Vehicle intercooler based on heat medium splitting technology

A technology of heat medium and intercooler, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of complicated porous plate design and practical application difficulty, and achieve good applicability and compatibility , high economy, heat exchange balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

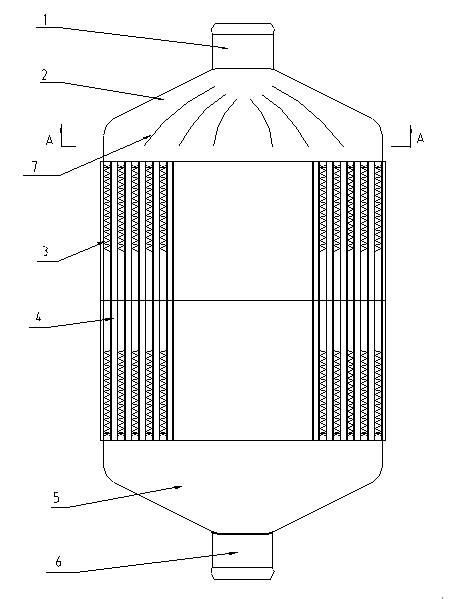

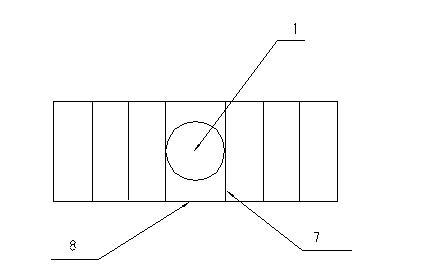

[0020] The principle of the invention is to reduce the internal resistance energy consumption of the intercooler and ensure that the overall heat exchange capacity of the intercooler is not damaged by adjusting the structure of the air chamber while keeping the other structures and dimensions unchanged. The main design idea of the present invention is: arrange the air inlet and outlet according to the same direction as the airflow direction of the internal channel of the intercooler, add several deflectors in the upper air chamber of the intercooler, and fix them in the air chamber by welding or other means. The sectional shape of the deflector vane is an elliptic curve segment, so as to achieve the purpose of diverting flow and reducing resistance. The number and position of the deflectors can be properly adjusted according to the number and position of the channels in the core of the intercooler.

[0021] The biggest difference between the intercooler air chamber of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com