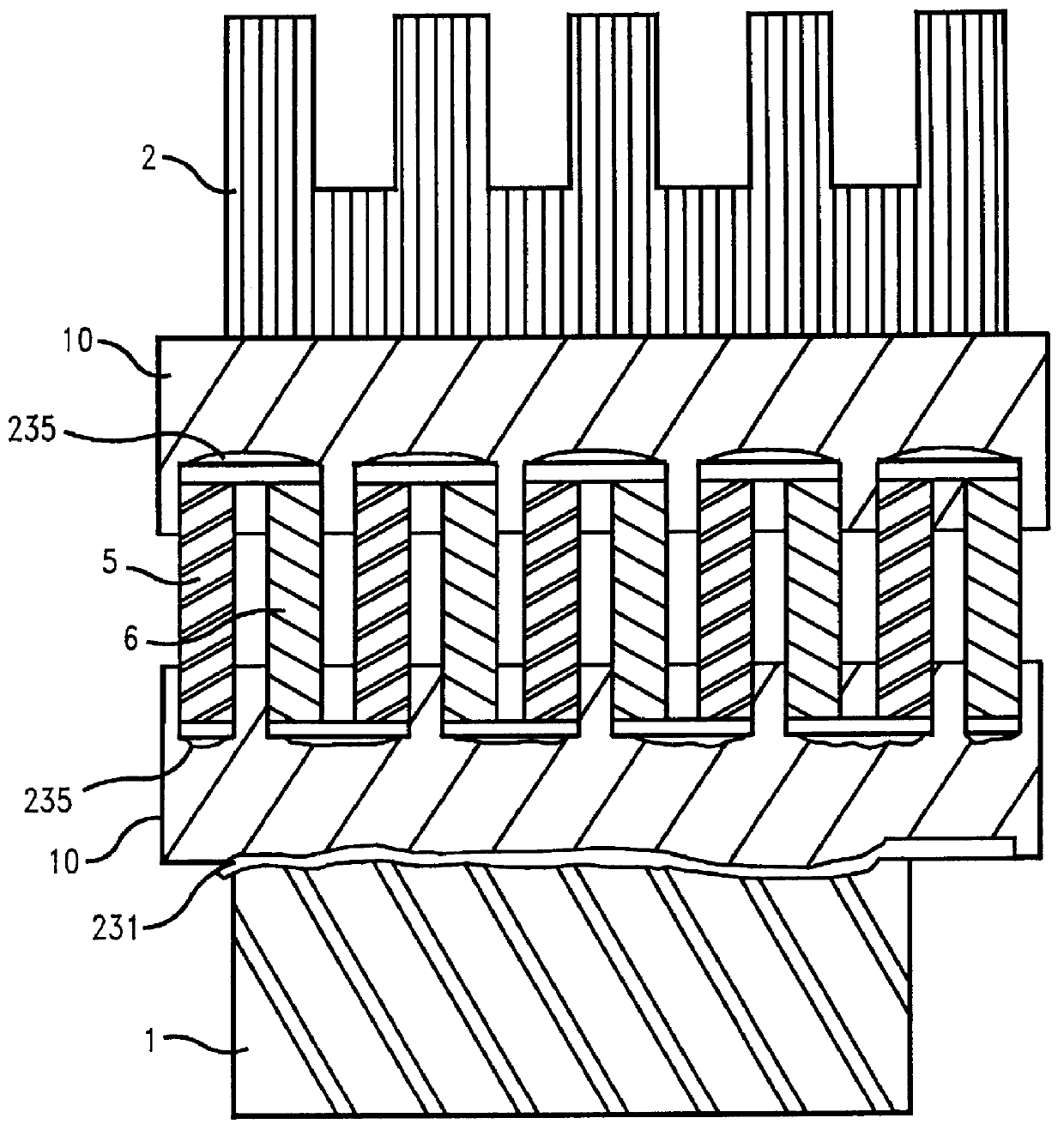

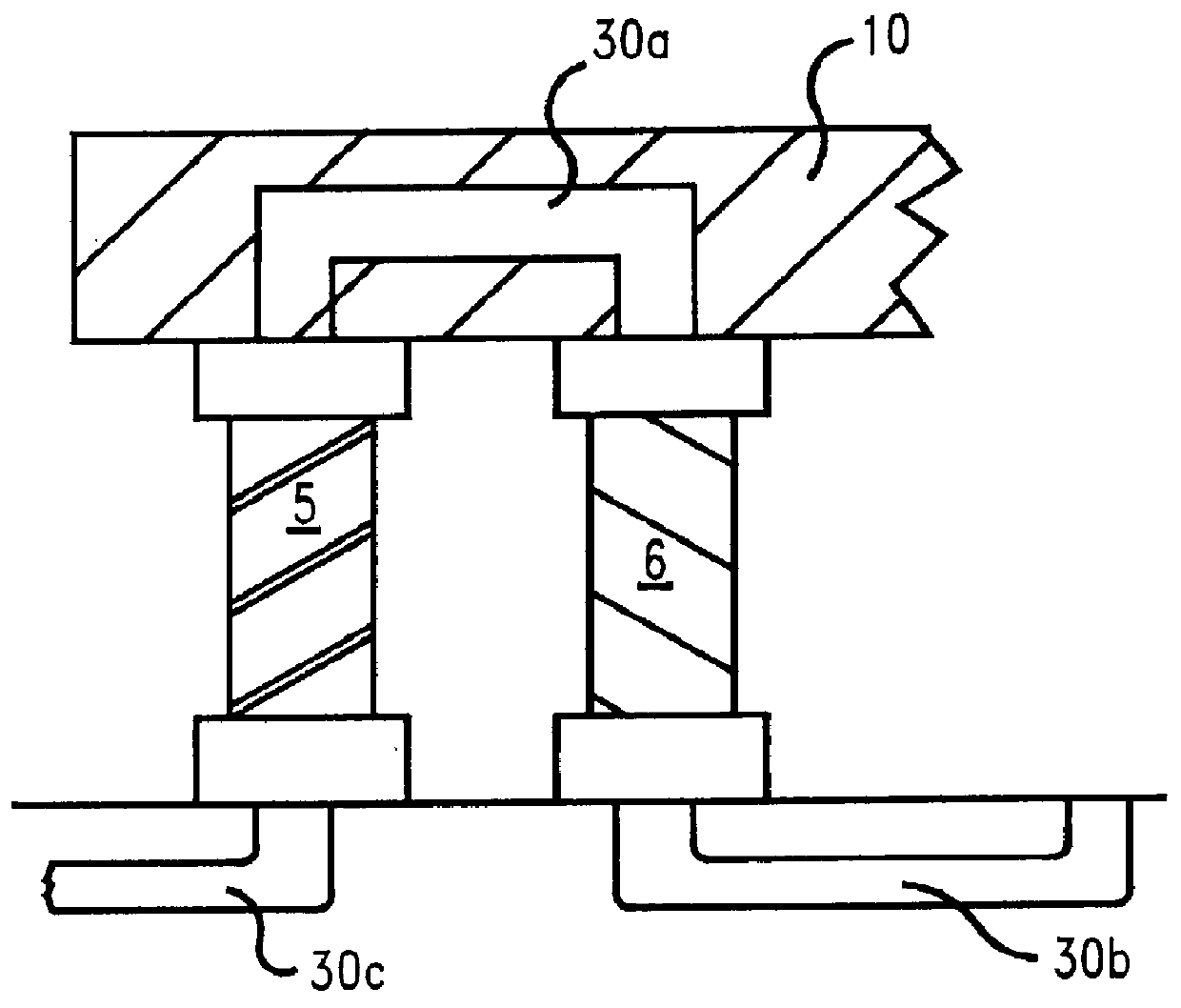

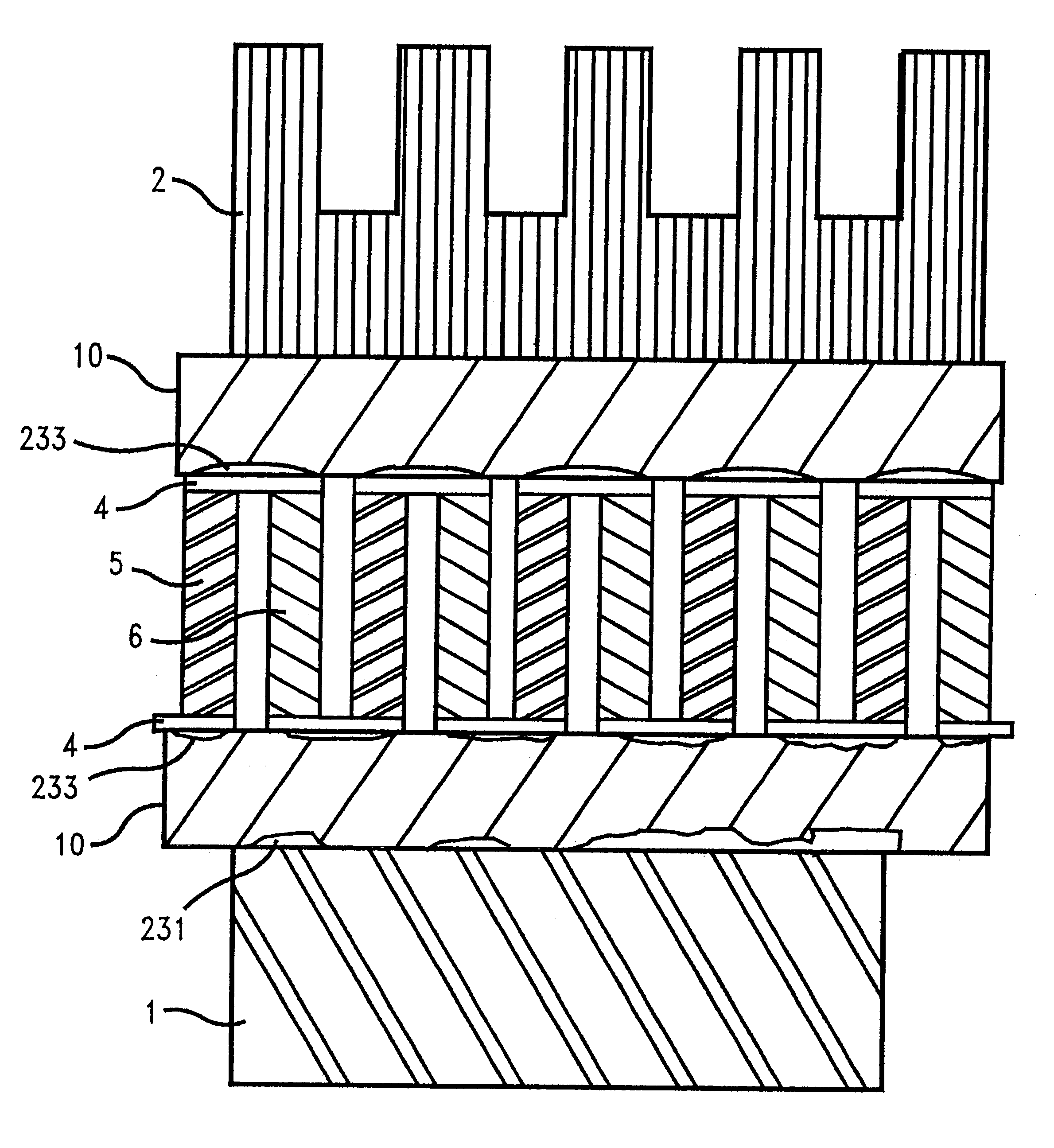

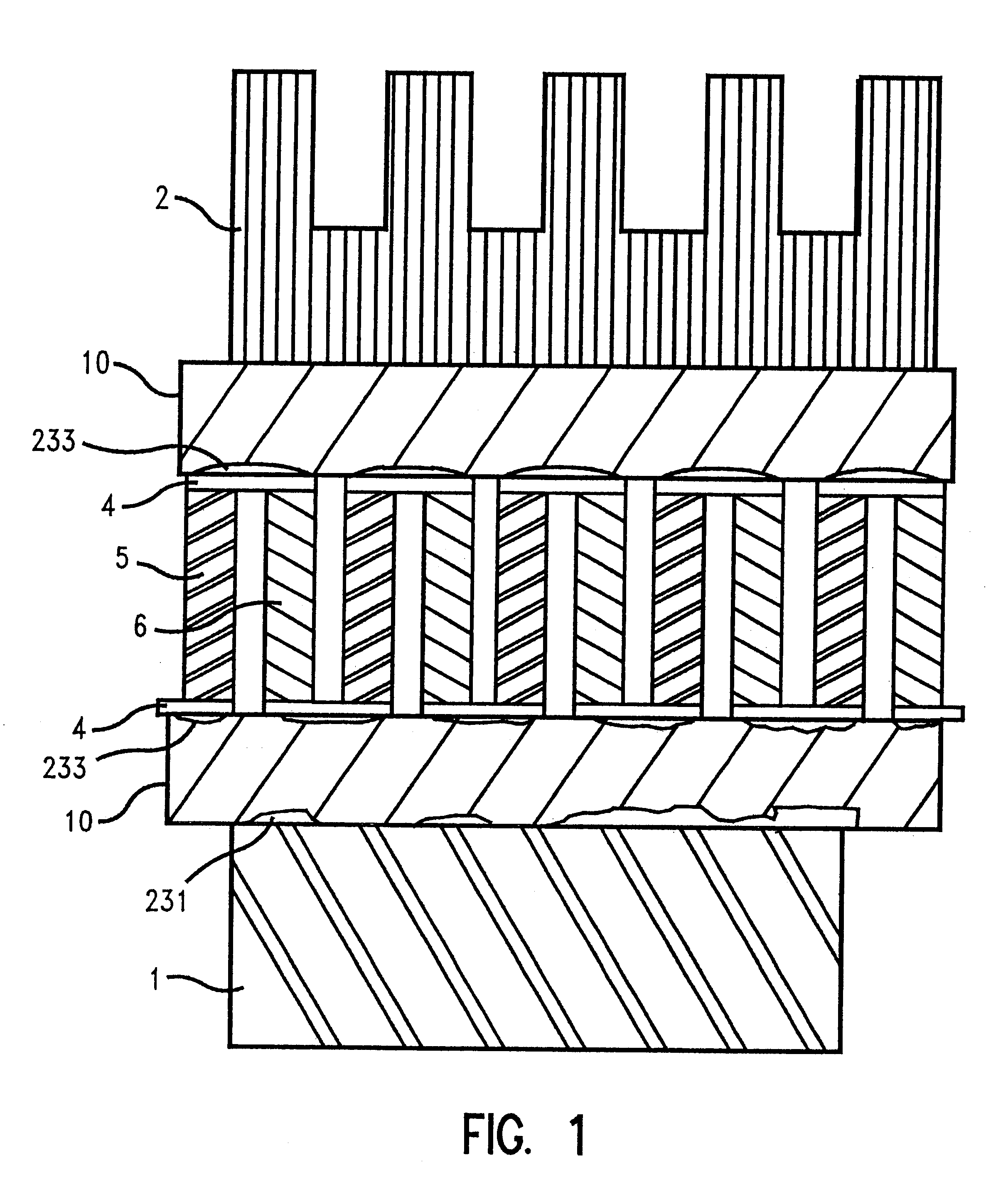

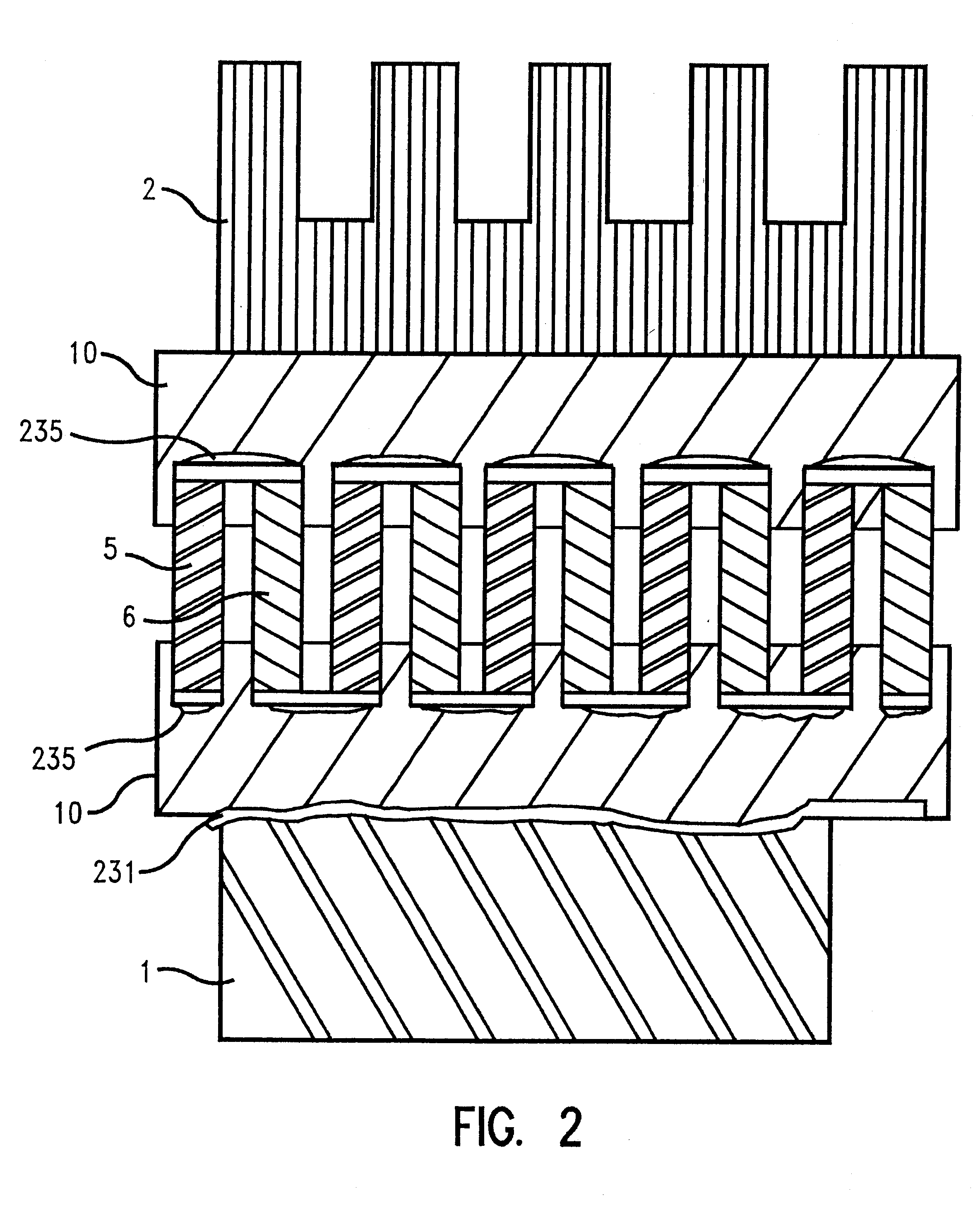

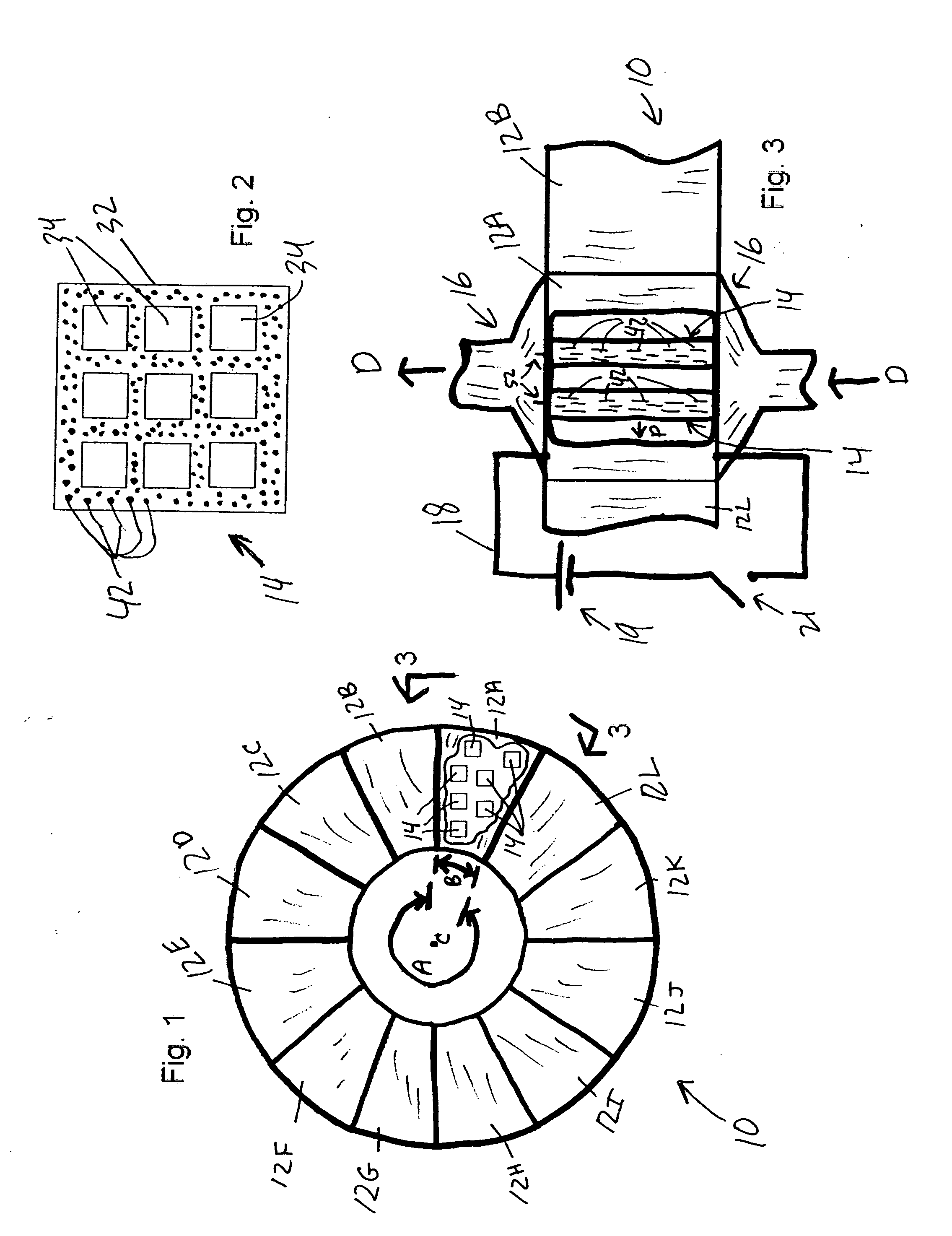

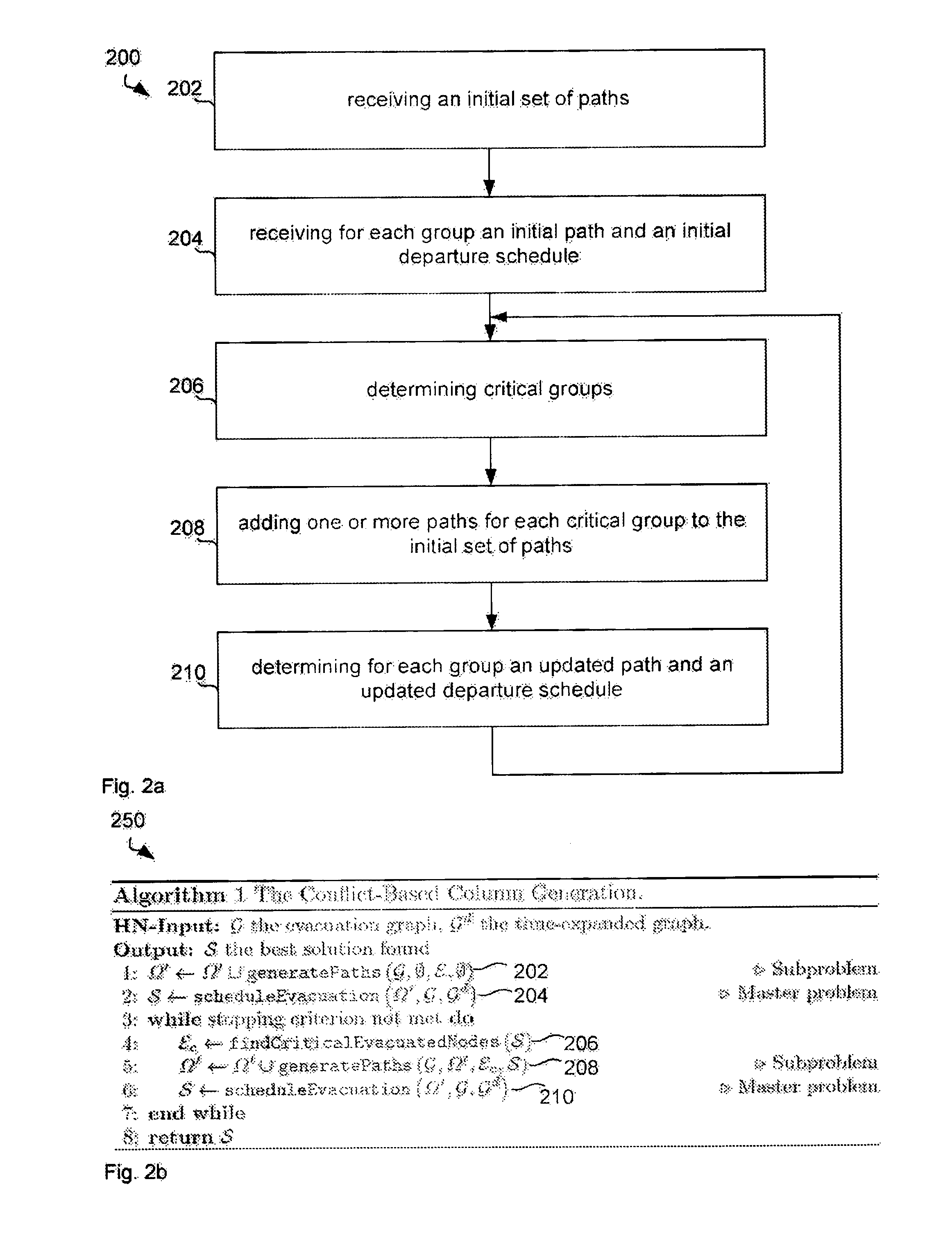

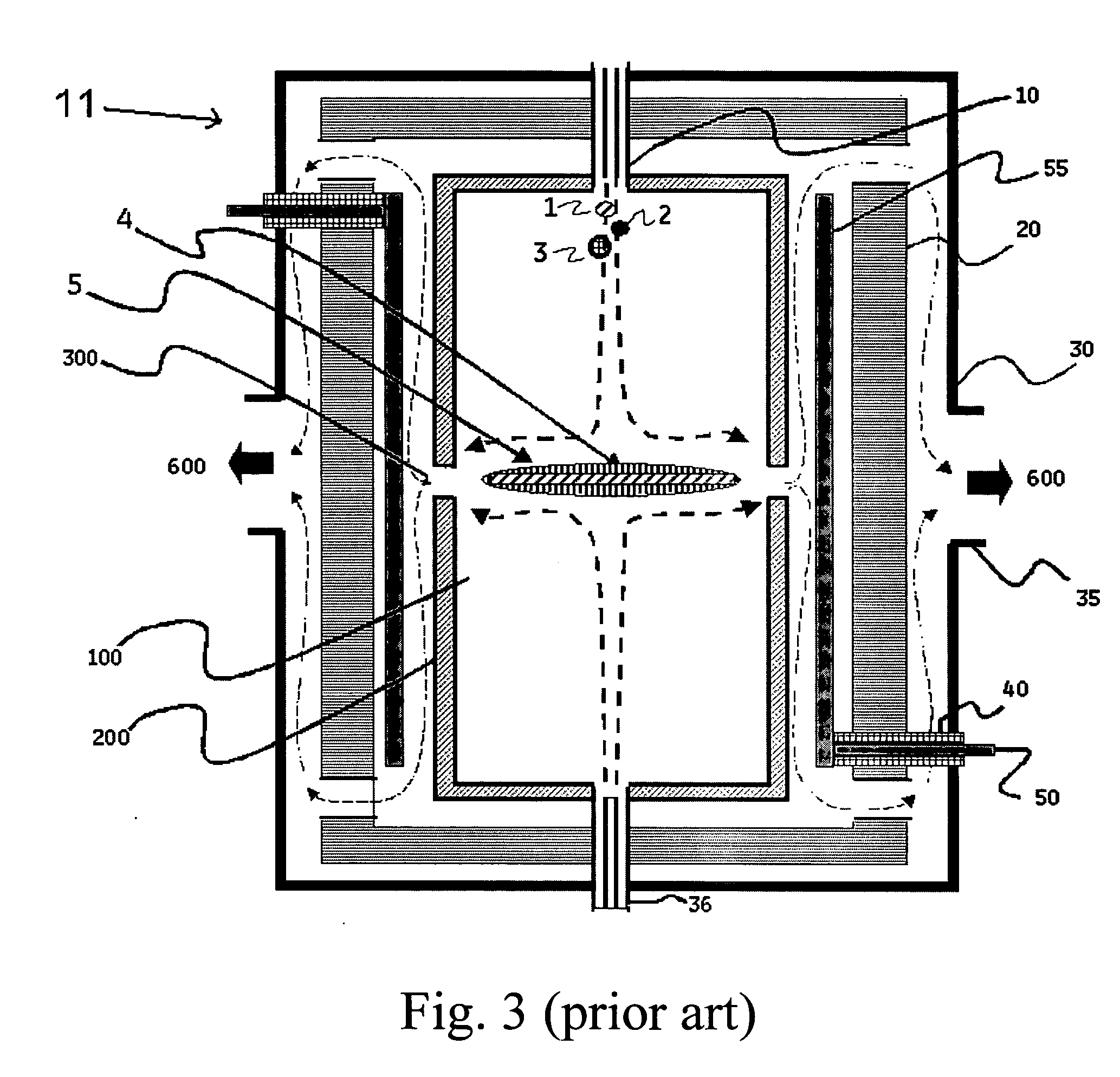

Thermoelectric devices and methods for making the same

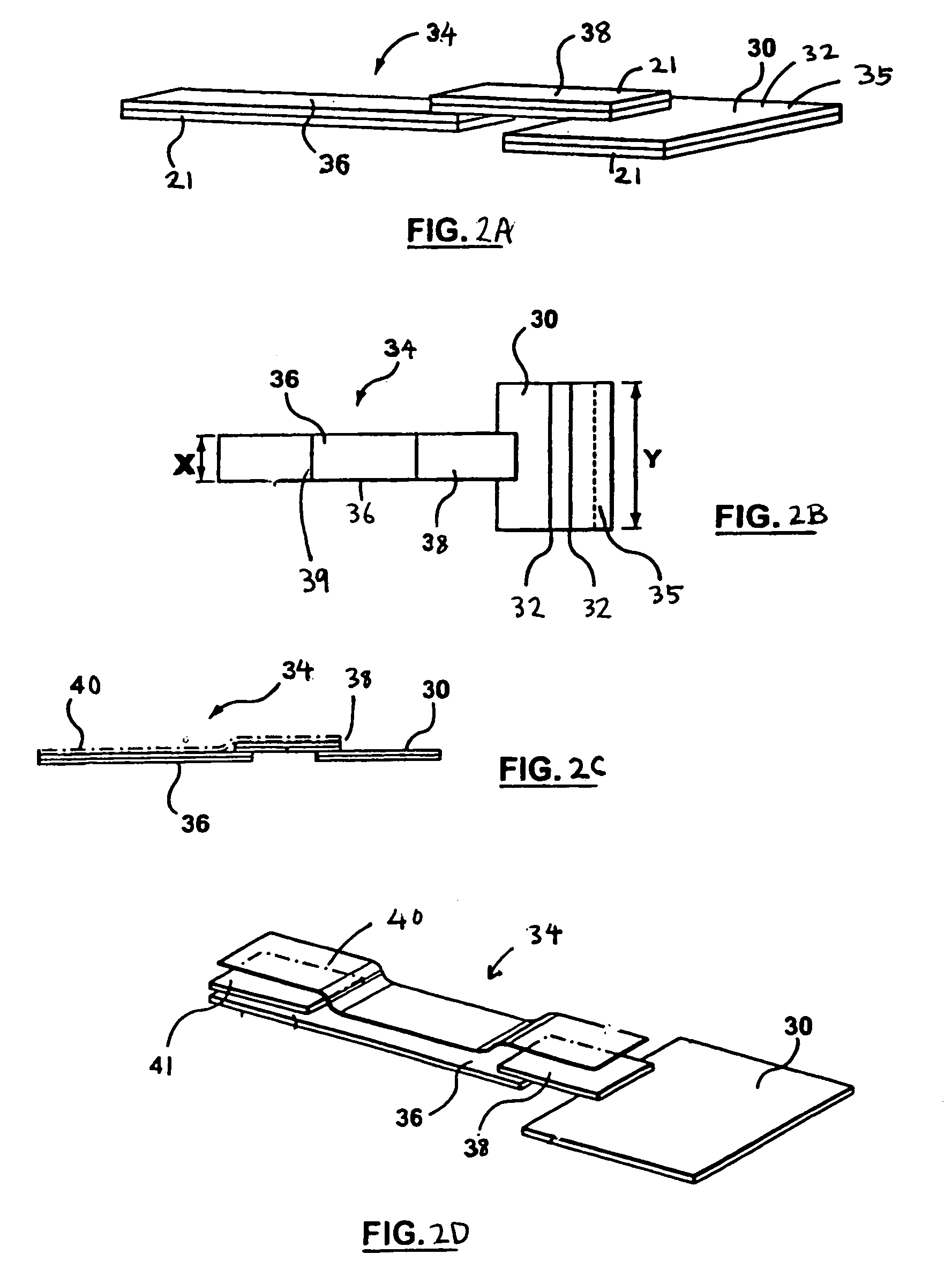

InactiveUS6121539AMaximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsScreening techniquesThermal energy

