Electric drive fracturing semitrailer with dual engines and dual pumps

A semi-trailer and fracturing technology, which is applied in the field of oil and gas field fracturing, can solve the problems of high fuel consumption per unit power, engine exhaust pollution, and high maintenance costs for engines and gearboxes, so as to reduce floor space, weight and equipment investment. Cost, unit power consumption cost reduction, the effect of improving the power density of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

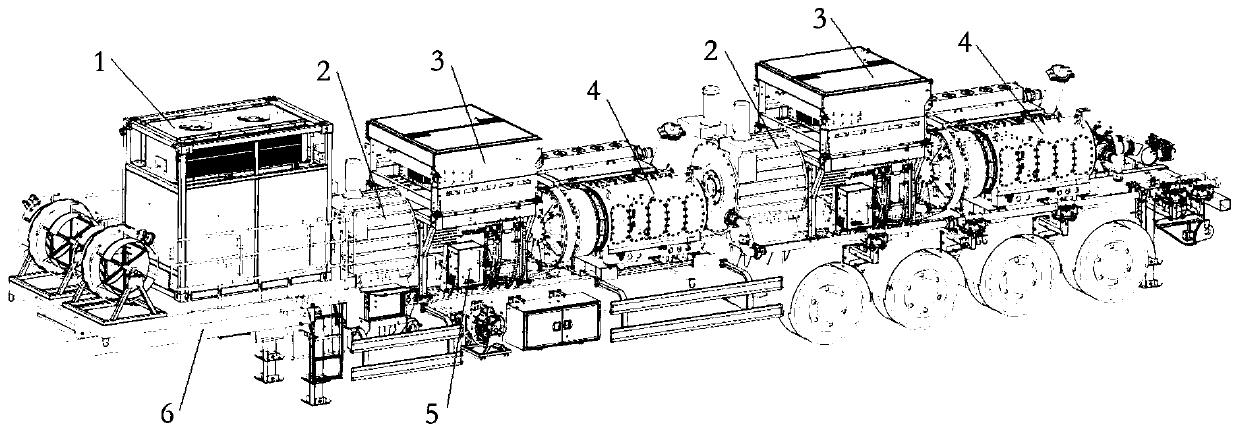

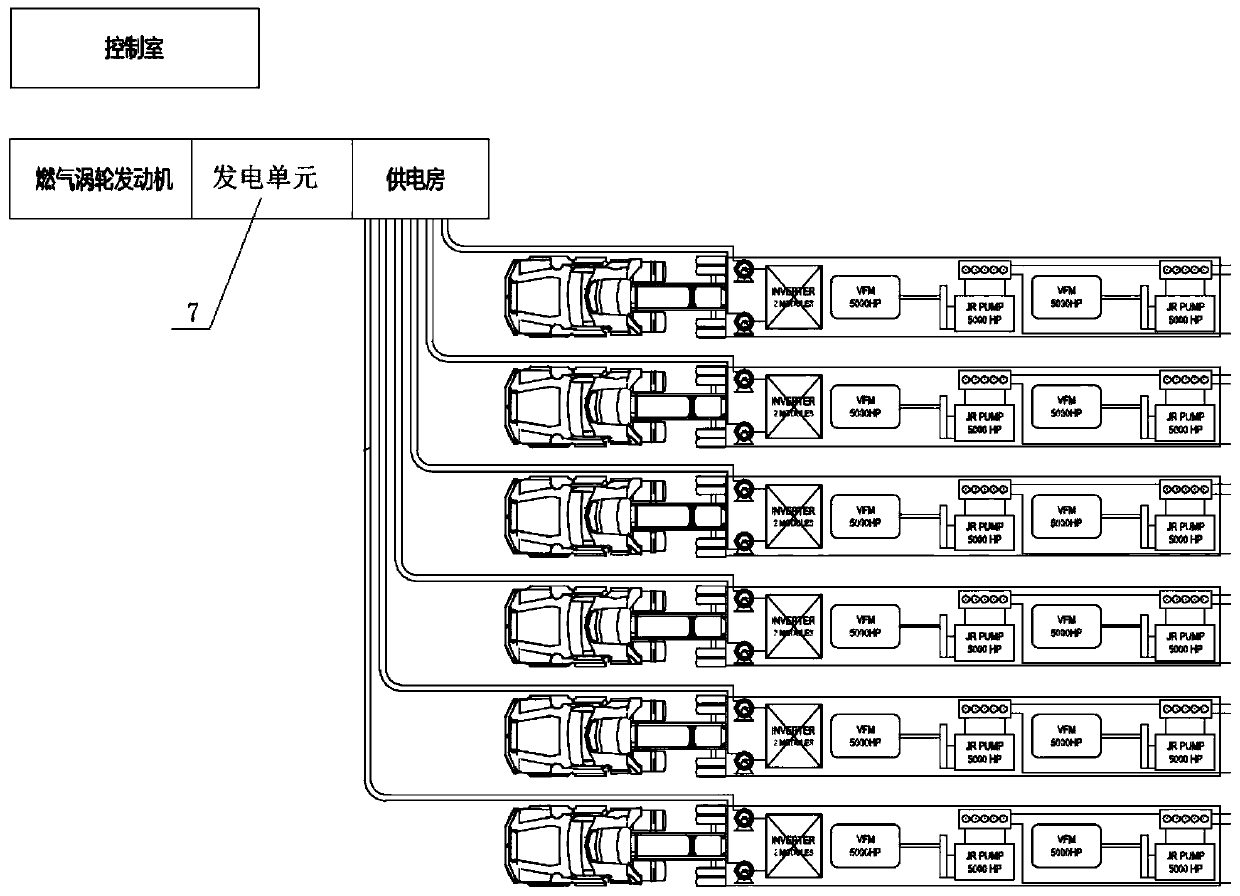

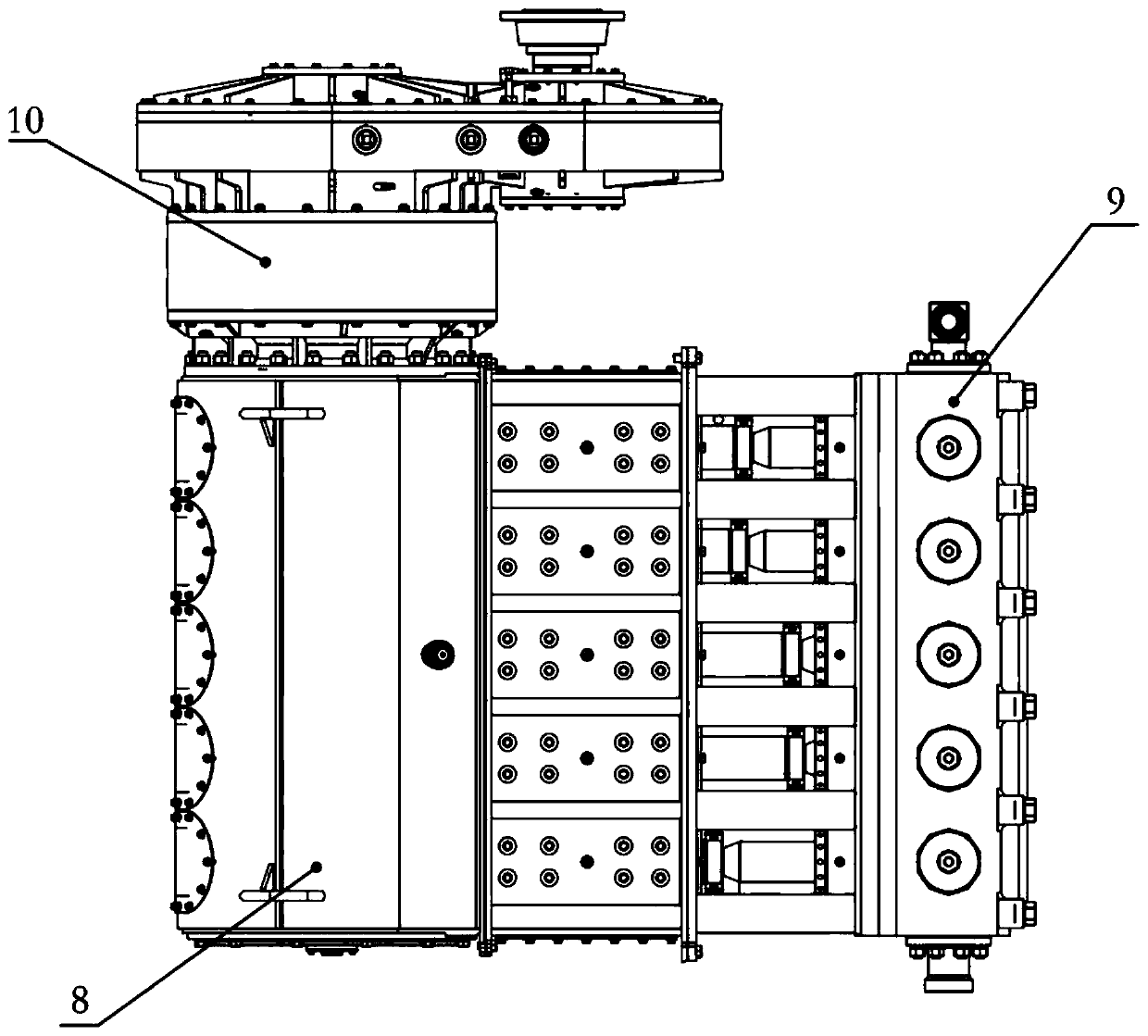

[0035] Examples such as Figures 1 to 11 As shown, a dual-machine double-pump electric drive fracturing semi-trailer includes a semi-trailer 6, a plunger pump 4, a radiator 3, an electrical control cabinet 5, a motor 2 and an inverter unit 1, and the plunger pump 4, The lubricating oil radiator 3, the electrical control cabinet 5, the motor 2 and the inverter unit 1 are integrated on the semi-trailer 6, and the number of axles of the semi-trailer 6 is more than four. The inverter unit 1 is set on the gooseneck of the semi-trailer 6, one end of the motor 2 is connected to the inverter unit 1, the other end of the motor 2 is connected to the plunger pump 4, and the radiator 3 cools the lubricating oil of the plunger pump 4 , through the electrical control cabinet 5 to realize the local control of the double-machine double-pump electric drive fracturing semi-trailer, there are two motors 2, two plunger pumps 4, and two radiators 3. In this application, the motor 2 and the plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com