Reciprocating type three-cylinder plunger pump for oil and gas field

A reciprocating, oil and gas field technology, applied in the direction of multi-cylinder pumps, variable displacement pump components, components of pumping devices for elastic fluids, etc., can solve the inconvenience of replacing packing, reverse spray, and insufficient lubrication of connecting rod big end bearing bushes and other issues to achieve the effect of improving life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

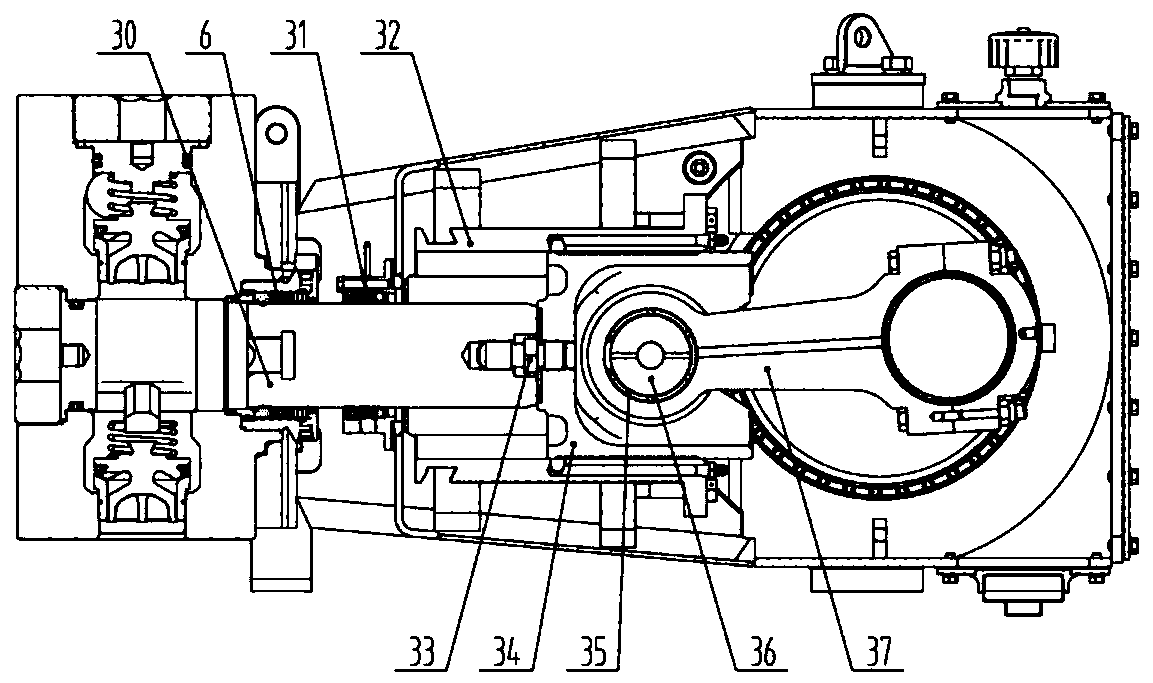

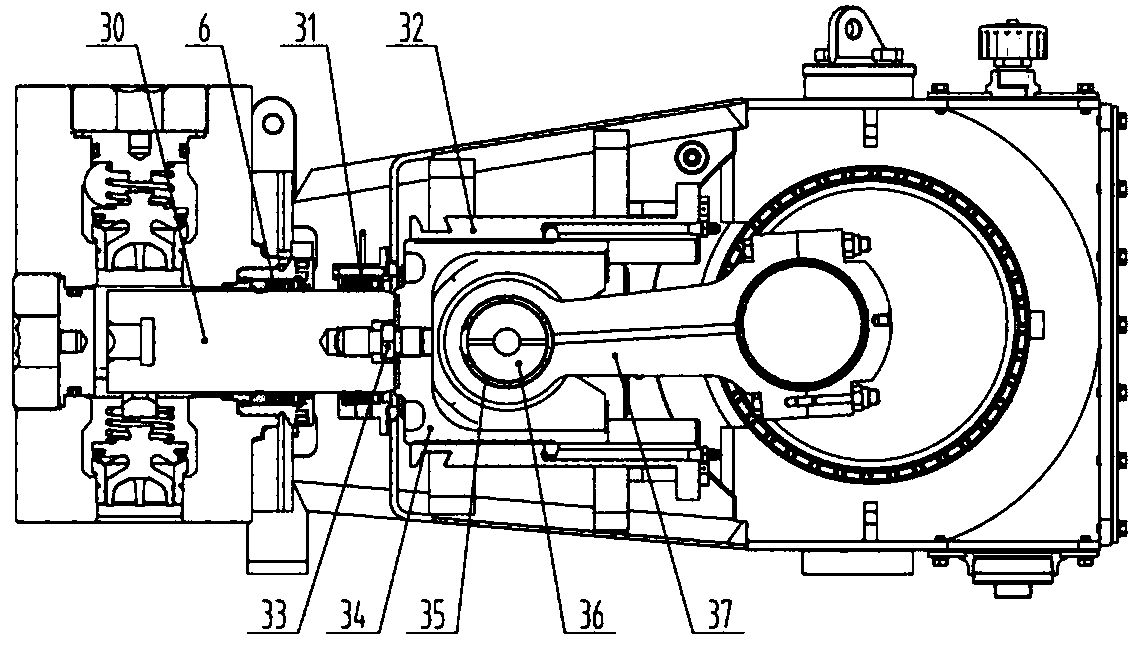

[0032] Existing technologies such as figure 2 , image 3 As shown, the plunger 30 is directly installed on the crosshead 34 inside the power end assembly through the plunger connecting bolt 33. On the one hand, when the packing 6 used to seal the plunger 30 in the liquid end assembly 3 is damaged , the high-pressure working medium inside the liquid end assembly 3 will leak directly along the plunger 30, and then contact and destroy the seal in the seal seat assembly 31 at the power end assembly 1, and finally the inside of the liquid end assembly 3 The working medium will be sprayed back into the power end assembly 1; on the other hand, in order to seal the high-pressure working medium inside the liquid end assembly 3, the packing 6 has a very large interference with the plunger 30, That is, the packing 6 will hold the plunger 30 tightly, and the surface of the plunger 30 will be worn after working for a long time, and there will be deep grooves, and the working medium leake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com