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods are employed for forming tunnels through lamination and etching. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates. Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer. Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:IBM CORP

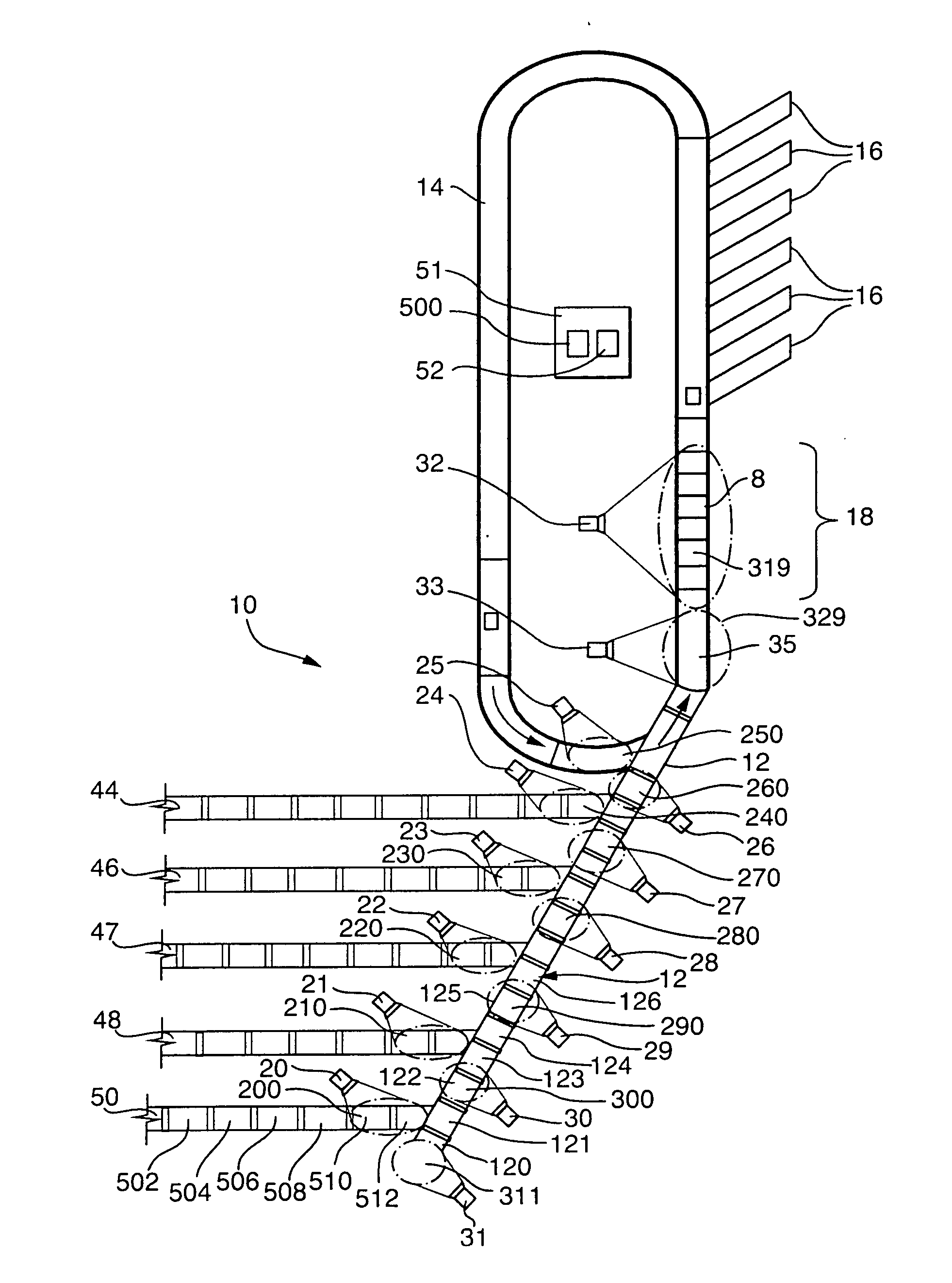

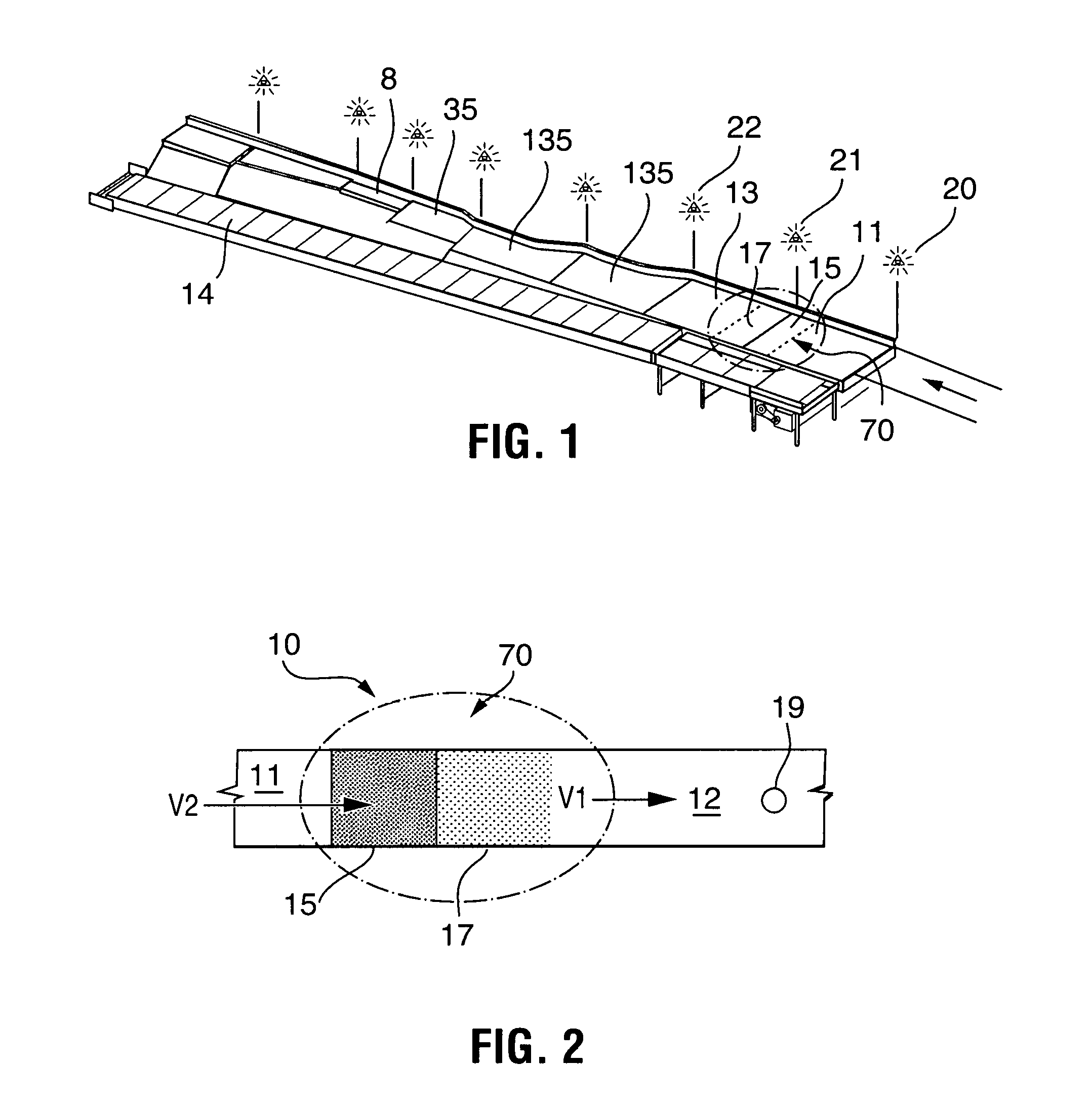

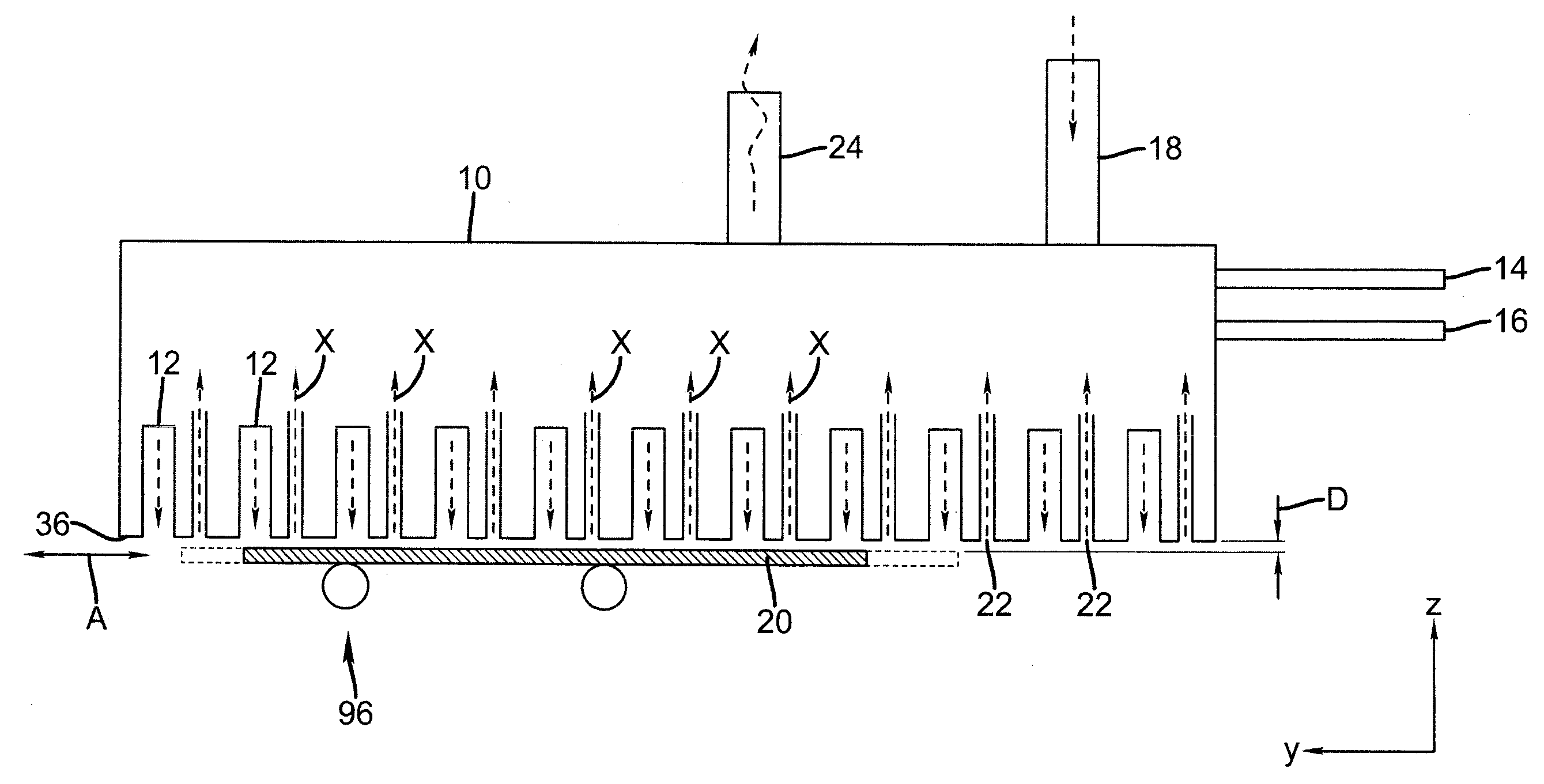

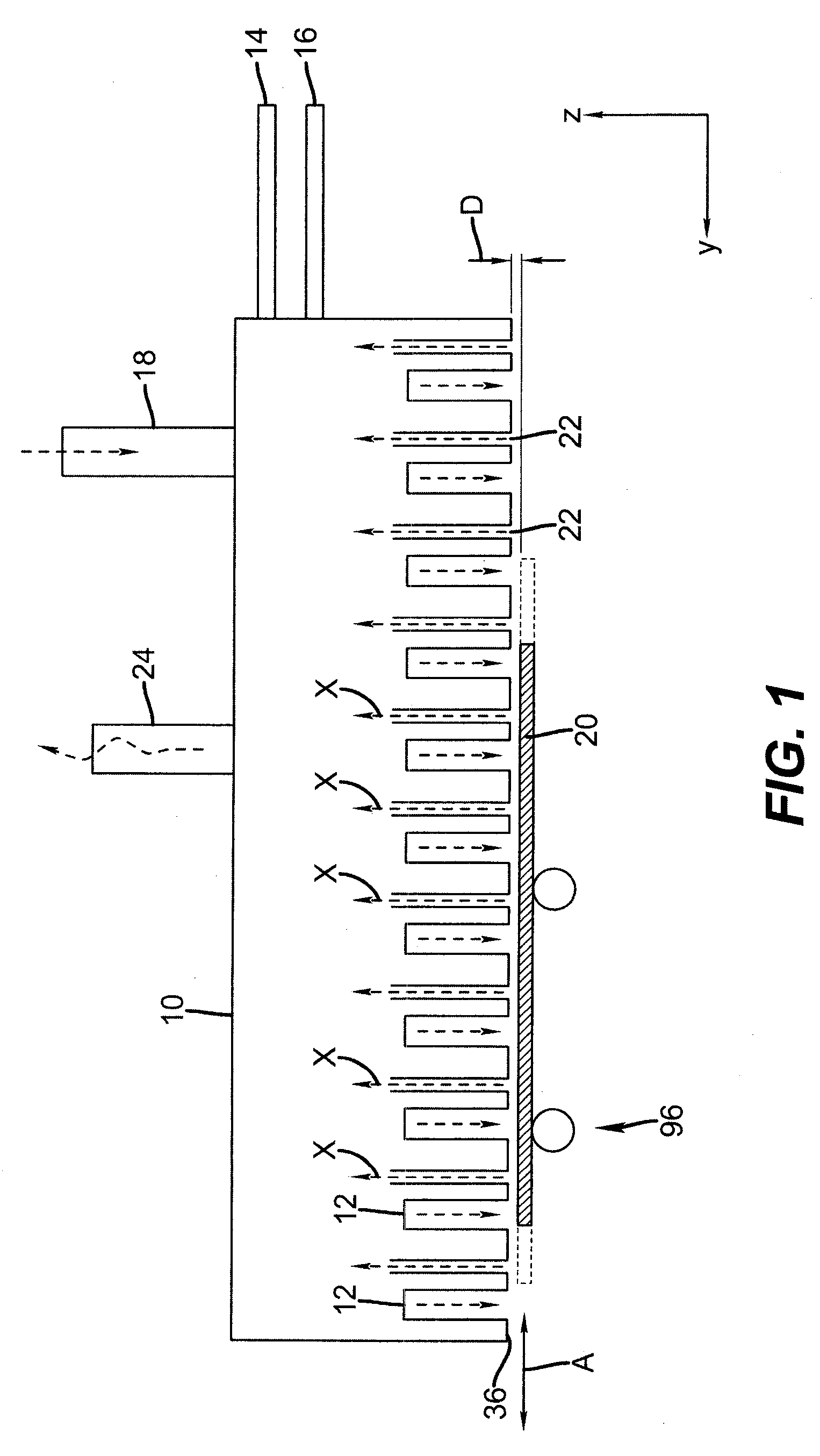

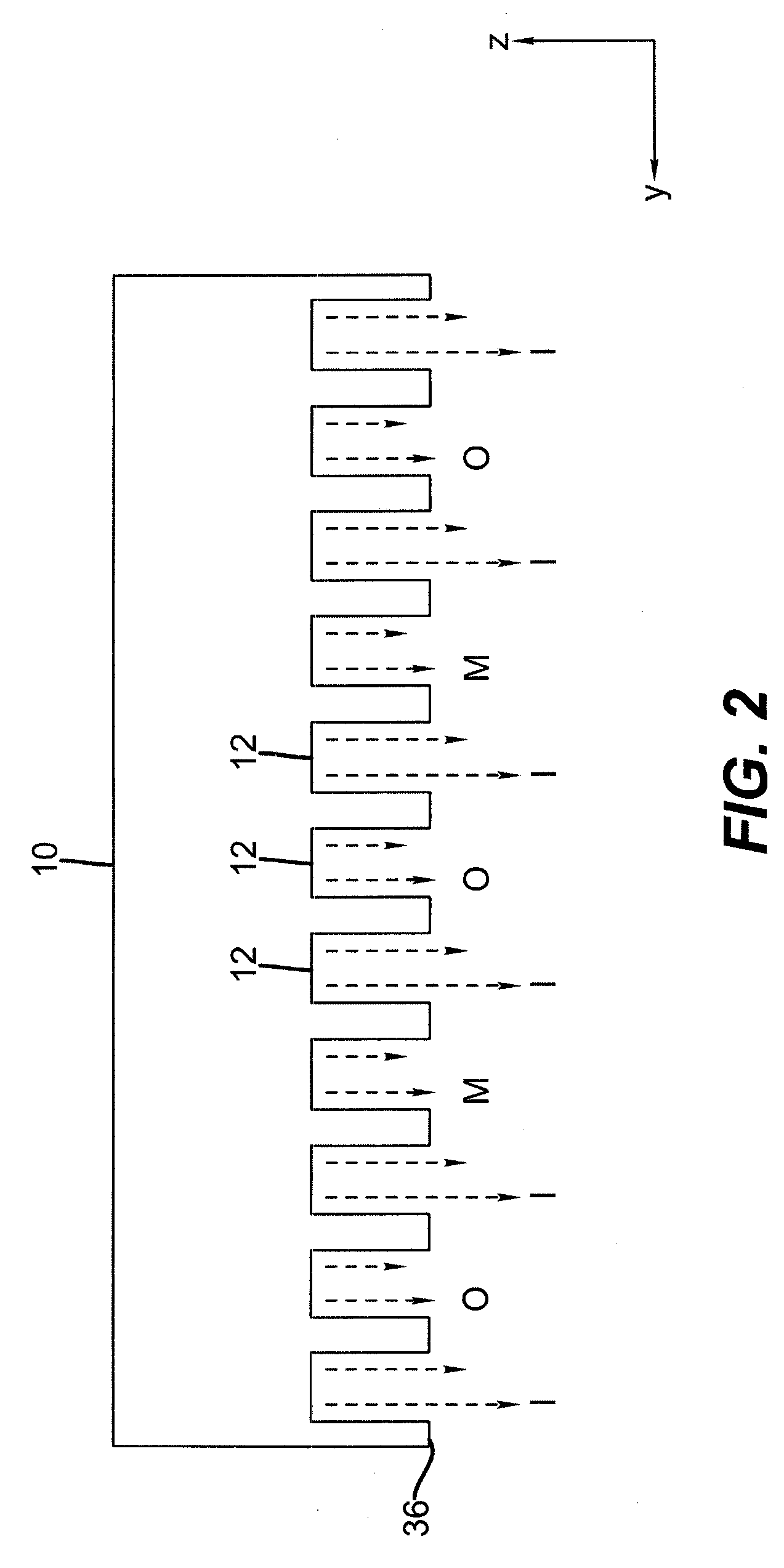

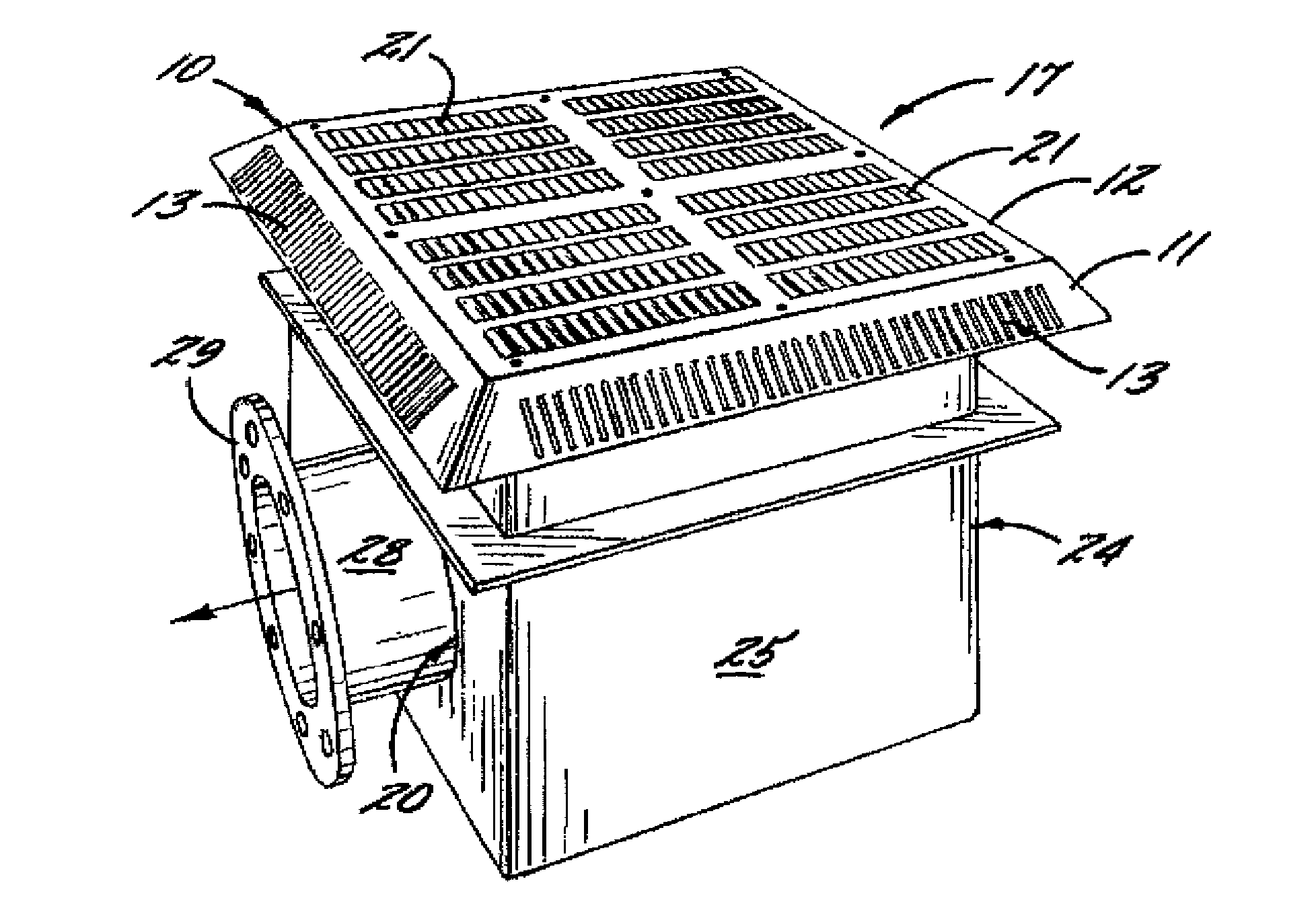

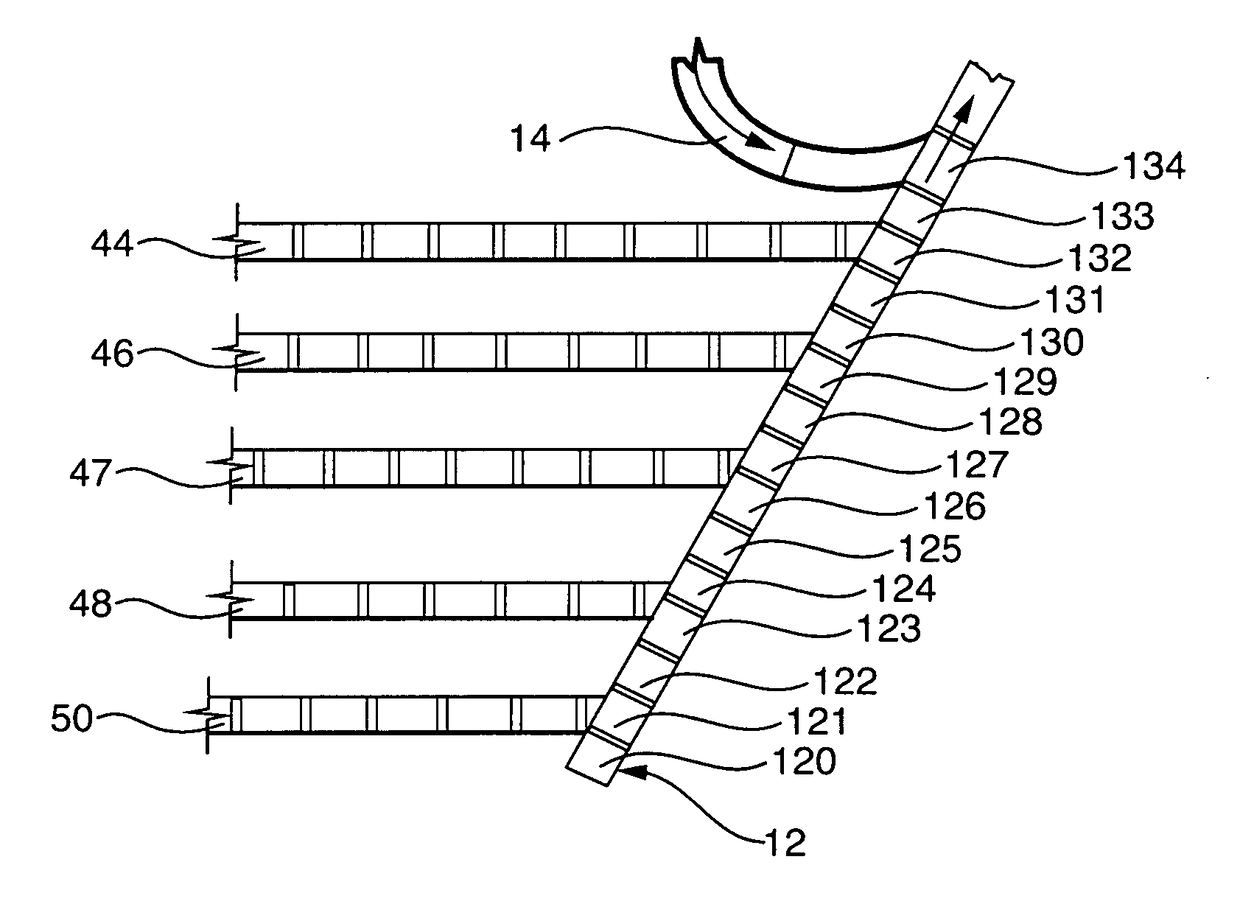

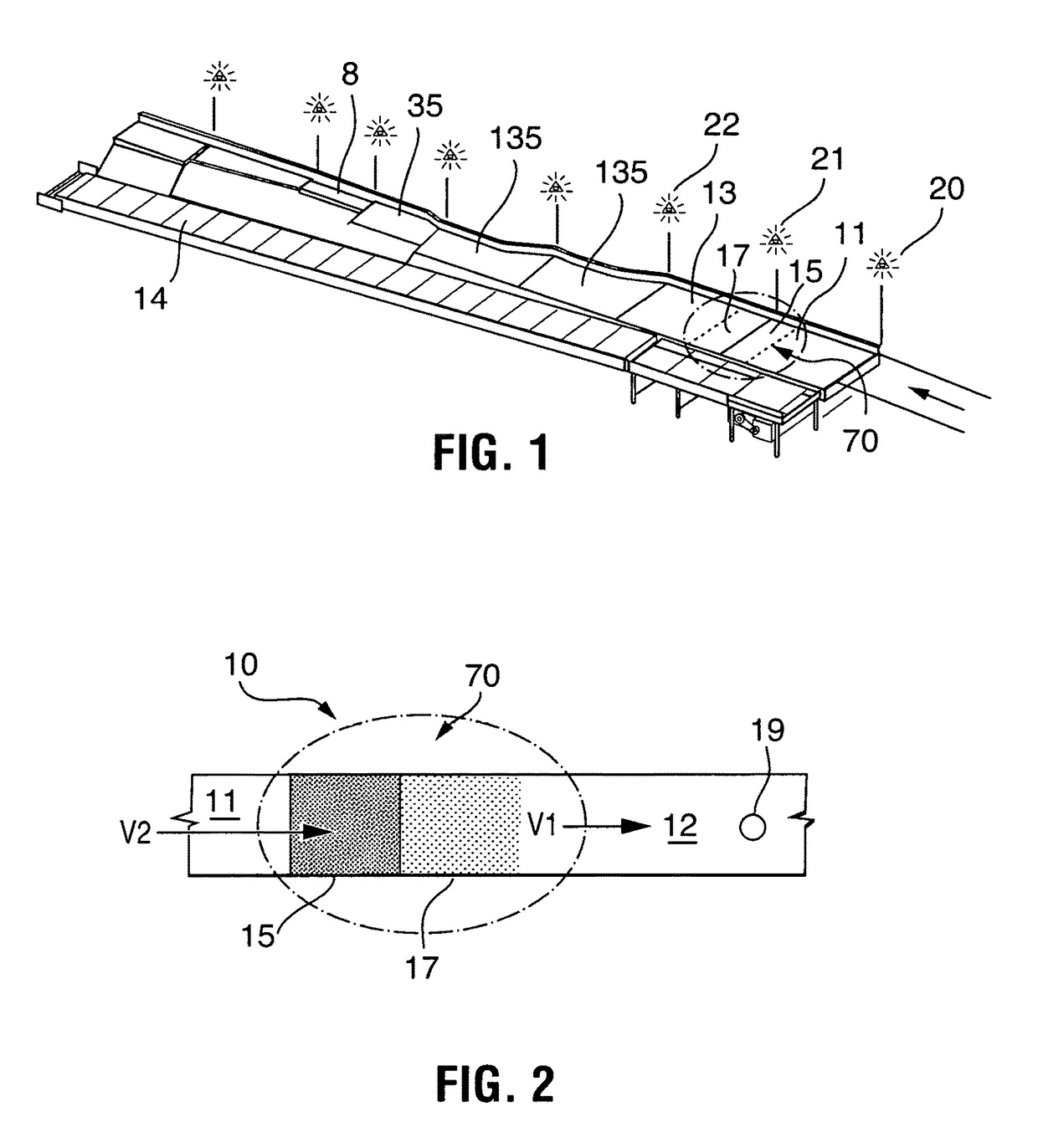

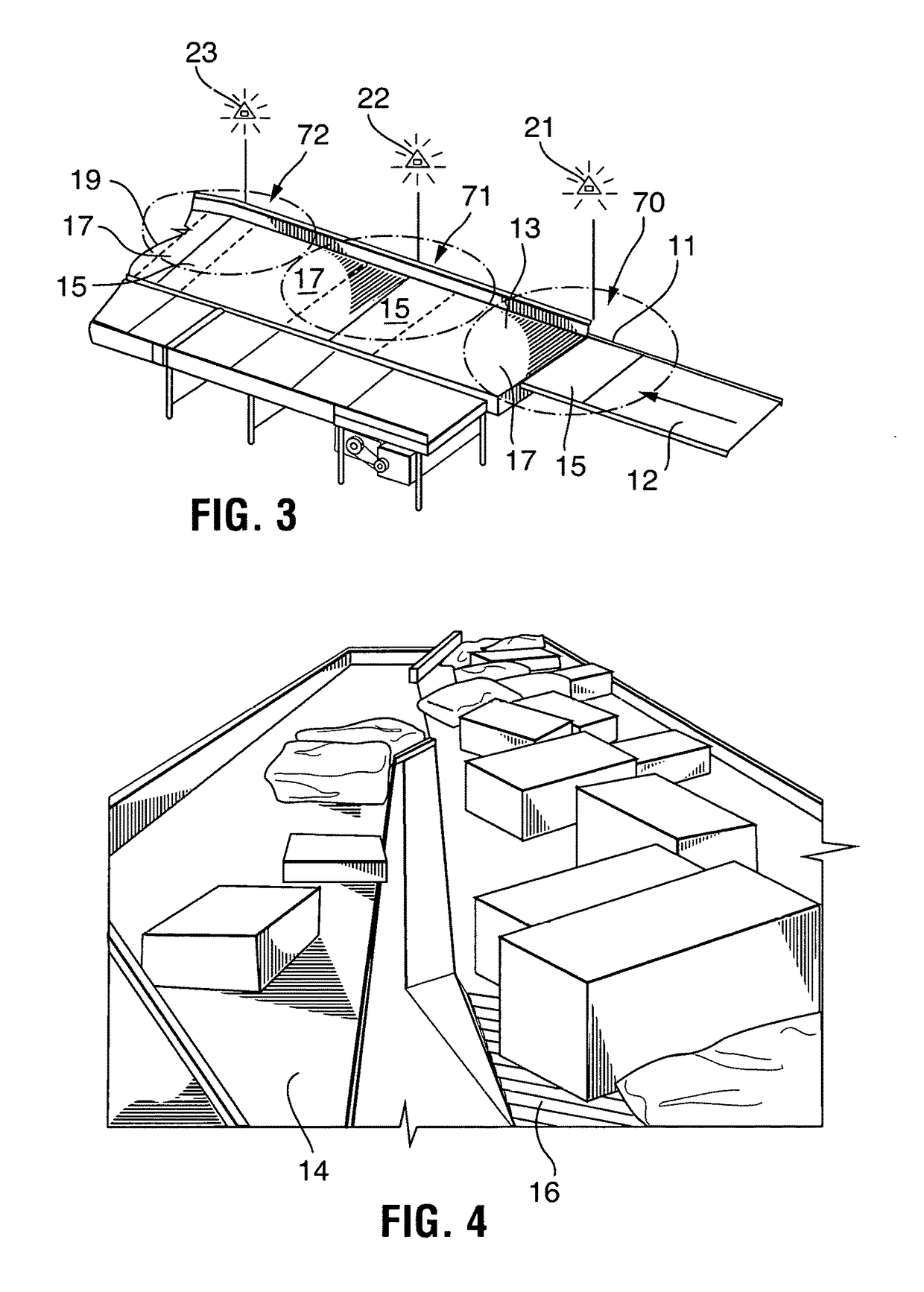

Vision based conveyor package flow management system

ActiveUS20160221762A1Improve efficiencyMaximize packing densityConveyorsControl devices for conveyorsIndividual itemEntry point

A camera based vision system that recognizes and maximizes belt area utilization. A plurality of cameras are positioned at flow entry points of feed conveyors and at the singulator. The control algorithm recognizes individual items area, the rate at which individual objects are passing, and the area utilization of the collector belt. The video camera and computer based conveyor package management system monitor and control the number and size of the packages present on the infeed conveyors, collector conveyor, singulator conveyor and sorting conveyor in a package handling system wherein the camera data is used to measure the available area or space on the conveyors to maintain a desired density of packages on selected conveyor(s). The conveyor speed is controlled as a function of occupancy on a collector or just prior to a singulator or receiver.

