High-power five-cylinder plunger pump

A high-power, cylinder-column technology, applied in the field of plunger pumps, can solve the problems of increased overall weight of turbo fracturing equipment, incompatibility of input rotation direction, and increased maintenance costs, etc., to solve the problem of more fracturing equipment and increased maintenance costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

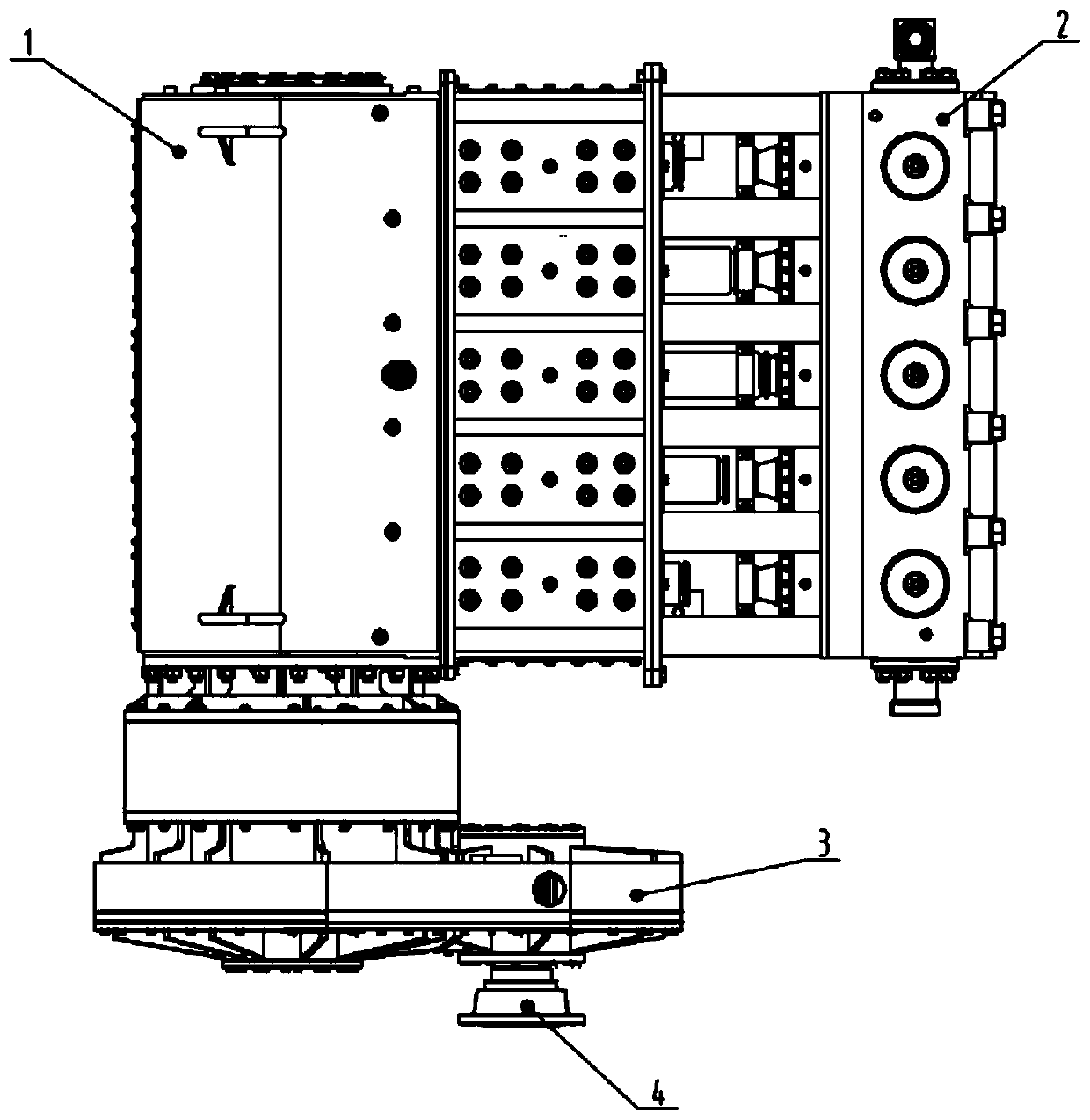

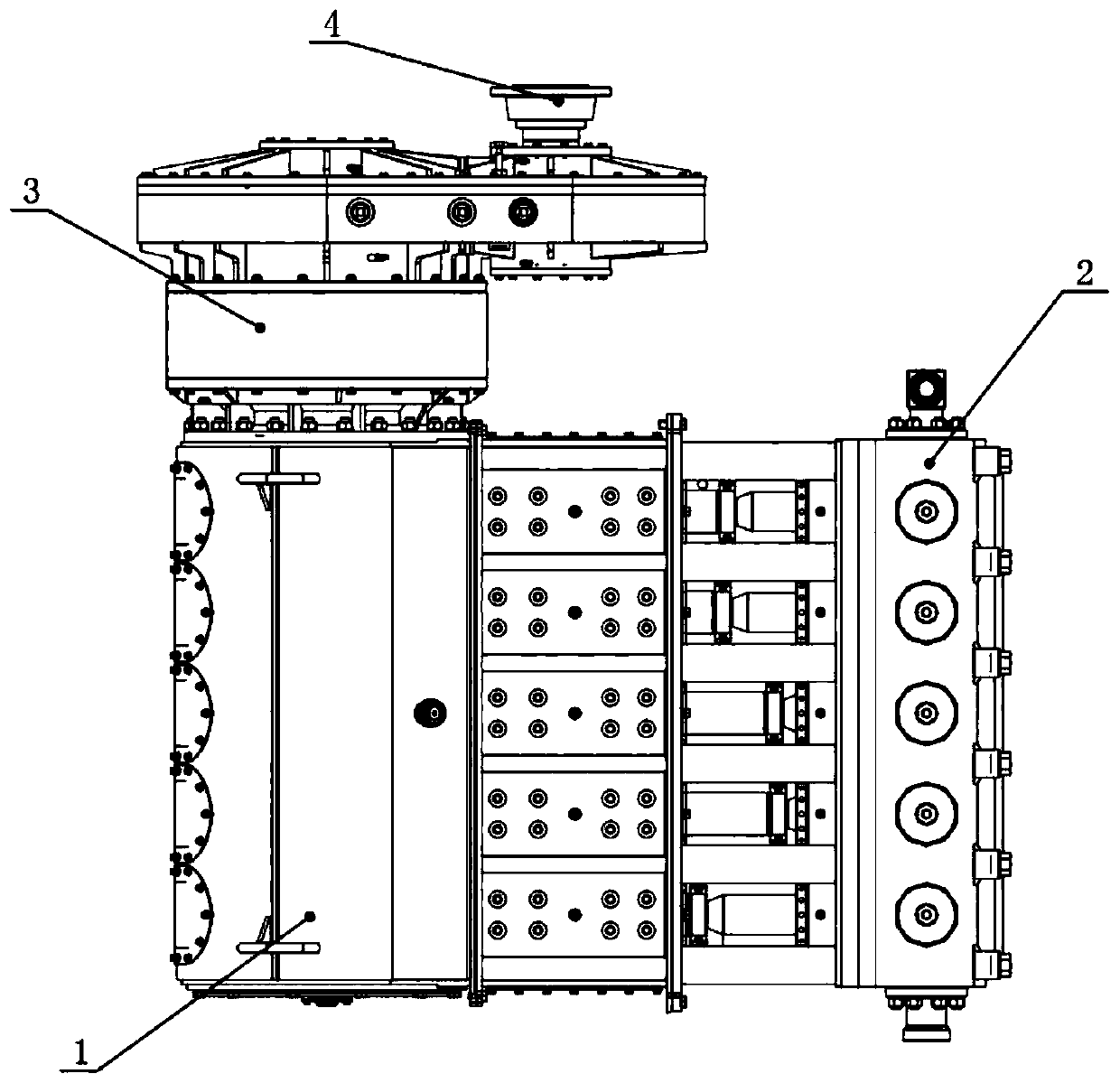

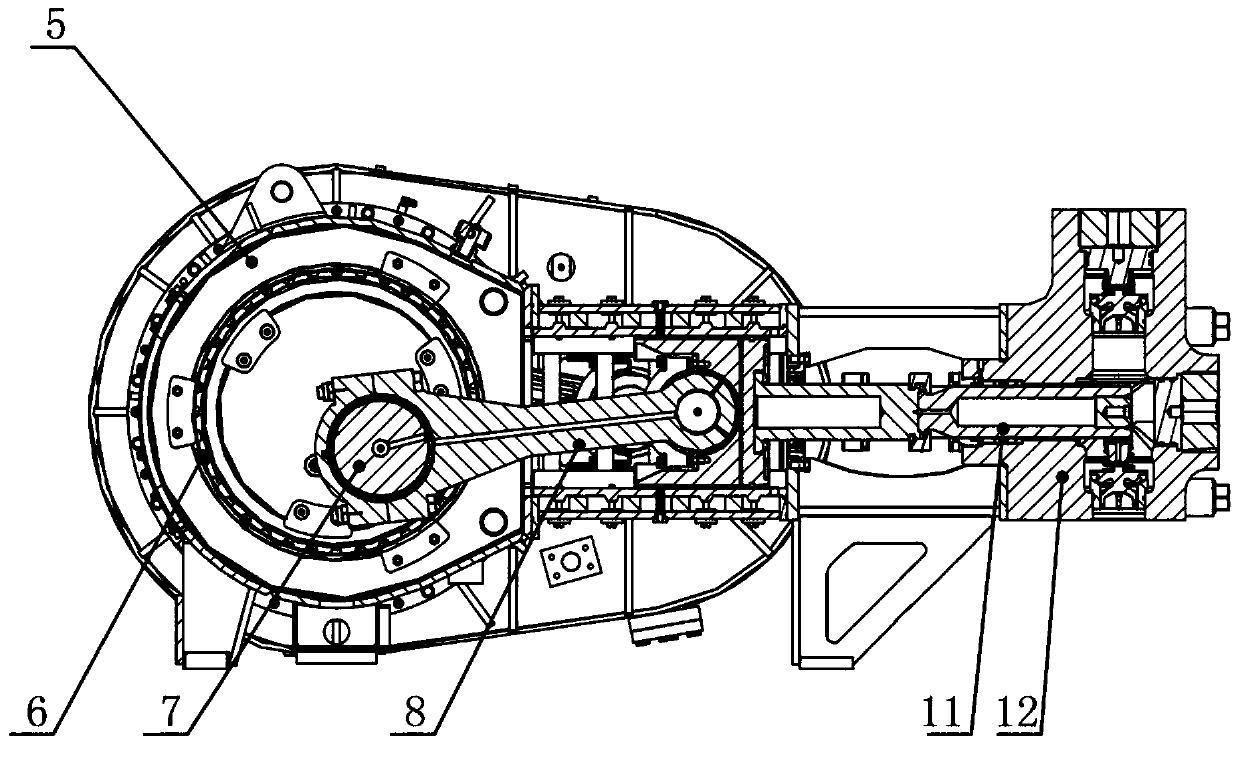

[0033] Such as Figures 1 to 10 As shown, a high-power five-cylinder plunger pump, the stroke of the high-power five-cylinder plunger pump is 10in, the cylinder spacing is 11.5in, and the braking power is 5000HP. The 10in stroke ensures a large displacement, that is, a high power and improves working efficiency. The cylinder spacing of 11.5in increases the load-bearing area of the connecting rod crosshead assembly 8 (connecting rod, crosshead and bearing bush), provides sufficient bearing capacity for the 5000HP five-cylinder plunger pump, and ensures its stable large displacement. output, the power of the five-cylinder plunger pump is increased, that is, the fracturing capacity of a single fracturing equipment is improved, so that it can reduce the total number of fracturing equipment in the well site, and effectively solve the problem of small well site area and relatively large fracturing equipment. There are many contradictions, and it can save time and effort to quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com