U shape tubular isothermal low-temperature methanol synthesis tower

A methanol synthesis tower, isothermal technology, applied in the preparation of hydroxyl compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of cold pipe and ring pipe weld cracking, affecting the uniform distribution of air flow, affecting production, etc. Achieve the effects of reduced material requirements, stable operation, and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

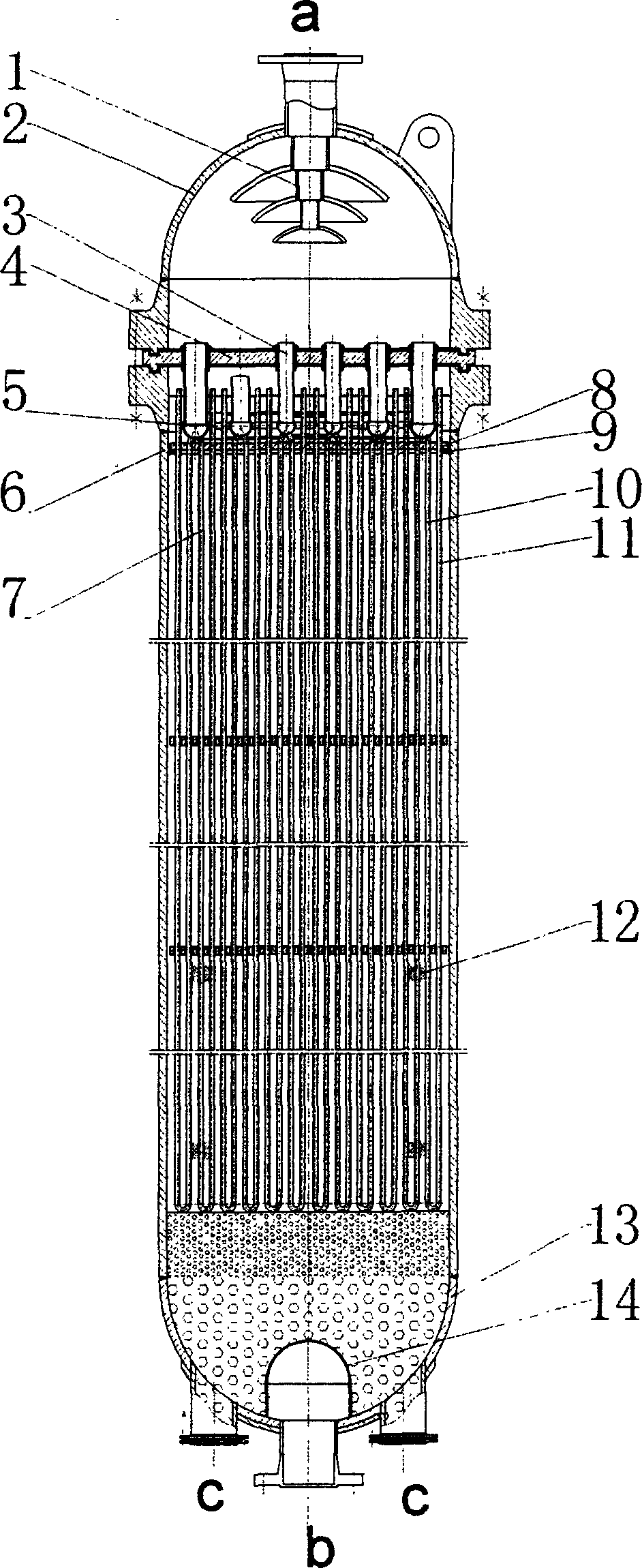

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] refer to figure 1 , the synthesis tower of the present invention is made up of two large parts of outer cylinder and internal parts, and outer cylinder comprises: gas distributor (1), upper sealing head (2), cylinder body (6), positioning ring (9), lower sealing head ( 13); the internal parts include: clapboard (4), cold tube liner (7), support ring (8), wherein cold tube liner (7) is composed of air induction tube (3), ring tube (5), descending cold tube ( 10), the ascending cold pipe (11) is assembled and welded, supported on the positioning ring (9) welded on the inner wall of the outer cylinder by the support ring (8), and the catalyst (12) is filled outside the cold pipe. The top of the last head (2) is welded with the air intake pipe a, the bottom of the lower head (13) is welded with the outlet pipe b, the top of the head is welded with the baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com