Fracturing Pump

a fracturing pump and pump body technology, applied in the direction of positive displacement liquid engines, borehole/well accessories, liquid fuel engines, etc., can solve the problems of more and more occupied, more complicated pump manifold layout, and single-machine power of fracturing pumps that is difficult to boost, etc., to achieve high working displacement, large single-machine power, and small occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

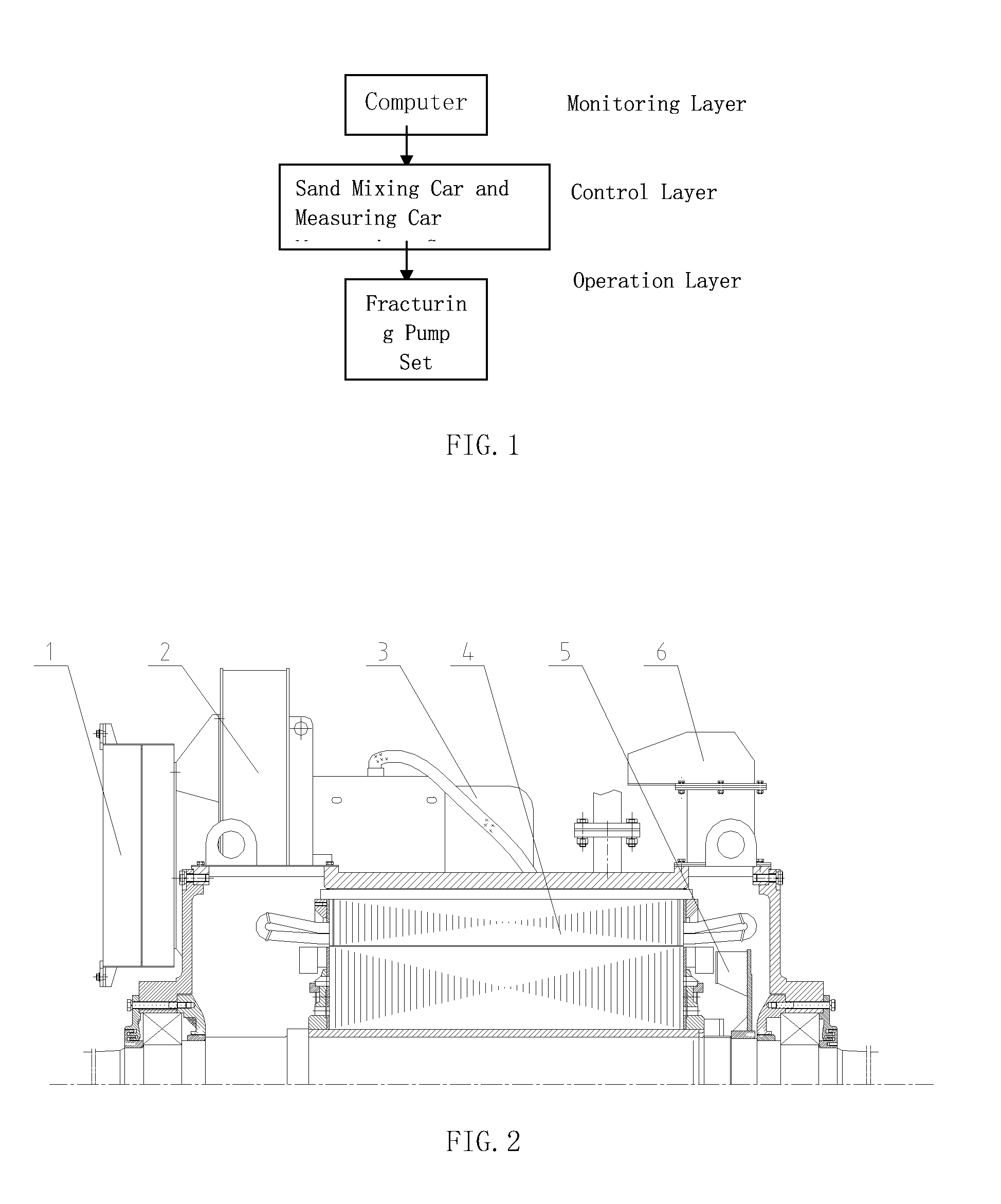

[0026]A fracturing pump and its support apparatus comprise three fracturing cars, a sand mixing car, a measuring car and their control systems. The fracturing pump comprises a cooling device and a control device. A motor is coupled on a shaft of the fracturing pump. The cooling device comprises an air-cooled device for cooling a rotor of the pump motor and a water-cooled device for cooling a stator of the pump motor. The control device is connected with the pump motor and the cooling device. A token ring is made with a shielded twisted pair by a Profibus for connection for the fracturing pump, the sand mixing car and the measuring car etc to make a network stable and easy scalable. Each of the apparatus is connected to the network with a Network Access device with bandwidth of 1.5 Mb / s.