Owner:FIVES INTRALOGISTICS SA

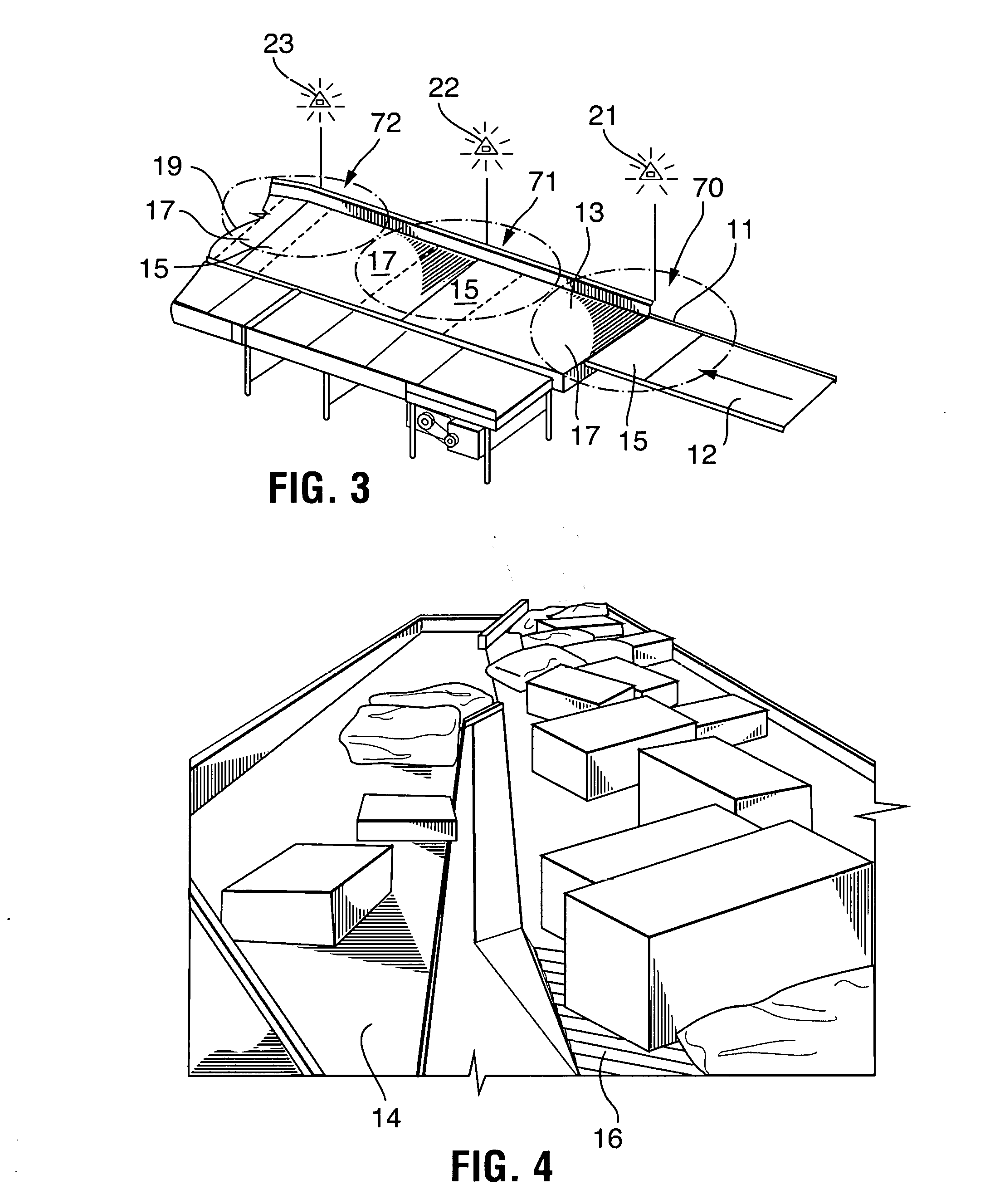

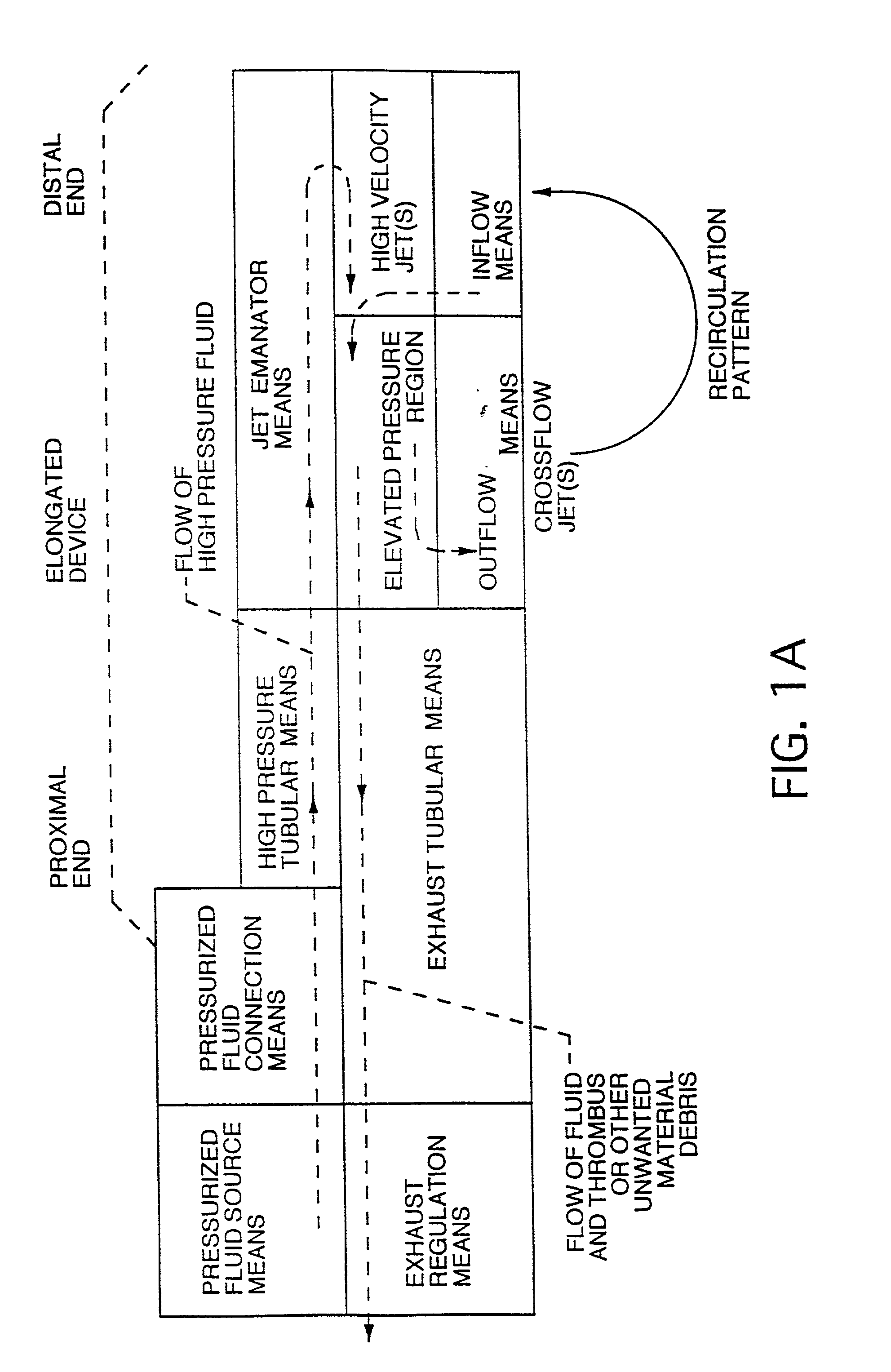

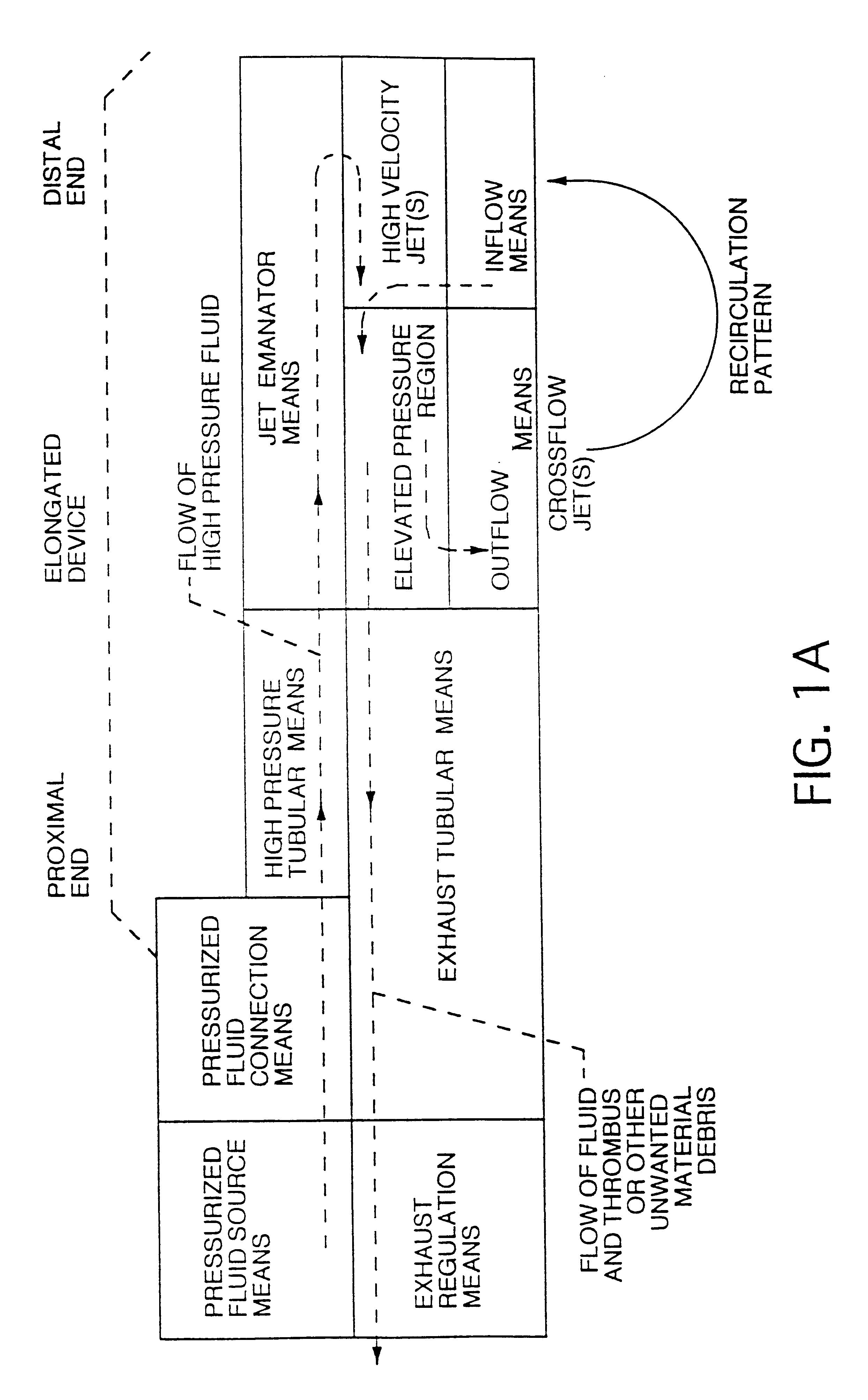

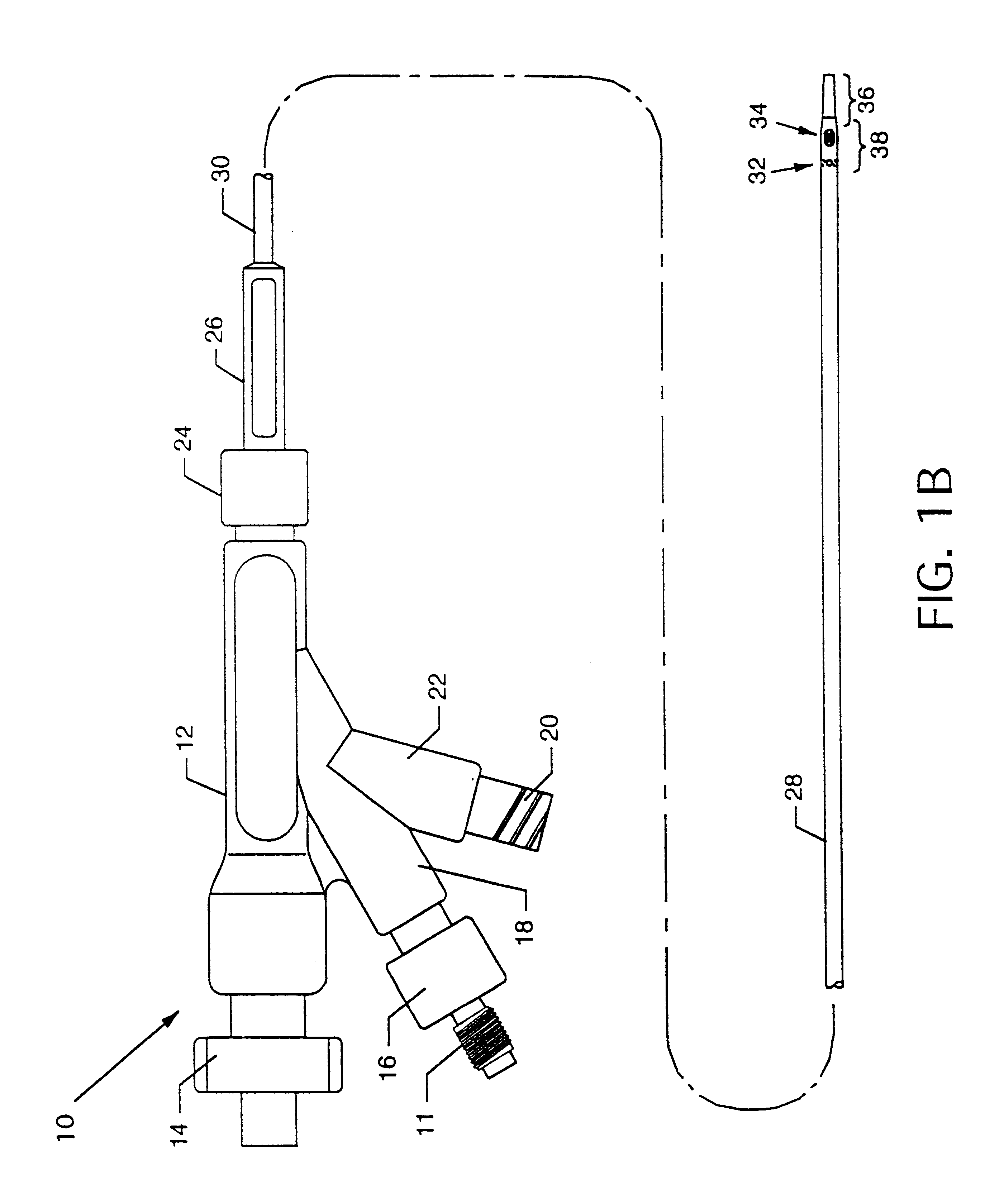

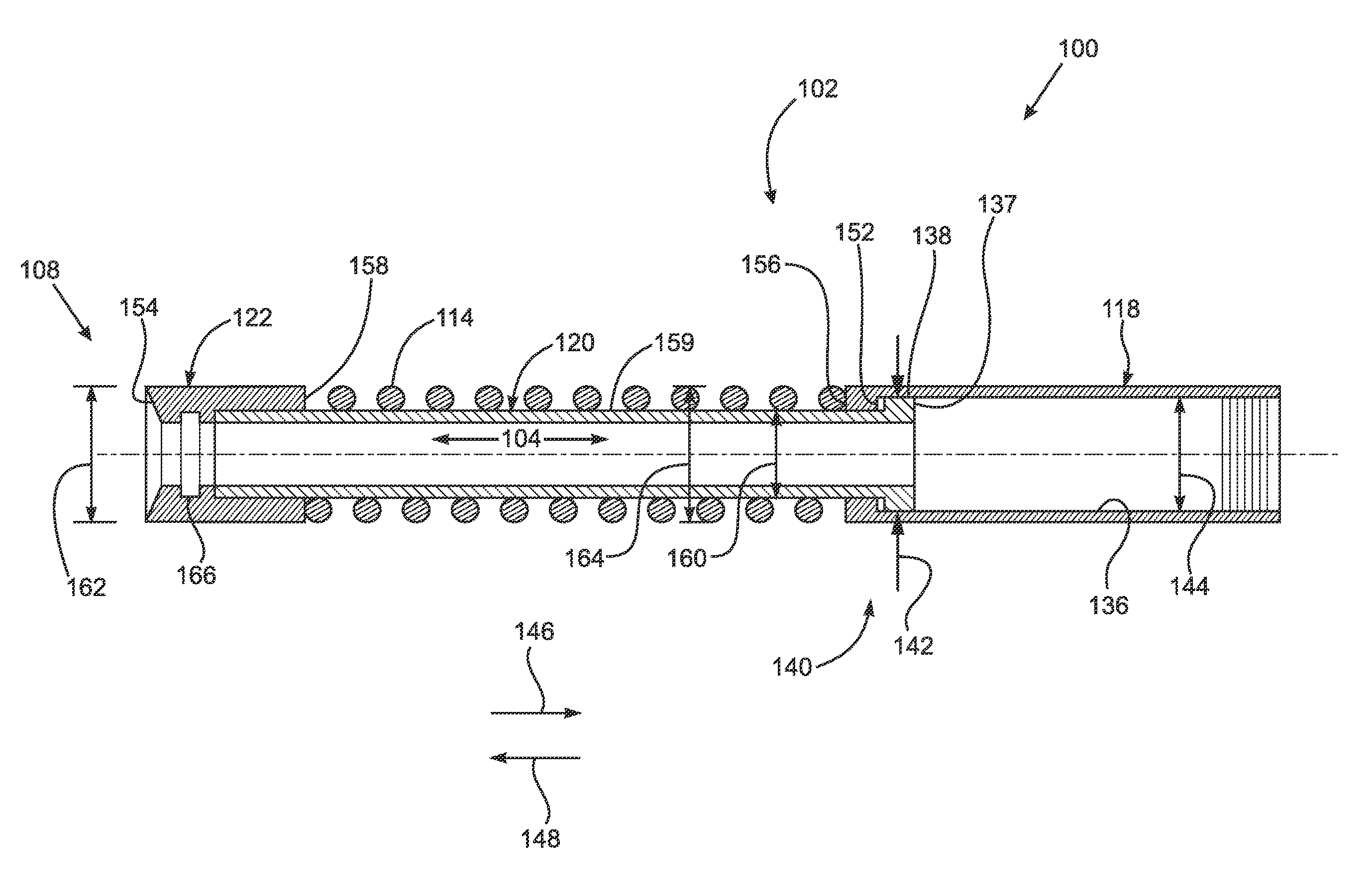

Thrombectomy catheter and system

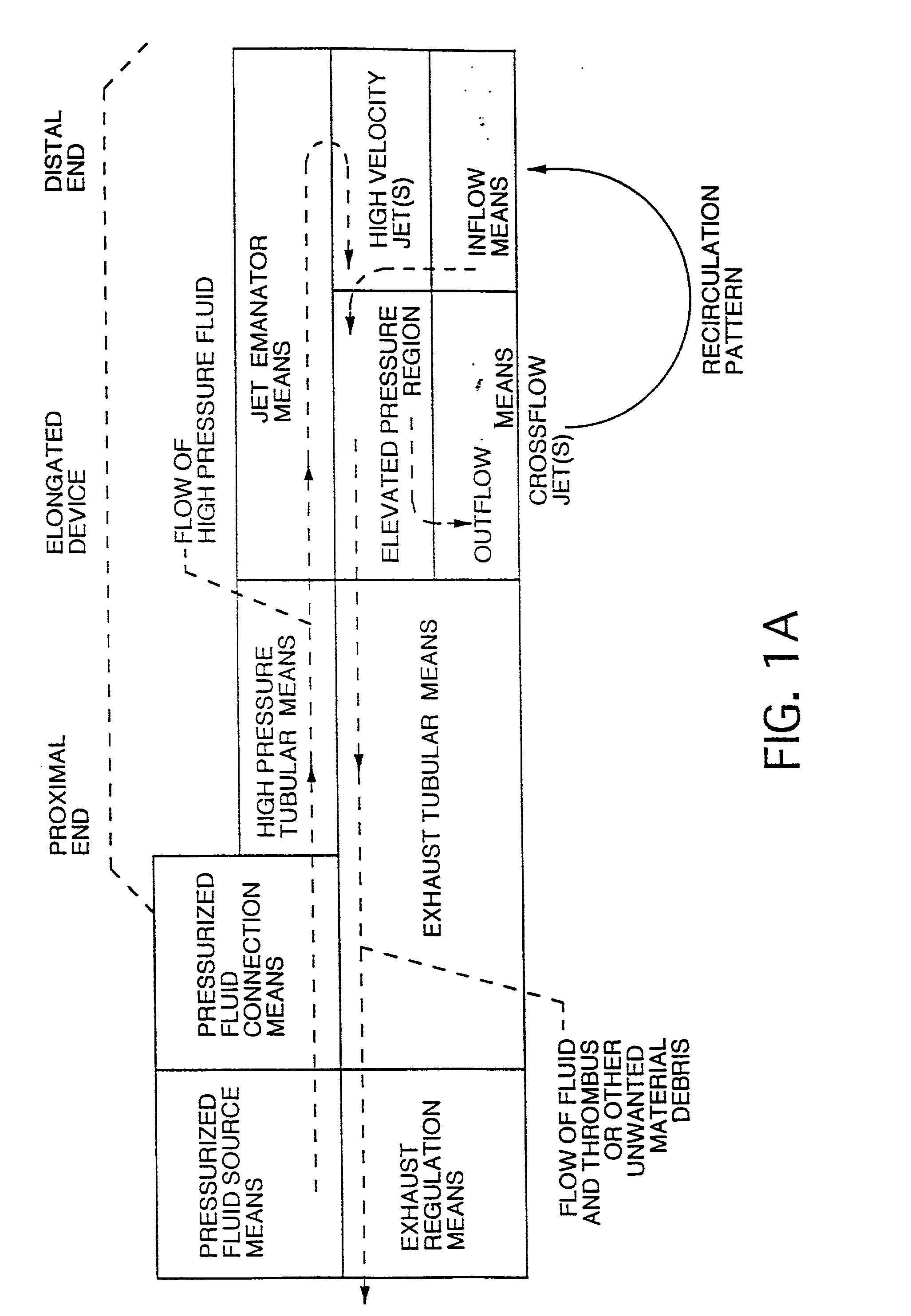

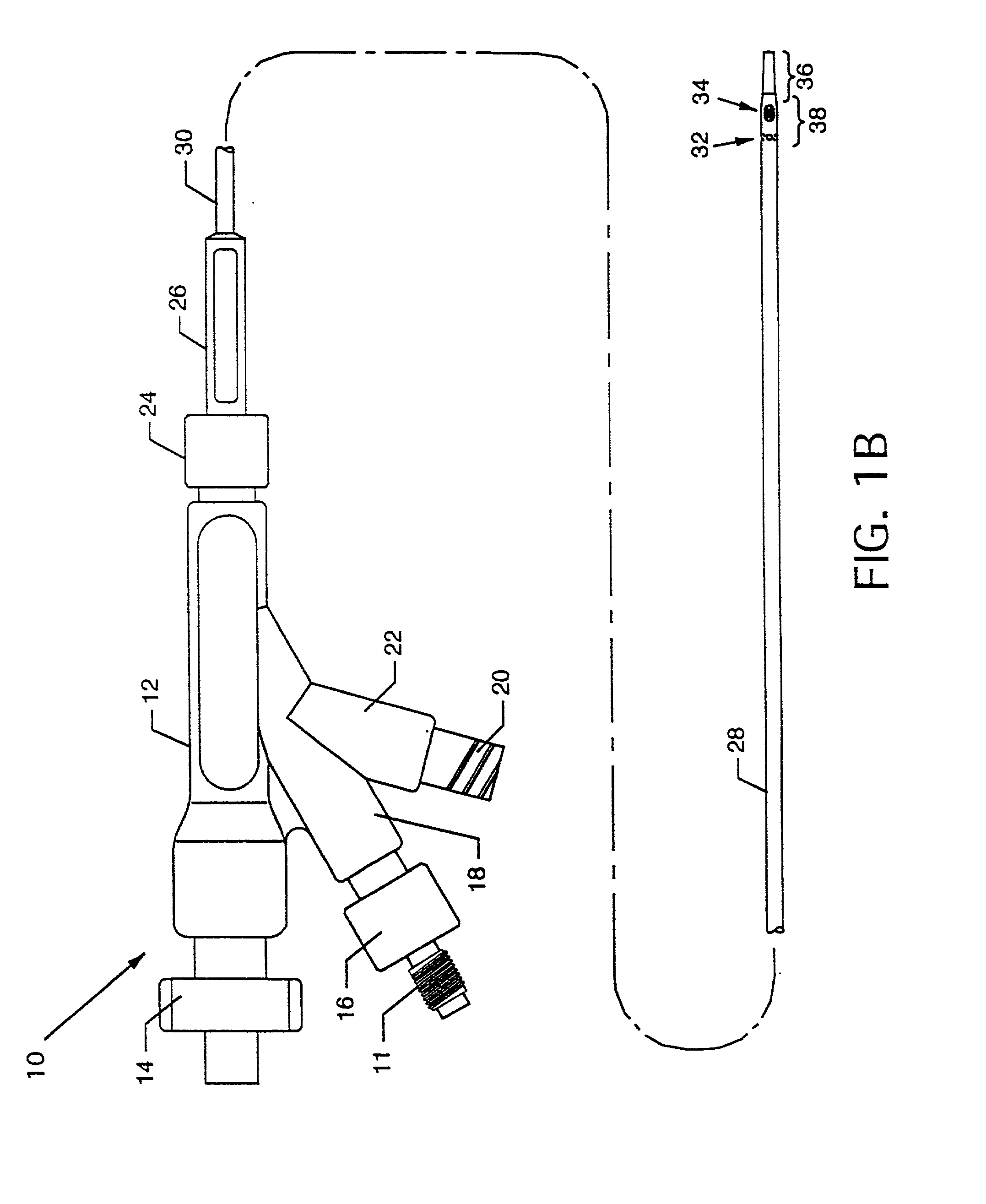

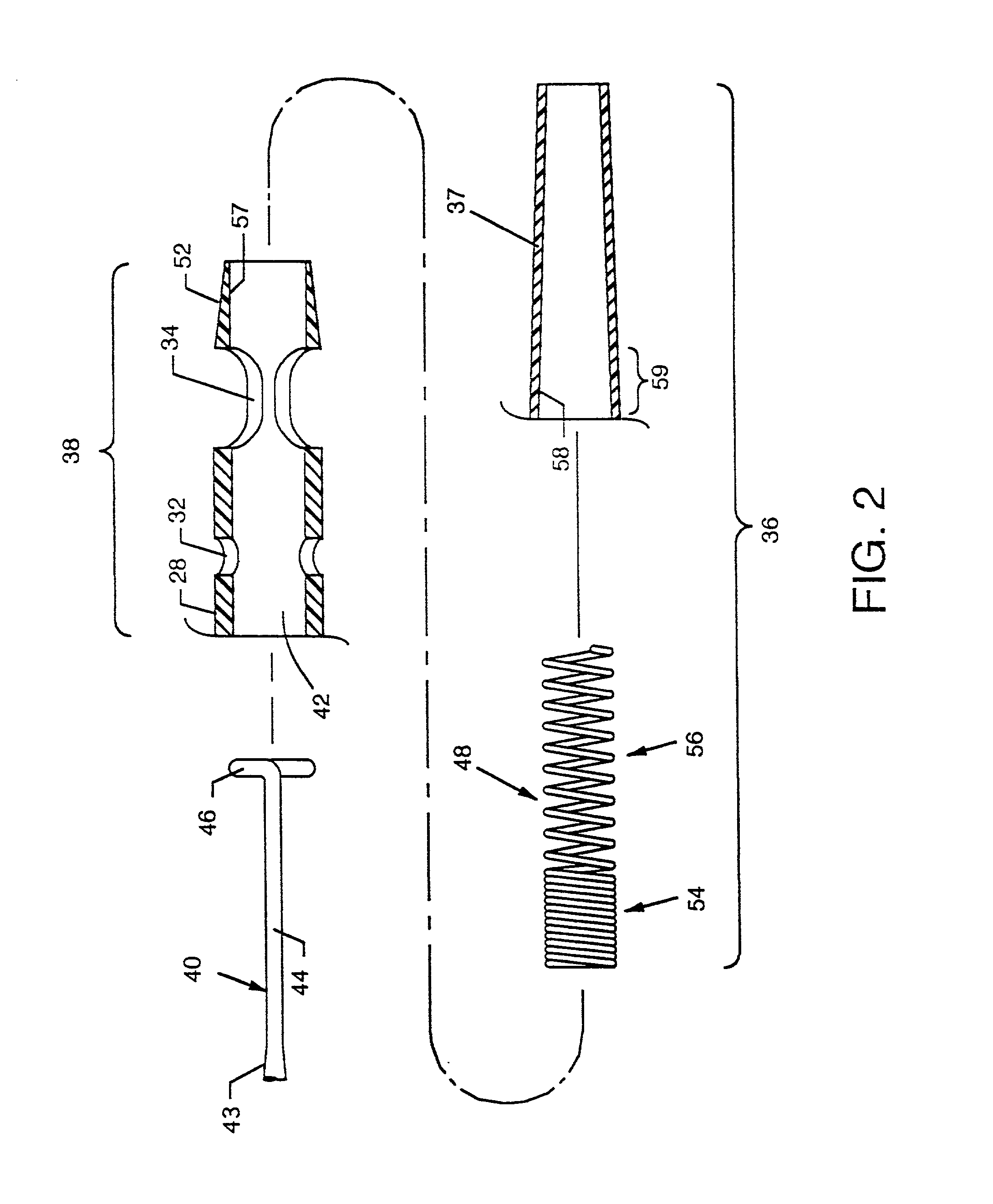

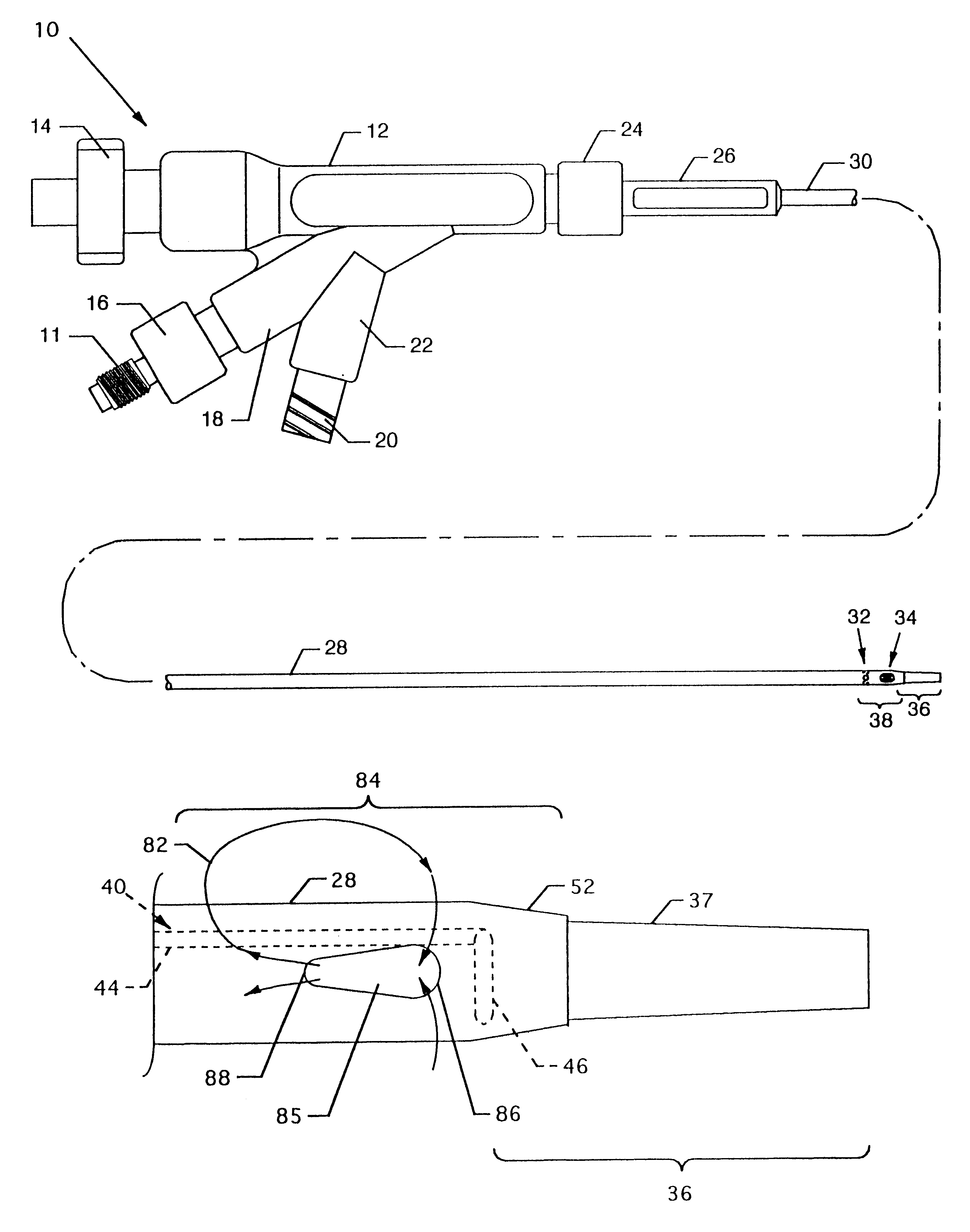

InactiveUS20010051811A1Increase resistanceMaximize flowCannulasIntravenous devicesThrombusThree vessels

Crossflow thrombectomy catheter and system for fragmentation and removal of thrombus or other material from blood vessels or other body cavities. High velocity saline jets emitted from a toroidal loop jet emanator or other jet emanator in a catheter distal end entrain fluid through inflow orifices, and with flow resistances create a back-pressure which drives crossflow streams through outflow orifices in a radial direction and thence radially and circumferentially to apply normal and drag forces on thrombotic deposits or lesions in the blood vessel or other body cavity, thereby breaking apart and transporting thrombus particles to be entrained through the inflow orifices, whereupon the high velocity jets macerate the thrombus particles which then transit an exhaust lumen or recirculate again via the outflow orifices.

Owner:MEDRAD INC.

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

Internal shunt and method for treating glaucoma

InactiveUS20070149915A1Lower eye pressureAvoid scaringEye surgeryOther blood circulation devicesIntra ocular pressureAqueous humor

