Cylindrical secondary battery bare electric core winding variable-tension control method

A secondary battery, tension control technology, applied in the direction of secondary battery, non-electric variable control, electrical program control, etc., can solve the problems that affect the battery cell too tight or too loose, prolong the battery production cycle, prolong the liquid injection time, etc. , to achieve the effect of being conducive to soaking, shortening the injection process time, and shortening the injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in combination with specific embodiments and with reference to the accompanying drawings.

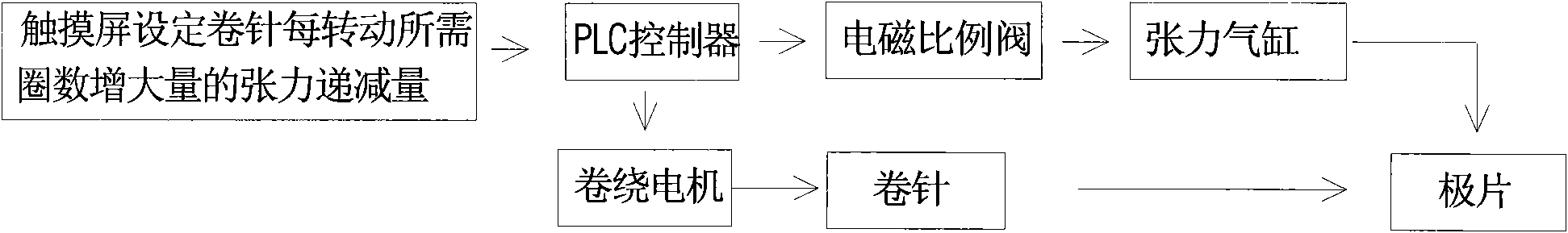

[0021] A method for controlling the variable tension of lithium-ion battery bare cell winding. The air pressure in the tension cylinder that pushes the tension rod device is controlled by an electromagnetic proportional valve that supplies gas to the tension cylinder. In the process of winding the battery cell, the PLC controller calculates the The number of coils is controlled according to the set law to control the electromagnetic proportional valve to reduce the air pressure in the tension cylinder, and gradually reduce the tension of the winding needle winding pole piece, so that the tension of the battery is large inside and small outside during the winding process;

[0022] The setting rule is that the tension of the pole piece is 0.35Mpa set by the touch screen when the pole piece is wound by the winding needle for the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com