A battery and liquid injection method

A battery and liquid injection technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of incomplete electrolyte infiltration, difficult discharge of cell bubbles, and reduced battery capacity, achieving good infiltration effect and shortening injection time. The effect of improving liquid time and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

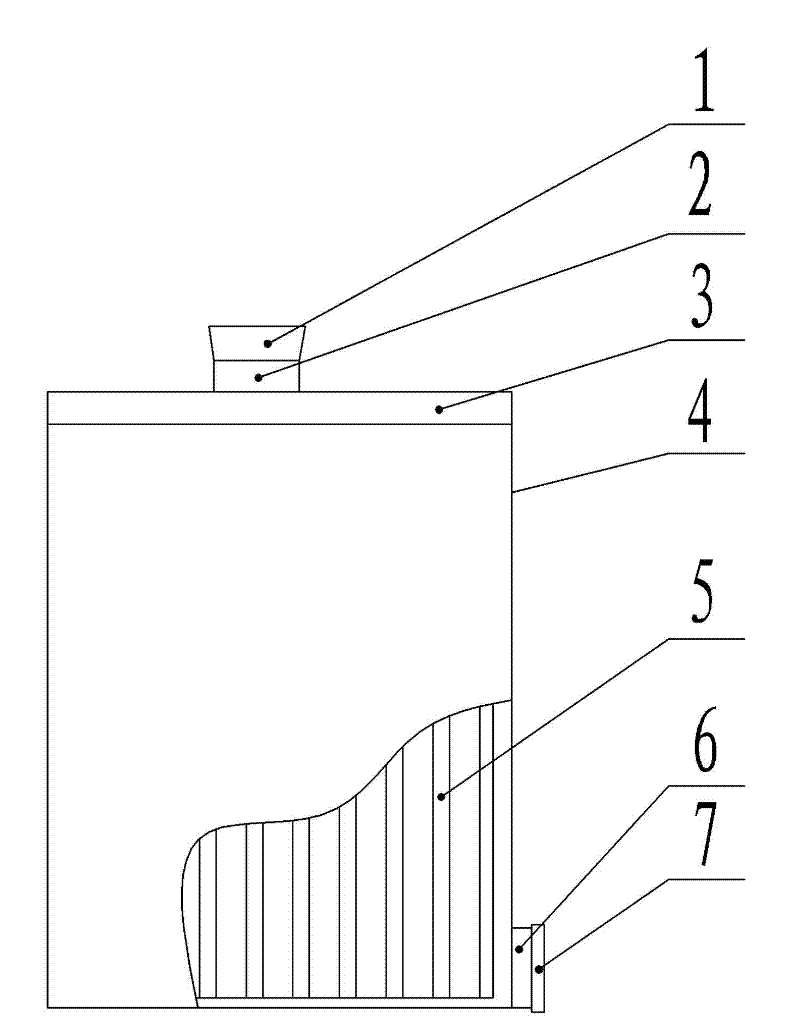

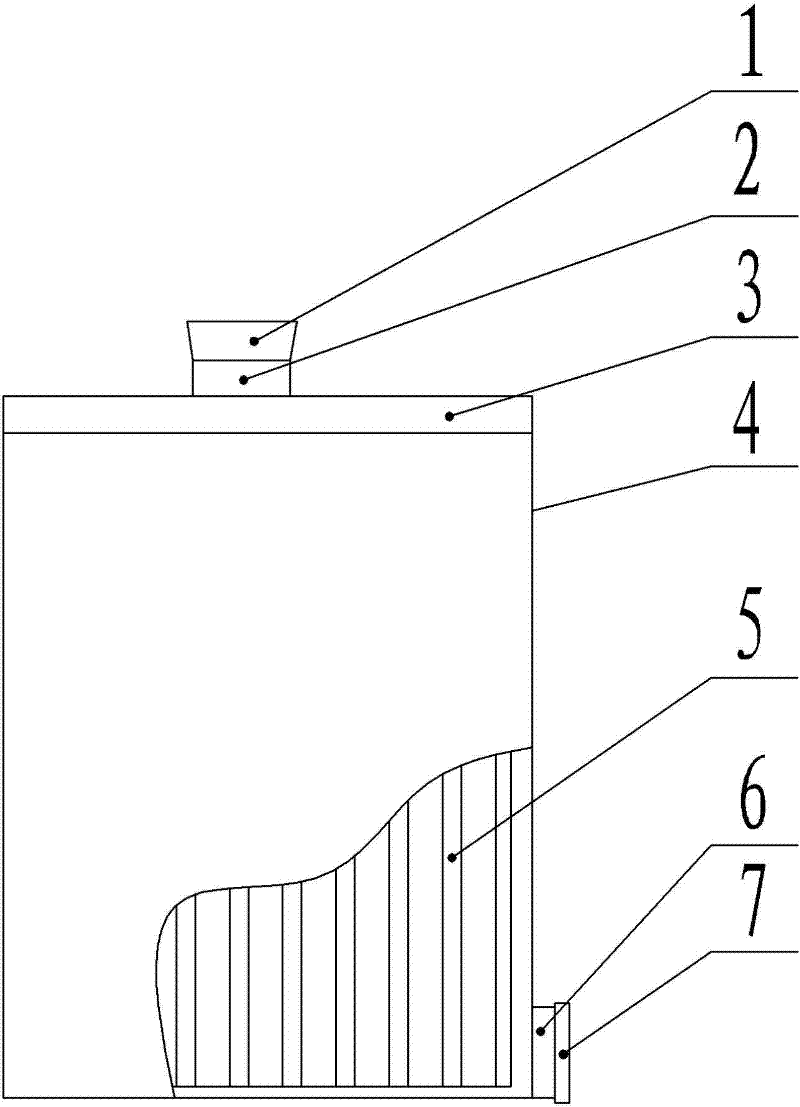

[0022] Such as figure 1 As shown, a battery provided in this embodiment includes a battery winding core 5, a casing 4 wrapped outside the battery winding core 5, and an end cap 3 covering the top of the casing 4, and also includes a safety valve hole 2 and The liquid injection hole 6 and the safety