A surgical technique wherein an indwelling shunt is placed in the eye of a patient having glaucoma. The shunt diverts aqueous humor from a deep scleral lake or directly from the anterior chamber to the suprachoroidal space from which it is removed by blood flowing in the choroidal and uveal tissues. This decreases the intra-ocular pressure. The indwelling shunt maintains the area of exposure of aqueous humor with the uvea by physically preventing scarring of the surrounding tissues. The method utilizes the 25 mm Hg driving force of the protein colloidal osmotic pressure of the blood to maximize the flow.

Owner:NOVARTIS AG

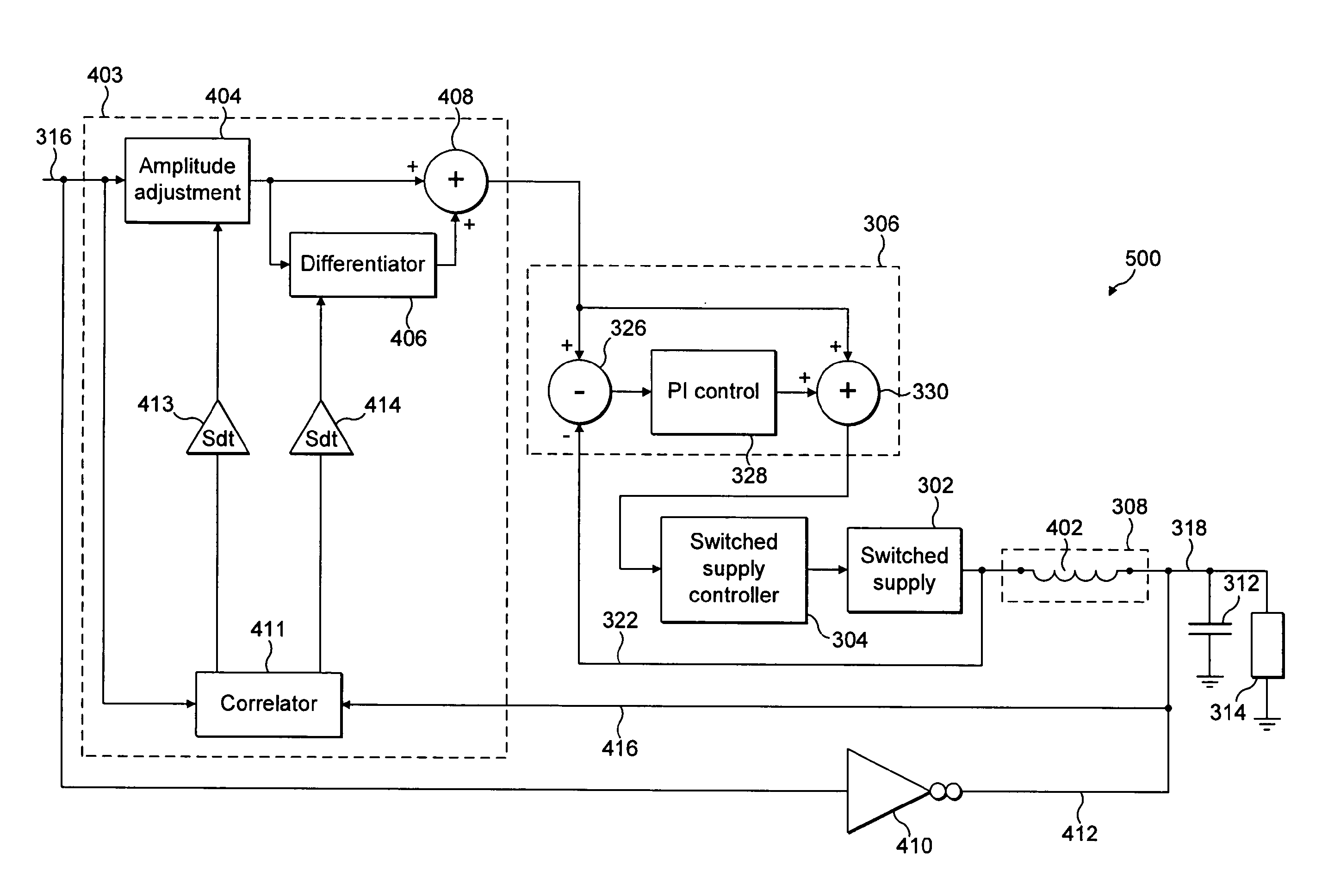

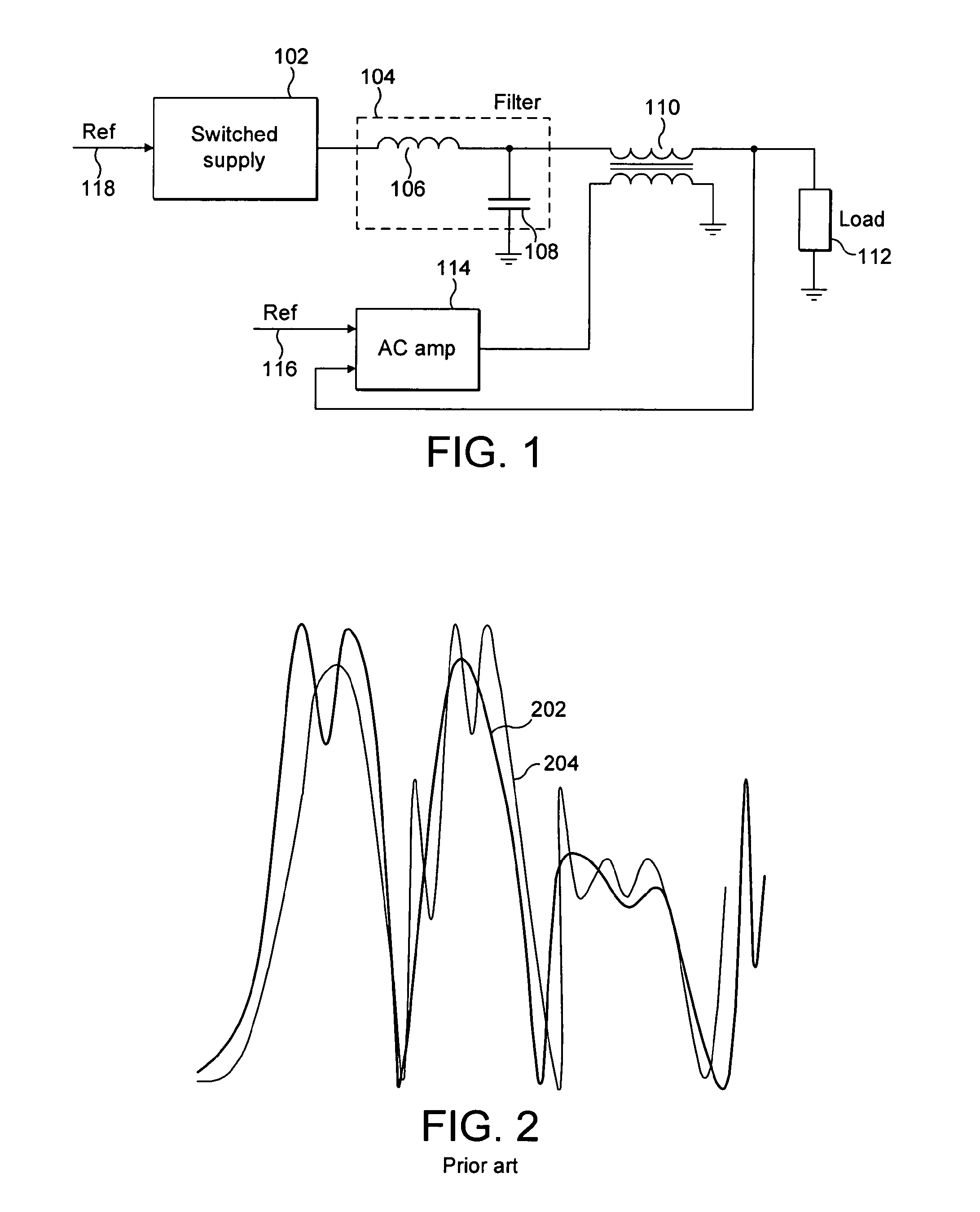

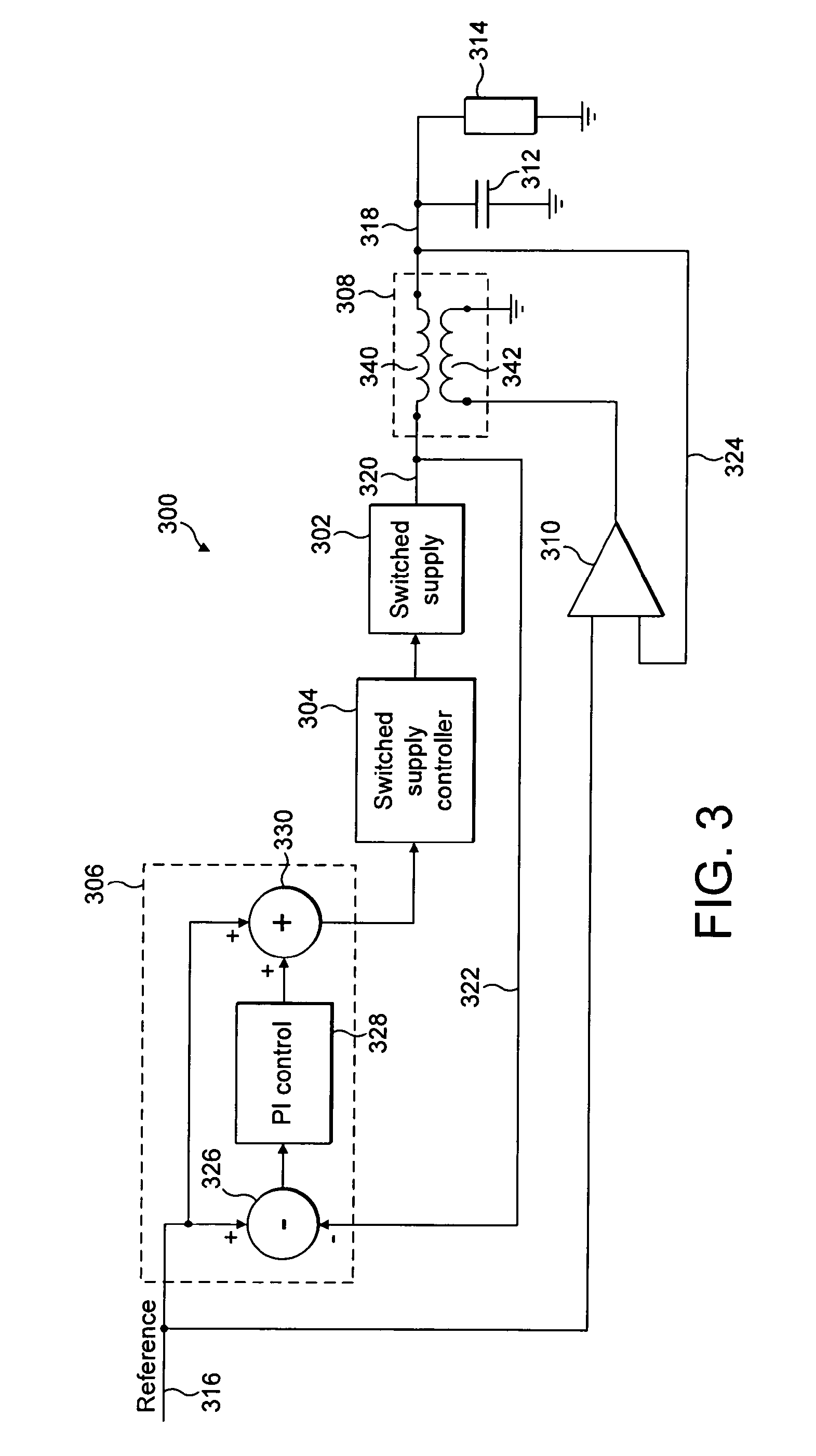

Modulated supply stage with feedback to switched supply

InactiveUS20110234182A1Maximize current flowingMinimize current flowingPower amplifiersAc-dc network circuit arrangementsEngineeringVIT signals

There is disclosed a voltage supply stage comprising: a selection means for selecting one of a plurality of power supply voltages in dependance on a reference signal representing a desired power supply voltage; a combining means for combining the selected power supply voltage with a correction signal to generate an adjusted power supply voltage; and an adjusting means adapted to generate the correction signal in dependence on the reference signal and the adjusted power supply voltage, wherein the selection means is arranged to select the one of the plurality of supply voltages further in dependence on a signal derived from one of the inputs to the combining means.

