Polyalcohol composition, application thereof and rigid polyurethane foam prepared from polyalcohol composition

A technology of polyol composition and rigid polyurethane, which is applied in the field of rigid polyurethane foam, can solve the problems of affecting the curing performance of polyurethane foam, increasing production cost, and prolonging demoulding time, so as to reduce the filling amount of the model, reduce the production cost, The effect of less filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

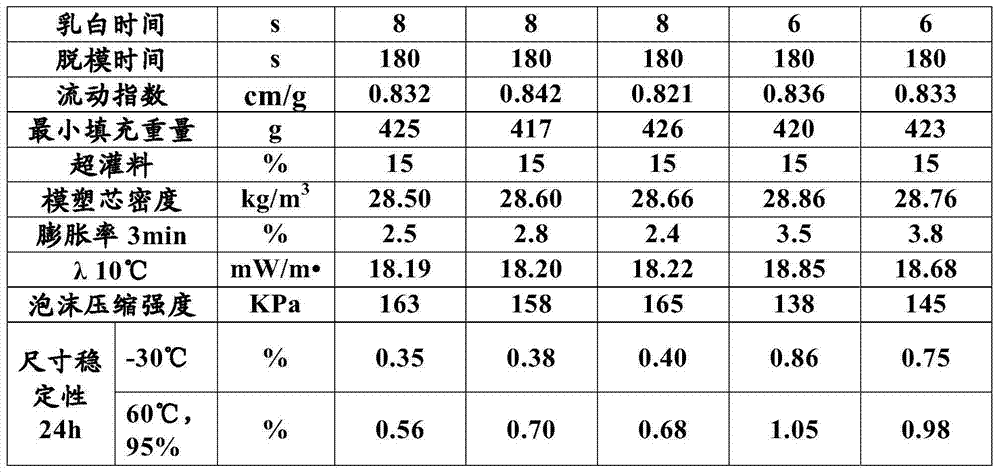

[0149] In Examples 1-3, by changing the proportions of polyol components a1) to a5) and the proportions of each component in the composite catalyst, polyurethane foam with high fluidity and low density can be prepared, see Table 1 for details. Wherein, the polyol composition of Comparative Example 1 only includes polyol components a3)-a5), and the polyol composition of Comparative Example 2 only includes polyol compositions a2)-a5).

[0150] Table 1

[0151]

[0152]

[0153] From Examples 1, 2, and 3 in Table 1 above, it can be seen that using a low-viscosity polyol composition and a suitable composite catalyst can produce a polyurethane foam with high fluidity, and the foam has good physical and mechanical properties.

[0154] It can be seen from the above table 1 that comparative example 1 does not contain polyol components a1) and a2), and comparative example 2 does not contain polyol component a1), the foam expansion rate and thermal conductivity increase significan...

Embodiment 4-5

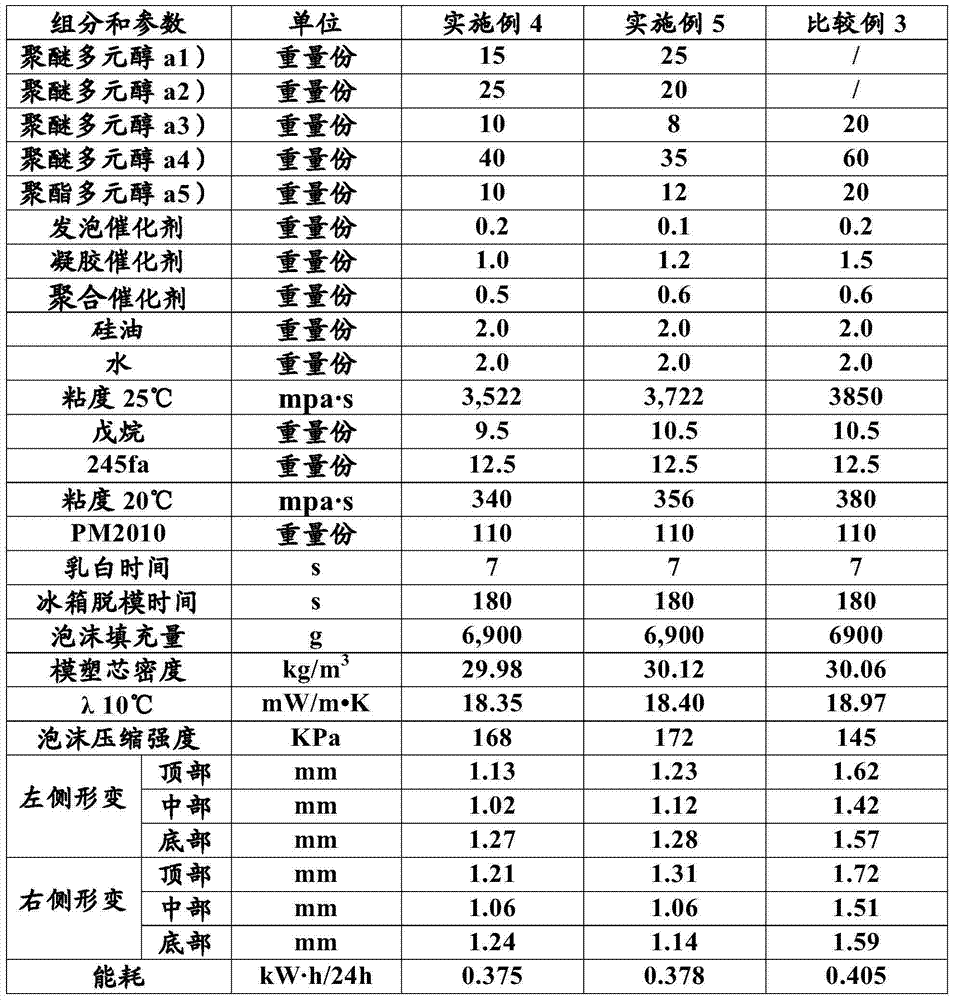

[0157] Examples 4, 5 and Comparative Example 3 are refrigerators made from the foams of Examples 1, 3 and Comparative Example 1, respectively. The experiment chose to make the same refrigerator model on the same equipment. The refrigerator is a 3-door air-cooled computer refrigerator, which has a freezing chamber with a foam thickness of 90mm, a refrigerating chamber with a thickness of 65mm, and a temperature-changing chamber after 65mm. The normal demoulding time of this refrigerator is 260s. See Table 2 for the component content and the properties of the prepared foam. After the refrigerator is demoulded, measure the difference between the thickness of the left and right sides of the box at the top, middle, and bottom and the thickness of the corresponding position of the box before foaming, that is, the deformation of the box before and after the refrigerator is demoulded (in mm), and take The average value, the difference between the maximum and minimum value of each pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com