Measuring system for critical heat flux density in horizontal pipe and regulation and control method

A technology of critical heat flux and measurement system, which is applied in the field of critical heat flux measurement system and control in horizontal tubes, can solve problems such as equipment burnout, inaccurate heat flux values, and temperature rise of heating walls, achieving high precision and simple measurement system reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

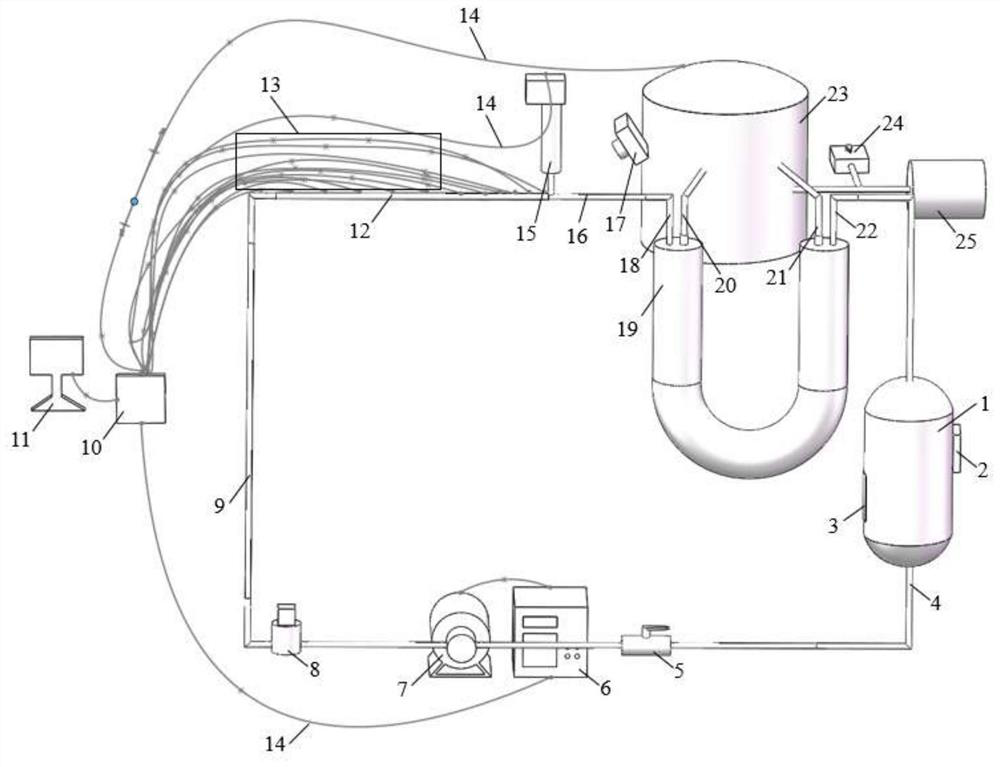

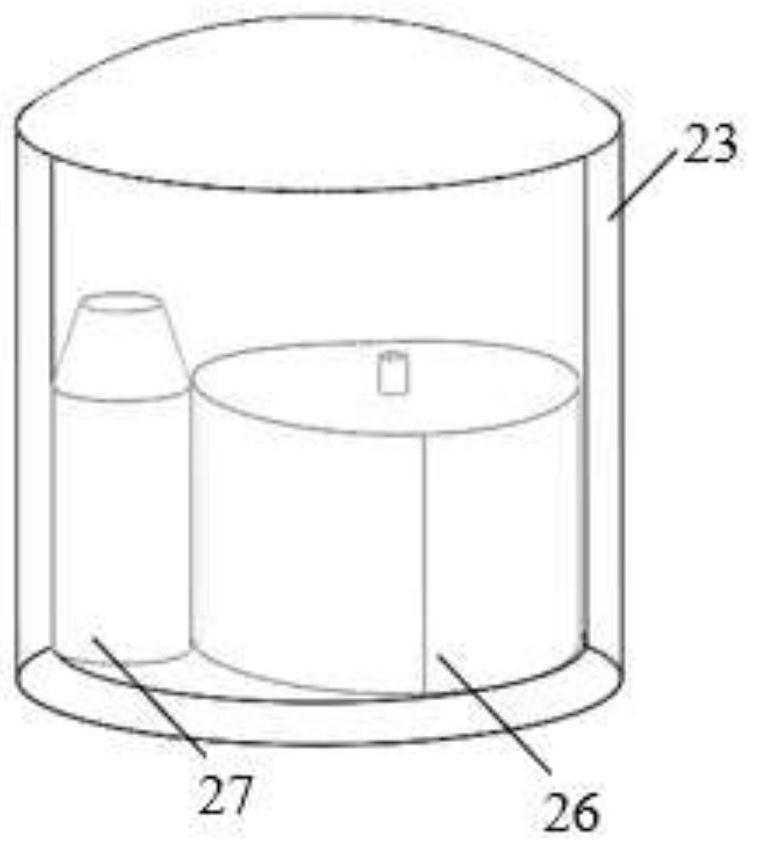

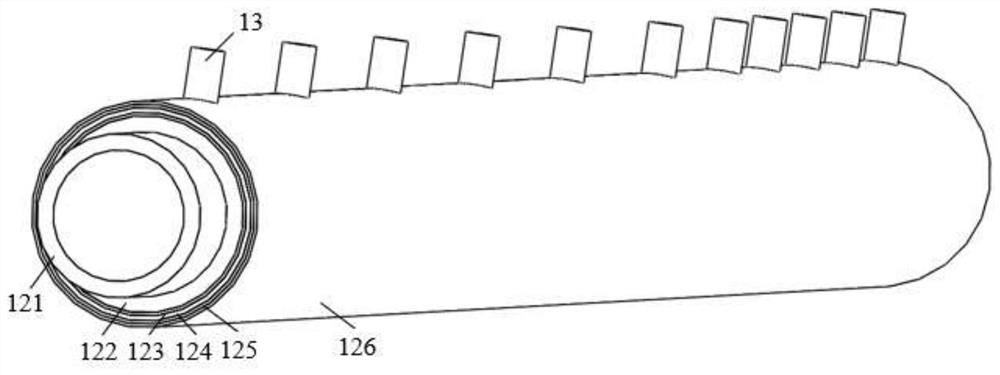

[0035] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0036] refer to Figure 1-Figure 3 As shown, a critical heat flux measurement system in a horizontal tube of the present invention includes: a refrigerant liquid storage tank 1, an electric fan 2, a heating plate 3, a circulation pipe 4, a ball valve switch 5, a frequency converter 6, a gear pump 7, a mass Flow meter 8, preheating section 9, data acquisition module 10, industrial computer 11, experimental section 12, T-type thermocouple 13, communication line 14, pressure sensor 15, visualization tube 16, high-speed camera 17, refrigerant inlet pipe 18 , U-shaped condenser 19, cooling water inlet pipeline 20, cooling water outlet pipeline 21, refrigerant outlet pipeline 22, water tank 23, el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com