Owner:SNAPTRACK

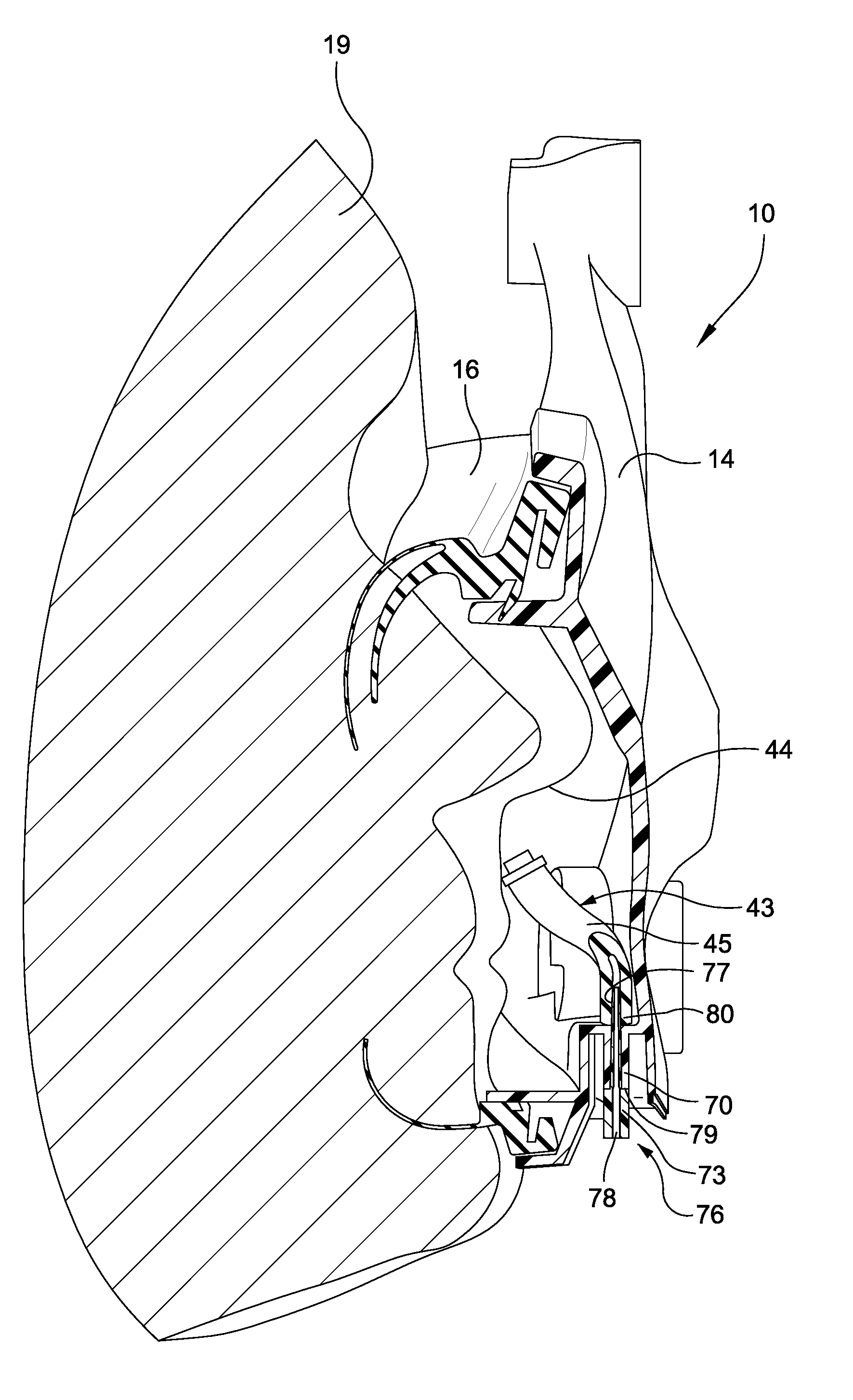

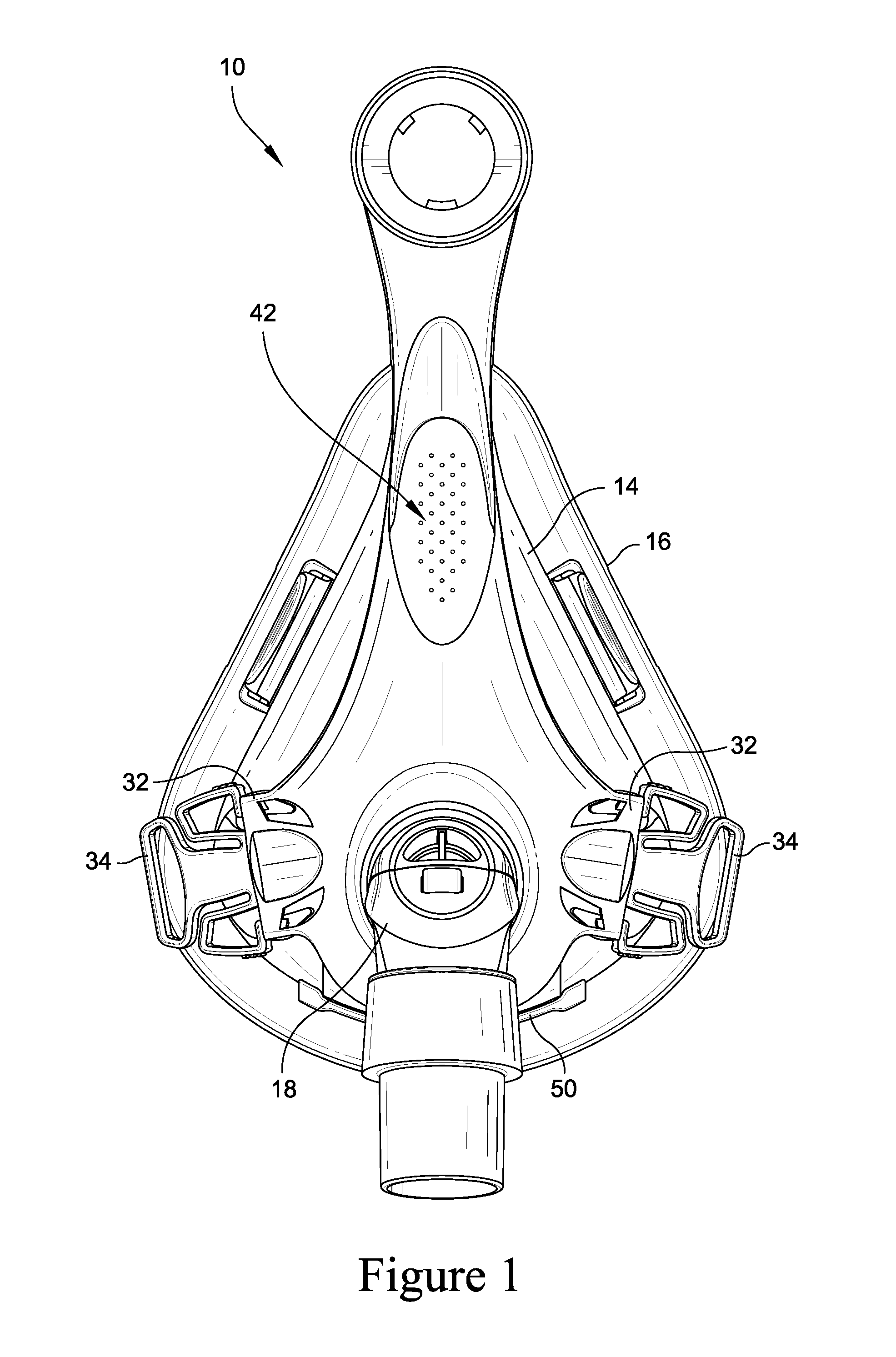

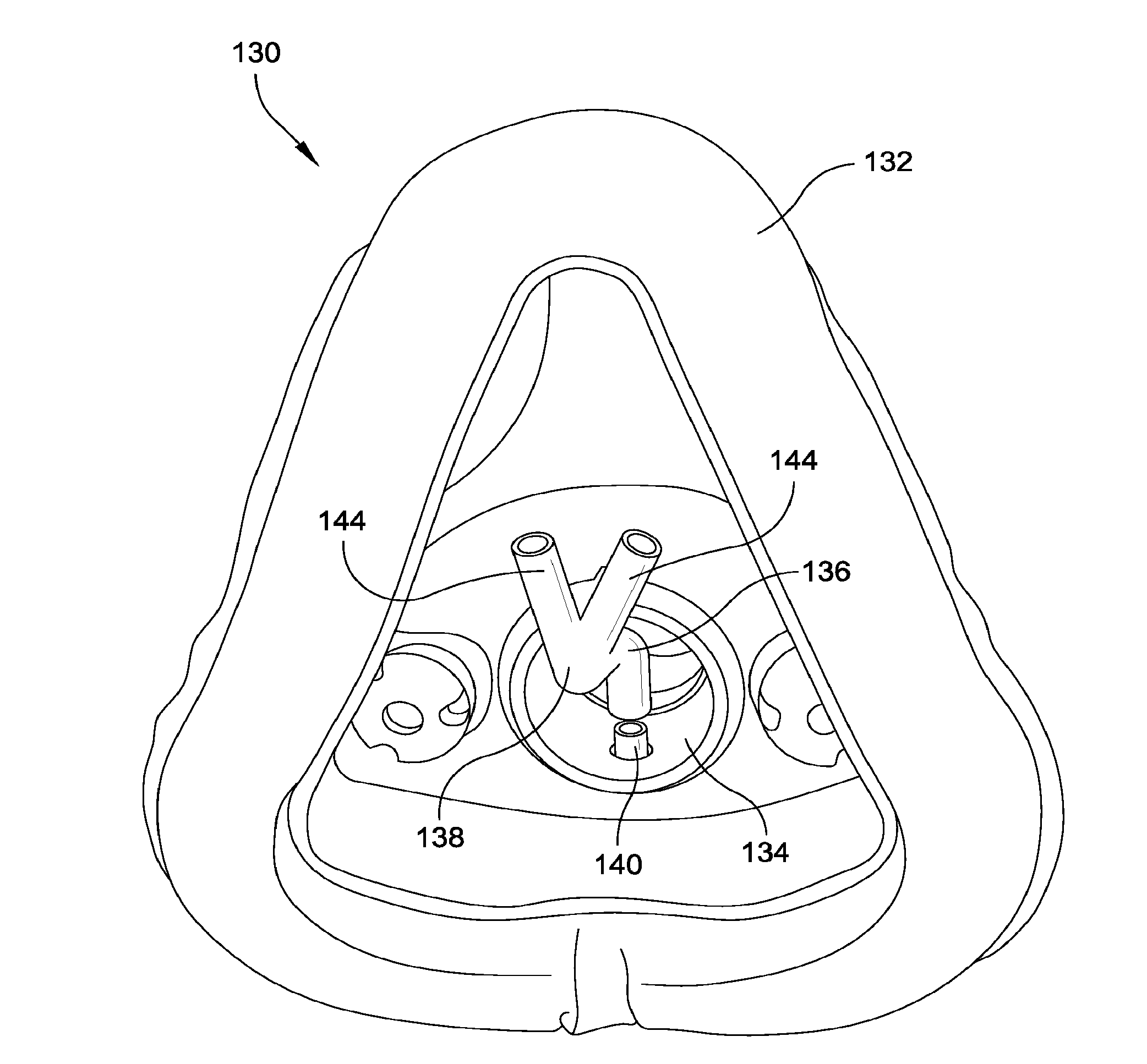

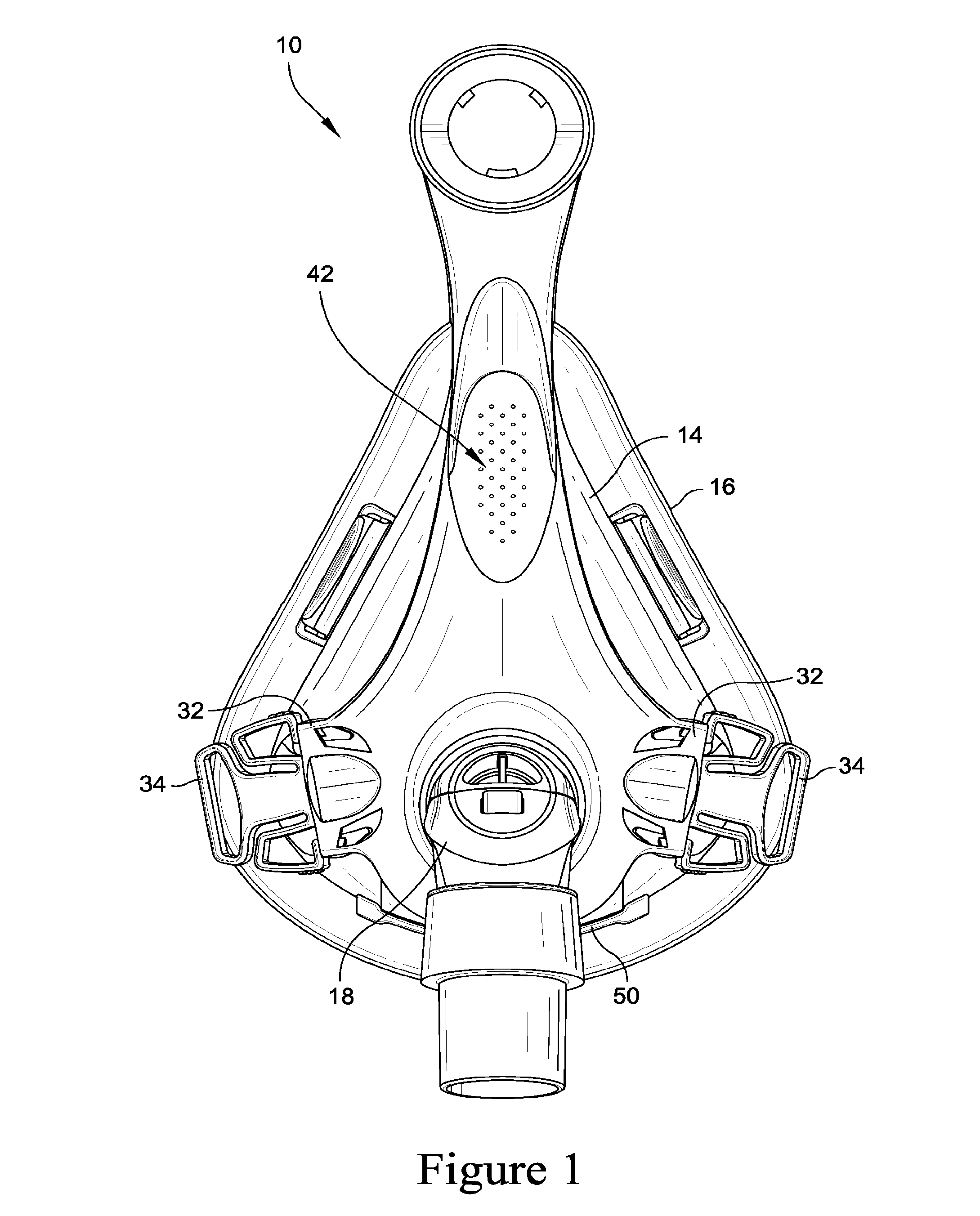

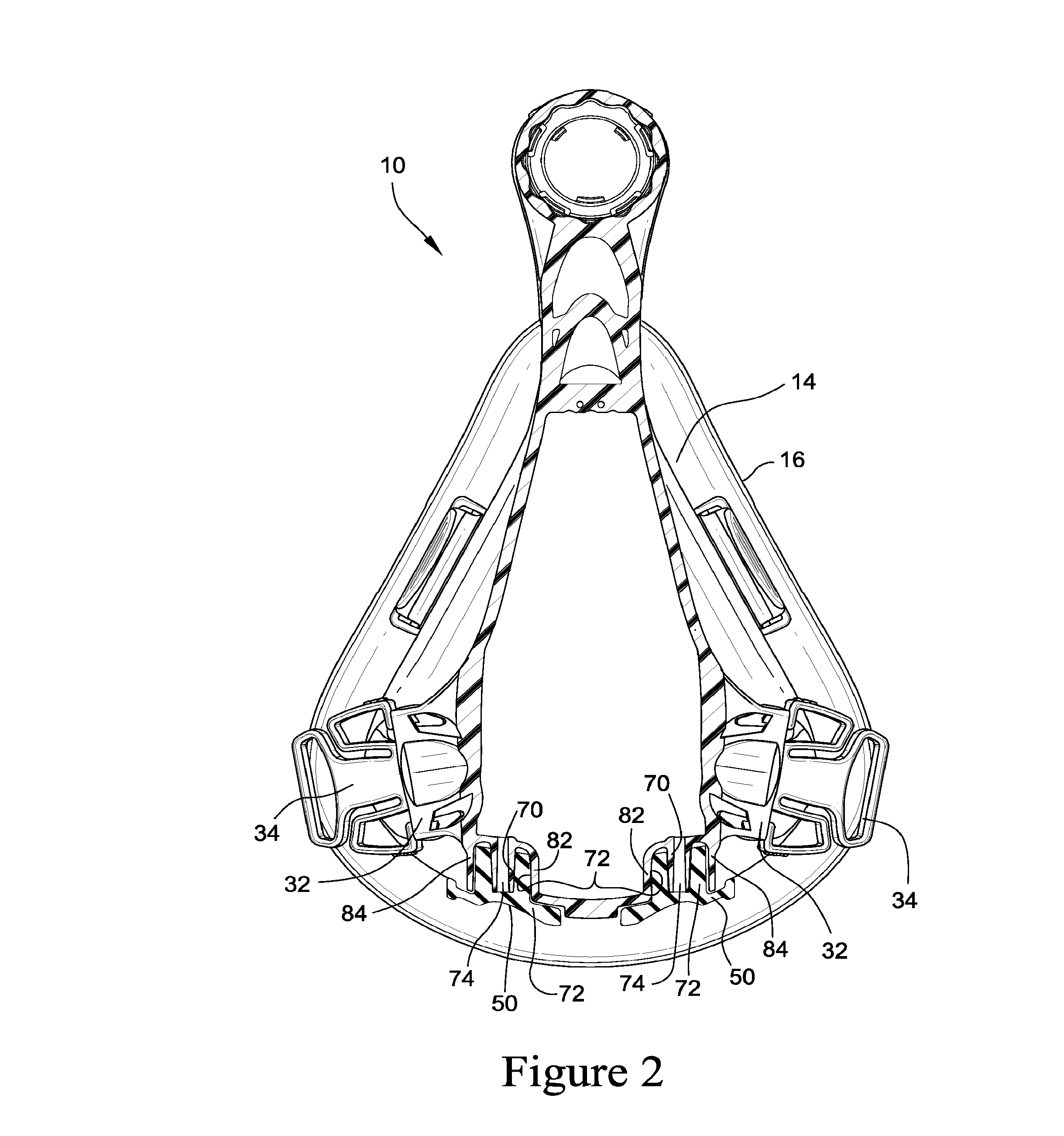

Supplemental gas delivery device for mask assembly

ActiveUS20110203591A1Good curative effectMaximize flowBreathing masksRespiratory masksEngineeringTreatment efficacy

A supplemental gas delivery device is described for a mask assembly having at least one supplemental gas port, the at least one supplemental gas port including an aperture in communication with an interior of the mask assembly. The mask assembly may include an aperture communicating with an interior of the mask assembly, and a cannula for communicating with the supplemental gas port. The cannula is positioned to deliver supplemental gas adjacent to the patient's nares and / or mouth, to increase an efficacy of treatment for the patient by more directly applying the flow of supplemental gas to the patient's nares. An optional bridging portion may be included to provide a connection between supplemental gas port and the cannula.

Owner:RESMED LTD

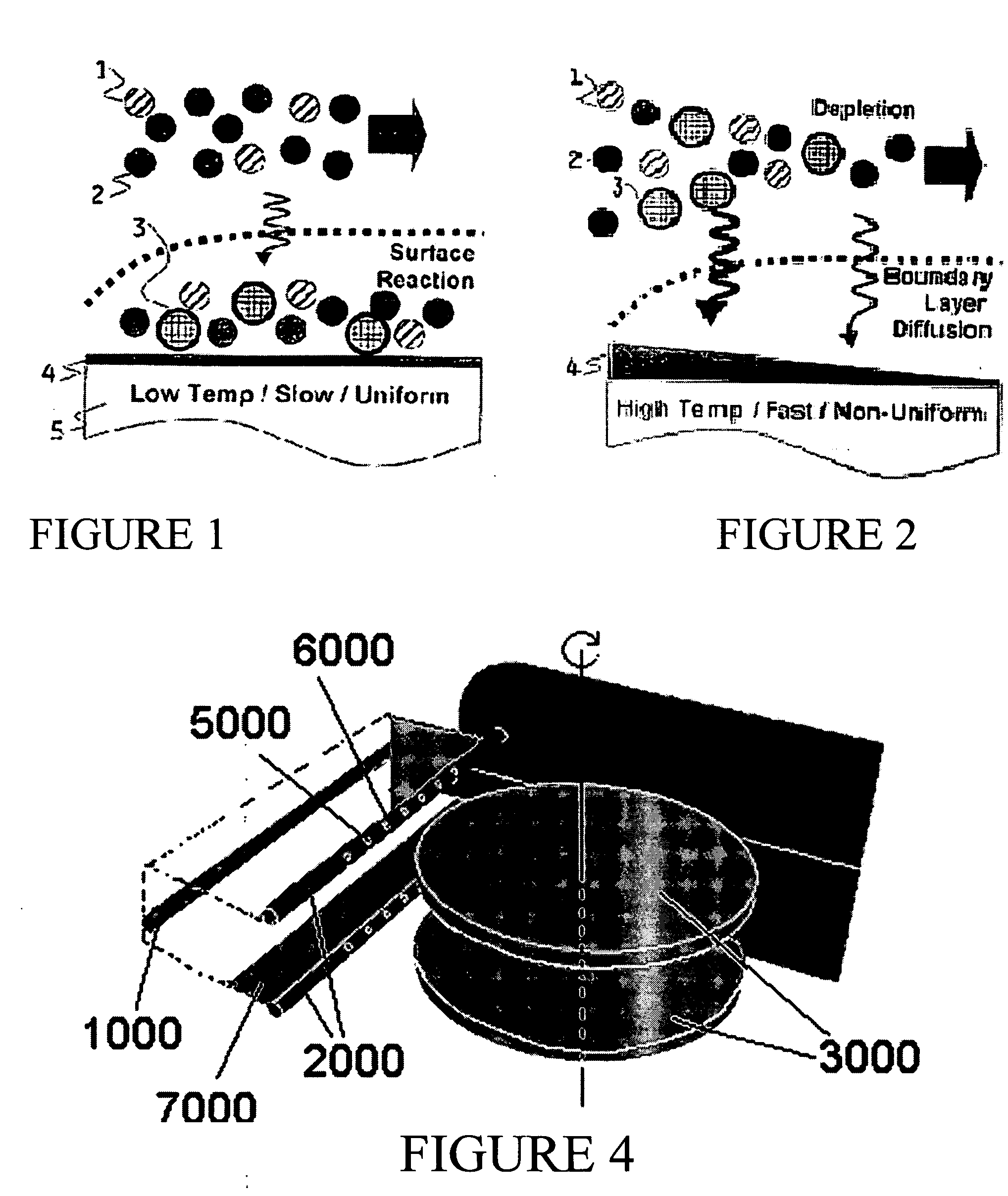

OLED display encapsulation with the optical property

InactiveUS20090081360A1Maximize flowGas residence time be minimizeSolid-state devicesPolarising elementsParallel channelChemistry

A process of making an optical film or optical array comprises: a) simultaneously directing a series of gas flows along elongated substantially parallel channels to form a first thin film on a substrate; wherein the series of gas flows comprises, in order, at least a first reactive gaseous material, an inert purge gas, and a second reactive gaseous material; wherein the first reactive gaseous material is capable of reacting with a substrate surface treated with the second reactive gaseous material to form the first thin film; b) repeating step a) a plurality of times to produce a first thickness of a first film layer with a first optical property; wherein the process is carried out at or above atmospheric pressure; c) repeating steps a) and b) to produce a second film layer; and wherein the process is carried out substantially at or above atmospheric pressure.

Owner:EASTMAN KODAK CO

Thrombectomy catheter and system

InactiveUS20010051785A1Increase resistanceMaximize flowCannulasIntravenous devicesThrombusThree vessels

Crossflow thrombectomy catheter and system for fragmentation and removal of thrombus or other material from blood vessels or other body cavities. High velocity saline jets emitted from a toroidal loop jet emanator or other jet emanator in a catheter distal end entrain fluid through inflow orifices, and with flow resistances create a back-pressure which drives crossflow streams through outflow orifices in a radial direction and thence radially and circumferentially to apply normal and drag forces on thrombotic deposits or lesions in the blood vessel or other body cavity, thereby breaking apart and transporting thrombus particles to be entrained through the inflow orifices, whereupon the high velocity jets macerate the thrombus particles which then transit an exhaust lumen or recirculate again via the outflow orifices.

Owner:MEDRAD INC.

Thrombectomy catheter and system

Owner:MEDRAD INC.

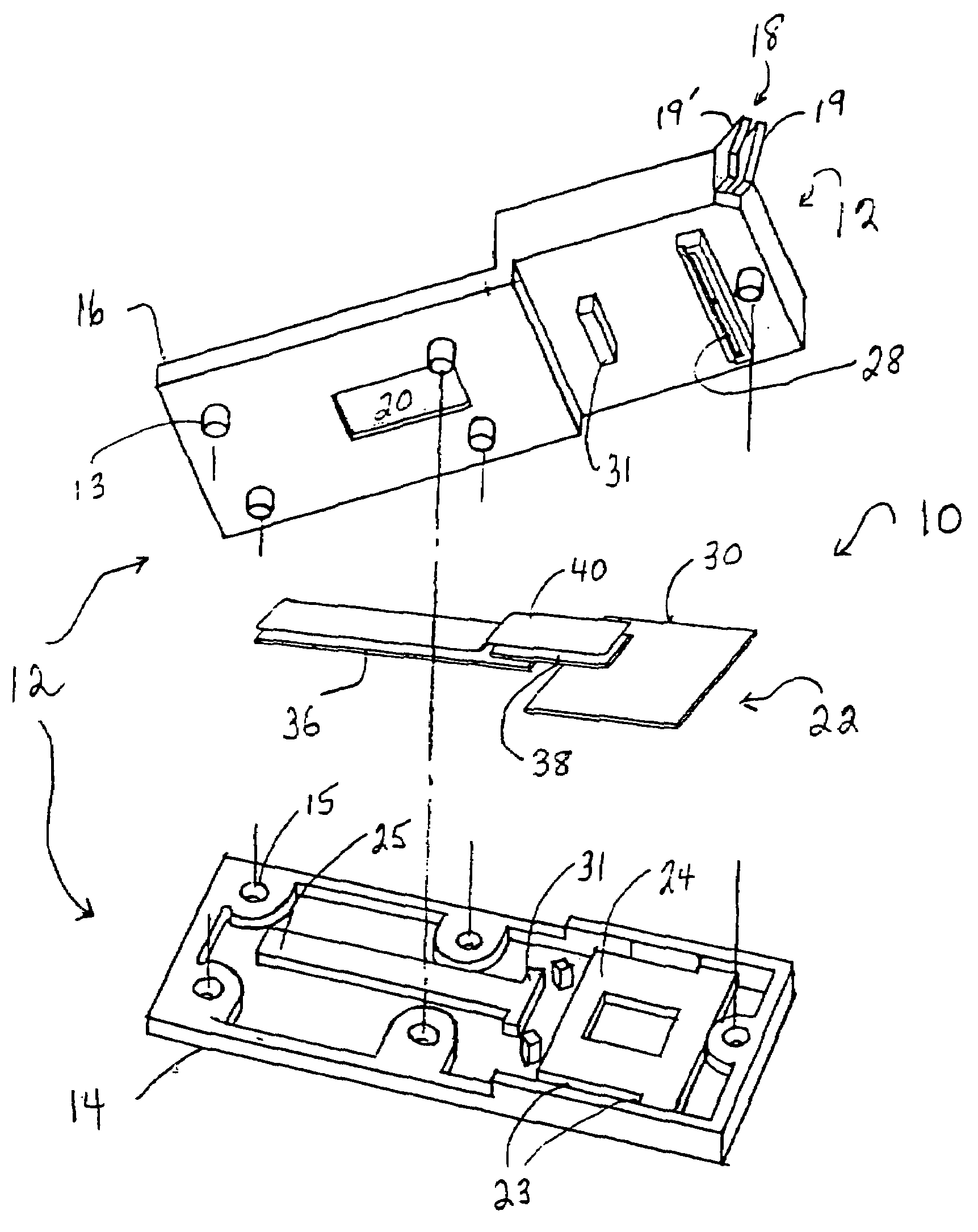

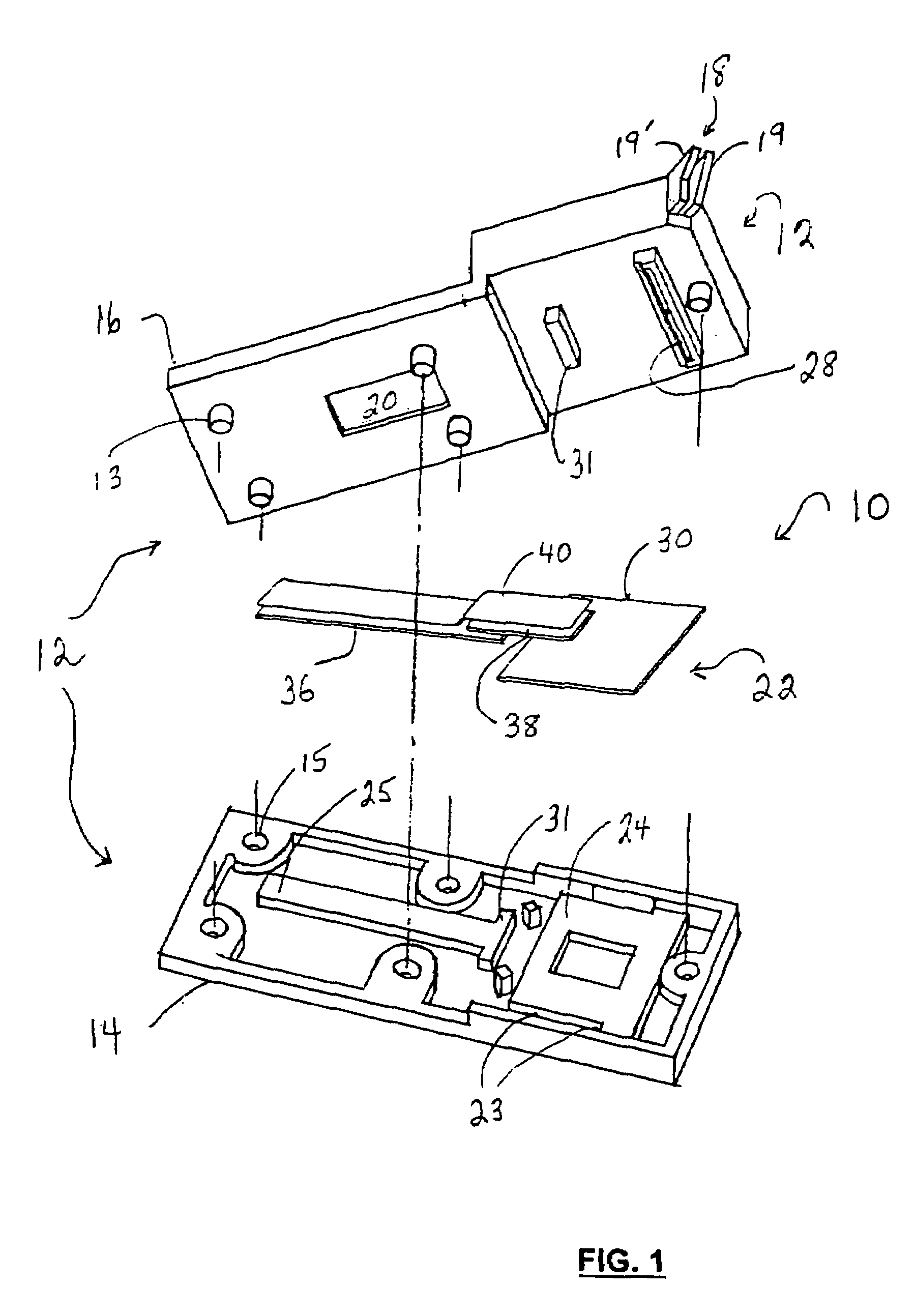

Diagnostic device for analyte detection

InactiveUS7256053B2Rapid and reliable resultLow costAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPhysicsDiagnostic accuracy

The present invention provides a hand-held device of the type useful to perform an in vitro immunodiagnostic assay for an analyte of interest. In embodiments of the invention, the device incorporates a carrier for conducting the assay which comprises an array of pads including a sample pad, a narrow detection pad for detecting analyte, and a bridging pad coupled in flow communication therebetween. The device is provided with a housing adapted to deliver sample onto the carrier as a linear band having a width greater than the detection pad. In combination, these features yield a device that retains the sensitivity required for diagnostic accuracy, yet is improved in terms of cost and ease of manufacture.

Owner:NEXUS DX

Damping and sealing device for a well pipe having an inner flow passage and method of using thereof

InactiveUS8286700B1Sufficient shock protectionMaximize flowDrilling rodsCleaning apparatusEngineeringMechanical engineering

A damping and sealing device for enabling gas or liquid flow from a well to a production tube in the well, including a body with a flow passage internal to the body and a spring disposed about a portion of the body. The flow passage includes a first opening at a first longitudinal end of the body and a second opening at a second longitudinal end of the body. The first end is arranged to contact a plunger for the well and the body is arranged to sealingly engage the production tube. In one embodiment, the body includes an inner circumferential surface and an outer circumferential surface, the inner circumferential surface forms the internal flow passage, and a portion of the outer circumferential surface is arranged to slide along a portion of the inner circumferential surface in response to the first end contacting a plunger.

Owner:FRANCHINI JACOB M

Tamper-evident bottle and closure having vents

A tamper-evident package with pressurized contents which includes a closure and associated container which cooperate to provide desired tamper-evidence upon initial removal of the closure from the container, while promoting convenient and comfortable removal and use by consumers.

