Falling-off test device and usage thereof

A testing device and technology to be tested, applied in measurement devices, impact testing, testing of machine/structural components, etc., can solve problems such as inconvenience, collision phenomenon, material cost burden, etc., and achieve the effect of reducing cost and improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

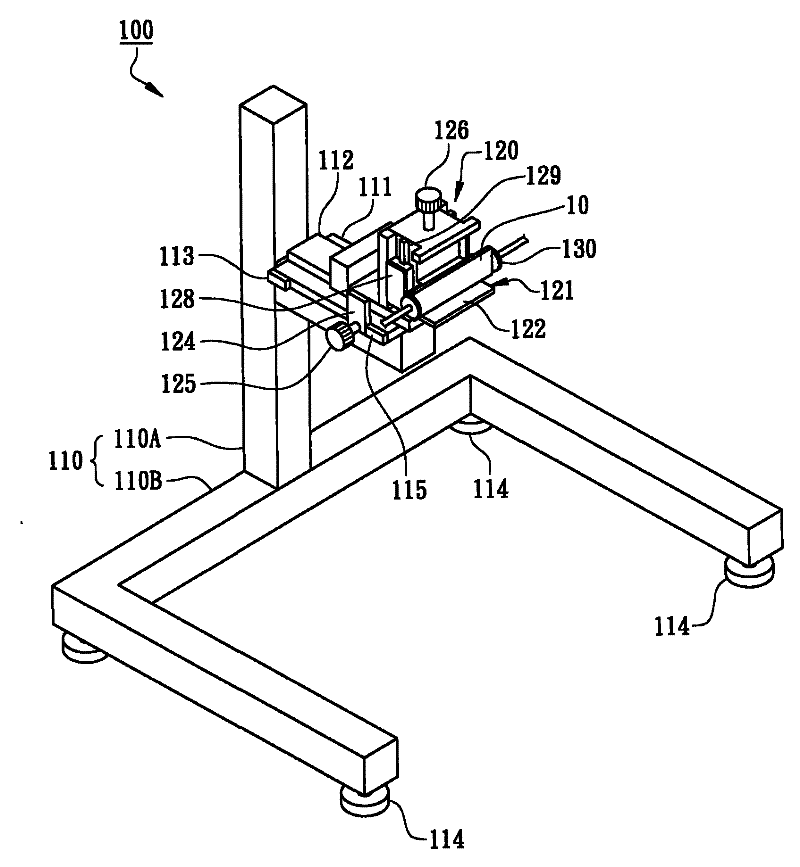

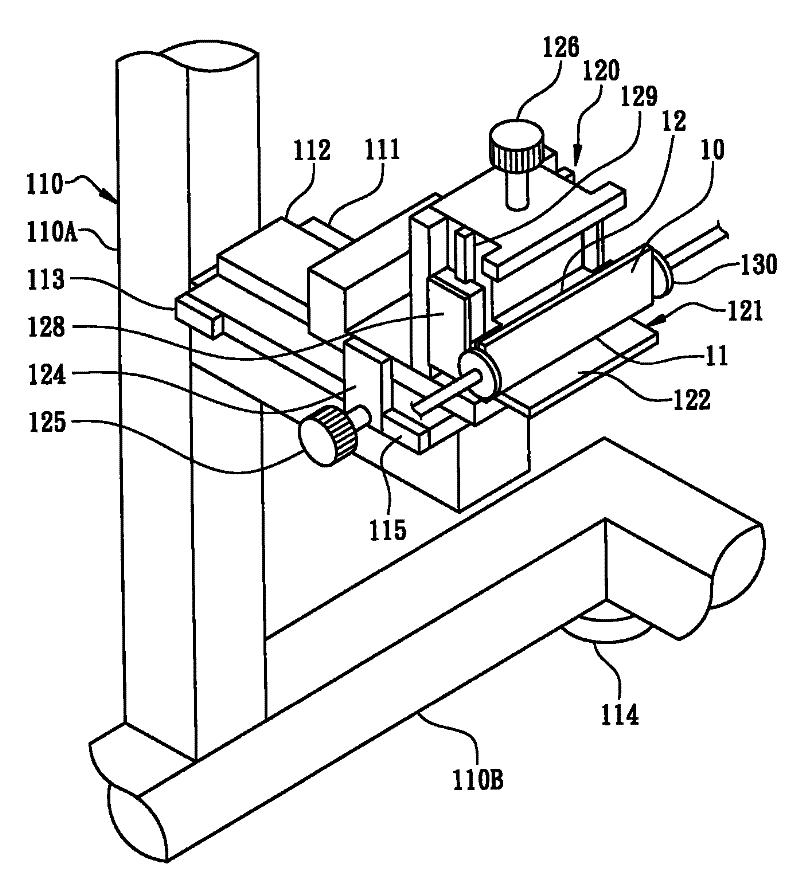

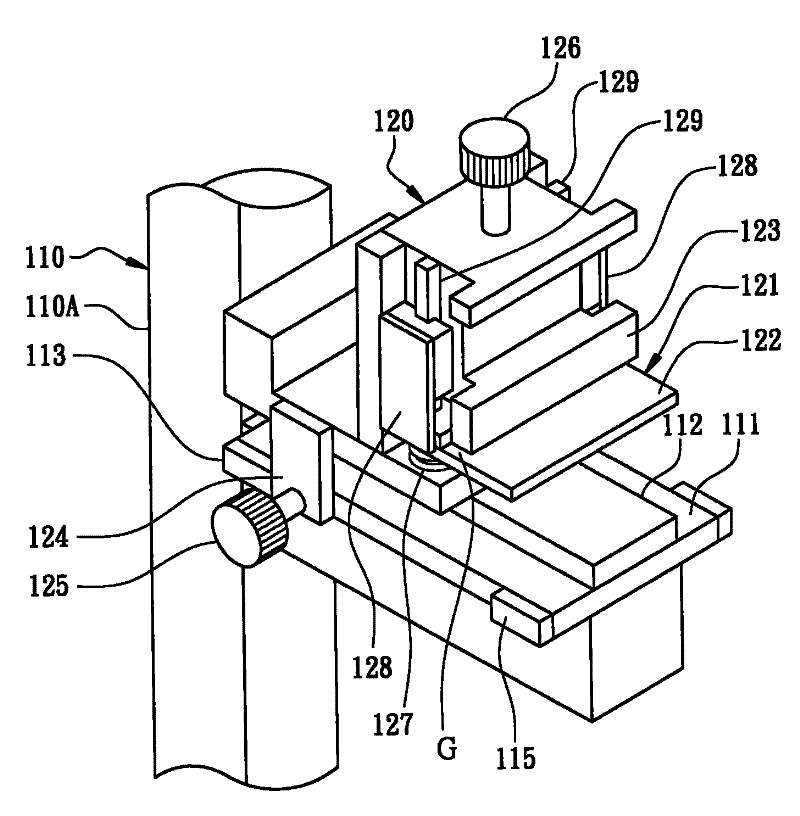

[0060] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, The method of use, steps, features and effects thereof are described in detail below.

[0061] Embodiments of the present invention will be described in detail below in conjunction with the attached drawings, but it should be noted that these drawings are simplified schematic diagrams, and are only used to illustrate the basic structure or implementation method of the present invention, so only the same as shown The relevant components and combination of this case are that the components shown in the figure are not drawn in proportion to the number, shape, and size of the actual implementation, and some dimensional ratios and other related dimensional ratios have been exaggerated or simplified to provide better Clear description. The number, shape and size ratio of the actual implementation is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com