Throttling and refrigerating freezing storage box with two-stage fractional condensation and separation reheating type mixed working medium

A technology of mixing working fluid and refrigerated storage, applied in the field of refrigerated storage tanks, can solve problems such as the decline of refrigeration efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

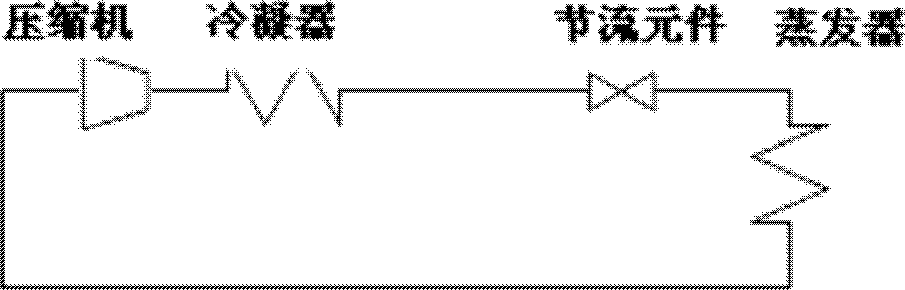

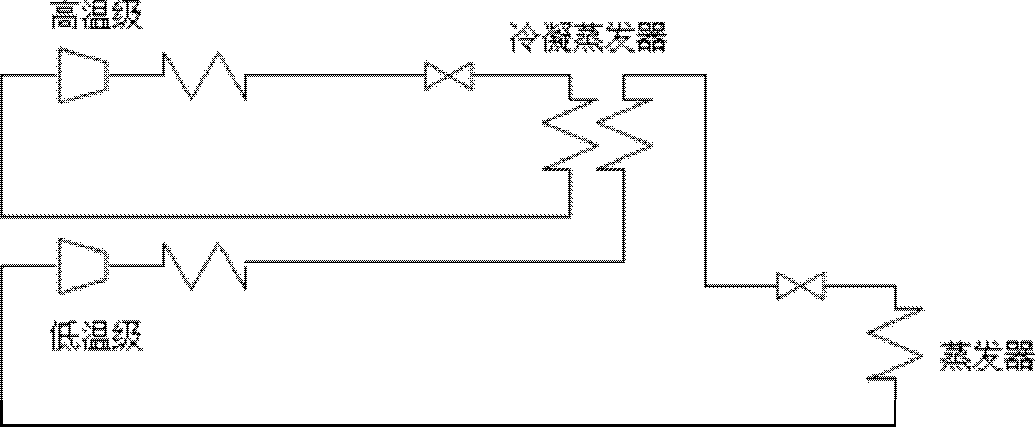

Method used

Image

Examples

Embodiment 1

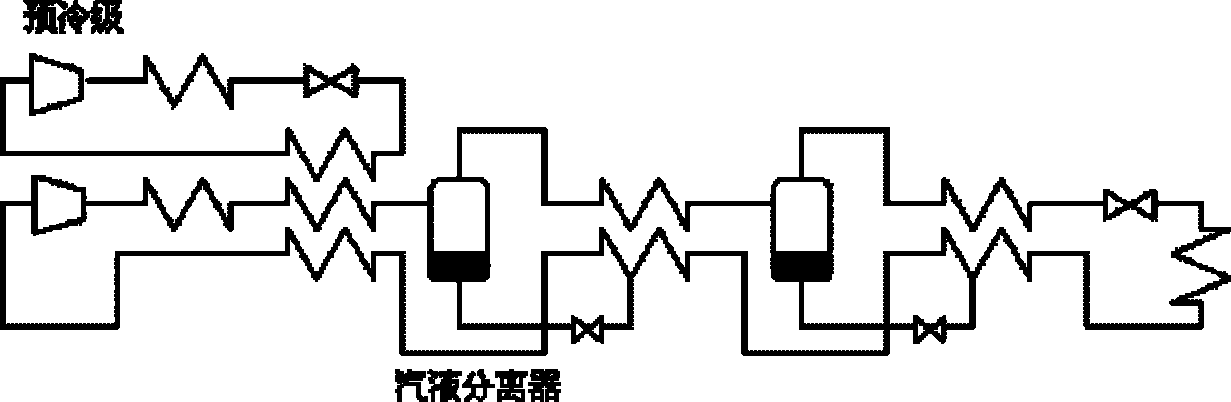

[0046] Embodiment 1: A low-temperature refrigerated storage tank with two-stage fractional condensation, separation, heat recovery and mixed working fluid throttling refrigeration.

[0047] Such as Figure 5 As shown, a refrigeration storage tank with two-stage separation and heat recovery mixed working fluid throttling refrigeration is composed of a refrigeration system R, a control system C and a box B. The refrigeration system R is with two-stage separation Separate the regenerative mixed working fluid throttling refrigeration system to provide the required refrigeration; the refrigeration system R consists of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and their connections The piping but the composition, its connection method is: the high-pressure outlet of the refrigeration compressor module CU is connected to the high-pressure refrigerant inlet of the regenerative heat exchanger module RU; t...

Embodiment 2

[0056] Embodiment 2: A low-temperature refrigeration storage tank with throttling refrigeration of the mixed working fluid with two-stage fractional condensation separation and heat recovery.

[0057] A refrigeration storage tank with a two-stage condensate separation and heat recovery type mixed working fluid throttling refrigeration, which is composed of a refrigeration system R, a control system C and a box body B. The refrigeration system R is with a two-stage condensate separation and heat recovery Type mixed working fluid throttling refrigeration system to provide the required refrigeration; the refrigeration system R consists of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and its connecting pipelines , The connection method is the same as that of Example 1; the refrigeration system R, the control system C and the box B are of split structure, the refrigeration compressor module CU of the ref...

Embodiment 3

[0063] Embodiment 3: A low-temperature refrigerated storage tank with throttling refrigeration of the mixed working fluid with two-stage fractional condensation separation and heat recovery.

[0064] A low-temperature refrigeration storage tank with one-stage condensate separation and regenerative mixed working fluid throttling refrigeration, which is composed of a refrigeration system R, a control system C and a box B, and a regenerative mixing process with one-stage condensate separation The mass-throttling refrigeration system provides the required refrigeration; the refrigeration system R is composed of a compressor module CU, a regenerative heat exchanger module RU, a throttling module JU, an evaporative heat exchange module EU and its connecting pipelines. Same as embodiment 1; the refrigeration system R, the control system C and the box B are of split structure, same as the embodiment 2. The compressor module CU is the same as the first embodiment.

[0065] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com