Owner:CLOSURE SYST INT INC

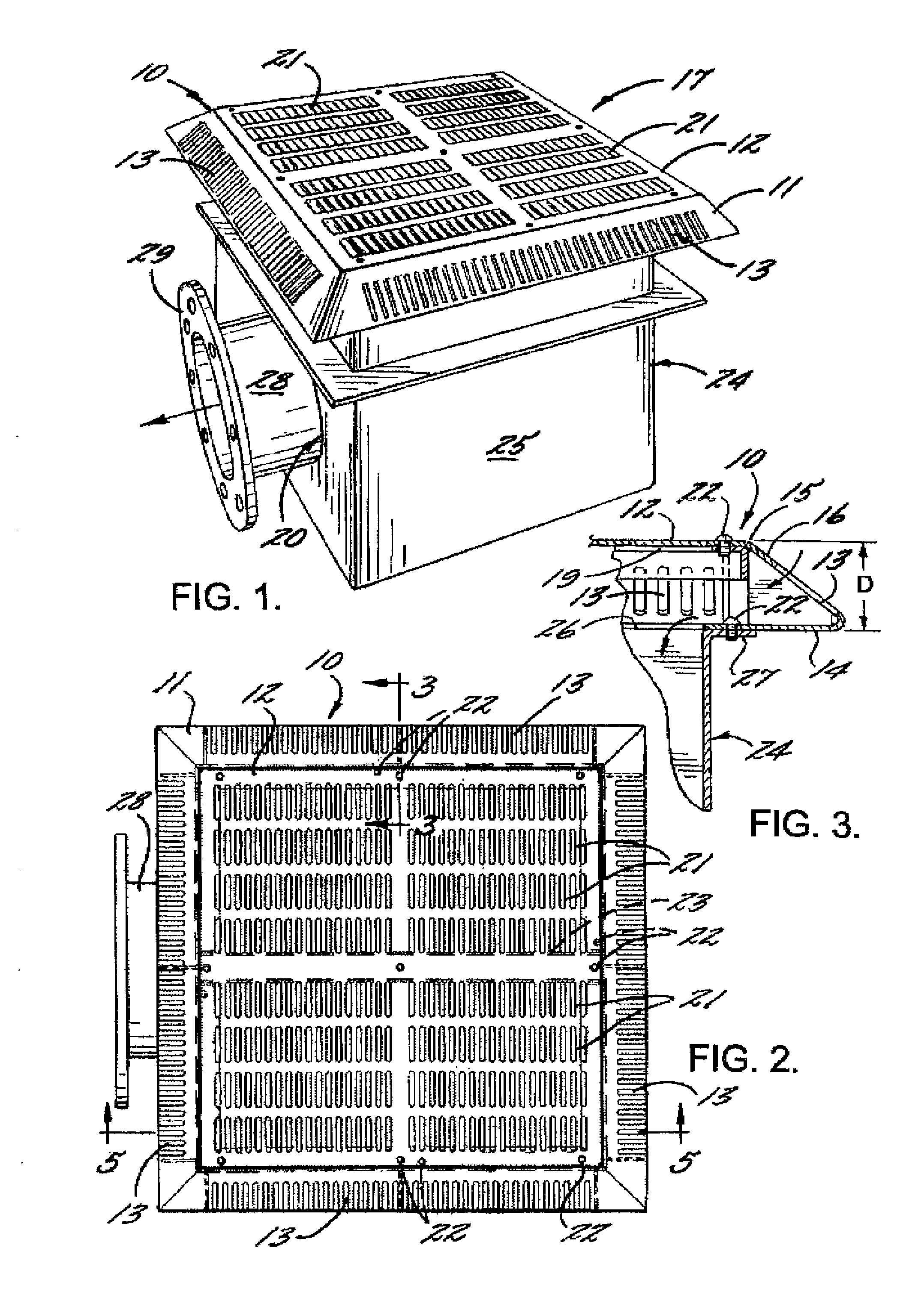

Cover and Sump Assembly For Preventing Suction Entrapment

InactiveUS20100050335A1Reduce water flow velocityReduce likelihoodWash-standsGymnasiumEngineeringSuction force

The invention relates to a cover and sump assembly for a main drain of a pool or spa that prevents suction entrapment, and specifically, to an assembly having a frame with openings, plates with openings positioned on the frame, and a sump for collecting water and receiving the frame. The assembly reduces the velocity of water flowing there through, uniformly distributes a suction force created by water flowing into the sump, prevents a vortex of flowing water above the assembly, and provides anti-entanglement features to minimize the likelihood of an individual becoming entrapped on the assembly by a suction force produced by a pump in the pool or spa filtering system. The assembly includes a conduit defining an opening along a lower portion thereof that reduces the velocity of flowing water at the suction opening in the sump by reorienting the suction port from a vertical to a horizontal orientation.

Owner:BAKER DONALD C

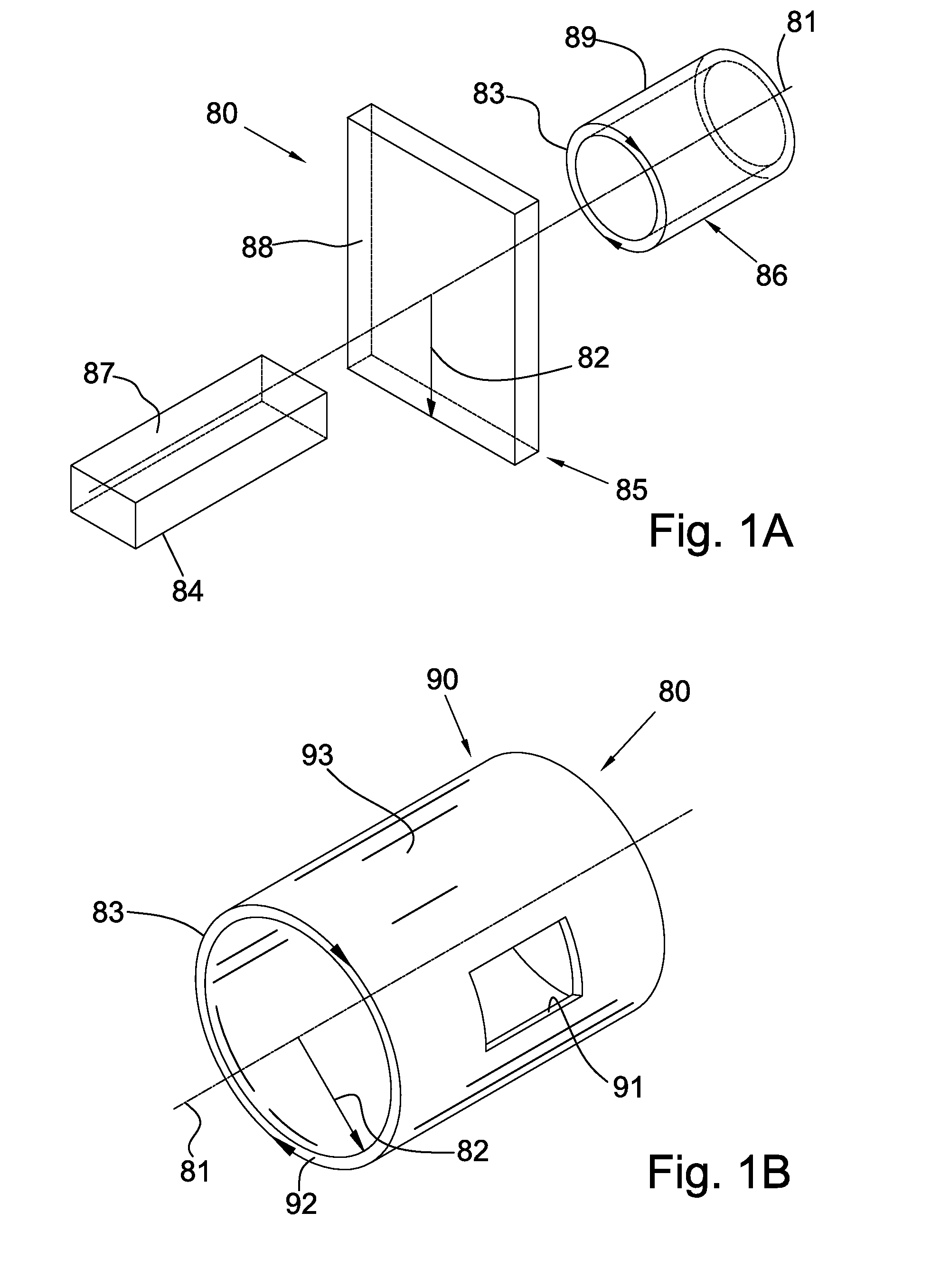

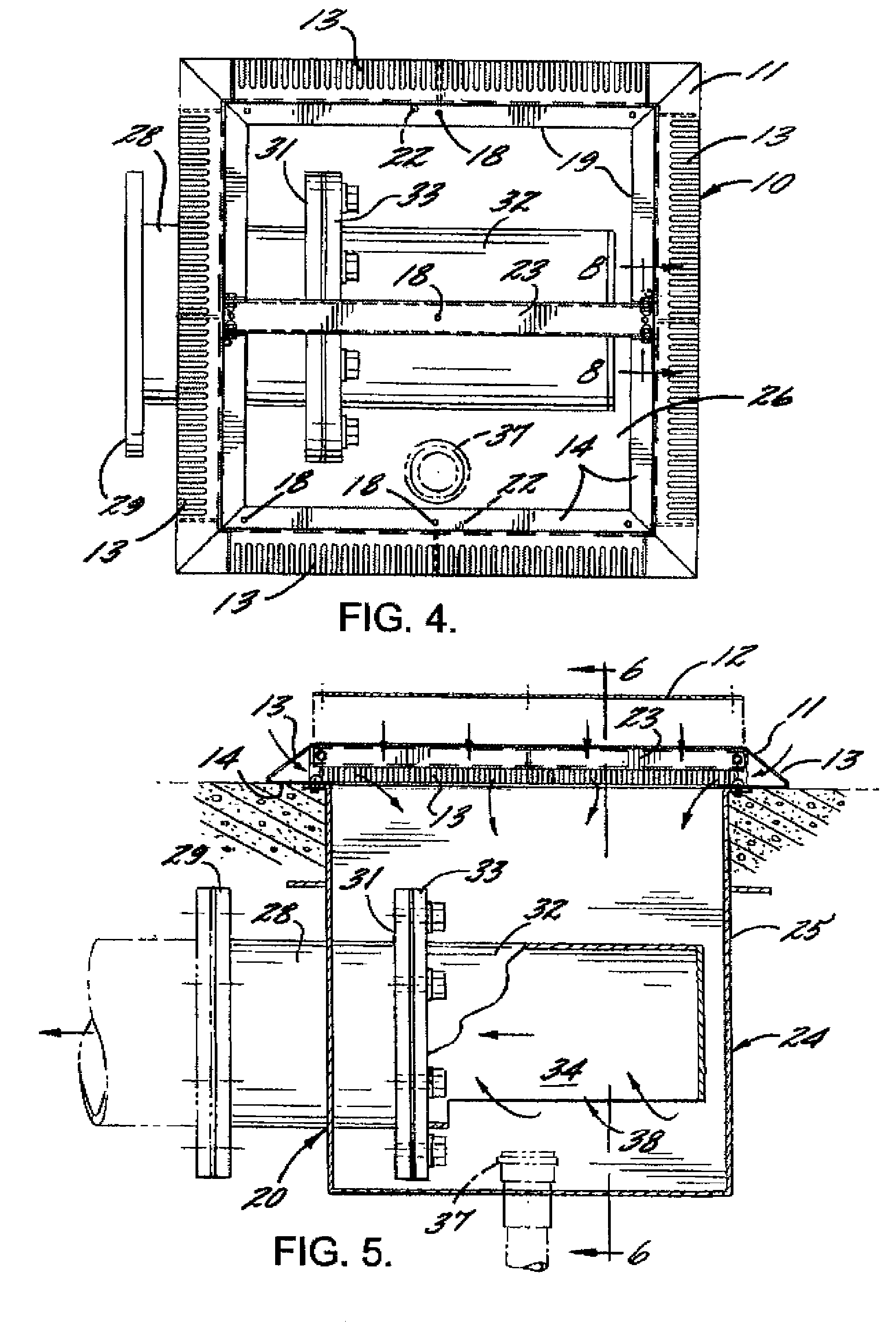

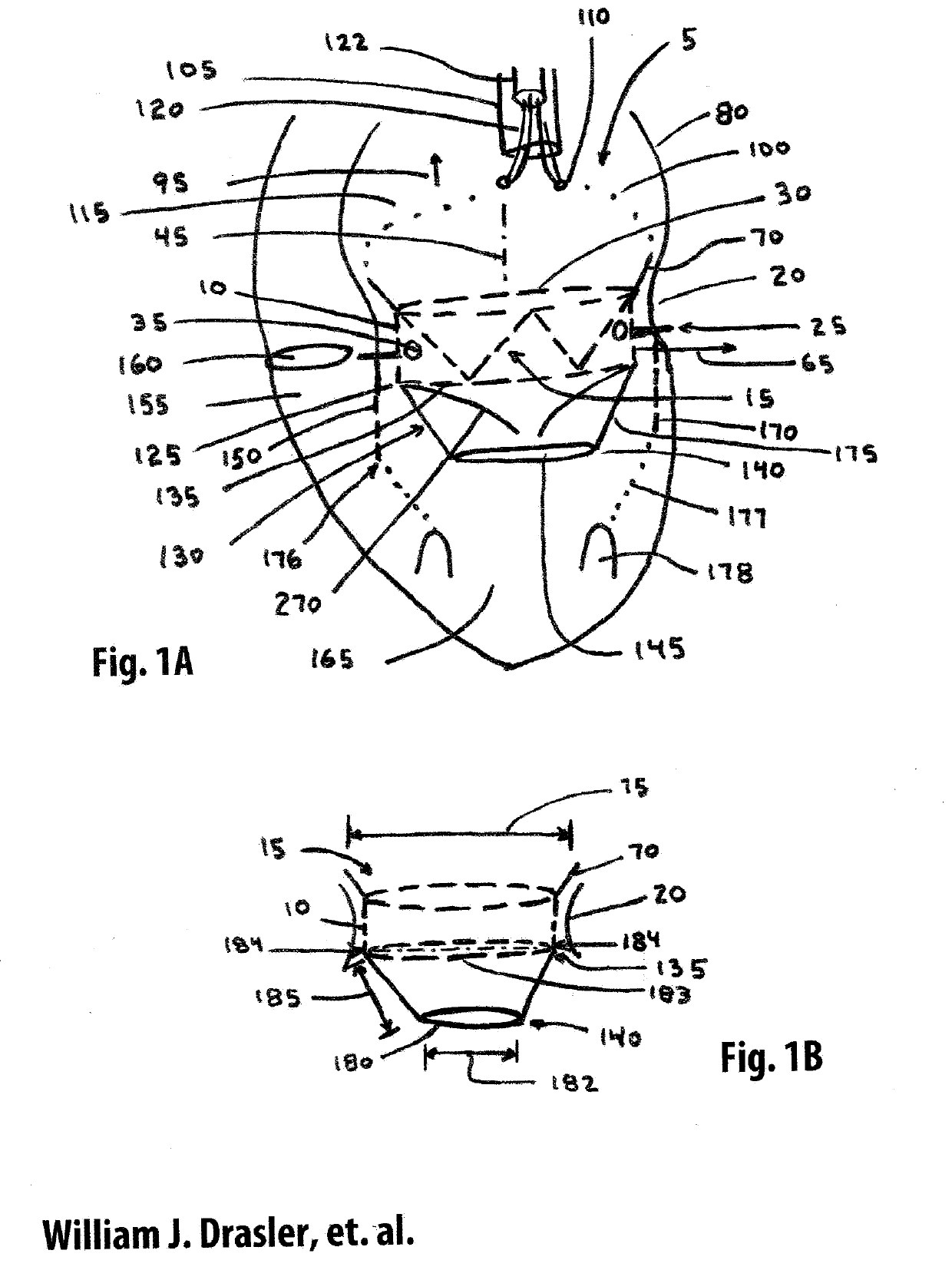

Straddle Annular Mitral Valve

ActiveUS20190142582A1Low profilePrevention of perivalvular leakageBalloon catheterHeart valvesLeft ventricular sizeTranscatheter approach

A two component system for replacing mitral valves using a transcatheter approach. The first component uses a torus balloon to activate barbs into the mitral annulus after the first component stent frame has been delivered. A closed ring in the first component provides a landing site for delivery of a second component that contains replacement leaflets. The second component straddles the mitral annulus such that impingement upon the left ventricular outflow track does not occur. The second component frame contains open regions that help to prevent blood stagnation.

Owner:DRASLER WILLIAM JOSEPH +1

Venturi apparatus for pouring and aereating beverages

ActiveUS8251352B2Maximize flowEasy to introduceFlow mixersUsing liquid separation agentBreatherAcute angle

An improved venturi apparatus for the incorporation of air into a liquid. The preferred embodiment of the invention comprises an entry section, a cylindrical section, and an outflow section. Lateral tubes extend from the cylindrical section so as to form an acute angle relative to both the central and cross-sectional axes of the cylindrical section, thereby preventing leakage of liquid out through the lateral tubes during use and subsequent handling. The entry section includes a breather tube connected to the cylindrical section.

