Combined PDC-thrust ball bearing long-life transmission shaft assembly

A technology for thrust ball bearings and transmission shafts, applied in ball bearings, percussion drilling, rotary drilling, etc., can solve the problems of reducing bearing capacity, reducing bearing service life, and limited structural space, so as to improve the overall life , prolong the service life and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

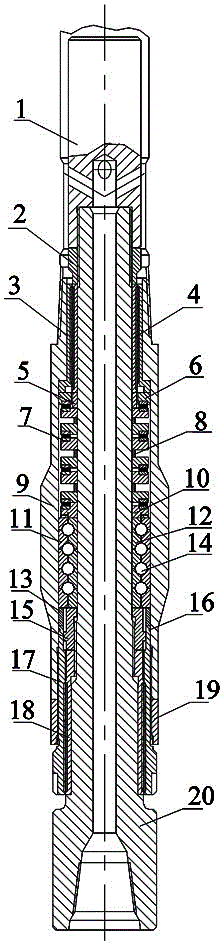

[0022] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0023] Such as figure 1 As shown, a combined PDC-thrust ball bearing long-life transmission shaft assembly includes a transmission shaft 20, a lower TC moving sleeve 18, a lower TC static sleeve 17, a thrust ball bearing group, a PDC bearing group, and an upper TC moving sleeve 4 , the upper TC static sleeve 3 and the transmission shaft housing 9, the lower TC movable sleeve 18 is arranged on the outer peripheral surface of the shaft head part of the transmission shaft 20, and the lower part of the lower TC movable sleeve 18 is connected with the transmission shaft 20 through threaded fit, The lower TC static sleeve 17 is matched and installed on the outer periphery of the lower TC movable sleeve 18, and the lower end of the lower TC static sleeve 17 is threadedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com