District cooling system and method adopting distributed variable-frequency triple-stage pumps

A three-stage pump, distributed technology, applied in air-conditioning systems, refrigerators, heating methods, etc., can solve the problems of waste of energy consumption and serious cooling loss of chilled water pump transportation, improve safety and service life, and reduce residual The effect of pressure head and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0031] Such as figure 1 As shown, the distributed frequency conversion three-stage pump regional cooling system of this embodiment includes a delivery pipe network, user distributed pumps, users, and the cold water produced by the cooling station passes through the delivery pipe network 1 (water supply pipe 11, return water pipe 12) and user branch pipe 2 (water supply pipe 21, return water pipe 22) distribution pump 3 (plan 1 31, plan 2 32) to the user 4.

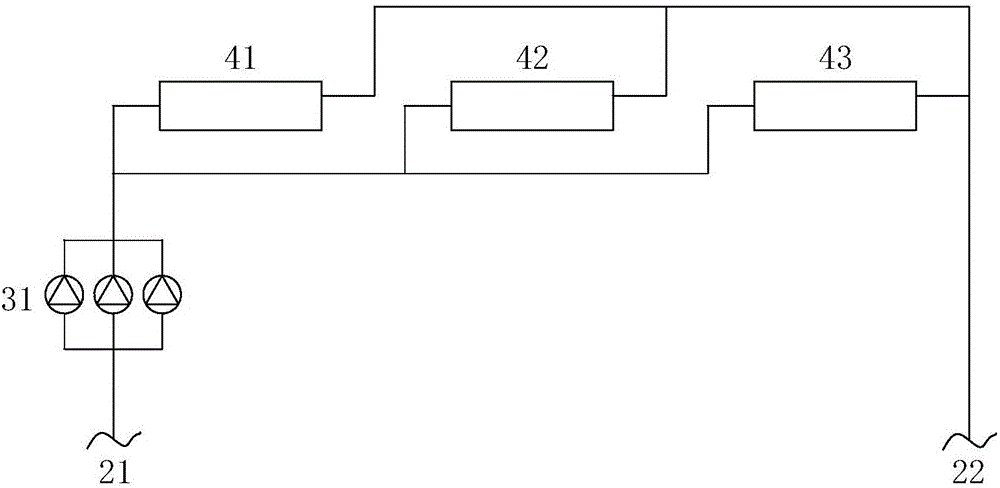

[0032] As shown in Figure 2, the user distributed pump system consists of two forms: adjacent users are grouped in parallel and then connected to three-stage pumps, diagram 2-1 ; After the user is connected in series with the three-stage pump, each user is connected in parallel, Figure 2-2 .

[0033] The design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com