Multifunctional concrete form book-pad

A concrete formwork, multi-functional technology, applied in the field of formwork/formwork components, building components on-site preparation, construction, etc., can solve the problems of affecting the durability of concrete, costing labor and money, and complicated construction, so as to avoid plastering and Decorative coating and wear-resistant coating, cost reduction, effect of improving surface strength and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

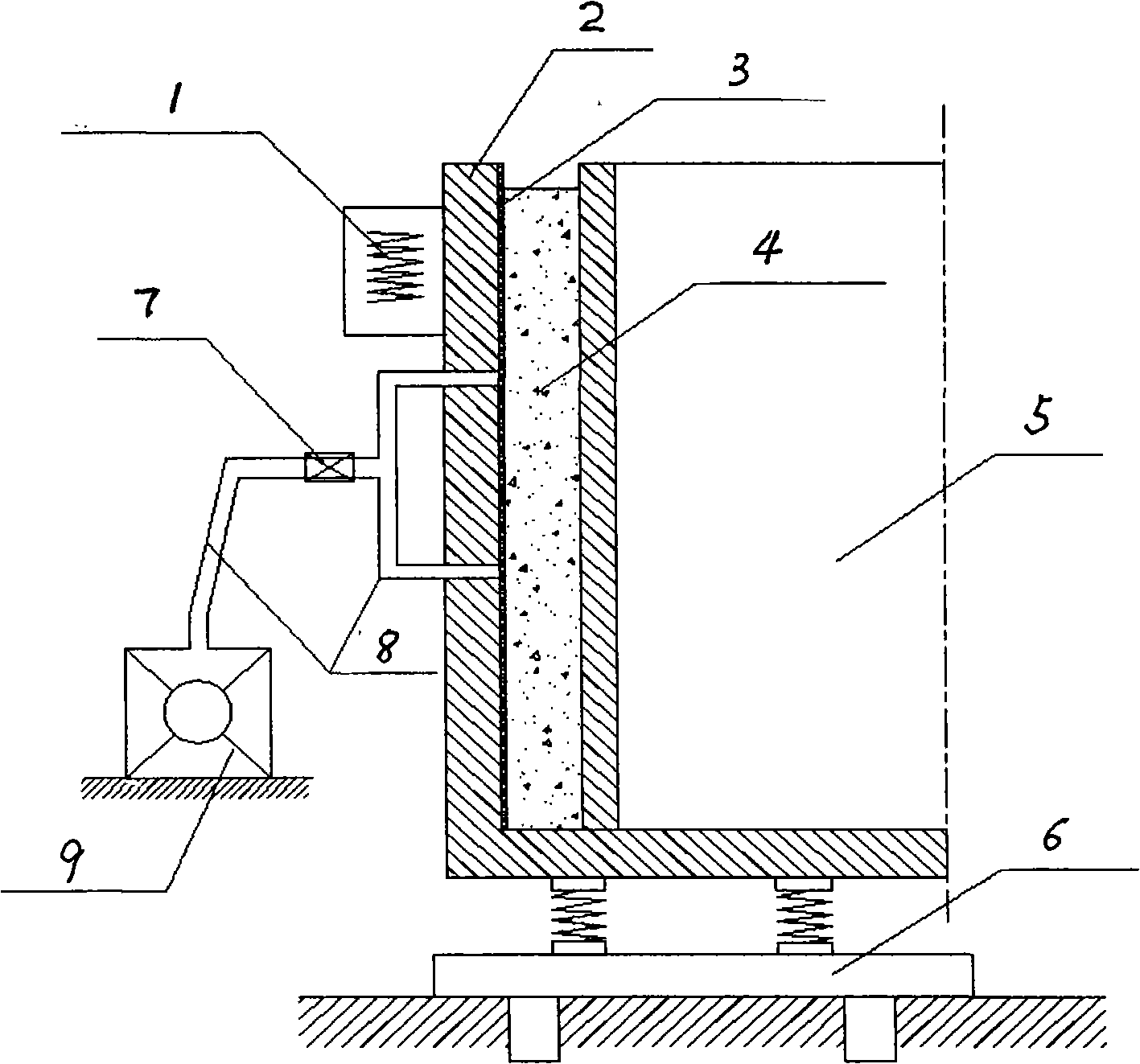

[0012] Embodiment 1, with reference to figure 1 .

[0013] use as figure 1 The shown method produces concrete U-shaped anti-seepage groove, and the prefabricated steel mold of concrete U-shaped anti-seepage groove 4 is made of steel inner mold 5 and steel outer mold 2. An attached vibrator 1 is arranged on the steel outer mold 2, and a spring support 6 is arranged at the lower part, which is beneficial to vibrating and compacting the concrete. Steel outer mold 2 is pre-set with dewatering holes and placed multi-functional concrete formwork liner 3, connected with vacuum dehydrator 9 through valve 7 and dehydration pipe 8 (mainly to improve production efficiency and capacity), and uses vacuum to remove excess concrete mixture. moisture.

[0014] During the precast production of concrete U-shaped anti-seepage tanks, the combination of placing multi-functional concrete formwork pads and vacuum dehydration production technology can make the concrete have initial consolidation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com