[0027]The signal of a sensor of the fracturing pump is transmitteed to a S7-300PLC of the measuring car via a distribution-type I / O apparatus. The S7-300PLC is connected with the Profibus monitoring l...

example 2

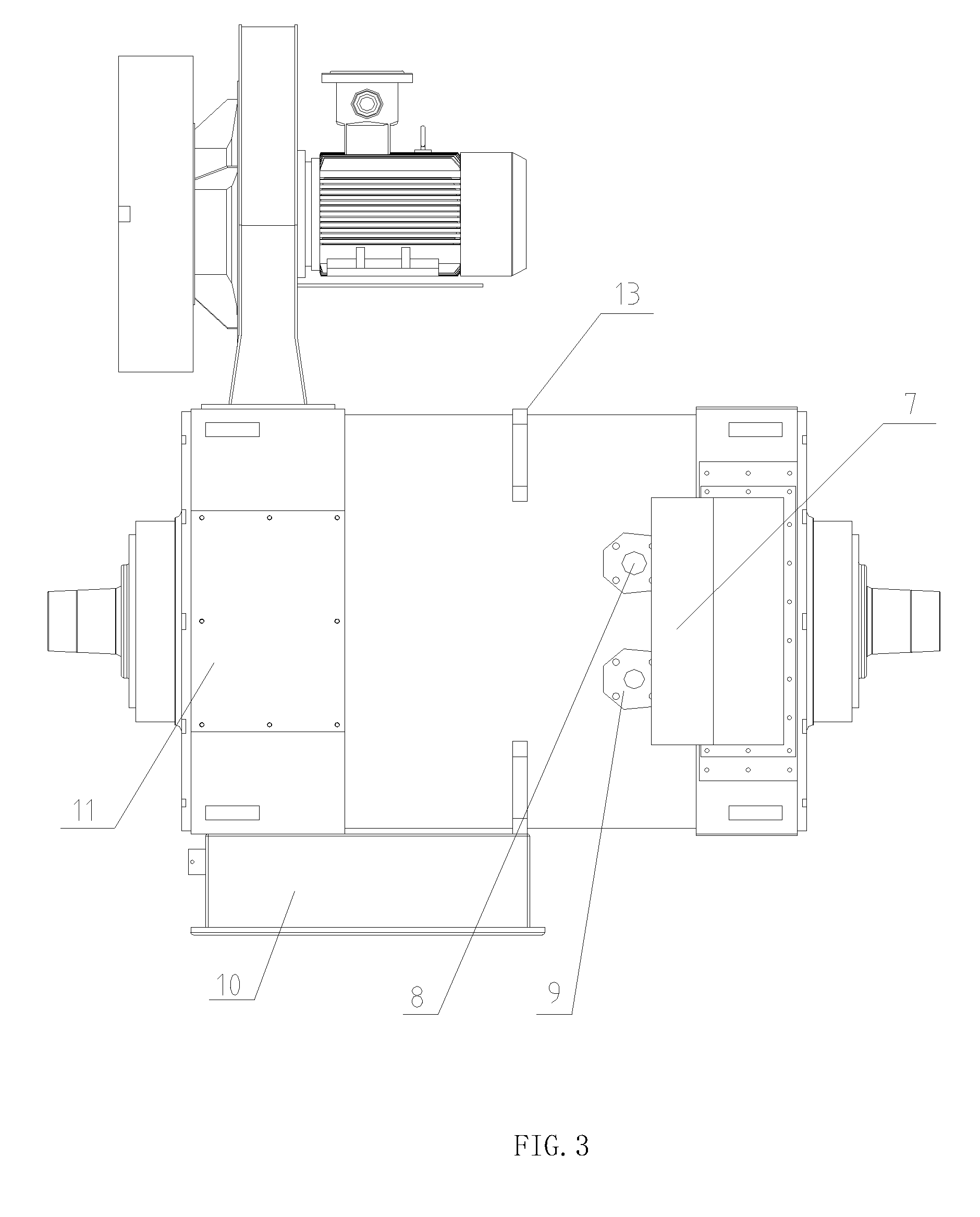

[0031]Being the same with example 1, preferably, two fracturing pumps are provided on a fracturing car. A cooling device is mounted between the two fracturing pumps.

example 3

[0032]Being the same with Example 2, preferably, a cooling device on a fracturing pump comprises an air-cooled device for the pump motor and a water-cooled device for the pump motor.