valve hole 2 are arranged on the end cover 3 , and the liquid injection hole 6 is arranged at the lower part of the housing 4 . The safety valve hole 2 is provided with a safety valve cover 1 , and the liquid injection hole 6 is provided with a liquid injection hole cover 7 .

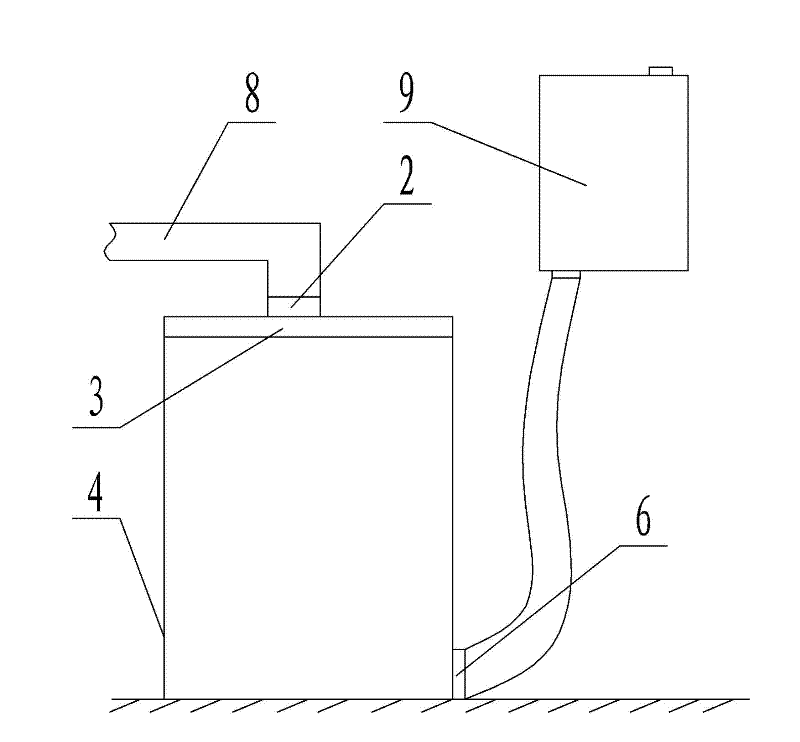

[0023] Such as figure 2 As shown, the battery injection method provided in this embodiment, the specific steps are as follows:

[0024] (1) Place the battery in dry air with a dew point of -50°C, remove the safety valve cover 1, and connect the safety valve hole 2 with the vacuum line 8;

[0025] (2) Remove the liquid injection hole cover 7 of the battery, connect the liquid injection hole 6 with the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com