Method for making oil product taking methane as raw material

A biogas and raw material technology, applied in chemical instruments and methods, petroleum industry, waste fuel, etc., can solve problems such as material flow and pressure imbalance, and achieve the effect of reducing difficulty, reducing quantity, and improving heat extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

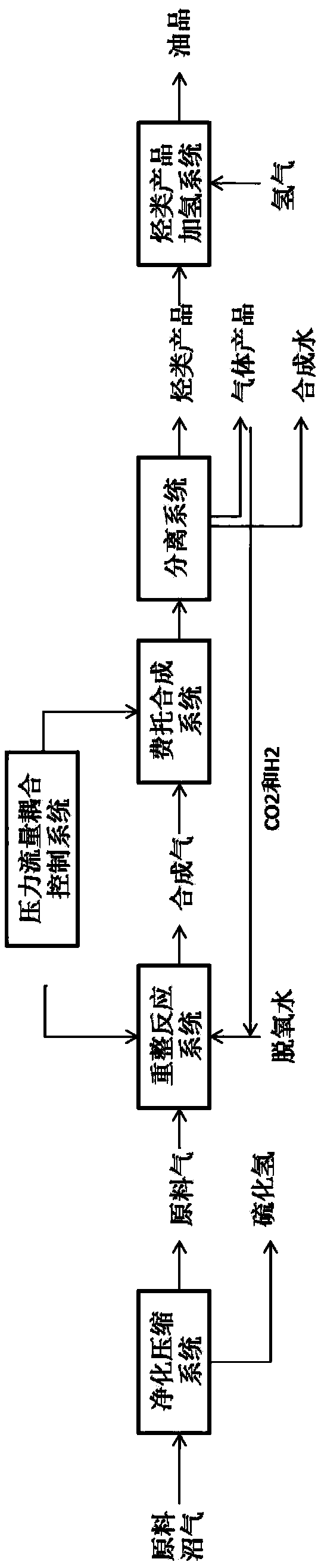

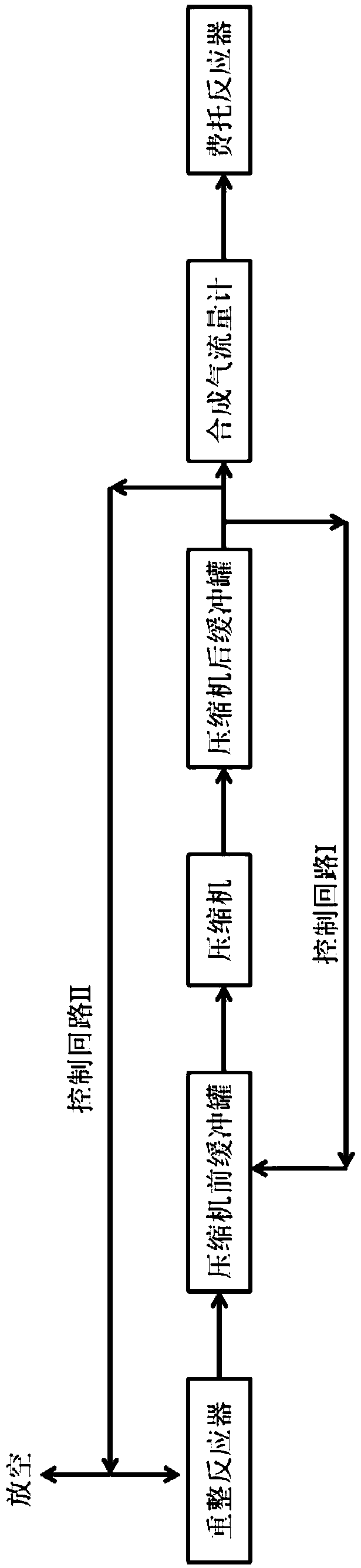

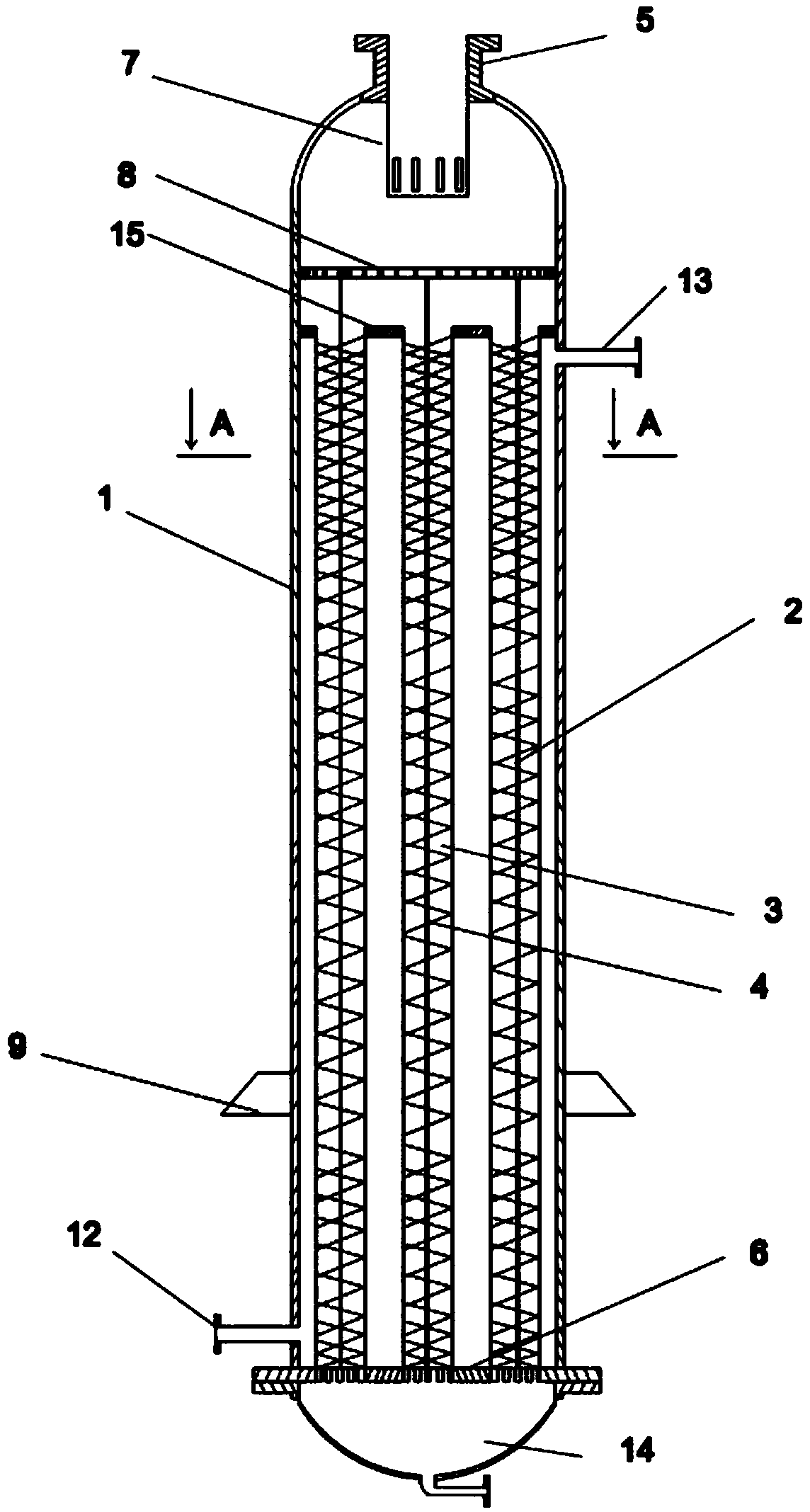

[0110] A method for producing oil products from biogas, the process is as follows figure 1 shown; including the following steps:

[0111] 1) Compression and purification: The raw biogas is passed through a gas-liquid separator to remove micro-droplets in the raw biogas, and the desulfurization tower is used to remove hydrogen sulfide from the biogas after the micro-droplets are removed (using zinc oxide as the desulfurizer to remove hydrogen sulfide to less than 20ppm), to obtain biogas with methane and carbon dioxide content of 99.99%, and then remove solid dust from the biogas after hydrogen sulfide removal through a filter, and compress it to 0.8MPa by a gas compressor After that, it is used as the raw material gas for the reforming reaction.

[0112] 2) Steam reforming reaction: Purified and compressed biogas (3.05kg / h) and deoxygenated water (2.05kg / h) are mixed into the steam reforming reactor at a mass ratio of 1.5:1, and are reacted with oxygen (2.86kg / h) The reformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com