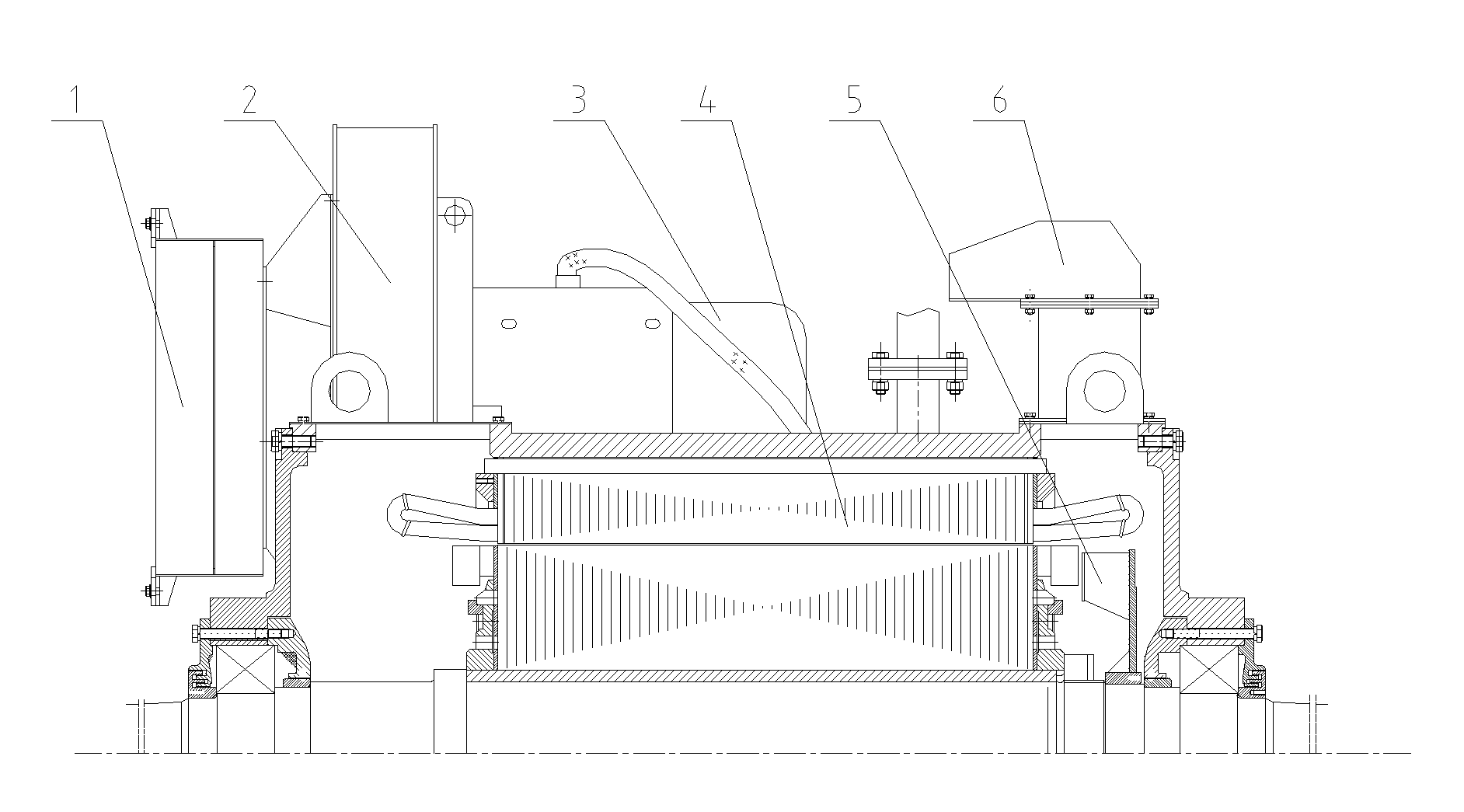

[0033]As shown in FIG. 2, the air-cooled device for the pump motor comprises a fan motor 3 and a pump motor core 4. One end of the fan motor 3 is provided with a fan 2 on which an air inlet 1 is provided. The pump motor core 4 is also provided thereon with a fan 5 on which an air outlet 6 is provided. The working principle of the air-cooled device for the pump motor is as follows: cooled air enters into the fan 2 via the air inlet 1 to make the cooled air compresssed by the centrifugal force of the fan 2, and the compressed air enters into the inner part of the pump motor, and takes away the heat generated by the pump motor core 4. The centrifugal force generated by the rotation of the fan 5 makes a lower pressure area near the fan 5 to fast the flow of the air in the pump motor, and discharges the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com