Owner:FRANMARA INC

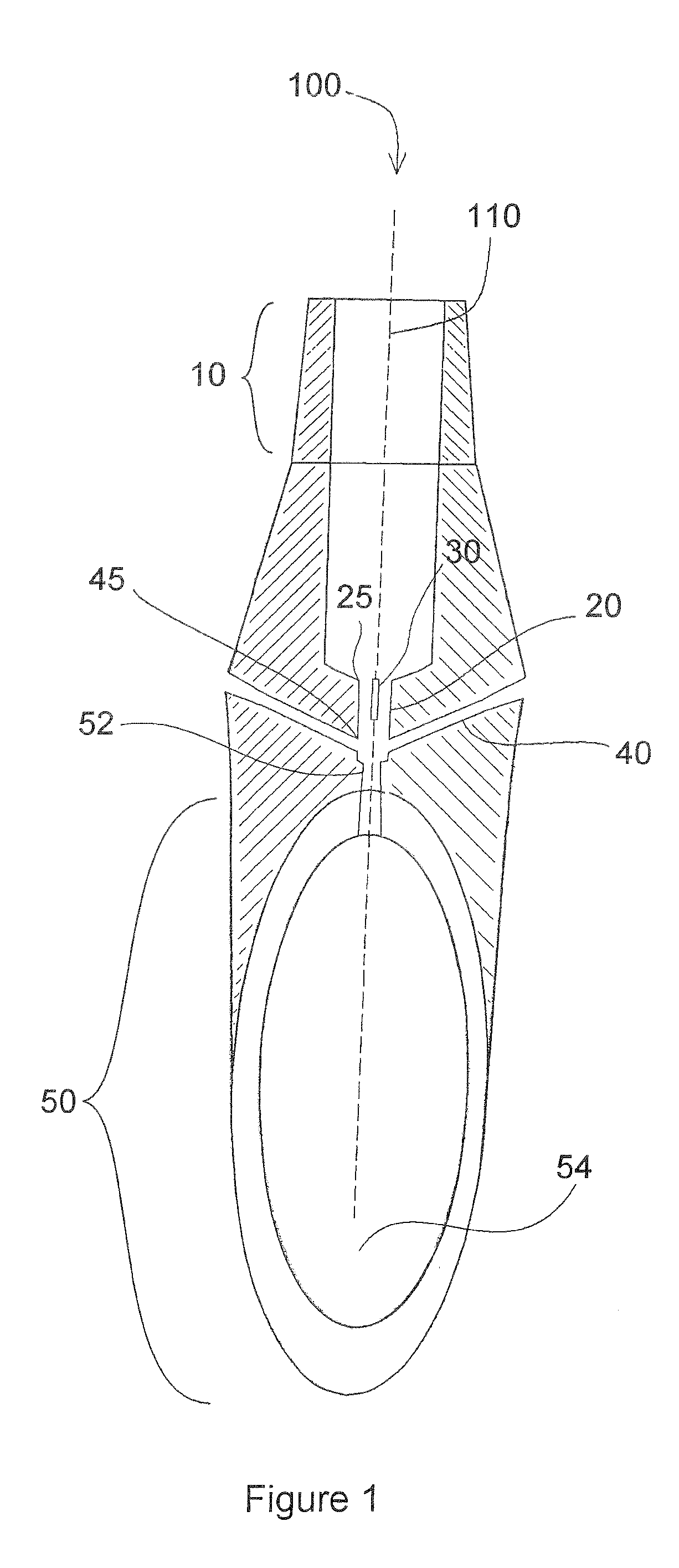

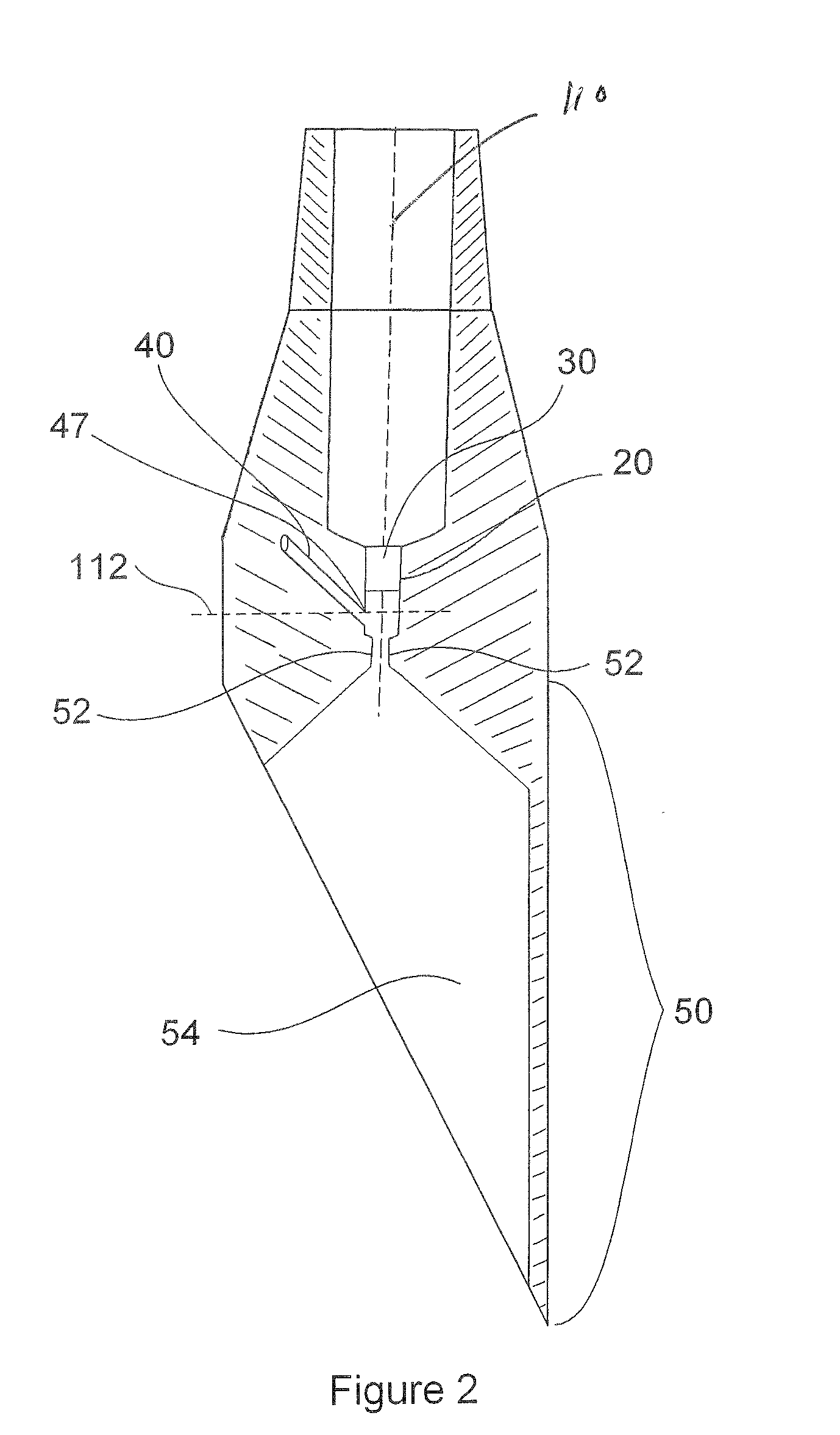

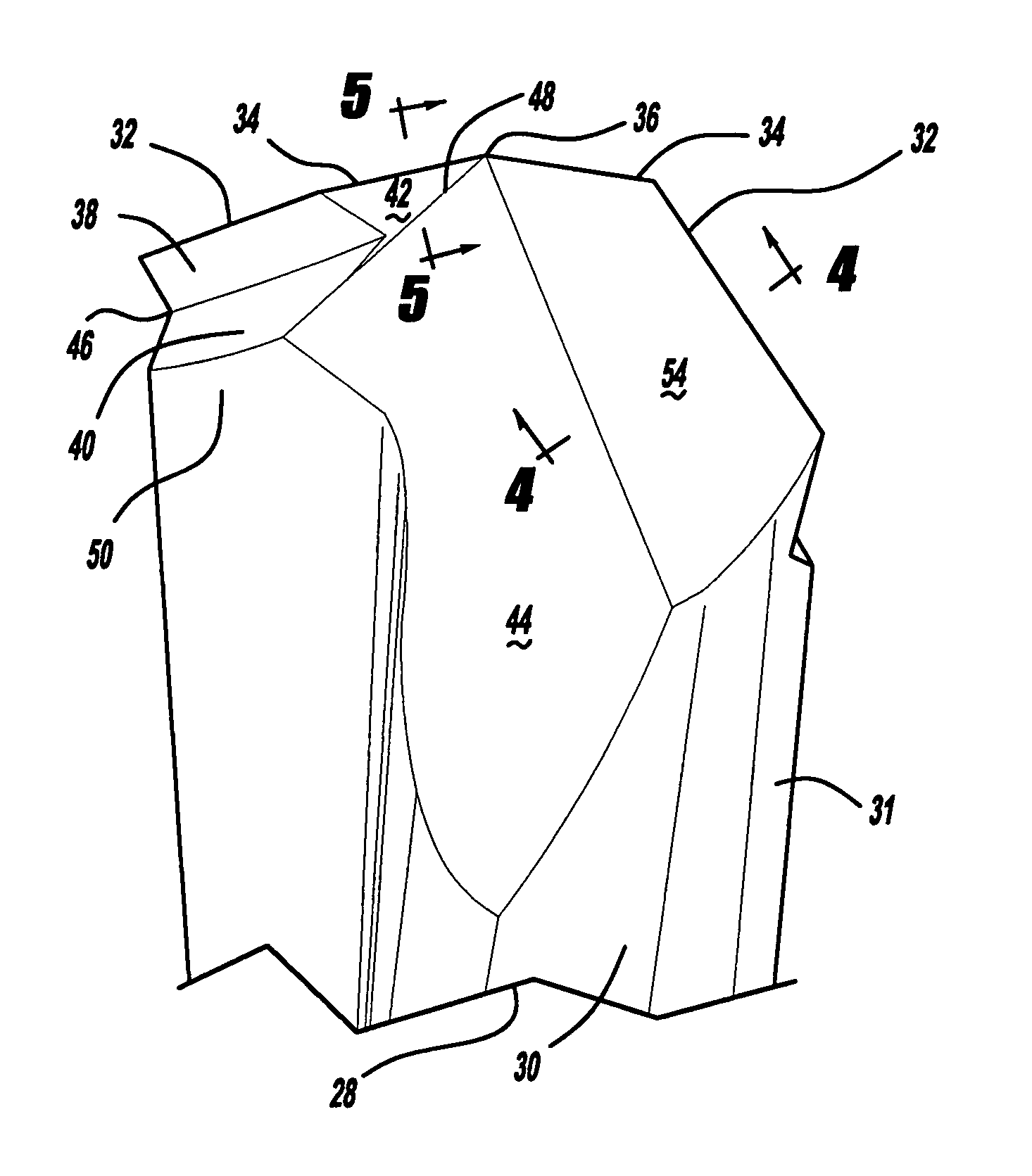

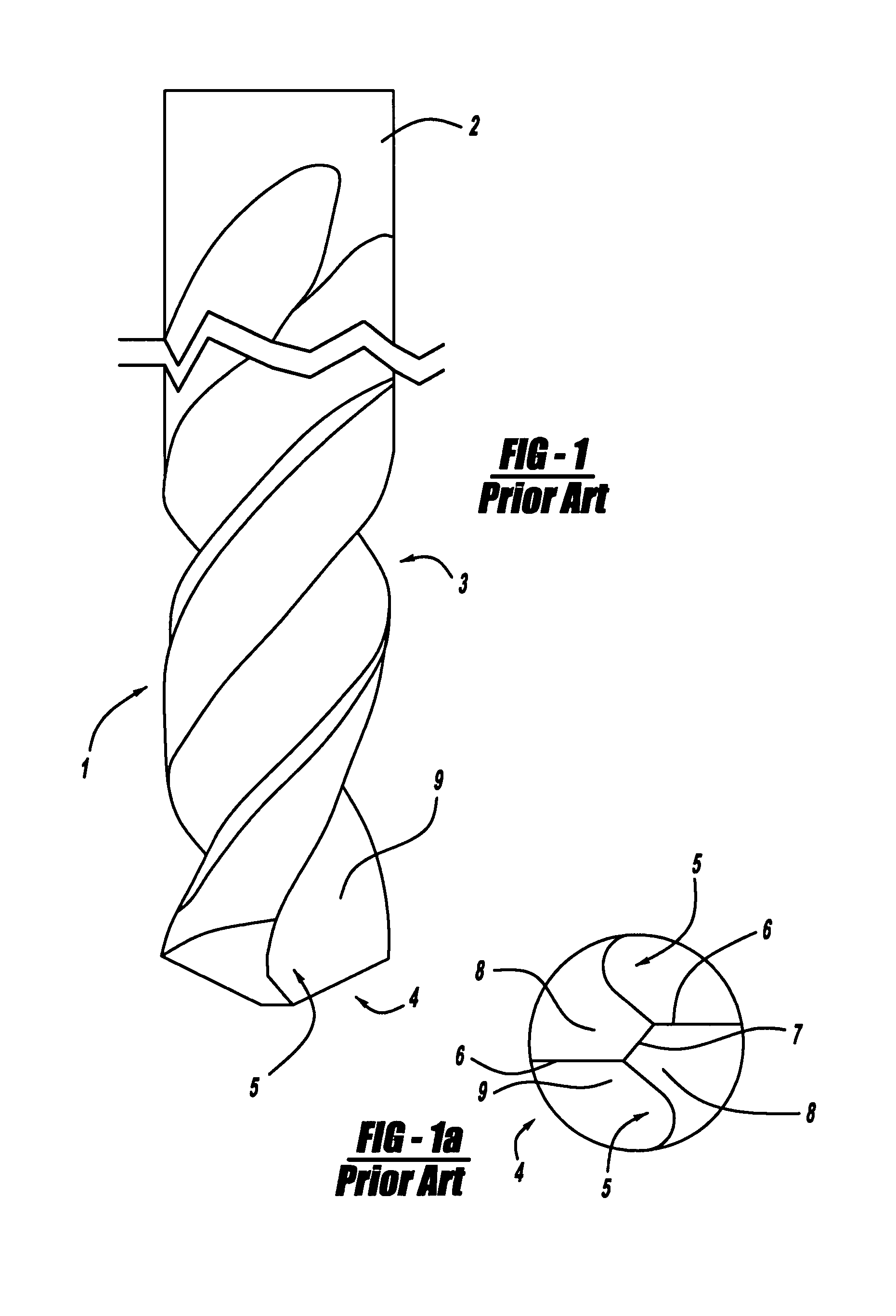

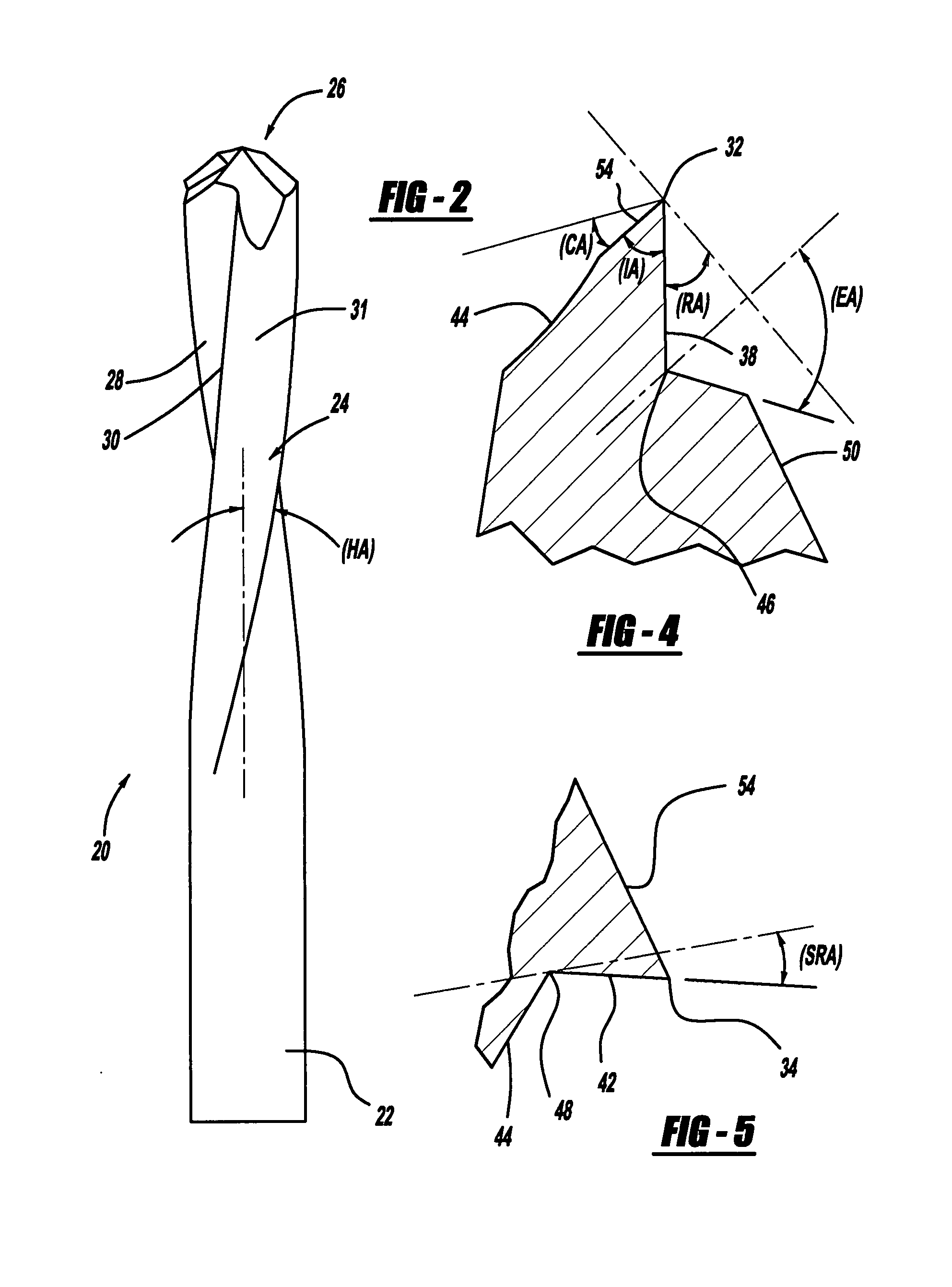

High speed metal drill bit

InactiveUS7237986B2Increase drilling speedMaterial removal can be maximizedWood turning toolsTransportation and packagingFluteEngineering

A metal cutting drill bit has a shank portion, a flute portion defining a helix angle and a tip. The tip has a primary cutting edge extending to an outer periphery of the drill bit. The primary cutting edge has a rake face defining a rake angle. The rake angle is different from the helix angle at the tip of the drill bit.

Owner:UNIV OF MARYLAND +1

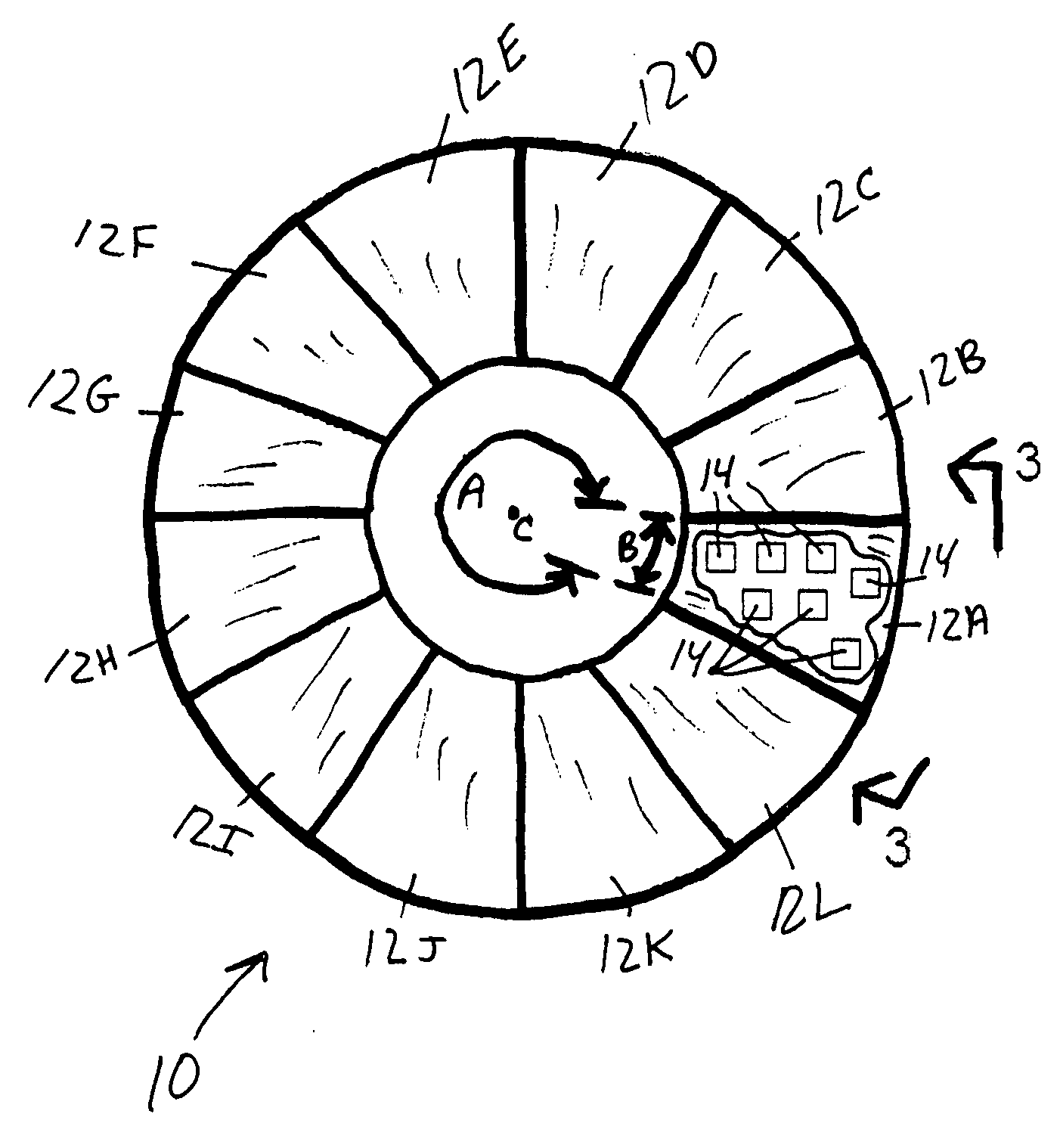

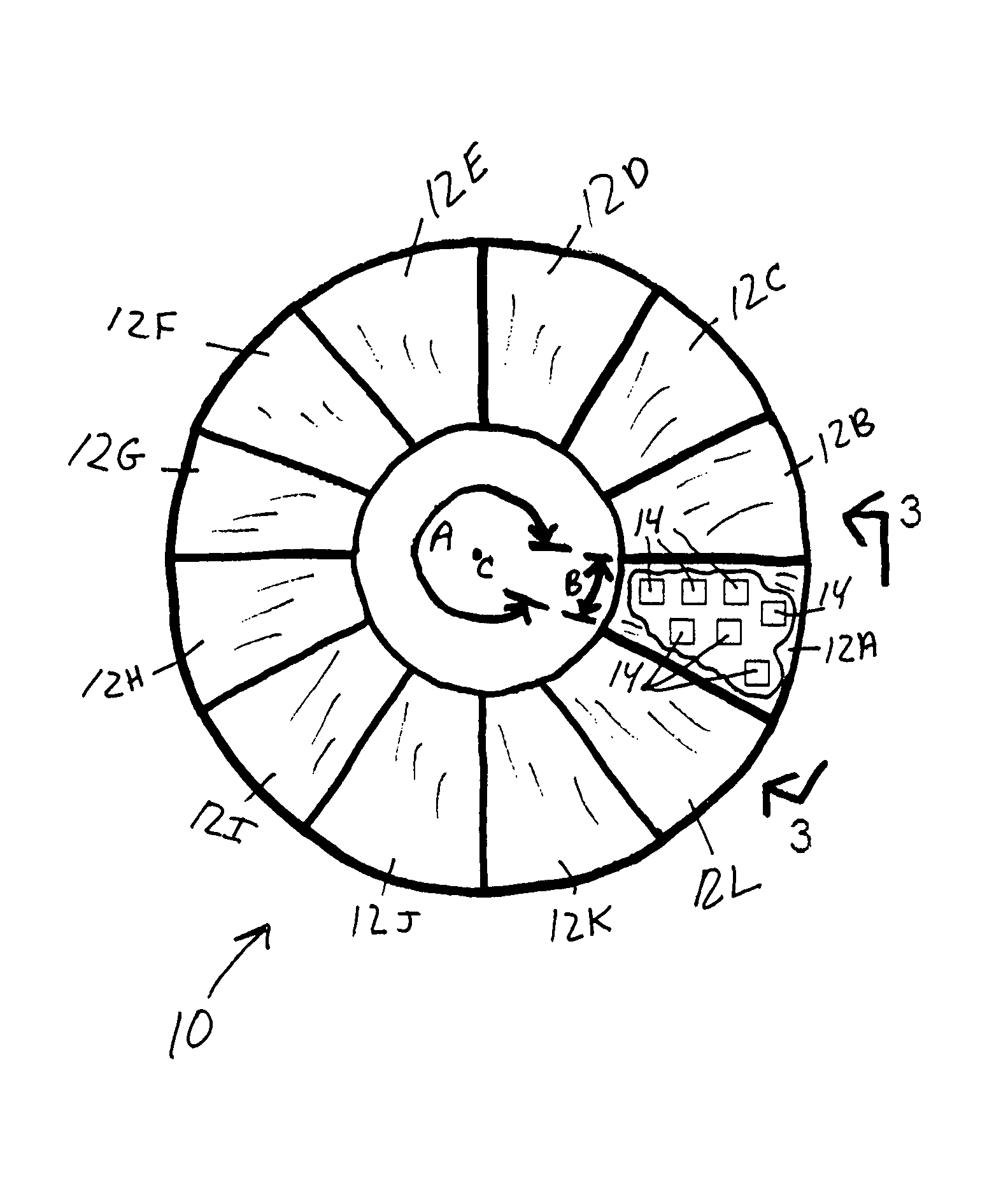

Rotary adsorbers for continuous bulk separations

A rotary adsorber for continuous bulk separations is disclosed. The rotary adsorber includes an adsorption zone in fluid communication with an influent adsorption fluid stream, and a desorption zone in fluid communication with a desorption fluid stream. The fluid streams may be gas streams or liquid streams. The rotary adsorber includes one or more adsorption blocks including adsorbent structure(s). The adsorbent structure adsorbs the target species that is to be separated from the influent fluid stream. The apparatus includes a rotary wheel for moving each adsorption block through the adsorption zone and the desorption zone. A desorption circuit passes an electrical current through the adsorbent structure in the desorption zone to desorb the species from the adsorbent structure. The adsorbent structure may include porous activated carbon fibers aligned with their longitudinal axis essentially parallel to the flow direction of the desorption fluid stream. The adsorbent structure may be an inherently electrically-conductive honeycomb structure.

Owner:UT BATTELLE LLC

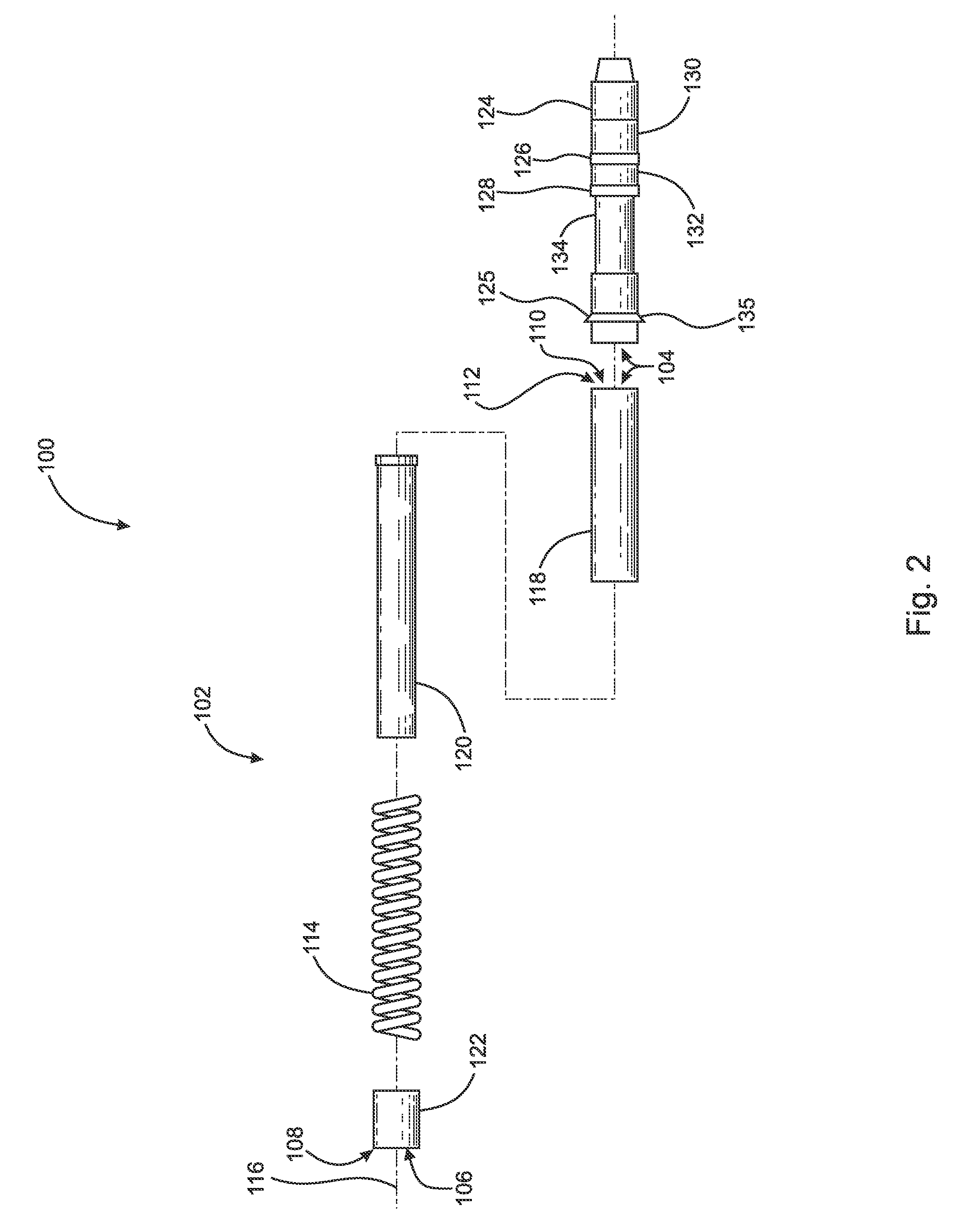

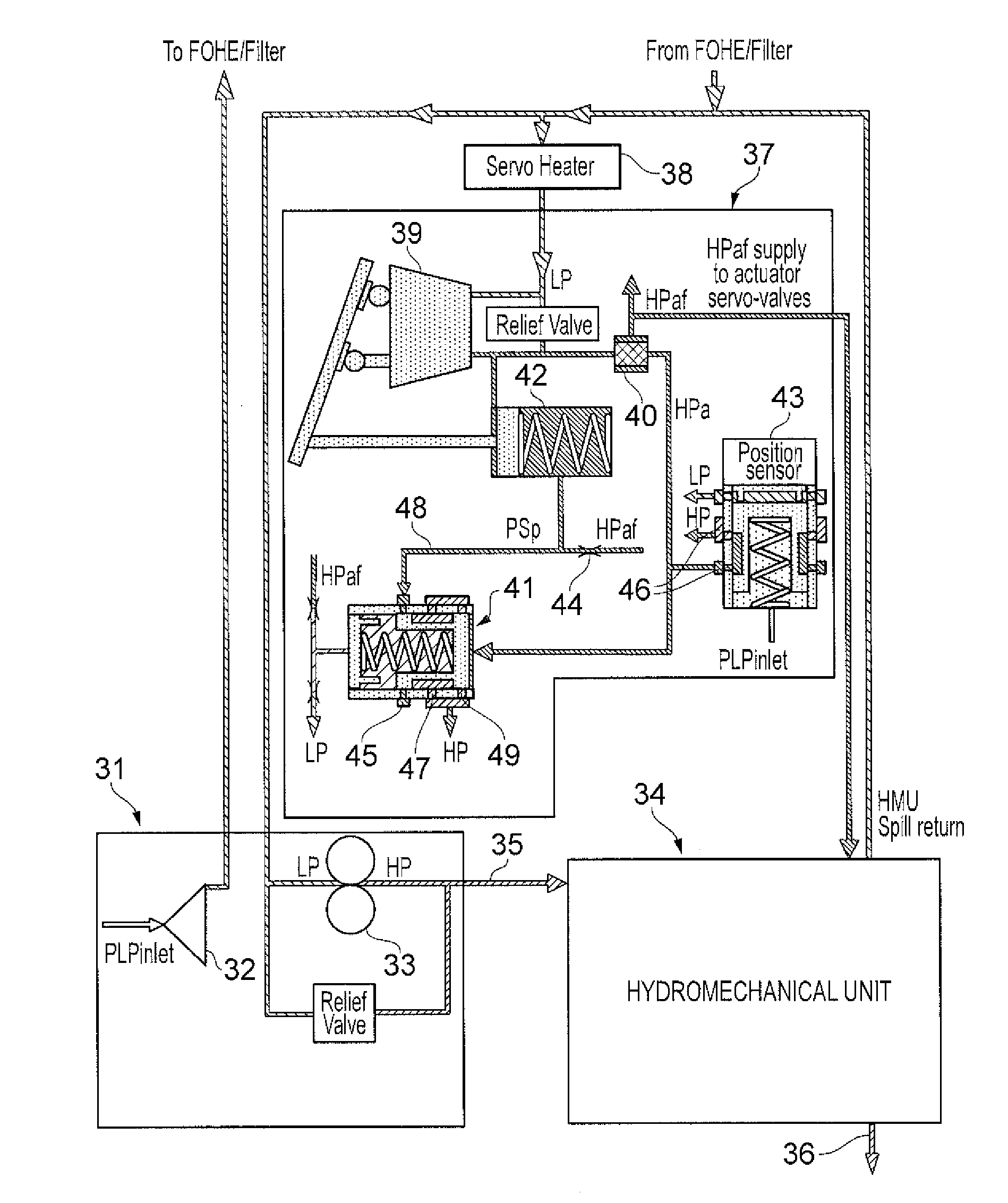

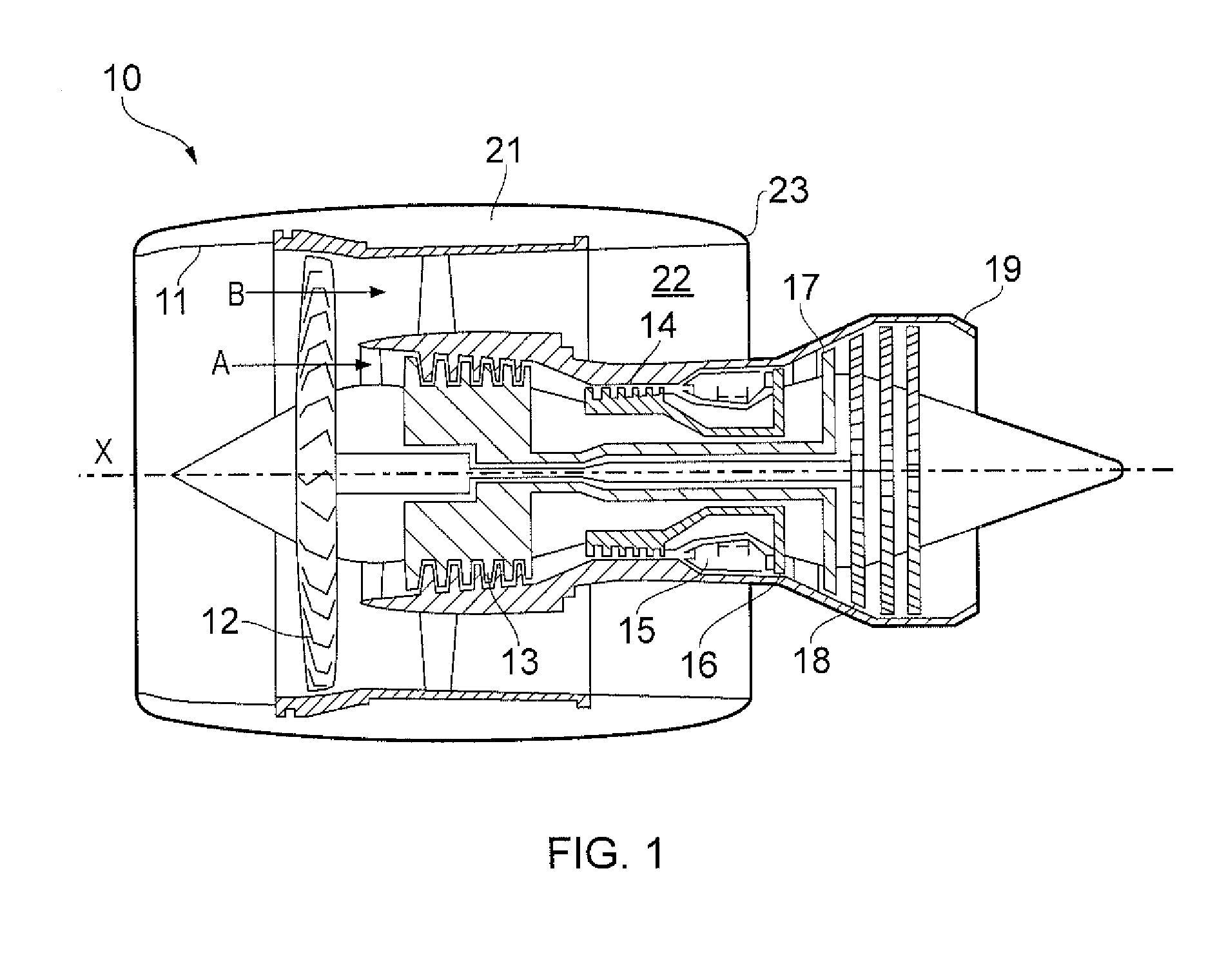

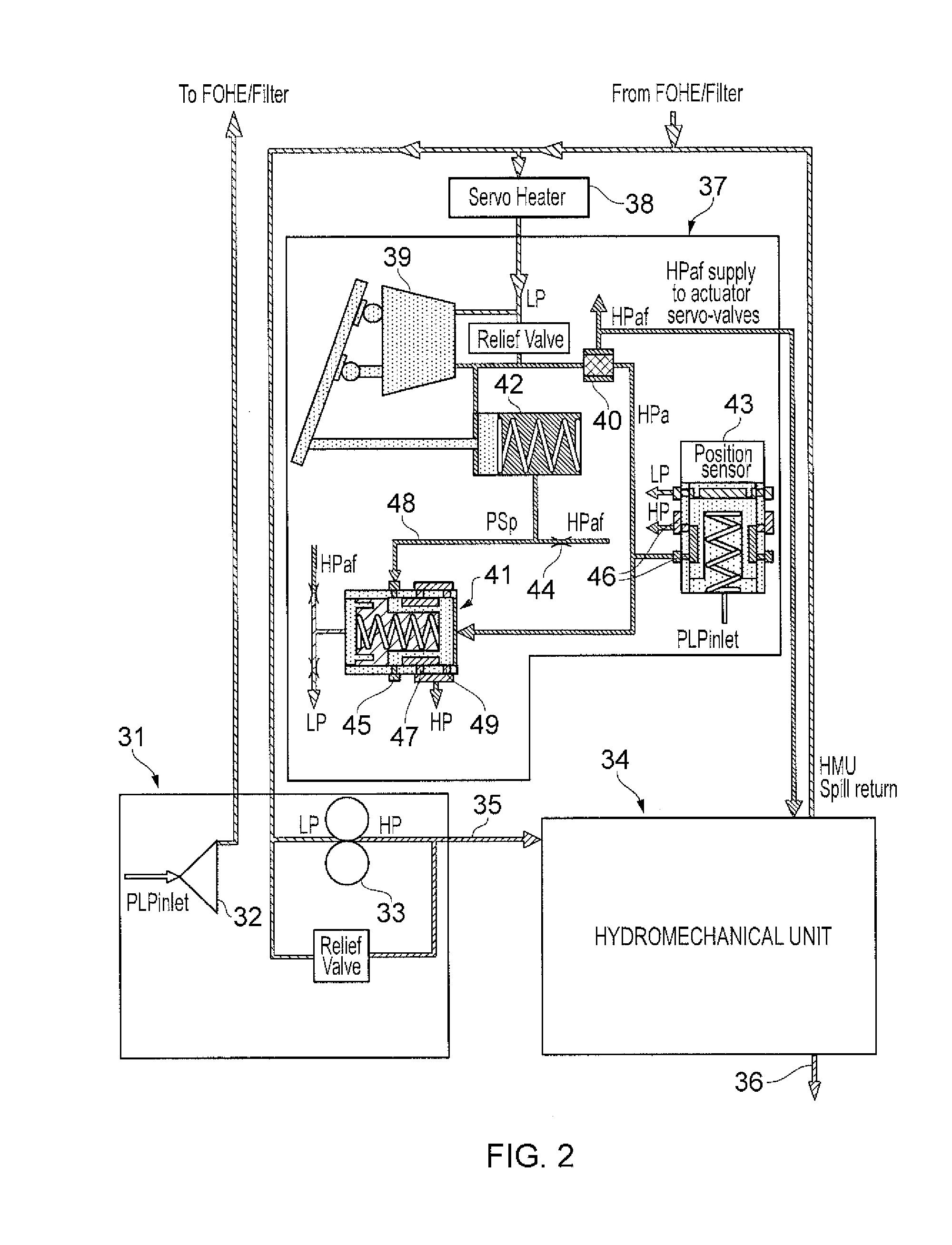

Engine fuel control system

ActiveUS20150192075A1Improve thermal efficiencyReduce loadEngine fuctionsTurbine/propulsion fuel deliveryControl systemHigh pressure

An engine fuel control system includes a fuel metering valve that controls the flow of fuel between supply and delivery lines which delivers fuel to engine burners. The fuel control system includes a fixed displacement main pump which receives fuel from a low pressure source and delivers the fuel at a first high pressure to the supply line, an augmenter pump which receives fuel from the low pressure source and delivers the fuel at a second high pressure to one or more fuel-pressure operated auxiliary engine devices, and a start valve which is actuated at low engine speeds to open a flow path which diverts fuel delivered by the augmenter pump away from the auxiliary engine devices to the supply line to augment the fuel delivered thereto by the main pump, the start valve being actuated at higher engine speeds to shut the flow path.

Owner:ROLLS ROYCE PLC

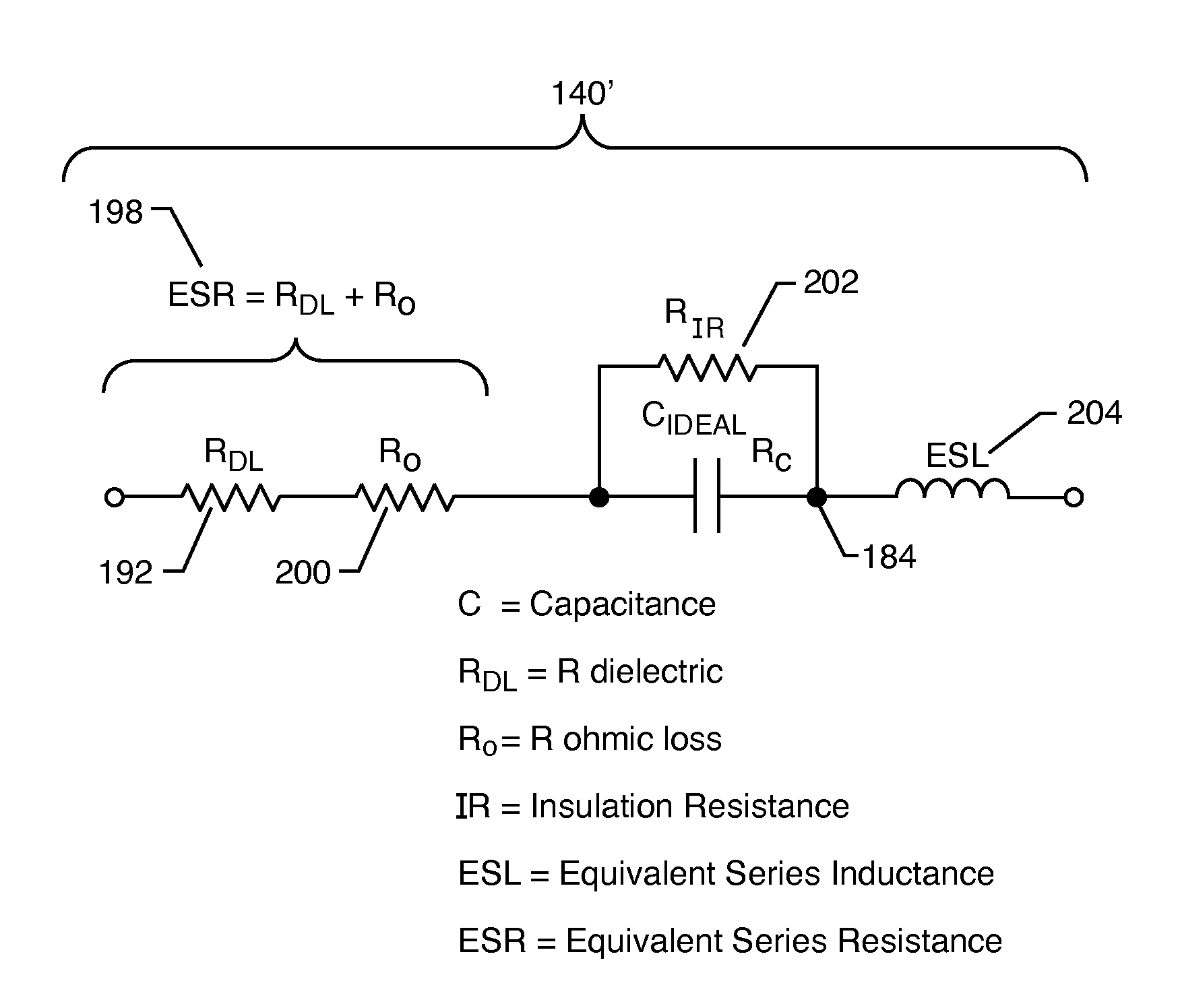

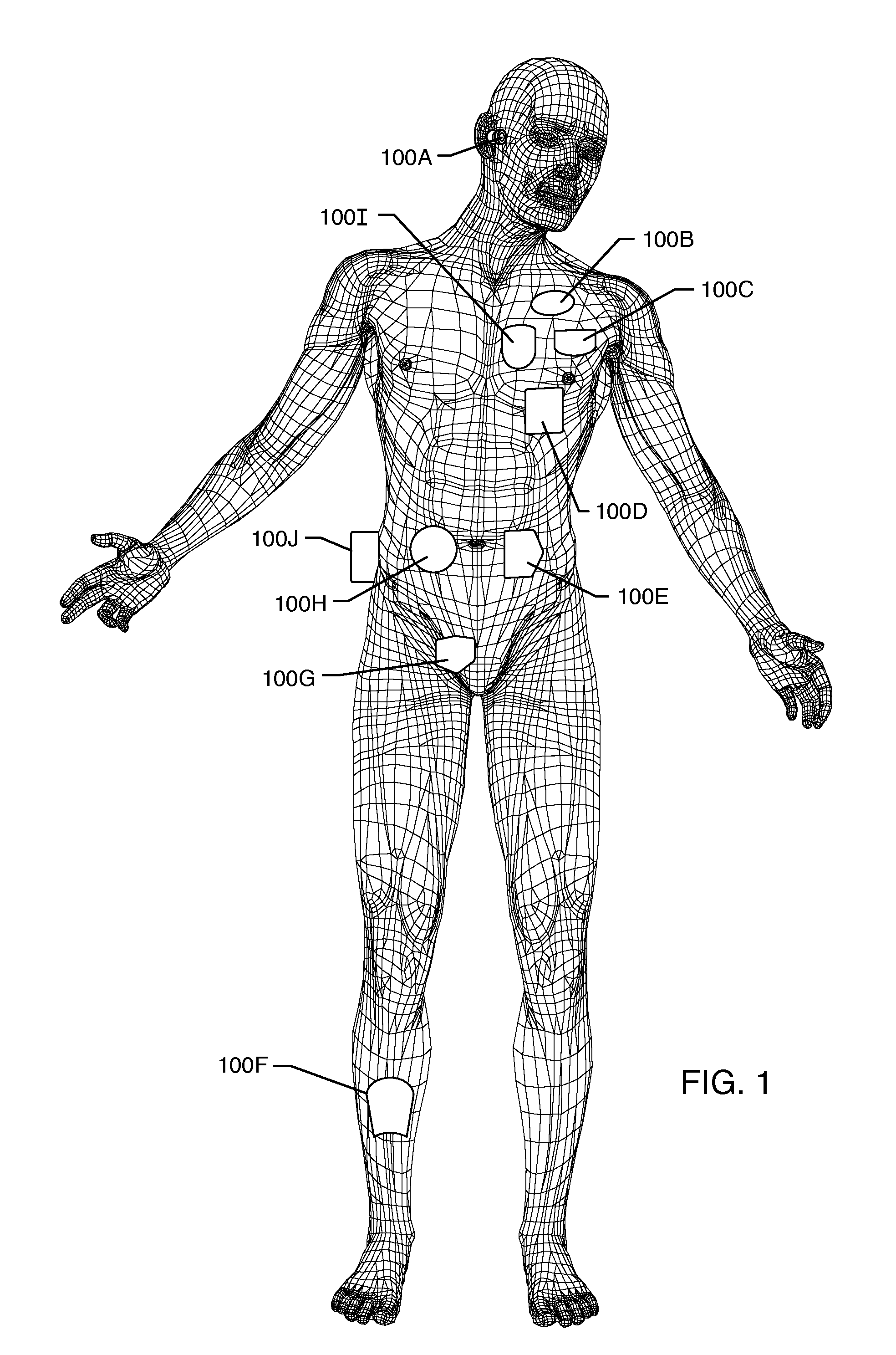

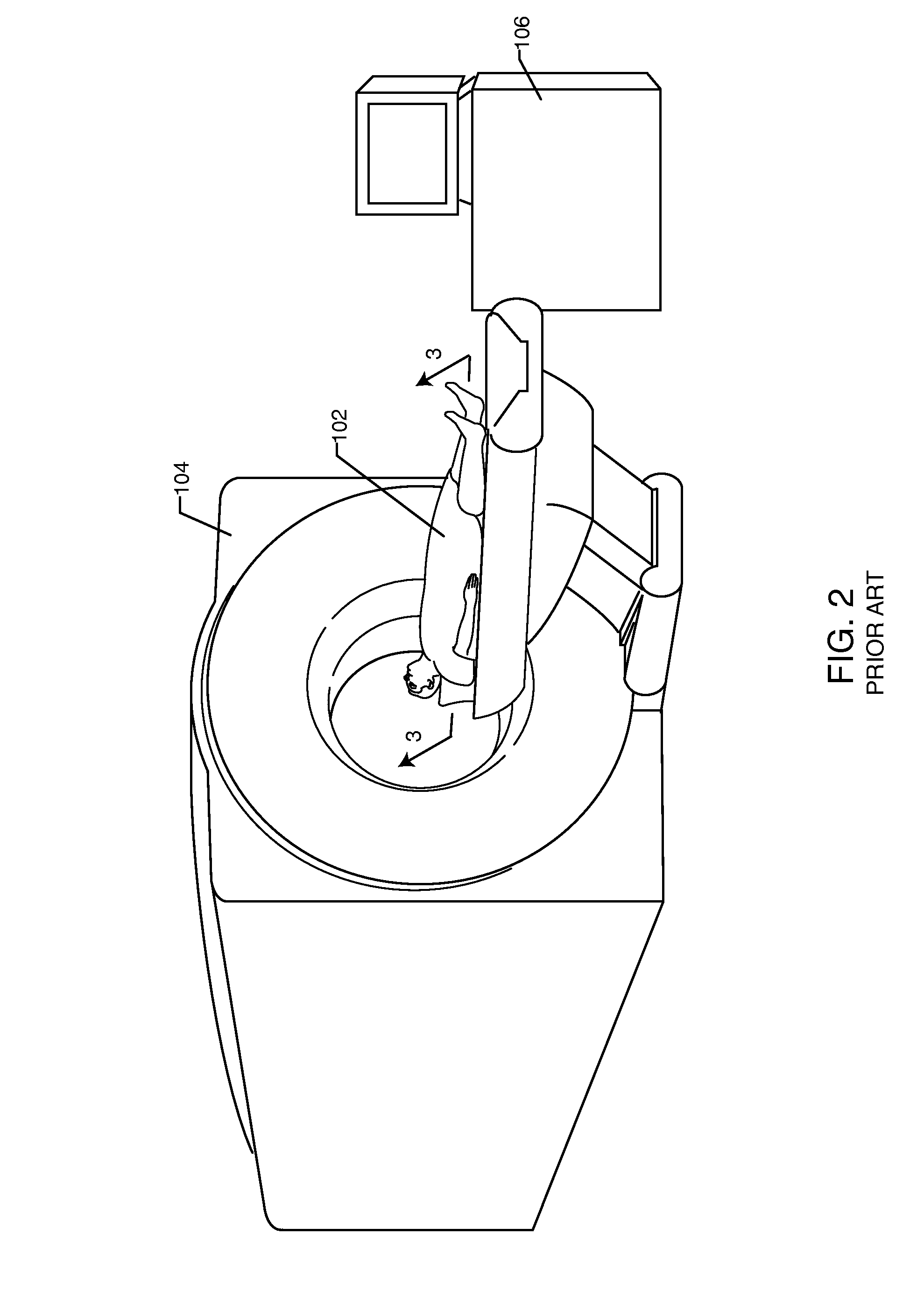

RF filter for an active medical device (AMD) for handling high RF power induced in an associated implanted lead from an external RF field

InactiveUS20120256704A1High RF powerMaximize flowMultiple-port networksAnti-noise capacitorsCapacitanceElectricity

An RF filter for an active medical device (AMD), for handling RF power induced in an associated lead from an external RF field at a selected MRI frequency or range frequencies includes a capacitor having a capacitance of between 100 and 10,000 picofarads, and a temperature stable dielectric having a dielectric constant of 200 or less and a temperature coefficient of capacitance (TCC) within the range of plus 400 to minus 7112 parts per million per degree centigrade. The capacitor's dielectric loss tangent in ohms is less than five percent of the capacitor's equivalent series resistance (ESR) at the selected MRI RF frequency or range of frequencies.

Owner:WILSON GREATBATCH LTD

Rotary adsorbers for continuous bulk separations

A rotary adsorber for continuous bulk separations is disclosed. The rotary adsorber includes an adsorption zone in fluid communication with an influent adsorption fluid stream, and a desorption zone in fluid communication with a desorption fluid stream. The fluid streams may be gas streams or liquid streams. The rotary adsorber includes one or more adsorption blocks including adsorbent structure(s). The adsorbent structure adsorbs the target species that is to be separated from the influent fluid stream. The apparatus includes a rotary wheel for moving each adsorption block through the adsorption zone and the desorption zone. A desorption circuit passes an electrical current through the adsorbent structure in the desorption zone to desorb the species from the adsorbent structure. The adsorbent structure may include porous activated carbon fibers aligned with their longitudinal axis essentially parallel to the flow direction of the desorption fluid stream. The adsorbent structure may be an inherently electrically-conductive honeycomb structure.

Owner:UT BATTELLE LLC

Vision based conveyor package flow management system

ActiveUS9771222B2Improve efficiencyMaximize packing densityConveyorsControl devices for conveyorsIndividual itemEntry point

A camera based vision system that recognizes and maximizes belt area utilization. A plurality of cameras are positioned at flow entry points of feed conveyors and at the singulator. The control algorithm recognizes individual items area, the rate at which individual objects are passing, and the area utilization of the collector belt. The video camera and computer based conveyor package management system monitor and control the number and size of the packages present on the infeed conveyors, collector conveyor, singulator conveyor and sorting conveyor in a package handling system wherein the camera data is used to measure the available area or space on the conveyors to maintain a desired density of packages on selected conveyor(s). The conveyor speed is controlled as a function of occupancy on a collector or just prior to a singulator or receiver.

Owner:FIVES INTRALOGISTICS SA

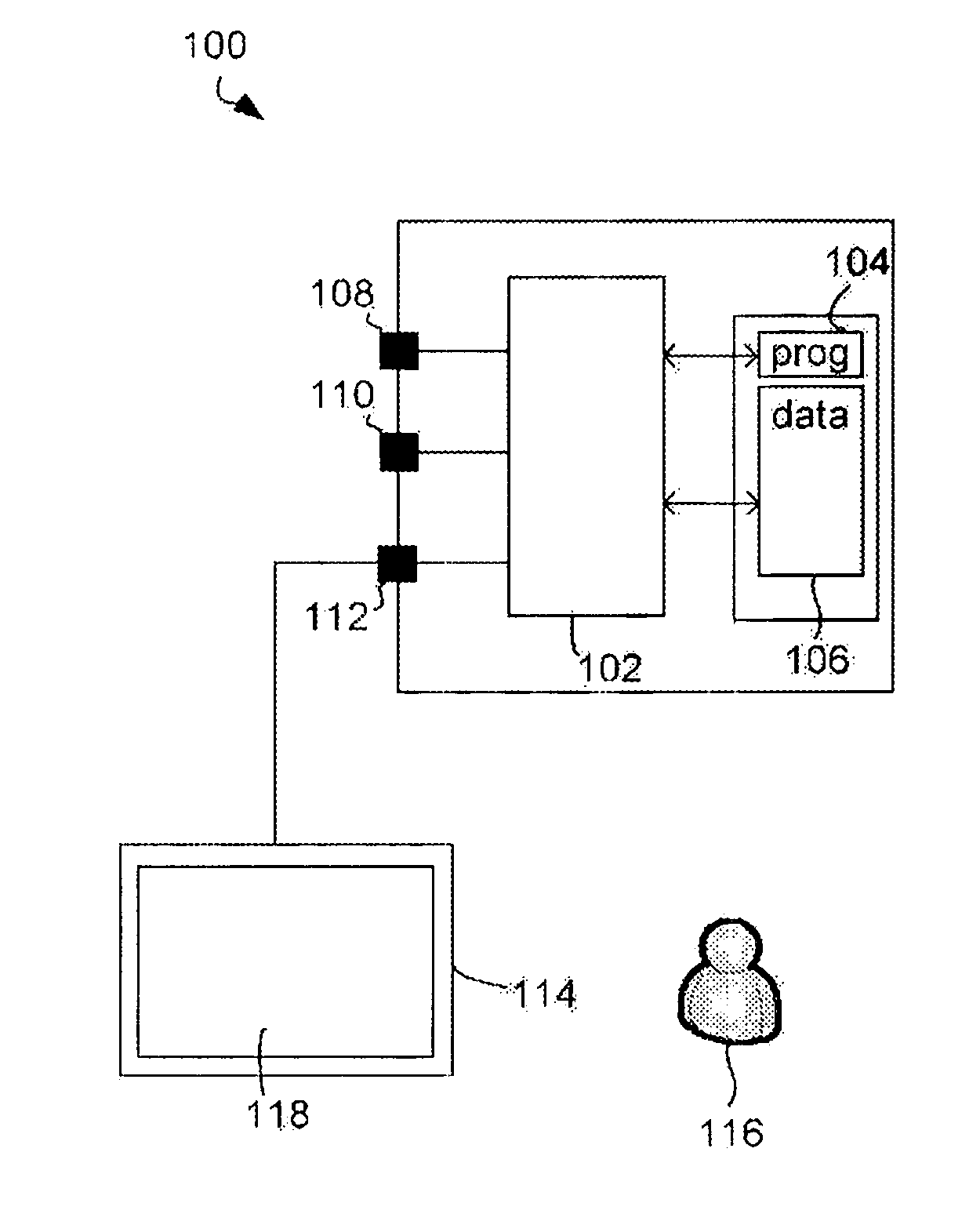

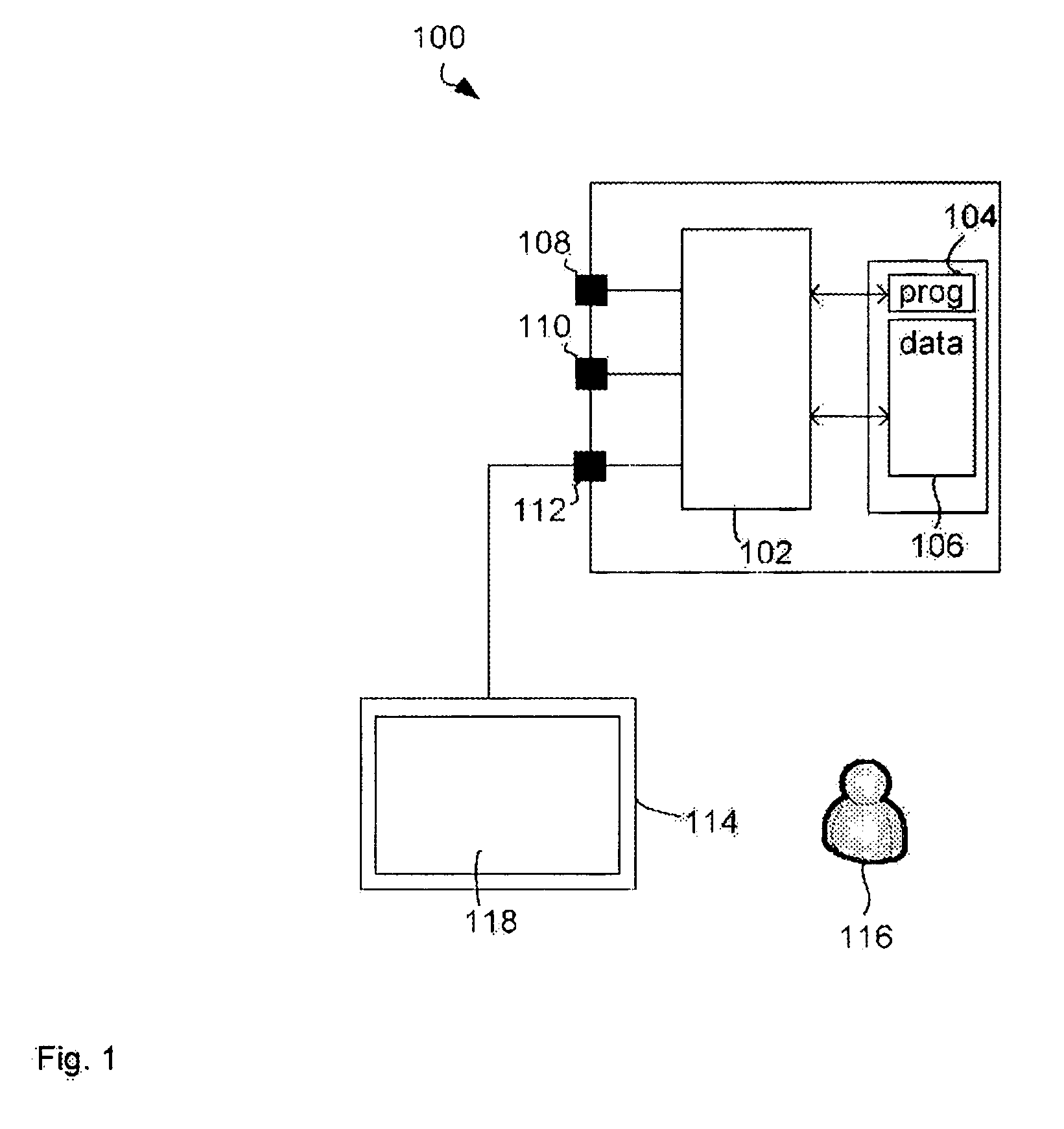

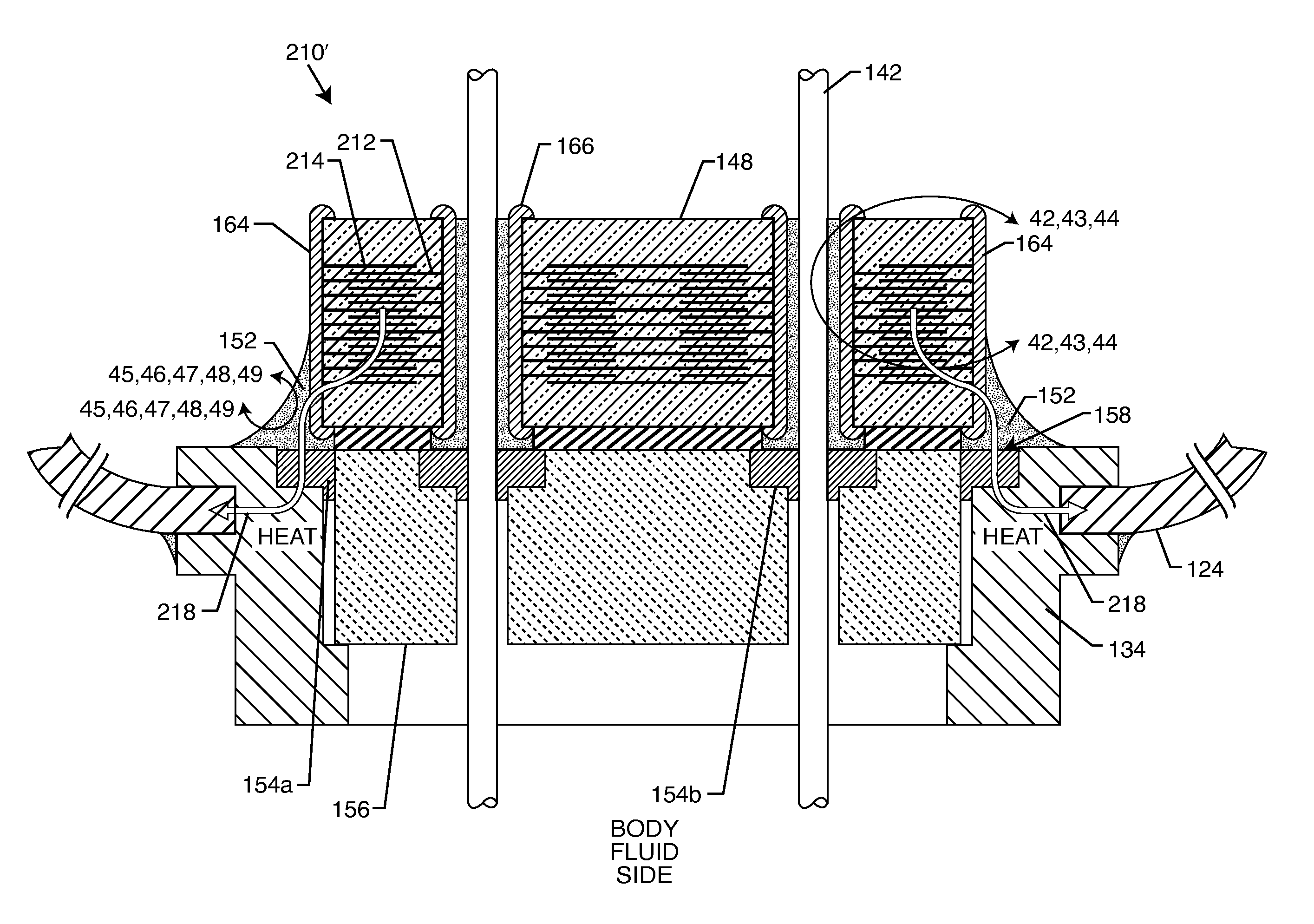

Evacuation plan design

InactiveUS20160314554A1Reduce in quantityMaximize flowInstruments for road network navigationData processing applicationsTime scheduleEvacuation plan

This disclosure relates to planning movement of multiple groups over a transport network, for example, but not limited to, the evacuation of persons from geographical zones. A processor receives an initial set of paths for the multiple groups to move through the transport network to respective arrival locations and for each group an initial path to the respective arrival location and an initial departure schedule. The processor then determines based on the initial departure schedules and initial paths one or more critical groups that violate a movement performance threshold and further determines based on the transport network an updated set of paths by adding one or more paths for each critical group to the initial set of paths. Finally, the processor determines for each group an updated path to the arrival location and an updated departure schedule based on the updated set of paths.

Owner:NAT ICT AUSTRALIA

RF filter for an active medical device (AMD) for handling high RF power induced in an associated implanted lead from an external RF field

ActiveUS20140168850A1Maximize flowMinimize the capacitor's high frequency ESRAnti-noise capacitorsImpedence networksCapacitanceElectricity

Owner:WILSON GREATBATCH LTD

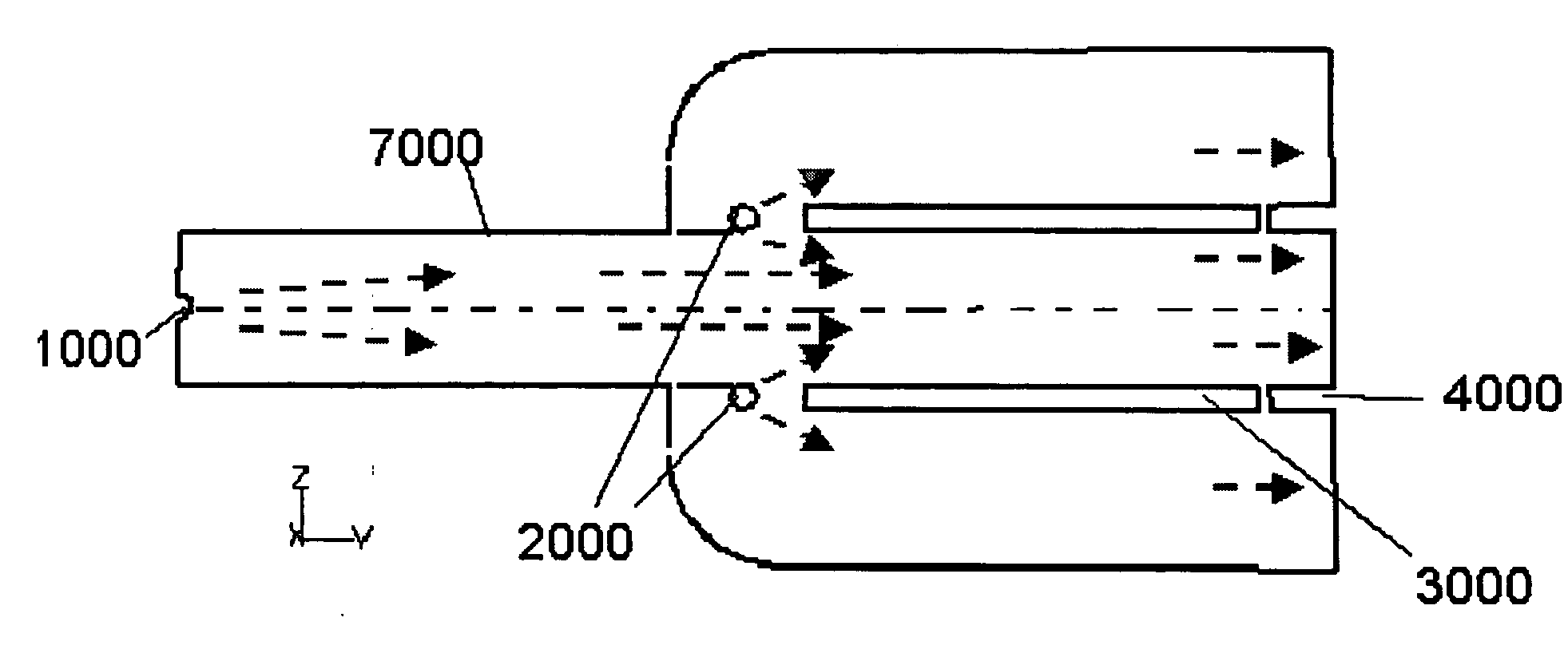

High temperature chemical vapor deposition apparatus

InactiveUS20060185591A1Uniform supplyMaximize flowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical compositionGas phase

Embodiments for an apparatus and method for depositing one or more layers onto a substrate or a freestanding shape inside a reaction chamber operating at a temperature of at least 700° C. and 100 torr are provided. The apparatus is provided with a feeding system having injection means for differential pre-reactions and / or pre-treating of a plurality of gases or gas mixtures, tailoring the distribution of a plurality of gas-phase species, yielding a deposit that is substantially uniform in thickness and chemical composition along the substrate surface. In one embodiment, the apparatus further comprises a sacrificial substrate that further helps achieving thickness and chemical uniformity on the substrate, by imitating a continuous surface to deposit on and thus preventing any disturbances in the flow pattern especially towards the edge of the substrate.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Supplemental gas delivery device for mask assembly

ActiveUS20140096773A1Good curative effectMaximize flowBreathing masksRespiratory masksEngineeringOral cavity

A supplemental gas delivery device is described for a mask assembly having at least one supplemental gas port, the at least one supplemental gas port including an aperture in communication with an interior of the mask assembly. The mask assembly may include an aperture communicating with an interior of the mask assembly, and a cannula for communicating with the supplemental gas port. The cannula is positioned to deliver supplemental gas adjacent to the patient's nares and / or mouth, to increase an efficacy of treatment for the patient by more directly applying the flow of supplemental gas to the patient's nares. An optional bridging portion may be included to provide a connection between supplemental gas port and the cannula.

Owner:RESMED LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com